Der Leitfaden für die Entwicklung nachhaltiger Baumaschinen 2025: 5 bewährte Upgrades für Ihre Blockmaschine

Oktober 21, 2025

Abstrakt

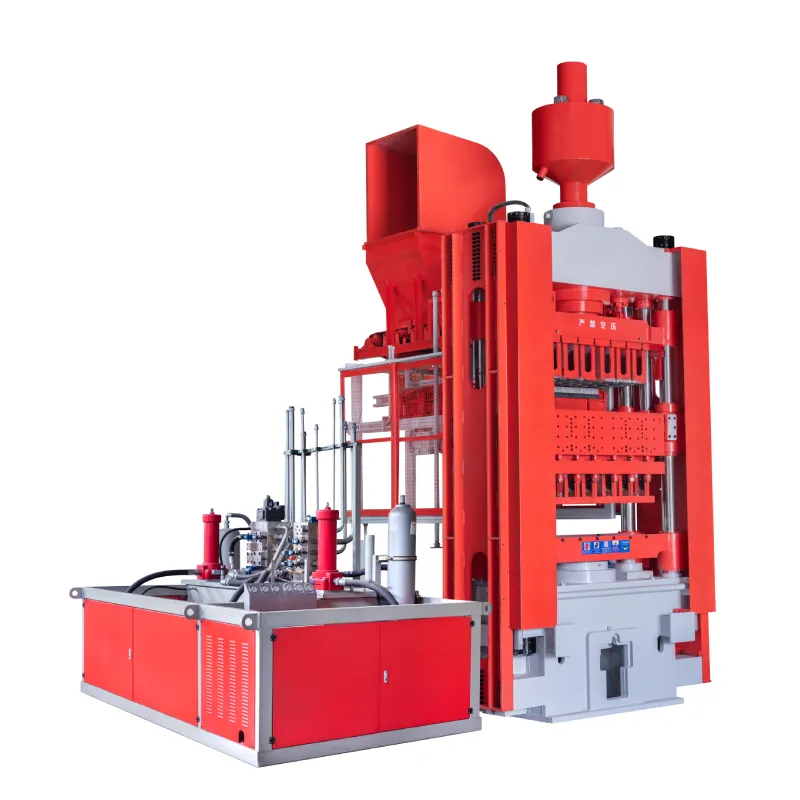

Die weltweite Bauindustrie befindet sich in einem tiefgreifenden Wandel, der durch das wachsende Bedürfnis nach ökologischer Verantwortung und wirtschaftlicher Effizienz angetrieben wird. Besonders ausgeprägt ist dieser Wandel in den sich rasch entwickelnden Regionen Südostasiens und des Nahen Ostens, wo die Nachfrage nach umweltfreundlichen Baulösungen eskaliert. In dieser Analyse wird die Entwicklung nachhaltiger Baumaschinen untersucht, wobei der Schwerpunkt auf Maschinen für die Betonsteinproduktion liegt. Sie bewertet fünf entscheidende technologische Verbesserungen, die die ökologische und ökonomische Leistung moderner Steinfertigungsmaschinen wie der QT-Serie und statischer hydraulischer Pressen verbessern. Zu diesen Fortschritten gehören die Integration ausgeklügelter Materialrecyclingsysteme, Durchbrüche beim energieeffizienten Betrieb, die Einführung intelligenter Automatisierung zur Abfallreduzierung, die Anwendung von Methoden zur Wassereinsparung in geschlossenen Kreisläufen und die Entwicklung langlebiger, hochpräziser Formen. Die Untersuchung zeigt, dass es sich bei diesen Innovationen nicht nur um inkrementelle Verbesserungen handelt, sondern um eine grundlegende Neuausrichtung des Herstellungsprozesses, die die Produktion hochwertiger, umweltfreundlicher Baustoffe ermöglicht, die mit den Grundsätzen einer Kreislaufwirtschaft in Einklang stehen.

Wichtigste Erkenntnisse

- Integrieren Sie recycelte Materialien wie Flugasche, um Abfall und Rohstoffkosten zu reduzieren.

- Durch die Umrüstung auf Servomotorsysteme lässt sich der Energieverbrauch um bis zu 30% senken.

- Nutzen Sie die intelligente Automatisierung für eine präzise Dosierung und minimieren Sie Materialabfälle und Fehler.

- Einführung eines geschlossenen Wasserkreislaufs, um eine lebenswichtige Ressource in der Produktion zu schonen.

- Investieren Sie in langlebige, wärmebehandelte Formen, um die Lebensdauer zu verlängern und die Ersatzkosten zu senken.

- Die Entwicklung einer nachhaltigen Gebäudeausrüstung ist eine Schlüsselstrategie für die Marktführerschaft.

- Berechnen Sie den langfristigen ROI grüner Technologien, um sich einen Wettbewerbsvorteil zu verschaffen.

Inhaltsübersicht

- Die sich wandelnde Landschaft des Bauwesens: Warum Nachhaltigkeit keine Option mehr ist

- Upgrade 1: Fortschrittliches Materialrecycling und Abfallintegrationssysteme

- Upgrade 2: Revolutionierung der Energieeffizienz in der Blockproduktion

- Upgrade 3: Die Kraft der Automatisierung und intelligente Steuerungen für Präzision und weniger Abfall

- Upgrade 4: Technologien zur Wassereinsparung bei der Herstellung von Betonsteinen

- Upgrade 5: Langlebige, hochpräzise Gussformen und Werkzeuge für eine lange Lebensdauer

- Häufig gestellte Fragen (FAQ)

- Schlussfolgerung

- Referenzen

Die sich wandelnde Landschaft des Bauwesens: Warum Nachhaltigkeit keine Option mehr ist

Der Boden, auf dem wir bauen, verändert sich, nicht nur physisch, sondern auch wirtschaftlich und ethisch. Jahrzehntelang war die Geschichte des Bauens von schierer Größe und Geschwindigkeit geprägt, ein Zeugnis menschlichen Ehrgeizes, das in Beton und Stahl geätzt wurde. Doch jetzt, im Jahr 2025, wirkt diese Geschichte unvollständig, fast archaisch. Es wird ein neues Kapitel geschrieben, in dem die Qualität unserer Entwicklung nicht nur an ihrer Höhe oder Breite gemessen wird, sondern an ihrem Fußabdruck - oder dem Fehlen eines solchen. Dieser Übergang zu einer gewissenhafteren Bauweise ist kein vorübergehender Trend, sondern eine grundlegende Neuausrichtung der Branche, eine Reaktion auf das Zusammentreffen mehrerer Faktoren, die in den dynamischen Märkten Südostasiens und des Nahen Ostens besonders akut sind. Das Verständnis dieses Wandels ist der erste Schritt, um die tiefgreifende Bedeutung der Entwicklung nachhaltiger Gebäudeausrüstung zu erkennen.

Stellen Sie sich vor, Sie sind ein Projektmanager in Dubai oder ein Bauunternehmer in Manila. Die Skyline ist in ständiger Bewegung, mit Kränen, die täglich neue Silhouetten in den Himmel zeichnen. Dieser Boom wird durch die wirtschaftliche Diversifizierung, das Bevölkerungswachstum und einen starken Modernisierungsdrang angeheizt. Doch mit diesem Wachstum geht auch ein gesteigertes Bewusstsein für seine Folgen einher. Die Rohstoffe, die wir abbauen, die Energie, die wir verbrauchen, und die Abfälle, die wir erzeugen, sind keine abstrakten Externalitäten mehr, sondern greifbare Kosten in den Bilanzen, Streitpunkte bei behördlichen Überprüfungen und Fragen des öffentlichen Gewissens.

Wirtschaftliche Triebkräfte in Südostasien und dem Nahen Osten

Die wirtschaftlichen Argumente für Nachhaltigkeit waren noch nie so überzeugend wie heute. Ursprünglich wurde "grünes Bauen" oft als Luxus wahrgenommen, als zusätzliche Kosten für einen Nischenmarkt. Diese Sichtweise wird nun durch die nackten wirtschaftlichen Realitäten entkräftet. Die Preisschwankungen bei Rohstoffen wie Sand und Zement machen die Abhängigkeit von neuen Ressourcen zu einem riskanten Unterfangen. Die Energiekosten, die einen erheblichen Teil der Betriebskosten bei der Herstellung ausmachen, steigen weiter an. Die Deponiesteuern und Abfallbeseitigungsgebühren werden immer empfindlicher.

In diesem Zusammenhang bietet die Entwicklung nachhaltiger Baumaschinen einen direkten Weg zu höherer Rentabilität. Eine Maschine, die Bau- und Abbruchabfälle oder industrielle Nebenprodukte wie Flugasche verarbeiten kann, ist nicht nur ein Umweltinstrument, sondern auch ein Schutzschild gegen Rohstoffpreisschocks. Eine hydraulische Blockpresse, die einen Servomotor anstelle einer konventionellen Hydraulikpumpe verwendet, kann die Stromkosten senken, was sich direkt auf den Gewinn des Betreibers auswirkt. Dies sind keine marginalen Gewinne. Sie stellen einen strategischen Schwenk hin zu einem widerstandsfähigeren und kostengünstigeren Geschäftsmodell dar. Der Markt selbst belohnt diese Umstellung. Eine wachsende Gruppe von Investoren, Firmenmietern und Hauskäufern zeigt eine klare Präferenz für Immobilien mit Umweltzertifizierung, da sie wissen, dass diese Gebäude niedrigere Betriebskosten und ein gesünderes Lebensumfeld versprechen.

