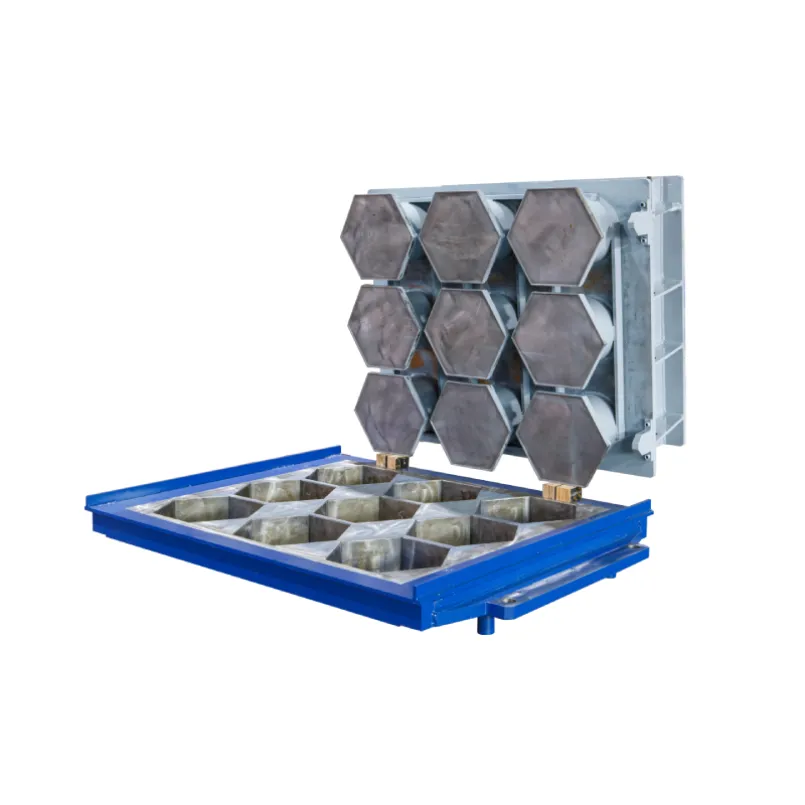

China Leading Manufacturer Kerb Stone Mould Kerbstone Block Mold for MASA HESS

China's Leading Kerb Stone Mold Manufacturer for MASA HESS Machines

Features of Our Molds

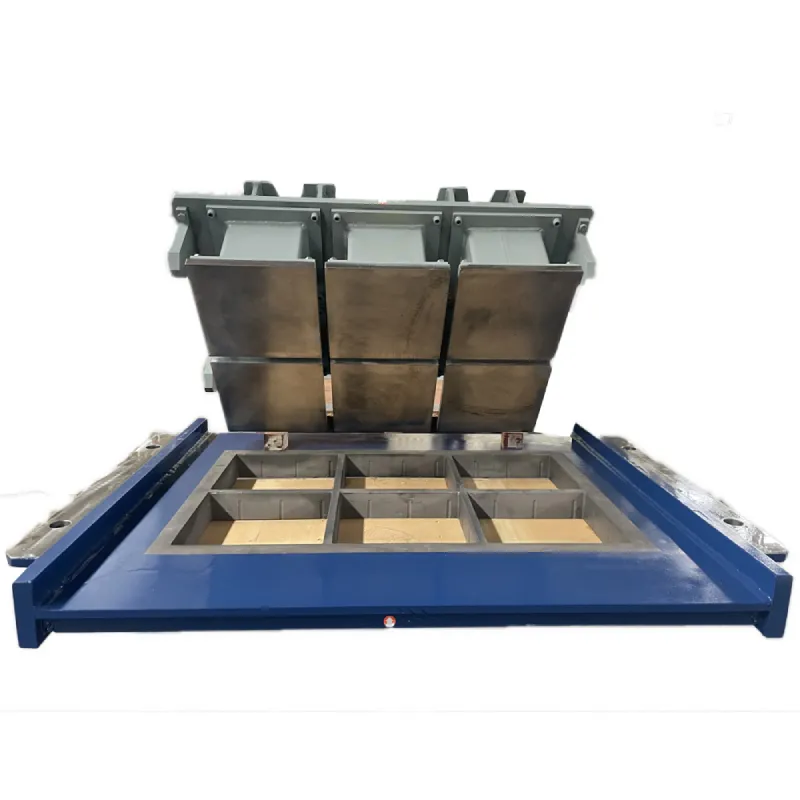

Advanced Assembly Process

-

Precision Welding & Stress Relief: We use advanced welding and de-stress treatments to prevent deformation in the cavity and core. This ensures accurate dimensions, shapes, and tolerances, avoiding jams or unusable components.

-

Press Foot Clearance: Maintained between 0.3–0.8mm for machine compatibility.

-

Durable Connections: High-strength bolts with anti-loosening treatment and standardized parts for easy replacement.

-

Wear-Resistant Steel Plates: High-quality plates for extended mold life.

-

Damping Function: Reduces vibration for smoother operation.

-

Digital Free Surface Design: Allows customized mold configurations.

Durability Treatment

-

Carbonitriding Heat Treatment (60-65 HRC): Die frame and press foot hardened for durability.

-

Minimum Hardening Depth: 1.2mm for enhanced strength.

FAQ

1. How can I get a quotation?

-

Send detailed block drawings for an accurate quote.

-

Without drawings, specify the block type (hollow, solid, etc.), provide a photo, and share dimensions (length × width × thickness in mm).

-

Provide pallet size, tamper head size, and down mold height.

-

Explain mold-to-machine connection; provide connection drawings if available.

2. Will the mold fit my machine?

-

We manufacture molds for multiple brands and maintain detailed records. Many molds are already compatible.

-

If needed, we can guide you digitally with photos and measurements, or an engineer can visit. We guarantee proper fit after confirmation.

3. Payment Terms

-

50% advance via T/T to start the order; remaining balance before shipment.

4. Contact Information

-

WeChat / WhatsApp: +86-1330506196 / +86-18960287187