Unternehmensnachrichten

-

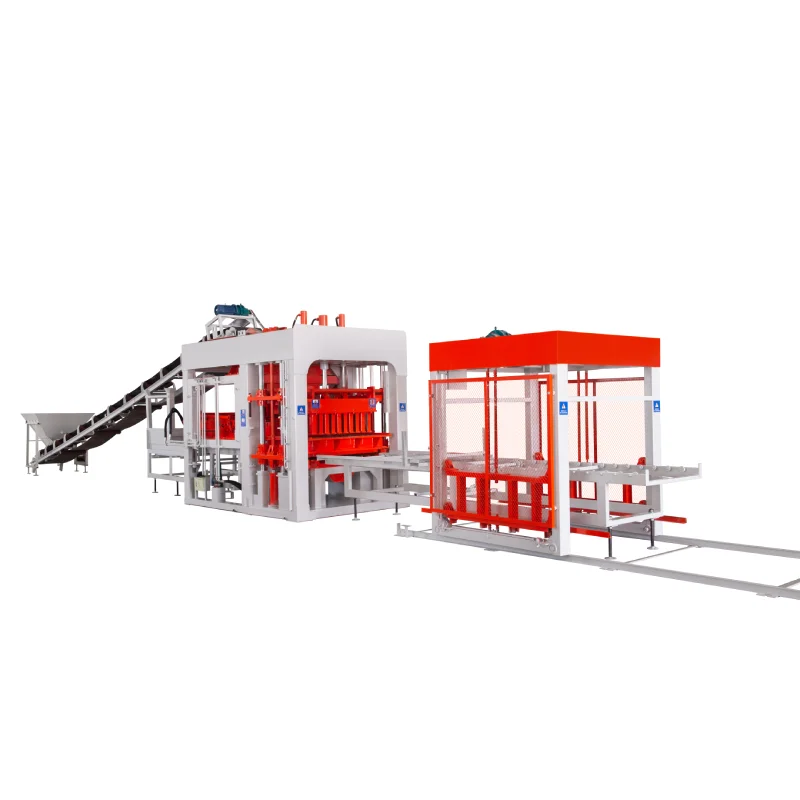

Wie Maschinen zur Herstellung von Ziegeln die Zukunft des Bauens prägen

Lesen Sie mehrEinleitung: Die Rolle von Ziegeln im modernen Bauwesen Ziegel sind seit langem ein fester Bestandteil des Bauwesens, denn sie bieten Haltbarkeit, Stärke und Vielseitigkeit. Im modernen Bauwesen sorgen Ziegel nicht nur für strukturelle Integrität, sondern tragen auch zu Energieeffizienz und Kosteneinsparungen bei. Angesichts der steigenden Nachfrage nach qualitativ hochwertigen Ziegeln setzt die Industrie zunehmend auf Maschinen zur Herstellung von Ziegeln, um [...]

-

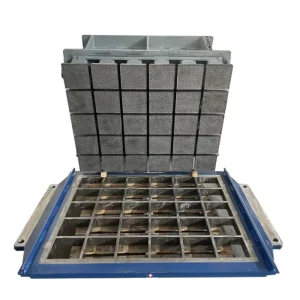

Ein umfassender Leitfaden für Hohlblockformen und Maschinen

Lesen Sie mehrIntroduction: The Growing Demand for Hollow Blocks Hollow blocks are increasingly popular in the construction industry due to their lightweight nature, thermal insulation properties, and cost-effectiveness. These blocks, made from a mixture of cement, aggregates, and water, are used in various construction applications, from foundations to partition walls. As demand for these blocks rises, manufacturers […]

-

Wie lässt sich Beton am besten aus Formen entfernen?

Lesen Sie mehrRemoving concrete from molds efficiently and without damage is a crucial step in block production. Whether you are working with concrete pavement moulds, concrete block making moulds, or concrete brick molds, understanding the best methods will ensure smooth operations and high-quality results. In this guide, we will explore proven techniques that improve mold removal while […]

-

Wie eine automatische Falzziegelmaschine die Effizienz beim Bau verbessert

Lesen Sie mehrThe construction industry is undergoing significant changes, with automation becoming a driving force behind efficiency improvements. Key innovations such as the automatic fly ash bricks machine, automatic interlocking brick machine, and fully automated brick making machine are transforming brick production. These machines provide higher output, improved consistency, and lower costs, ultimately boosting construction project timelines […]

-

Steigern Sie Ihr Geschäft mit einer vollautomatischen Ziegelsteinproduktionslinie

Lesen Sie mehrWhy Invest in a Fully Automated Brick Production Line? Investing in a fully automated brick production line offers significant advantages for businesses in the construction industry. As the demand for durable, sustainable, and high-quality building materials continues to rise, automated production lines provide a way to meet these needs efficiently. Key benefits include: Automation not […]

-

Welche Vorteile bietet die Gründung eines Unternehmens der Ziegelherstellung?