Regulatorischer Druck und Green-Building-Zertifizierungen

Die Regierungen in beiden Regionen sind nicht länger passive Beobachter. Sie sind sich der ökologischen und wirtschaftlichen Tragweite bewusst und führen strengere Bauvorschriften und Umweltbestimmungen ein. In den Vereinigten Arabischen Emiraten setzen Initiativen wie das Estidama Pearl Rating System in Abu Dhabi und die Dubai Green Building Regulations feste Maßstäbe für Ressourceneffizienz. In ähnlicher Weise schaffen Länder in Südostasien, wie Singapur mit seinem Green Mark System, ein Regelwerk, bei dem Nachhaltigkeit eine Voraussetzung für die Genehmigung ist und nicht nur ein nachträglicher Gedanke.

Diese Rahmenbedingungen schaffen einen starken Anreiz von oben nach unten für Auftragnehmer und Hersteller. Wer sich um große öffentliche und private Projekte bewerben und diese gewinnen will, muss in der Lage sein, Materialien zu liefern, die diese strengen Kriterien erfüllen. Hier werden die Fähigkeiten Ihrer Maschinen zu Ihrem Wettbewerbsvorteil. Kann Ihre Betonsteinfertigungsmaschine Blöcke mit einem bestimmten Prozentsatz an recyceltem Material herstellen? Können Sie den Nachweis erbringen, dass die Steine in einem energie- und wasserarmen Verfahren hergestellt werden? Diese Fragen stehen heute im Mittelpunkt von Beschaffungs- und Ausschreibungsverfahren. Die Entwicklung nachhaltiger Gebäudeausrüstungen ist unmittelbar damit verbunden, Unternehmen dabei zu helfen, diese Fragen mit einem sicheren "Ja" zu beantworten. Zertifizierungen wie LEED (Leadership in Energy and Environmental Design) und BREEAM (Building Research Establishment Environmental Assessment Method) fungieren als globale Standards, und die Ausrichtung der Produktionsmethoden an deren Anforderungen eröffnet ein Premium-Marktsegment.

Der moralische und ökologische Imperativ

Jenseits der Tabellenkalkulationen und Regelungsdokumente liegt eine tiefere, menschlichere Dimension dieses Wandels. Die greifbaren Auswirkungen der Umweltzerstörung sind nicht mehr nur ferne Nachrichtenmeldungen. Der städtische Wärmeinseleffekt, die Luft- und Wasserverschmutzung und die sichtbaren Berge von Bauschutt sind für Millionen von Menschen tägliche Realität. Es gibt ein wachsendes Gefühl der kollektiven Verantwortung und die Erkenntnis, dass die Art und Weise, wie wir bauen, einen direkten Einfluss auf die Gesundheit unserer Gemeinden und das Erbe hat, das wir künftigen Generationen hinterlassen.

Dieser moralische Imperativ fördert ein Umfeld der Innovation. Sie fordert Ingenieure und Hersteller auf, über die unmittelbare Funktion einer Maschine hinaus zu denken und ihren gesamten Lebenszyklus zu berücksichtigen. Sie fordert uns auf, Abfall nicht als etwas zu betrachten, das weggeworfen werden muss, sondern als eine Ressource, die wiederverwertet werden kann. Sie zwingt uns, Energie und Wasser nicht als unendlichen Input zu betrachten, sondern als kostbare Ressourcen, die es mit Einfallsreichtum zu bewahren gilt. Das Streben nach einer nachhaltigen Entwicklung der Gebäudeausrüstung ist in diesem Sinne eine Übung in angewandter Ethik. Es geht darum, unsere industriellen Kapazitäten mit unseren Werten in Einklang zu bringen und Werkzeuge zu schaffen, die nicht nur Strukturen aufbauen, sondern auch zu einer lebenswerteren und widerstandsfähigeren Welt beitragen. Es ist eine Antwort auf die leise, aber hartnäckige Frage: Wie können wir die Zukunft aufbauen, ohne sie von unseren Kindern zu borgen?

Upgrade 1: Fortschrittliches Materialrecycling und Abfallintegrationssysteme

Im Mittelpunkt eines jeden Bauprojekts steht die Umwandlung von Materialien. Wir nehmen die Erde - Sand, Kies, Kalkstein - und formen sie zu den Fundamenten unserer Städte um. Seit Jahrhunderten ist dies ein weitgehend linearer Prozess: Gewinnen, verwenden, wegwerfen. Das Ergebnis ist ein doppeltes Problem: die Erschöpfung endlicher natürlicher Ressourcen und die Entstehung riesiger Mengen an Bau- und Abbruchabfällen. Im Jahr 2025 ist dieses Modell nicht nur unhaltbar, sondern auch wirtschaftlich unhaltbar. Die erste und vielleicht einflussreichste Grenze bei der Entwicklung nachhaltiger Gebäudeausrüstung ist die Fähigkeit, diese lineare Kette zu durchbrechen und Abfallströme durch fortschrittliches Materialrecycling und Integration in Wertströme zu verwandeln.

Stellen Sie sich eine herkömmliche Steinfertigungsanlage vor. Es ist ein hungriger Betrieb, der ständig neue Zuschlagstoffe und Zement benötigt. Stellen Sie sich nun den Abriss eines alten Gebäudes nur wenige Kilometer entfernt vor. Lastwagenladungen mit zerkleinertem Beton, zerbrochenen Ziegeln und anderem Schutt werden auf eine Deponie gebracht, wo sie jahrhundertelang lagern werden. Das ist eine tiefe Kluft. Die Lösung liegt darin, eine Brücke zwischen der Abbruchstelle und dem Ziegelwerk zu schlagen, und moderne Maschinen sind diese Brücke.

Das Problem der Bau- und Abbruchabfälle (C&D)

Das Ausmaß des Problems der Bau- und Abbruchabfälle kann kaum überschätzt werden. Es kann zwischen 10% und 30% aller weltweit auf Deponien abgelagerten Abfälle ausmachen. In den schnell urbanisierenden Landschaften Südostasiens und des Nahen Ostens liegt diese Zahl oft am oberen Ende des Spektrums. Diese Abfälle sind nicht nur ein Schandfleck, sondern bedeuten auch einen massiven Verlust an gebundener Energie und Ressourcen. Die Energie, die für den Abbau, die Verarbeitung und den Transport der ursprünglichen Materialien aufgewendet wurde, wird einfach weggeworfen. Die Mülldeponien füllen sich, und die Kosten für die Entsorgung steigen.

Darüber hinaus fordert die unerbittliche Gewinnung von Rohstoffen wie Sand und Kies ihren eigenen hohen ökologischen Tribut. Sie kann zur Erosion von Flussbetten, zur Zerstörung von Lebensräumen an der Küste und zu sozialen Konflikten über die Landnutzung führen. Die Herausforderung besteht also darin, C&D-Abfälle neu zu konzipieren. Anstatt ihn als Problem am Ende des Lebenszyklus zu sehen, müssen wir ihn als Rohstoffquelle betrachten, als eine Art "urbaner Bergbau", der die Rohstoffe für neue Gebäude liefert. Dieser philosophische Wandel wird durch die gezielte Entwicklung nachhaltiger Baugeräte in die Praxis umgesetzt.

Integration von rezyklierten Gesteinskörnungen: Von Flugasche zu gebrochenem Beton

Die gute Nachricht ist, dass viele Bestandteile von Bau- und Abbruchabfällen durchaus als Ersatz für neue Zuschlagstoffe verwendet werden können. Zerkleinerter Beton zum Beispiel kann so aufbereitet und sortiert werden, dass er einen großen Teil des natürlichen Kieses und Sandes in einer Betonmischung ersetzt. Industrielle Nebenprodukte bieten eine weitere reichhaltige Quelle für Möglichkeiten. Flugasche, ein feines Pulver, das als Nebenprodukt in Kohlekraftwerken anfällt, ist eine besonders wertvolle Ressource. Wird es einer Betonmischung zugesetzt, weist es puzzolanische Eigenschaften auf, d. h. es reagiert mit Kalziumhydroxid (einem Nebenprodukt der Zementhydratation) und bildet zusätzliche zementhaltige Verbindungen. Dadurch wird nicht nur die benötigte Zementmenge - der kohlenstoffintensivste Bestandteil von Beton - reduziert, sondern auch die langfristige Festigkeit und Haltbarkeit des Endprodukts verbessert.

Andere Materialien, wie gemahlene Hochofenschlacke (GGBFS) aus der Stahlherstellung oder Silikastaub aus der Siliziumproduktion, bieten ähnliche Vorteile. Entscheidend ist, dass die Anlagen mit der Variabilität dieser Materialien umgehen können. Im Gegensatz zu neuen Gesteinskörnungen, die eine hohe Konsistenz aufweisen, können rezyklierte Materialien in Größe, Form, Feuchtigkeitsgehalt und chemischer Zusammensetzung variieren. Hier kommt der fortschrittlichen Maschinenkonstruktion eine entscheidende Bedeutung zu.

