Ziegelsteinform

-

Why the QT4-15 is Ideal for Medium-Scale Concrete Production

Lesen Sie mehrFor medium-scale concrete block production, businesses need a solution that strikes the perfect balance between efficiency, affordability, and quality. The QT4-15 hydraulic block making machine provides just that. Designed for producers seeking high output with manageable investment costs, the QT4-15 stands as a perfect choice for those looking to optimize their production without overcommitting on […]

-

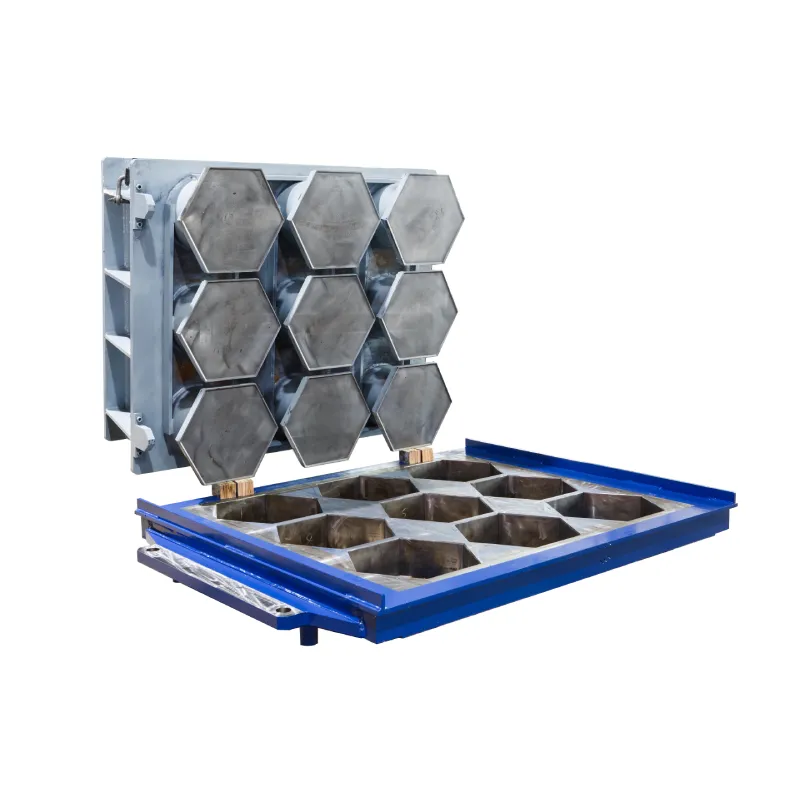

Wie Sie die richtige Hohlblockform für Ihre Produktionslinie auswählen

Lesen Sie mehrSelecting the right hollow block mould is crucial for ensuring the efficiency and quality of your concrete block production line. With so many options available, understanding the types, materials, and features of hollow block moulds will help you make an informed decision. Important factors to consider include hollow block mould design, material selection, price, and choosing the right supplier to […]

-

How to Clean Precast Concrete Block Moulds After Use

Lesen Sie mehrPrecast concrete block moulds play a crucial role in concrete block production, and maintaining their quality is essential for smooth and efficient manufacturing. At KBL Machinery, we specialize in precast concrete block moulds made from high-quality materials such as Q355 steel and premium Italian steel, ensuring both durability and reliability. These materials help our moulds withstand repeated use […]

-

How to Operate the QT4-15 Block Making Machine

Lesen Sie mehrA block making machine is a vital piece of equipment used in the construction industry to produce concrete blocks. These blocks are essential for building walls, pavements, and various other structures. By automating the production process, block making machines enhance efficiency, reduce labor costs, and improve the consistency of the final products. Among all available […]