Lesen Sie mehrZiegel sind im Bauwesen unverzichtbar und werden aufgrund ihrer Langlebigkeit und Vielseitigkeit auch in Zukunft gefragt sein. Mit dem Wachstum der Städte und der Vervielfachung der Bauprojekte bietet die Ziegelindustrie beträchtliche Chancen. Darüber hinaus hat sich die Ziegelherstellung mit dem wachsenden Bewusstsein für Nachhaltigkeit weiterentwickelt und bietet Unternehmern neue Geschäftsmöglichkeiten. Hohe Marktnachfrage Der Bedarf an Ziegeln [...]

-

Why the QT4-15 is Ideal for Medium-Scale Concrete Production

Lesen Sie mehrFor medium-scale concrete block production, businesses need a solution that strikes the perfect balance between efficiency, affordability, and quality. The QT4-15 hydraulic block making machine provides just that. Designed for producers seeking high output with manageable investment costs, the QT4-15 stands as a perfect choice for those looking to optimize their production without overcommitting on […]

-

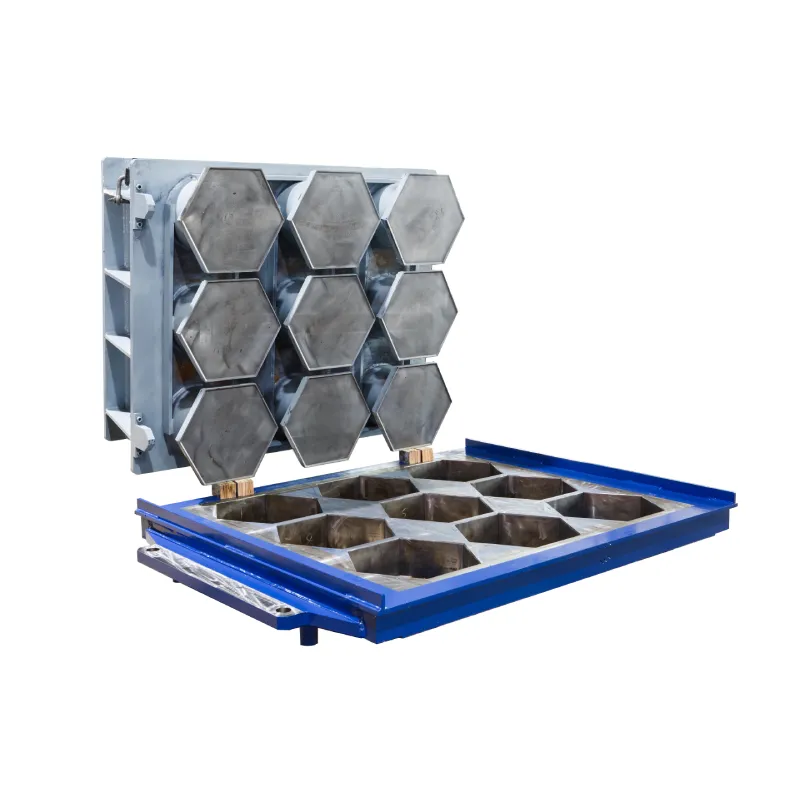

Zukünftige Trends bei Interlocking Molds: Was kommt als Nächstes?

Lesen Sie mehrInterlocking molds play an increasingly important role in concrete block production. As industries strive for higher efficiency, customization, and sustainability, these molds are evolving to meet these demands. The future of interlocking molds looks promising. Several key trends are emerging that will shape their development in the coming years. 1. Advanced Materials for Better Durability […]

-

Wie Sie die richtige Hohlblockform für Ihre Produktionslinie auswählen

Lesen Sie mehrSelecting the right hollow block mould is crucial for ensuring the efficiency and quality of your concrete block production line. With so many options available, understanding the types, materials, and features of hollow block moulds will help you make an informed decision. Important factors to consider include hollow block mould design, material selection, price, and choosing the right supplier to […]

-

How to Clean Precast Concrete Block Moulds After Use

Lesen Sie mehrPrecast concrete block moulds play a crucial role in concrete block production, and maintaining their quality is essential for smooth and efficient manufacturing. At KBL Machinery, we specialize in precast concrete block moulds made from high-quality materials such as Q355 steel and premium Italian steel, ensuring both durability and reliability. These materials help our moulds withstand repeated use […]