Wie moderne Maschinen der QT-Serie mit unterschiedlichen Materialien umgehen

Die neueste Generation von Vollautomatische Betonsteinmaschinenwie die QT-Serie, sind speziell für diese Herausforderung entwickelt worden. Sie gehen über den Einheitsansatz älterer Modelle hinaus. Und so machen sie es:

- Fortschrittliche Dosier- und Wägesysteme: Präzision ist alles. Diese Maschinen verwenden Zuschlagstofftrichter mit mehreren Behältern, die jeweils mit hochpräzisen Wägezellen ausgestattet sind. Das Steuersystem kann so programmiert werden, dass für jede Charge ein bestimmtes, variables Verhältnis verschiedener Materialien - z. B. 60% Rohsand, 30% gebrochener Beton und 10% Flugasche - verwendet wird. Dies gewährleistet ein konsistentes Mischungsdesign, selbst wenn mehrere, unkonventionelle Einsatzstoffe verwendet werden.

- Hocheffiziente Zwangsmischer: Es reicht nicht aus, diese unterschiedlichen Materialien einfach zusammenzukippen'. Ein moderner Zwangsmischer mit seinen kräftigen, gegenläufig rotierenden Schaufeln erzeugt eine erzwungene Scher- und Taumelwirkung. Dadurch wird sichergestellt, dass die feinen Partikel der Flugasche gründlich dispergiert werden, dass die kantigen rezyklierten Zuschlagstoffe ordnungsgemäß mit Zementleim umhüllt werden und dass jedes Mal eine homogene, verarbeitbare Mischung entsteht. Dies ist ein großer Unterschied zu älteren, weniger kräftigen Trommelmischern.

- Adaptive Vibrationstechnologie: Auch der Verdichtungsprozess muss intelligent sein. Die optimale Vibrationsfrequenz und -amplitude für eine Mischung mit leichter Flugasche unterscheidet sich von einer Mischung mit dichtem Recyclingbeton. Moderne Systeme verwenden frequenzvariable Antriebe (VFDs) an ihren Vibrationsmotoren. Der Bediener kann die Vibrationsprofile auf das jeweilige Mischgut abstimmen oder sogar vorprogrammieren, um eine maximale Verdichtung und Dichte für jeden Blocktyp zu gewährleisten und so eine gleichbleibende Festigkeit und Qualität zu garantieren. Dieses Maß an Kontrolle ist von grundlegender Bedeutung für den Erfolg der Entwicklung nachhaltiger Baumaschinen.

Eine Fallstudie: Abbruchschutt in Profit verwandeln

Betrachten wir ein hypothetisches, aber realistisches Szenario. Ein Bauunternehmen in Jeddah, Saudi-Arabien, investiert in eine moderne Steinfertigungsanlage der Serie QT. Bei einem großen Stadterneuerungsprojekt in der Nähe fallen Tausende von Tonnen Betonschutt an. Anstatt für die Entsorgung dieser Abfälle Deponiegebühren zu zahlen, richtet das Unternehmen vor Ort einen einfachen Brech- und Siebbetrieb ein. Der aufbereitete Recycling-Betonzuschlag (RCA) wird dann zu seinem neuen Steinwerk transportiert.

Durch die Substitution von 40% der neuen Gesteinskörnung durch RCA und 15% des Zements durch lokal bezogene Flugasche erzielt das Unternehmen mehrere bemerkenswerte Ergebnisse. Erstens sinken die Rohstoffkosten um über 25%. Zweitens generiert das Unternehmen eine neue Einnahmequelle, indem es für die Annahme des Abbruchmaterials eine Kippgebühr erhebt (die niedriger ist als die Deponiegebühren). Drittens können die von ihnen hergestellten Blöcke, die alle erforderlichen Festigkeitsanforderungen erfüllen, als "grüne" Produkte vermarktet werden, so dass sie einen lukrativen Auftrag für eben dieses Stadterneuerungsprojekt erhalten. So entsteht ein perfekter Kreislauf der Wirtschaft. Die alte Stadt wird buchstäblich für den Bau der neuen genutzt. Dies ist keine futuristische Fantasie, sondern die praktische, gewinnbringende Realität, die durch die heutige Entwicklung nachhaltiger Gebäudeausrüstung ermöglicht wird.

Upgrade 2: Revolutionierung der Energieeffizienz in der Blockproduktion

In der Welt der Fertigung ist Energie das Lebenselixier. Sie treibt die Motoren an, heizt die Öfen und treibt die Hydraulik an, die die Rohstoffe in Fertigprodukte verwandelt. Bei der Herstellung von Betonsteinen ist dieser Energieverbrauch traditionell immens und stellt einen großen Kostenfaktor und eine erhebliche Umweltbelastung dar. Der zweite große Sprung nach vorn in der Entwicklung nachhaltiger Baumaschinen ist ein direkter Angriff auf diese Ineffizienz. Durch eine Kombination aus intelligentem Design, Elektrifizierung und optimierten Prozessen verändern moderne Maschinen die Energiegleichung grundlegend und machen die Steinproduktion nicht nur sauberer, sondern auch deutlich wirtschaftlicher.

Stellen Sie sich das Geräusch und das Gefühl einer alten Hydraulikpresse vor. Ein konstantes, leises Brummen des Elektromotors, der ständig läuft, um die Hydraulikflüssigkeit unter Druck zu halten und für den Moment der Verdichtung bereit zu halten. Selbst wenn die Maschine zwischen den Zyklen im Leerlauf ist, zieht dieser Motor Strom. Das ist so, als würde man den Motor seines Autos an jeder roten Ampel laufen lassen. Das ist Verschwendung. Stellen Sie dem das Geräusch einer modernen servoelektrischen Maschine gegenüber: präzise, kontrollierte Energieausbrüche, gefolgt von fast völliger Stille. Dieser Unterschied im Klang ist der hörbare Ausdruck einer Revolution in der Energieeffizienz.

Von der Hydraulik zur Servo-Vibration: Der energiesparende Sprung

Das Herzstück einer Steinfertigungsmaschine ist ihr Verdichtungs- und Vibrationssystem. Hier wird die lose Betonmischung zu einem festen Block verdichtet. Jahrzehntelang wurde dies mit Hilfe von Hydraulik mit brachialer Gewalt bewerkstelligt. Ein großer Elektromotor treibt eine Pumpe an, die Öl unter Druck setzt, um massive Zylinder zu bewegen, die das Gemisch verdichten, während andere Hydraulikmotoren Exzentergewichte antreiben, die Vibrationen erzeugen. Dieses System ist leistungsstark und robust, aber auch notorisch ineffizient.

Der entscheidende Wendepunkt war die Einführung der Servomotoren-Technologie, einem Kernstück der modernen Entwicklung nachhaltiger Gebäudeausrüstung. Ein Servomotor ist ein hochpräziser Elektromotor, der bei Bedarf Energie liefert. So verändert er den Prozess:

- Strom auf Abruf: Im Gegensatz zu einer ständig laufenden Hydraulikpumpe verbraucht ein Servomotor nur während der wenigen Sekunden der eigentlichen Verdichtungs- und Rüttelphase des Zyklus viel Energie. In der übrigen Zeit des Zyklus - wenn der Formkasten gefüllt oder die fertigen Blöcke ausgeworfen werden - ist der Motor entweder ausgeschaltet oder verbraucht nur eine geringe Menge an Energie. Diese einfache Änderung kann den Gesamtenergieverbrauch der Maschine um 20-40% senken.

- Präzision und Kontrolle: Servomotoren bieten eine unvergleichliche Kontrolle über Geschwindigkeit, Drehmoment und Position. Dies ermöglicht die Erstellung eines "Vibrationsprofils". Anstelle einer einzigen, groben Frequenz kann das System mit einer niederfrequenten Vibration mit hoher Amplitude beginnen, um das Material zu beruhigen, und dann zu einer hochfrequenten Vibration mit niedriger Amplitude für die endgültige Verdichtung übergehen. Dies spart nicht nur Energie durch intelligenteren Einsatz, sondern führt auch zu einem dichteren, stärkeren und gleichmäßigeren Block.

- Geringerer Wartungsaufwand und geringeres Umweltrisiko: Hydraulische Systeme sind anfällig für Leckagen, erfordern regelmäßige Filterwechsel und erfordern die Entsorgung von gebrauchtem Hydrauliköl, das ein gefährliches Material ist. Bei servoelektrischen Systemen entfallen diese Probleme. Es gibt kein Öl, das auslaufen kann, keine Filter, die verstopfen, und kein komplexes Netzwerk von Schläuchen und Ventilen, das gewartet werden muss. Dies reduziert die Ausfallzeiten, senkt die Wartungskosten und beseitigt ein erhebliches Umweltrisiko in der Fabrikhalle.

Die nachstehende Tabelle bietet einen klaren Vergleich und veranschaulicht die greifbaren Vorteile dieser technologischen Entwicklung.

| Merkmal | Traditionelles hydraulisches System | Modernes servoelektrisches System |

|---|---|---|

| Energieverbrauch | Kontinuierliche Leistungsaufnahme von Motor und Pumpe, hohe Standby-Verluste. | Power-on-demand, minimaler Energieverbrauch während der Leerlaufzeiten. |

| Kontrolle der Präzision | Begrenzte Kontrolle über Schwingungsfrequenz und -amplitude. | Hochgradig programmierbare Vibrationsprofile für optimale Verdichtung. |

| Betriebsgeräusche | Konstantes Brummen des Hydraulikaggregats mit hoher Lautstärke. | Geringere Betriebsgeräusche, mit Spitzenwerten nur während des Arbeitszyklus. |

| Wartung | Erfordert Ölwechsel, Filterwechsel und Schlauchinspektionen. | Praktisch wartungsfreie Elektromotoren und Antriebe. |

| Auswirkungen auf die Umwelt | Gefahr des Austretens von Hydrauliköl, Probleme bei der Ölentsorgung. | Kein Hydrauliköl, wodurch Leckagerisiken und Entsorgungskosten vermieden werden. |

| Zyklusgeschwindigkeit | Begrenzt durch die Durchflussmenge der Hydraulikflüssigkeit. | Schnellere, reaktionsfreudigere Bewegungen, die die Anzahl der Zyklen erhöhen können. |

Optimierung von Härtungsprozessen: Niedrigenergetische, hochfeste Methoden

Die Energiegeschichte ist noch nicht zu Ende, wenn der Block die Maschine verlässt. Der Aushärtungsprozess, bei dem der Block seine endgültige Festigkeit erhält, ist ein weiterer Bereich, der optimiert werden kann. Traditionell haben viele Hersteller die Dampfhärtung eingesetzt, um diesen Prozess zu beschleunigen, insbesondere in kälteren Klimazonen. Dabei werden große Mengen an Dampf in isolierte Öfen gepumpt, ein Prozess, der große Mengen an Brennstoff oder Strom verbraucht, um das Wasser zu erhitzen.

Die nachhaltige Alternative, die perfekt zu Blöcken aus hochwertigen Maschinen passt, ist die kontrollierte Aushärtung bei Raumtemperatur. Durch die Herstellung eines perfekt verdichteten Steins mit einem optimalen Wasser-Zement-Verhältnis wird die Notwendigkeit einer beschleunigten, energieintensiven Aushärtung reduziert. Moderne Best Practices konzentrieren sich auf:

- Vernebelungssysteme: Anstelle von Hochtemperaturdampf verwenden diese Systeme Hochdruckdüsen, um einen feinen Nebel in der Aushärtekammer zu erzeugen. Dadurch wird eine Umgebung mit hoher Luftfeuchtigkeit (über 90%) aufrechterhalten, die verhindert, dass Wasser von der Oberfläche des Blocks verdampft, so dass der Zementhydratationsprozess effizient ablaufen kann. Dabei wird nur ein Bruchteil der Energie eines Dampfkessels verbraucht.

- Isolierte Kammern: Einfach, aber effektiv. Gut isolierte und abgedichtete Nachbehandlungsräume fangen die natürliche Wärme ein, die durch die exotherme Reaktion der Zementhydratation entsteht. In vielen Klimazonen, insbesondere in den warmen Regionen des Nahen Ostens und Südostasiens, reicht diese selbst erzeugte Wärme aus, um eine ordnungsgemäße Aushärtung ohne externe Energiezufuhr zu gewährleisten.

Die Rolle intelligenter Energiemanagementsysteme

Die fortschrittlichsten Anlagen integrieren jetzt intelligente Energiemanagementsysteme, die die gesamte Fabrik als ein einziges Ökosystem betrachten. Diese Systeme, die häufig Teil einer umfassenderen Plattform für das industrielle Internet der Dinge (IIoT) sind, überwachen den Energieverbrauch in Echtzeit, vom Mischer über die Blockmaschine bis hin zum Aushärtungssystem.

Sie können ineffiziente Geräte identifizieren und kennzeichnen, energieintensive Prozesse für Zeiten außerhalb der Stromspitzen planen, um Kosten zu senken, und detaillierte Datenanalysen bereitstellen, die den Managern helfen, fundierte Entscheidungen über die Produktionsplanung und die Aufrüstung von Geräten zu treffen. Dieser datengesteuerte Ansatz ist ein Eckpfeiler der nächsten Generation der Entwicklung nachhaltiger Gebäudeausrüstungen, die von einzelnen effizienten Maschinen zu einer vollständig optimierten, energieintelligenten Produktionslinie übergehen.

Berechnung des ROI für eine energieeffiziente Modernisierung

Für einen Geschäftsinhaber ist die Entscheidung, in neue Technologie zu investieren, immer eine Frage der Kapitalrendite (ROI). Das Schöne an energieeffizienten Upgrades ist, dass der ROI oft überraschend schnell und einfach zu berechnen ist.

Stellen wir uns ein mittelgroßes Blockwerk in Malaysia vor, das eine ältere hydraulische Maschine 10 Stunden pro Tag und 250 Tage im Jahr betreibt. Das Aggregat dieser Maschine verbraucht durchschnittlich 75 kW. Sie rüsten auf eine neue Maschine mit Servoantrieb um, deren durchschnittlicher Verbrauch bei 45 kW liegt.

- Tägliche Energieeinsparungen: (75 kW - 45 kW) * 10 Stunden = 300 kWh

- Jährliche Energieeinsparungen: 300 kWh/Tag * 250 Tage/Jahr = 75.000 kWh

- Jährliche Kosteneinsparungen: Geht man von einem Strompreis von $0,12 USD pro kWh aus, so ergibt sich eine jährliche Einsparung von 75.000 kWh * $0,12 = $9.000.

Diese $9.000 sind eine direkte Einsparung, eine jährliche Rente, die durch die Technologie selbst zurückgezahlt wird. Rechnet man die geringeren Wartungskosten (kein Austausch von Hydrauliköl, Filtern oder Schläuchen) und das Potenzial für Produktionssteigerungen aufgrund schnellerer Zykluszeiten hinzu, kann die Amortisationszeit für die Erstinvestition oft nur 3-5 Jahre betragen. Dies macht die Einführung energieeffizienter Maschinen nicht nur zu einer umweltfreundlichen Entscheidung, sondern auch zu einer leistungsstarken Finanzstrategie.

Upgrade 3: Die Kraft der Automatisierung und intelligente Steuerungen für Präzision und weniger Abfall

Das Bild der Fertigung ist oft von physischer Kraft geprägt - das Pressen von Formen, das Mischen von Aggregaten. Doch die wahre Revolution in der modernen Industrie und eine der wichtigsten Säulen der Entwicklung nachhaltiger Baugeräte findet im Bereich des Immateriellen statt: in Daten, in Steuerungssystemen und in der Intelligenz, die die Maschine steuert. Automatisierung und intelligente Steuerungen verwandeln die Blockproduktion von einem Handwerk, das auf die Intuition des Bedieners angewiesen ist, in eine Wissenschaft der Präzision. Dieser Wandel hat tiefgreifende Auswirkungen auf die Nachhaltigkeit, vor allem durch den Kampf gegen Verschwendung in all ihren Formen: verschwendetes Material, verschwendete Energie und verschwendetes menschliches Potenzial.

Stellen Sie sich vor, Sie backen einen Kuchen mit der Hand. Sie könnten das Mehl mit einem Löffel abmessen, die Wassermenge schätzen und so lange mischen, bis es sich "richtig anfühlt". Das Ergebnis kann gut sein, aber es ist selten identisch. Stellen Sie sich nun eine professionelle Bäckerei vor, in der jede Zutat grammgenau abgewogen wird, die Mischzeit und die Geschwindigkeit genau kontrolliert werden und die Ofentemperatur auf den Bruchteil eines Grades genau gesteuert wird. Das Ergebnis ist perfekte Konsistenz, Charge für Charge. Dies ist der Wandel, den die intelligente Automatisierung in der Welt der Betonsteinherstellung bewirkt.

Mehr als einfache Automatisierung: Das Aufkommen von IoT und Datenanalyse

Die frühe Automatisierung in Blockanlagen konzentrierte sich auf einfache, sich wiederholende Aufgaben: das Bewegen von Paletten oder das Stapeln von Würfeln. Heute geht es bei der "intelligenten" Automatisierung darum, ein vernetztes, selbstbewusstes System zu schaffen. Dies ist das industrielle Internet der Dinge (IIoT), bei dem die Maschinen mit einer Reihe von Sensoren ausgestattet sind, die ständig Daten sammeln. Diese Sensoren messen alles: den Feuchtigkeitsgehalt des Sandes, die Temperatur der Mischung, die Vibrationsfrequenz der Form, die Stromaufnahme der Motoren.

Diese Daten werden in eine zentrale speicherprogrammierbare Steuerung (SPS) oder einen moderneren Industrie-PC eingespeist. Dieses "Gehirn" führt nicht nur eine feste Abfolge von Befehlen aus; es analysiert die Daten in Echtzeit und nimmt Mikroeinstellungen vor. Wenn es feststellt, dass der Sand feuchter als üblich ist, kann es automatisch die dem Mischer zugeführte Wassermenge reduzieren, um das perfekte Wasser-Zement-Verhältnis zu erhalten. Diese Verlagerung von vorprogrammierten Aktionen zu datengesteuerten Reaktionen ist das, was eine wirklich intelligente Fabrik ausmacht. Die aus diesen Daten gewonnenen Erkenntnisse sind ein wichtiger Bestandteil der kontinuierlichen Entwicklung nachhaltiger Gebäudeausrüstung und ermöglichen eine kontinuierliche Verbesserung.

Präzises Dosieren und Mischen: Eliminierung von Materialverschwendung

Die unmittelbarste Auswirkung der intelligenten Automatisierung betrifft den Materialverbrauch. In einer traditionellen Anlage wird ein gewisser Abfall als unvermeidlich akzeptiert. Ein Bediener könnte den Formkasten leicht überfüllen, um einen vollständigen Block zu erhalten, wobei das überschüssige Material (der "Kragen") abgekratzt und oft weggeworfen oder schlecht wieder eingebaut wird. Chargen von Mischungen können zurückgewiesen werden, weil die Konsistenz falsch ist. Die kumulative Wirkung dieser kleinen Unzulänglichkeiten kann erheblich sein.

Intelligente Kontrollsysteme bekämpfen diese Verschwendung an ihrer Quelle:

- Feuchtigkeitsfühler und automatische Kompensation: In den Zuschlagstoffbehältern und im Mischer installierte Mikrowellen-Feuchtigkeitssonden liefern Echtzeitdaten zum Wassergehalt. Das Steuerungssystem nutzt diese Informationen, um die exakte Wassermenge zu berechnen, die für die Charge benötigt wird, und kompensiert dabei die Umgebungsfeuchtigkeit oder feuchte Rohstoffe. Auf diese Weise wird verhindert, dass zu nasse (was zu schwachen Blöcken führt) oder zu trockene (was eine schlechte Verdichtung zur Folge hat) Mischungen hergestellt werden, so dass Ausschussware praktisch ausgeschlossen ist.

- Wiegen und Dosieren mit Wägezellen: Anstatt sich auf die volumetrische Messung (Befüllen eines Eimers) zu verlassen, verwenden moderne Systeme hochpräzise Wägezellen, um jede einzelne Komponente der Mischung - Zement, Sand, Kies, Wasser und Zusatzmittel - zu wiegen. Dadurch wird gewährleistet, dass jede Charge die gleiche Zusammensetzung hat und perfekt mit dem vorgegebenen Mischungsentwurf übereinstimmt. Dank dieser Präzision können die Hersteller näher an den Mindestanforderungen arbeiten, ohne die Qualität zu gefährden, und teure Materialien wie Zement einsparen.

- Intelligente Formbefüllung: Moderne Systeme verwenden Sensoren, um die Befüllung des Formkastens zu überwachen. Sie können die Geschwindigkeit der Zufuhrschublade und die Intensität einer Vorvibration steuern, um sicherzustellen, dass das Material gleichmäßig verteilt wird, ohne es zu überfüllen. Dadurch wird die Menge an Kragenmaterial, die abgekratzt werden muss, auf ein Minimum reduziert, so dass bei jedem einzelnen Zyklus weniger Abfall anfällt und Material eingespart wird.

Vorausschauende Wartung: Verhinderung von Ausfallzeiten und Ressourcenverlusten

Bei Abfall geht es nicht nur um weggeworfene Materialien. Auch ein unerwarteter Maschinenausfall ist eine massive Abfallquelle. Die Produktion kommt zum Stillstand, eine Betoncharge kann im Mischer aushärten, und ein Team von Arbeitern bleibt untätig. Intelligente Systeme verlagern die Industrie von der reaktiven Wartung (die Dinge repariert, wenn sie kaputt gehen) zur vorausschauenden Wartung.

Die gleichen Sensoren, die den Produktionsprozess überwachen, überwachen auch den Zustand der Maschine selbst. Das Steuerungssystem kann Motortemperaturen, Vibrationsmuster in Lagern und Hydraulikdruckkurven verfolgen. Durch die Anwendung von Algorithmen des maschinellen Lernens auf diese Daten kann das System subtile Anomalien erkennen, die darauf hindeuten, dass eine Komponente zu versagen beginnt, lange bevor es zu einem katastrophalen Ausfall kommt.

So könnte beispielsweise eine leichte Zunahme der Schwingungssignatur eines Lagers eine Warnung an das Wartungsteam auslösen, das Lager beim nächsten geplanten Stillstand zu überprüfen und zu schmieren. Ein allmählicher Abfall der hydraulischen Leistung könnte ein Zeichen für ein sich entwickelndes internes Leck sein. Auf diese Weise können Wartungsarbeiten proaktiv geplant werden, um unerwartete Stillstände zu vermeiden. Diese vorausschauende Fähigkeit ist eine ausgeklügelte Facette der Entwicklung nachhaltiger Gebäudeausrüstung, die Energie spart, die Verschwendung von Materialien während eines Stillstands verhindert und die produktive Lebensdauer der Maschinen maximiert.

Wie die Automatisierung die Sicherheit der Arbeiter und die Entwicklung ihrer Fähigkeiten verbessert

Eine weit verbreitete Befürchtung ist, dass die Automatisierung Arbeitsplätze vernichtet. Im Zusammenhang mit modernen Blockheizkraftwerken sollte man eher sagen, dass sie Arbeitsplätze umwandelt. Die gefährlichsten, sich wiederholenden und körperlich anstrengenden Aufgaben - wie die manuelle Beseitigung von Verstopfungen oder die Handhabung schwerer Bauteile - werden zunehmend von Maschinen übernommen. Dies schafft ein sichereres Arbeitsumfeld und verringert das Verletzungsrisiko.

Gleichzeitig entstehen neue Anforderungen an die Fähigkeiten. Die Anlage braucht nicht mehr einen Arbeiter, der einen Hebel betätigt, sondern einen Techniker, der einen Kontrollbildschirm überwachen, Produktionsdaten interpretieren und das System für eine optimale Leistung feinabstimmen kann. Dies bedeutet eine Verlagerung von manueller Arbeit zu Wissensarbeit. Die Investition in intelligente Automatisierung ist auch eine Investition in die Qualifizierung der Arbeitskräfte. Die Mitarbeiter werden zu Systemmanagern und nicht nur zu Maschinenbedienern, was zu höherem Engagement, größerer Arbeitszufriedenheit und einem widerstandsfähigeren und leistungsfähigeren Team führt. Für den Unternehmer bedeutet dies eine stabilere, qualifizierte Belegschaft, die aktiv zur Effizienz und Qualität des Betriebs beitragen kann.

Upgrade 4: Technologien zur Wassereinsparung bei der Herstellung von Betonsteinen

Wasser ist der stille, wesentliche Partner bei der Herstellung von Beton. Es ist der Katalysator, der die chemische Reaktion der Hydratation auslöst, die ein trockenes Pulver in ein steinähnliches Material verwandelt. Doch in vielen Teilen der Welt, insbesondere in den trockenen Landschaften des Nahen Ostens und in den zunehmend wasserarmen Regionen Südostasiens, wird dieser wesentliche Bestandteil zu einem knappen und kostbaren Gut. Der vierte entscheidende Schritt auf dem Weg zur Entwicklung nachhaltiger Baumaterialien ist das gezielte Bemühen um eine drastische Reduzierung des Wasserverbrauchs bei der Blockproduktion. Dabei geht es nicht nur darum, weniger Wasser zu verbrauchen, sondern auch jeden möglichen Tropfen in einem geschlossenen Kreislaufsystem aufzufangen und wiederzuverwenden.

Lassen Sie uns eine Analogie verwenden. Stellen Sie sich vor, Ihre Fabrik ist wie ein Garten. Ein traditioneller Ansatz besteht darin, ihn mit einem offenen Schlauch zu bewässern, wobei ein Großteil des Wassers abläuft, verdunstet und für immer verloren ist. Der moderne, nachhaltige Ansatz besteht darin, ein Tropfbewässerungssystem zu installieren, das genau die benötigte Wassermenge direkt an die Wurzeln jeder Pflanze liefert, und das Regenwasser oder den Abfluss in einer Tonne aufzufangen, um es wieder zu verwenden. Dies ist genau die Philosophie, die heute bei Betonsteinwerken angewandt wird.

Der Wasser-Fußabdruck der traditionellen Blockproduktion

Der Wasserverbrauch in einem herkömmlichen Steinwerk geht weit über das Wasser hinaus, das in der Betonmischung selbst enthalten ist. Eine beträchtliche Menge an Wasser wird für:

- Waschen von Aggregaten: Sand und Kies müssen oft gewaschen werden, um Schlick und Ton zu entfernen, die die Zementbindung beeinträchtigen können.

- Reinigungsgeräte: Mischer, Trichter und Förderbänder müssen regelmäßig gewaschen werden, um die Ablagerung von gehärtetem Beton zu verhindern. Dies ist eine der Hauptquellen für den Wasserverbrauch.

- Staubunterdrückung: Das Besprühen mit Wasser ist eine gängige Methode zur Bekämpfung von Staub in der Luft und in der Umgebung der Anlage.

- Dampfhärtung: Wie bereits erwähnt, müssen bei der traditionellen Dampfhärtung große Mengen Wasser gekocht werden, was zu erheblichen Verlusten durch Dampfabgabe und Kondensat führt.

In einer schlecht geführten Anlage kann die für die Reinigung und andere Hilfsprozesse verbrauchte Wassermenge um ein Vielfaches größer sein als die Menge, die tatsächlich in die Betonsteine gelangt. Dieses mit Zementpartikeln und Zuschlagstoffen beladene "Grauwasser" wird häufig in die örtliche Umwelt oder das kommunale Abwassersystem eingeleitet, was eine zusätzliche Belastung für die Behandlung und ein potenzielles Verschmutzungsrisiko darstellt.

Geschlossene Kreislaufsysteme für Wasser

Der Eckpfeiler der Wassereinsparung in einem modernen Werk ist das geschlossene Kreislaufsystem. Das Konzept ist einfach und elegant: Das gesamte Prozesswasser wird aufgefangen, aufbereitet und wiederverwendet. Ein typisches System funktioniert wie folgt:

- Sammlung: Das gesamte Niederschlagswasser aus dem Mischer, der Blockmaschine und dem Werksboden wird über geneigte Rinnen und Abflüsse in eine zentrale Sammelgrube oder einen Sumpf geleitet.

- Ansiedlung und Abtrennung: Im Primärsumpf setzen sich die schwersten Feststoffpartikel - Sand und kleine Zuschlagstoffe - am Boden ab. Dieser Schlamm kann in regelmäßigen Abständen entfernt und in einigen Fällen wieder in den Zuschlagstoffvorrat eingebracht werden.

- Klarstellung: Das noch mit feinen Zement- und Schlickpartikeln getrübte Wasser wird dann in ein größeres Klärbecken oder eine Reihe von Absetzbecken gepumpt. Hier können sich die feineren Partikel aufgrund der geringeren Wassergeschwindigkeit allmählich absetzen. Manchmal wird ein Flockungsmittel - eine Chemikalie, die bewirkt, dass feine Partikel verklumpen und schneller absinken - hinzugefügt, um diesen Prozess zu beschleunigen.

- Wiederverwendung: Das geklärte Wasser aus dem oberen Teil des Tanks, das nun weitgehend frei von Feststoffen ist, wird in einen Vorratsbehälter zurückgepumpt. Von hier aus kann es für eine Vielzahl von Zwecken verwendet werden: als Mischwasser für neue Betonchargen (seine leicht alkalische Beschaffenheit ist durchaus akzeptabel), zum ersten Waschen von Zuschlagstoffen oder zum erneuten Abwaschen von Geräten.

Durch den Einsatz eines solchen Systems kann ein Blockheizkraftwerk seinen Bedarf an kommunalem Frischwasser um bis zu 90% senken. Dies schont nicht nur eine lebenswichtige natürliche Ressource, sondern führt auch zu erheblichen Kosteneinsparungen bei den Wasserrechnungen und Abwassergebühren. Diese Technologie ist ein hervorragendes Beispiel dafür, wie die Entwicklung nachhaltiger Gebäudeausrüstung einen positiven Kreislauf aus wirtschaftlichen und ökologischen Vorteilen schafft.

Innovative Aushärtungstechniken zur Minimierung des Wasserverbrauchs

Wie bereits im Zusammenhang mit der Energieeffizienz erwähnt, hat die Abkehr von der traditionellen Dampfhärtung auch massive Vorteile für die Wassereinsparung. Nebel- oder Vernebelungssysteme mit hoher Luftfeuchtigkeit liefern die für die Aushärtung erforderliche Feuchtigkeit mit einem Bruchteil der für die Dampferzeugung erforderlichen Wassermenge.

Darüber hinaus bietet die Entwicklung chemischer Zusatzmittel, die als "interne Nachbehandlungsmittel" bekannt sind, einen weiteren Weg. Diese Mittel, die häufig aus superabsorbierenden Polymeren bestehen, werden der Betonmischung zugesetzt. Sie halten einen Teil des Wassers in der Mischung fest und geben es im Laufe der Zeit langsam ab, direkt an den Stellen, an denen es für die Hydratation benötigt wird. Diese "interne" Wasserversorgung reduziert die Abhängigkeit von externen Nachbehandlungsmethoden und minimiert den Wasserverlust durch Oberflächenverdunstung, was sie zu einer idealen Strategie für heiße, trockene Klimazonen macht. Die Synergie zwischen fortschrittlichen fortschrittliche Blockpressenausrüstung die dichte Blöcke erzeugt, und diese intelligenten Aushärtungsmethoden sind der Schlüssel zur Minimierung des gesamten Wasserverbrauchs.

Anpassung an die Wasserknappheit in Trockengebieten wie dem Nahen Osten

Für Unternehmen, die in Ländern wie den VAE, Saudi-Arabien oder Jordanien tätig sind, ist der sparsame Umgang mit Wasser nicht nur eine "grüne" Initiative, sondern eine Frage des betrieblichen Überlebens. Die Wasserkosten sind hoch, und die Vorschriften für die Wassernutzung werden immer strenger. In diesen Regionen ist die Einführung eines geschlossenen Wasserkreislaufs keine Option, sondern eine Notwendigkeit.

In der nachstehenden Tabelle werden die Ansätze zur Wasserbewirtschaftung gegenübergestellt, wobei die entscheidende Bedeutung moderner Systeme in diesen spezifischen geografischen Kontexten hervorgehoben wird.

| Aspekt | Traditionelle Wasserwirtschaft | Modernes Closed-Loop-System |

|---|---|---|

| Wasserquelle | Hauptsächlich frische kommunale oder Grundwasserversorgung. | Hauptsächlich recyceltes Prozesswasser; Frischwasser nur zum Auffüllen. |

| Reinigungsprozess | Verschlauchung mit großem Volumen, wobei das gesamte Wasser als Abfall abgeleitet wird. | Waschen mit hohem Druck und geringem Volumen; das gesamte Wasser wird für das Recycling aufgefangen. |

| Entladung | Große Mengen an Grauwasser werden in die Kanalisation oder in die Umwelt abgeleitet. | Minimale bis keine Ableitung von Prozesswasser. |

| Operative Kosten | Hohe und steigende Kosten für Frischwasser und Abwasserentsorgung. | Drastisch reduzierte Wasser- und Entsorgungskosten; schneller ROI des Systems. |

| Regulatorisches Risiko | Anfällig für Wassernutzungsbeschränkungen und Bußgelder für Verschmutzung. | Hohe Einhaltung der Umweltvorschriften; verbesserte soziale Kompetenz. |

| Anwendbarkeit in ariden Regionen | Nicht nachhaltig und wirtschaftlich riskant. | Wesentlich für die langfristige Lebensfähigkeit und Rentabilität. |

Durch Investitionen in Anlagen und Systeme, die auf maximale Wassereffizienz ausgelegt sind, verschafft sich ein Blockproduzent in einer wasserarmen Region einen starken Wettbewerbsvorteil. Er ist weniger anfällig für Preiserhöhungen und Rationierungen, seine Betriebskosten sind niedriger, und er kann sein Unternehmen als verantwortungsvollen Verwalter einer wertvollen lokalen Ressource präsentieren. Dieser proaktive Ansatz zum Ressourcenmanagement ist das Markenzeichen eines zukunftsorientierten Unternehmens und ein zentrales Ziel der Entwicklung nachhaltiger Gebäudeausrüstung.

Upgrade 5: Langlebige, hochpräzise Gussformen und Werkzeuge für eine lange Lebensdauer

In der Sinfonie einer Steinfertigungsmaschine ist die Form das Hauptinstrument. Sie ist die Komponente, die dem Endprodukt seine präzise Form, seine scharfen Kanten und seine gleichmäßigen Abmessungen verleiht. Die gesamte Kraft der Vibration und der Verdichtung wird durch diesen Stahlkasten kanalisiert. Aus diesem Grund sind die Qualität und Haltbarkeit der Form und der dazugehörigen Werkzeuge (Stempelkopf oder Presskopf) keine Kleinigkeiten, sondern von grundlegender Bedeutung für die Qualität des Produkts und die langfristige Nachhaltigkeit des Betriebs. Die fünfte und oft unterschätzte Verbesserung bei der Entwicklung nachhaltiger Gebäudeausrüstung ist die Investition in hochwertige, langlebige Formen.

Es ist einfach, sich auf die großen, sichtbaren Teile der Maschine zu konzentrieren, aber die Form ist der Ort, an dem der "Gummi auf die Straße trifft". Eine abgenutzte oder schlecht gefertigte Form ist eine ständige Quelle von Verschwendung und Ineffizienz. Es ist, als würde man versuchen, einen perfekt quadratischen Kuchen in einer verbeulten, verzogenen Form zu backen. Egal wie gut Ihr Rezept oder Ihr Ofen ist, das Ergebnis wird immer mangelhaft sein.

Die versteckten Umweltkosten des häufigen Austauschs von Schimmelpilzen

Eine Form ist ein Verbrauchsartikel, aber es kommt sehr darauf an, wie schnell sie verbraucht wird. Formen minderer Qualität, die oft aus Standardstahl ohne spezielle Behandlung hergestellt werden, nutzen sich schnell ab. Der starke Abrieb durch die Aggregate und die Hochdruckverdichtung führen dazu, dass die Formwände dünn werden, die Ecken sich abrunden und die Gesamtabmessungen sich verziehen.

Wenn sich eine Form abnutzt, führt dies zu verschiedenen Problemen:

- Ablehnung des Produkts: Die produzierten Blöcke entsprechen nicht mehr den Maßvorgaben. Sie können etwas zu groß oder zu klein sein und haben abgerundete Kanten, die den Steinmetzen die Arbeit erschweren. Dies führt zu einer höheren Ausschussrate, was eine direkte Verschwendung von Material, Energie und Arbeit bedeutet.

- Erhöhter Zementverbrauch: Um die schlechte Passform einer abgenutzten Form und eines abgenutzten Stempelkopfes auszugleichen, müssen die Bediener oft eine etwas feuchtere, reichhaltigere Mischung verwenden, um saubere Kanten zu erhalten. Dies bedeutet, dass mehr Zement verwendet wird als strukturell notwendig ist, was sowohl die Kosten als auch den CO2-Fußabdruck jedes Blocks erhöht.

- Die Verschwendung der Form an sich: Eine Form ist ein großes Stück Stahl. Eine typische Form für eine Standard-Steinformmaschine kann mehrere hundert Kilogramm wiegen. Häufiges Auswechseln bedeutet, dass diese großen Teile aus hochwertigem Stahl verschrottet werden. Der Stahl ist zwar wiederverwertbar, doch der Energieaufwand für das Einschmelzen und Umformen ist erheblich. Die Verlängerung der Lebensdauer der Form ist ein direkter Weg, diesen Kreislauf des industriellen Verbrauchs zu reduzieren.

Diese versteckten Kosten machen die anfänglichen Einsparungen durch den Kauf einer billigen Form zu einer falschen Einsparung. Die wahren Kosten müssen die zurückgewiesenen Produkte, den übermäßigen Materialverbrauch und die häufigen Austausch- und Ausfallzeiten einschließen.

Innovationen in der Metallurgie und Wärmebehandlung für Formen

Führende Hersteller haben dies erkannt und stark in die Materialwissenschaft investiert, die der Herstellung von Formen zugrunde liegt. Dies ist ein entscheidender, wenn auch weniger sichtbarer Aspekt der Entwicklung nachhaltiger Gebäudeausrüstung. Das Ziel besteht darin, eine Form zu schaffen, die der brutalen Betriebsumgebung über Millionen von Zyklen hinweg ohne nennenswerten Verschleiß standhalten kann. Die wichtigsten Innovationen sind:

- Fortschrittliche Stahllegierungen: Statt aus gewöhnlichem Baustahl werden hochwertige Formen aus speziellen Chrom-Mangan- oder anderen kohlenstoffreichen Stahllegierungen hergestellt. Diese Werkstoffe besitzen von Natur aus eine größere Härte und Abriebfestigkeit.

- Aufkohlung und Wärmebehandlung: Dies ist der wichtigste Schritt. Die hergestellte Form wird in einem speziellen Ofen mit einer kohlenstoffreichen Atmosphäre bei sehr hoher Temperatur gelagert. Die Kohlenstoffatome dringen bis zu einer bestimmten Tiefe in die Oberfläche des Stahls ein. Anschließend wird die Form schnell abgeschreckt (abgekühlt). Durch dieses Verfahren entsteht eine extrem harte "Hülle" oder Außenschicht auf dem Stahl mit einer Rockwell-Härte von über 60 HRC, die härter ist als eine Feile. Diese Hülle ist außergewöhnlich verschleißfest.

- Präzisionsbearbeitung und Schleifen: Nach der Wärmebehandlung wird die Form mit hochpräzisen CNC-Schleifmaschinen (Computer Numerical Control) fertiggestellt. Dadurch wird sichergestellt, dass alle Innenmaße bis auf Bruchteile eines Millimeters genau sind. Die Oberflächen werden so geschliffen, dass sie vollkommen glatt sind, was die Reibung beim Verdichten und Auswerfen verringert, die Lebensdauer der Form weiter verlängert und die Oberfläche des Blocks verbessert.

Eine Form, die diesem strengen Verfahren unterzogen wurde, hält oft zwei- bis dreimal so lange wie eine unbehandelte Standardform und produziert Millionen von maßlich perfekten Blöcken, bevor sie ersetzt werden muss.

Die Verbindung zwischen Werkzeugpräzision und Produktqualität

Die Präzision der Form hat einen direkten und unmittelbaren Einfluss auf die Qualität des Endprodukts. Eine hochpräzise Form gewährleistet:

- Maßgenauigkeit: Alle Blöcke sind identisch. Dies ist nicht nur ein ästhetischer Aspekt. Für Maurer bedeutet eine einheitliche Blockgröße einen schnelleren, einfacheren und stabileren Wandaufbau mit einheitlichen Mörtelfugen.

- Scharfe, saubere Kanten: Eine präzise Passung zwischen dem Formkasten und dem Stempelkopf (mit Abständen von oft weniger als 0,5 mm) verhindert, dass die Betonmischung während der Verdichtung herausgedrückt wird. Dies führt zu Blöcken mit scharfen, gut definierten Erhebungen, was ein wichtiger Indikator für Qualität ist.

- Konsistente Dichte: Ein perfekt flacher und paralleler Stampferkopf sorgt dafür, dass die Verdichtungskraft gleichmäßig über die gesamte Oberfläche des Blocks aufgebracht wird, was zu einer gleichmäßigen Dichte und Festigkeit führt.

Wenn ein Hersteller hochwertige Formen verwendet, stellt er nicht nur Blöcke her, sondern erwirbt sich auch einen guten Ruf für Qualität. Ihre Produkte werden von Bauunternehmern bevorzugt, erzielen einen besseren Preis und tragen zu besseren, haltbareren Endgebäuden bei.

Langfristige Kosten-Nutzen-Analyse von Premium Tooling

Lassen Sie uns eine einfache Kosten-Nutzen-Analyse durchführen. Ein Unternehmen hat die Wahl zwischen zwei Werkzeugen für seine Maschine der QT-Serie:

- Form A (Standard): Anschaffungskosten: $4.000. Lebensdauer: 800.000 Zyklen.

- Form B (Premium, wärmebehandelt): Anschaffungskosten: $7.000. Lebensdauer: 2.000.000 Zyklen.

Oberflächlich betrachtet, scheint Form A billiger zu sein. Aber schauen wir uns die Kosten pro produziertem Block an.

- Kosten pro 1000 Zyklen (Form A): $4,000 / 800 = $5.00

- Kosten pro 1000 Zyklen (Form B): $7,000 / 2,000 = $3.50

Die Premiumform ist über ihre Lebensdauer pro Block tatsächlich 30% billiger. In dieser Berechnung sind die zusätzlichen Einsparungen durch Form B noch nicht einmal berücksichtigt:

- Geringere Stillstandszeiten beim Formenwechsel.

- Geringere Rückweisungsraten bei Produkten.

- Mögliche Einsparungen beim Zementverbrauch.

Diese Analyse zeigt, dass die Investition in langlebige, hochpräzise Werkzeuge keine Ausgabe ist, sondern eine Investition mit hoher Rendite. Sie ist ein perfektes Beispiel dafür, wie die Grundsätze der nachhaltigen Entwicklung von Baumaschinen - die Konzentration auf die Lebenszyklusleistung und nicht nur auf den Anschaffungspreis - direkt zu einer höheren Rentabilität und einem besseren Produkt führen. Es unterstreicht die Idee, dass auf dem modernen Baumarkt Qualität und Nachhaltigkeit zwei Seiten derselben Medaille sind.

Häufig gestellte Fragen (FAQ)

Was sind die Hauptvorteile der Umrüstung auf eine nachhaltige Steinfertigungsmaschine?

Die Aufrüstung bietet einen doppelten Vorteil: einen wirtschaftlichen und einen ökologischen. In wirtschaftlicher Hinsicht profitieren Sie von deutlich niedrigeren Betriebskosten durch geringeren Energieverbrauch, weniger Rohstoffabfälle und die Möglichkeit, billigere recycelte Materialien zu verwenden. Aus ökologischer Sicht verringern Sie Ihren CO2-Fußabdruck, sparen Wasser und beteiligen sich an der Kreislaufwirtschaft, indem Sie Abfälle von den Deponien fernhalten. Dies stärkt auch den Ruf Ihrer Marke und macht Ihre Produkte für ökologische Bauprojekte attraktiver.

Können ältere Betonsteinfertigungsmaschinen mit diesen nachhaltigen Merkmalen nachgerüstet werden?

Einige Nachrüstungen sind eher machbar als andere. Oft ist es möglich, ältere Anlagen mit einem geschlossenen Wasserkreislauf nachzurüsten oder den Mischer und die Dosieranlage für eine bessere Präzision aufzurüsten. Die Umrüstung des Hauptantriebssystems einer Maschine von einem hydraulischen auf ein vollständig servoelektrisches System kann jedoch komplex und teuer sein. In vielen Fällen machen die kombinierten Vorteile einer neuen Maschine - einschließlich höherer Geschwindigkeit, besserer Vibrationen und integrierter intelligenter Steuerungen - einen vollständigen Austausch zu einer sinnvolleren langfristigen Investition als eine teilweise Nachrüstung.

Wie wirken sich recycelte Materialien auf die Qualität von Betonsteinen aus?

Bei ordnungsgemäßer Verarbeitung und Verwendung in einer von einem Betontechnologen entwickelten Rezeptur können aus recycelten Materialien Blöcke hergestellt werden, die den Blöcken aus 100%-Neuware gleichwertig oder in einigen Fällen sogar überlegen sind. So kann beispielsweise die puzzolanische Reaktion von Flugasche die langfristige Festigkeit und chemische Beständigkeit erhöhen. Der Schlüssel dazu sind Konsistenz und Qualitätskontrolle. Der Einsatz moderner Maschinen mit präzisen Dosier- und Mischfunktionen ist von entscheidender Bedeutung, um die Variabilität der rezyklierten Rohstoffe in den Griff zu bekommen und zu gewährleisten, dass jeder Stein die Festigkeits- und Haltbarkeitsnormen wie ASTM oder BS erfüllt oder übertrifft.

Wie lange amortisiert sich eine Investition in energieeffiziente Maschinen in der Regel?

Die Amortisationszeit bzw. der Return on Investment (ROI) hängt von den örtlichen Energiekosten, dem Grad der Maschinenauslastung und der Effizienz der zu ersetzenden alten Ausrüstung ab. Bei einer typischen Umrüstung von einer älteren hydraulischen Maschine auf ein neues Modell mit Servoantrieb können jedoch allein die Energieeinsparungen zu einer Amortisationszeit von 3 bis 5 Jahren führen. Berücksichtigt man die geringeren Wartungskosten, den geringeren Materialabfall und den potenziell höheren Ausstoß, wird die finanzielle Argumentation noch überzeugender.

Wie wirkt sich die Entwicklung nachhaltiger Gebäudeausrüstungen auf Zertifizierungen für grüne Gebäude aus?

Sie hat einen direkten und positiven Einfluss. Ökologische Gebäudebewertungssysteme wie LEED, BREEAM und regionale Standards wie Estidama vergeben Punkte für verschiedene Faktoren, die Sie mit Ihren Geräten beeinflussen können. Dazu gehören die Verwendung von Materialien mit recyceltem Inhalt, die Beschaffung von Materialien vor Ort (was bei der Verwendung von lokalem Bauschutt einfacher ist) und der Nachweis der Ressourceneffizienz bei der Herstellung. Durch die Verwendung nachhaltiger Geräte können Sie die Dokumentation liefern, die Ihren Kunden hilft, diese wertvollen Zertifizierungspunkte zu erhalten, so dass Ihre Produkte die bevorzugte Wahl für hochrangige Projekte sind.

Gibt es staatliche Anreize für die Einführung dieser Technologie in Südostasien oder im Nahen Osten?

Ja, viele Regierungen in diesen Regionen fördern aktiv die Einführung grüner Technologien. Anreize können verschiedene Formen annehmen, darunter Steuergutschriften für den Kauf energieeffizienter Geräte, Zuschüsse für Investitionen in Recyclingtechnologien, Vorzugsbehandlung bei staatlichen Ausschreibungen und vereinfachte Genehmigungsverfahren für umweltfreundliche Anlagen. Es ist ratsam, sich bei den örtlichen Industrieentwicklungsagenturen oder Handelsabteilungen zu erkundigen, welche spezifischen Programme in Ihrem Land zur Verfügung stehen, da diese die Amortisationszeit Ihrer Investition erheblich verkürzen können.

Schlussfolgerung

Der Weg in die Zukunft für die Bauindustrie, insbesondere in den dynamischen Volkswirtschaften Südostasiens und des Nahen Ostens, ist eindeutig mit den Prinzipien der Nachhaltigkeit verbunden. Die Ära des Bauens ohne Rücksicht auf Ressourcenverbrauch und Umweltauswirkungen neigt sich dem Ende zu und wird durch einen intelligenteren, verantwortungsvolleren und letztlich profitableren Ansatz abgelöst. Die fünf hier untersuchten Hauptverbesserungen - Integration von Abfallstoffen, Energieeffizienz, intelligente Automatisierung, Wassereinsparung und langlebige Werkzeuge - sind keine isolierten Merkmale. Sie sind miteinander verknüpfte Elemente einer ganzheitlichen Philosophie. Diese Philosophie definiert eine Betonsteinmaschine nicht als einfache Presse, sondern als hochentwickeltes Werkzeug für die Umwandlung von Ressourcen neu.

Investitionen in die Entwicklung nachhaltiger Gebäudeausrüstung sind nicht länger eine Entscheidung zwischen Gewissen und Profit. Wie wir gesehen haben, sind die Technologien, die die Umweltbelastung verringern, dieselben, die die Betriebskosten senken, die Produktqualität verbessern und ein stabiles Geschäftsmodell aufbauen. Eine Maschine, die rezyklierte Zuschlagstoffe verwendet, ist auch eine Maschine, die von der Volatilität der Rohstoffpreise unabhängig ist. Eine servogesteuerte Presse, die Energie spart, liefert auch ein gleichmäßigeres, hochwertigeres Produkt. Ein geschlossener Wasserkreislauf, der eine kostbare Ressource schont, senkt auch die Stromrechnungen.

Für Hersteller und Entwickler im Jahr 2025 ist die Einführung dieser fortschrittlichen Technologien eine wichtige strategische Entscheidung. Es ist eine Gelegenheit, der regulatorischen Entwicklung einen Schritt voraus zu sein, die wachsende Marktnachfrage nach grünen Materialien zu befriedigen und eine Führungsposition einzunehmen. Es geht darum, ein Vermächtnis zu schaffen, das nicht nur aus Bauwerken besteht, die den Himmel berühren, sondern auch aus einem Unternehmen, das den Boden, auf dem es steht, respektiert. Die Zukunft des Bauwesens wird mit Intelligenz, Präzision und einem ausgeprägten Verantwortungsbewusstsein gebaut werden, und zwar mit Geräten, die für eine intelligentere und sauberere Welt entwickelt wurden.

Referenzen

Gesoğlu, M., Özturan, T., & Güneyisi, E. (2004). Eine Studie über die Durchlässigkeit und Mikrostruktur von Beton mit Flugasche und Silikastaub. N-W.F.P. University of Engineering & Technology Research Journal, 21(1), 1-9.

Hossain, M. U., Wu, Z., & Poon, C. S. (2017). Vergleichende ökologische und ökonomische Bewertungen des Managements von Bau- und Abbruchabfällen: A case study in China. Resources, Conservation and Recycling, 126, 207-216.

Imbabi, M. S., Carrigan, C., & McKenna, S. (2012). Trends und Entwicklungen in der grünen Zement- und Betontechnologie. International Journal of Sustainable Built Environment, 1(2), 194-216.

Li, J., & Zhang, X. (2013). Study on energy consumption of hydraulic system of concrete block machine. Applied Mechanics and Materials, 347-350, 1373-1377. https://doi.org/10.4028/www.scientific.net/AMM.347-350.1373

Marinković, S., Radonjanin, V., Malešev, M., & Ignjatović, I. (2010). Vergleichende Umweltbewertung von Beton mit natürlichen und rezyklierten Betonzuschlägen. Waste Management, 30(11), 2255-2264.

Mehta, P. K. (2002). Ökologisierung der Betonindustrie für eine nachhaltige Entwicklung. Concrete International, 24(7), 23-28.

Peng, G.-F., Liu, C.-L., & Huang, Y.-H. (2015). Forschung über die Anwendung von Servomotoren im Vibrationssystem einer Steinfertigungsmaschine. Journal of Vibroengineering, 17(8), 4379-4391. https://www.jvejournals.com/article/16281

Poulikakos, L. D., Papadaskalopoulou, C., Hofko, B., Gschösser, F., & Cannone Falchetto, A. (2017). Das unerforschte Potenzial von anspruchsvollen Materialien in Asphaltmischungen nutzen. Applied Sciences, 7(8), 806. https://doi.org/10.3390/app7080806

Tam, V. W. Y., & Tam, C. M. (2006). Ein Überblick über die praktikable Technologie für das Recycling von Bau- und Abbruchabfällen. Resources, Conservation and Recycling, 47(3), 209-221.

Zain, M. F. M., Islam, M. N., & Basri, H. (2005). Ein Überblick über den Einfluss der Nachbehandlungsbedingungen auf die Eigenschaften von Beton. Jurnal Kejuruteraan Awam, 17(1), 33-46.