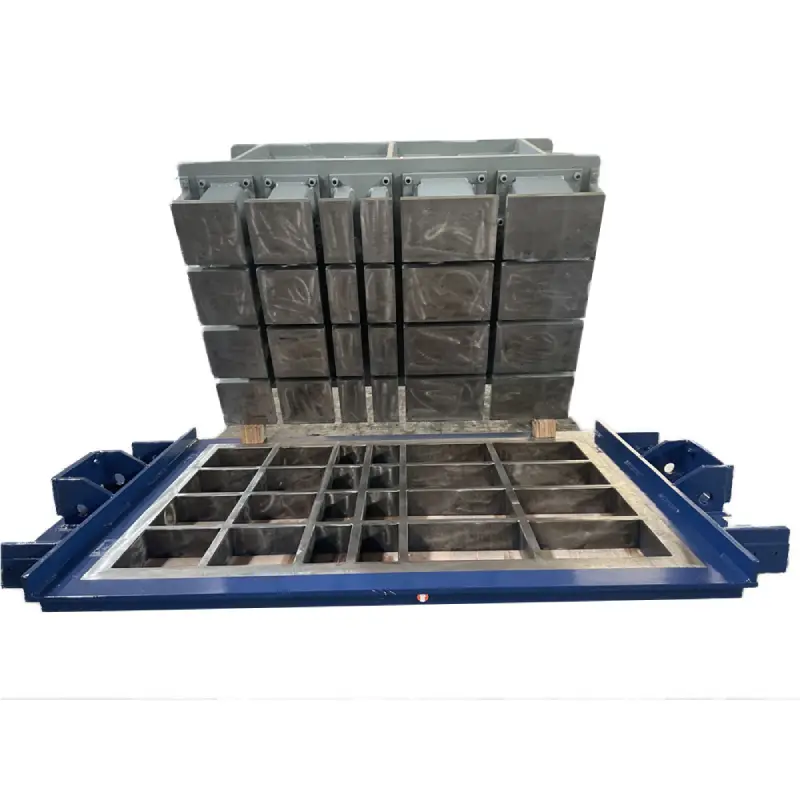

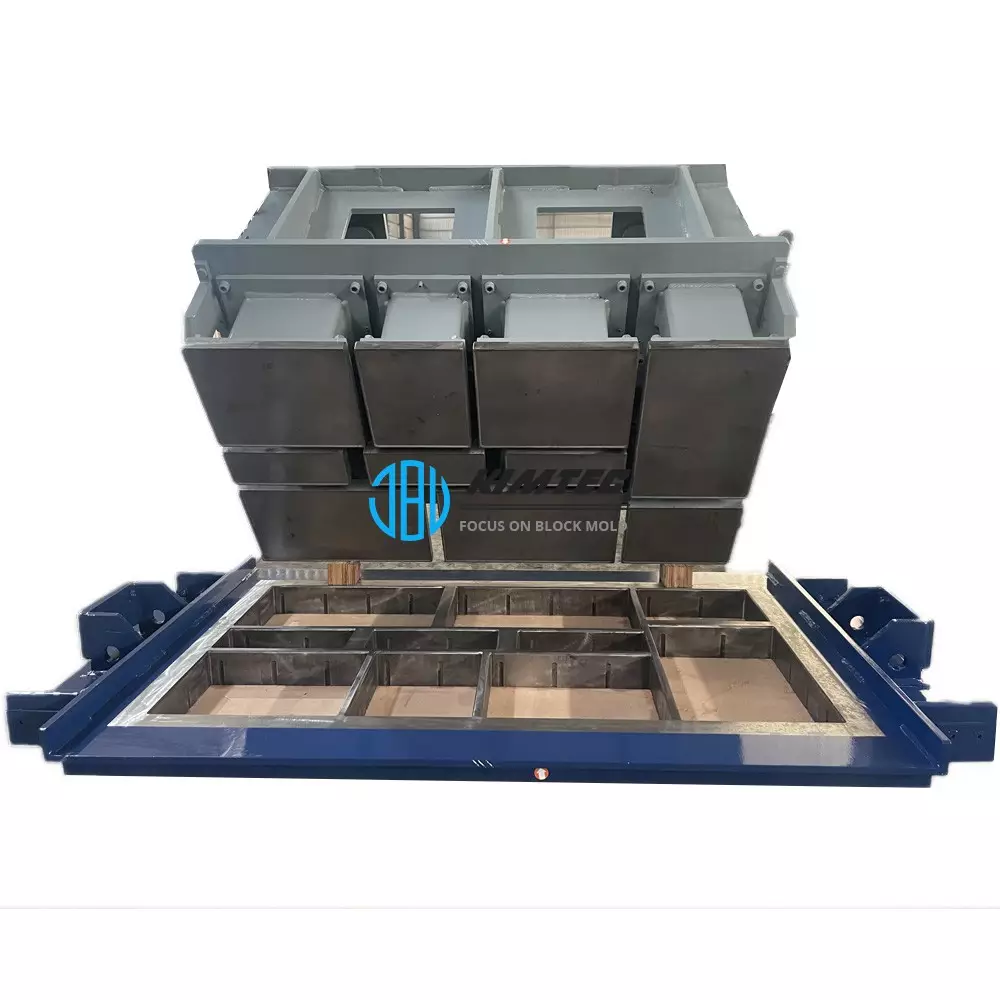

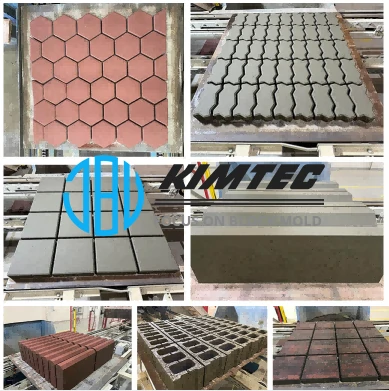

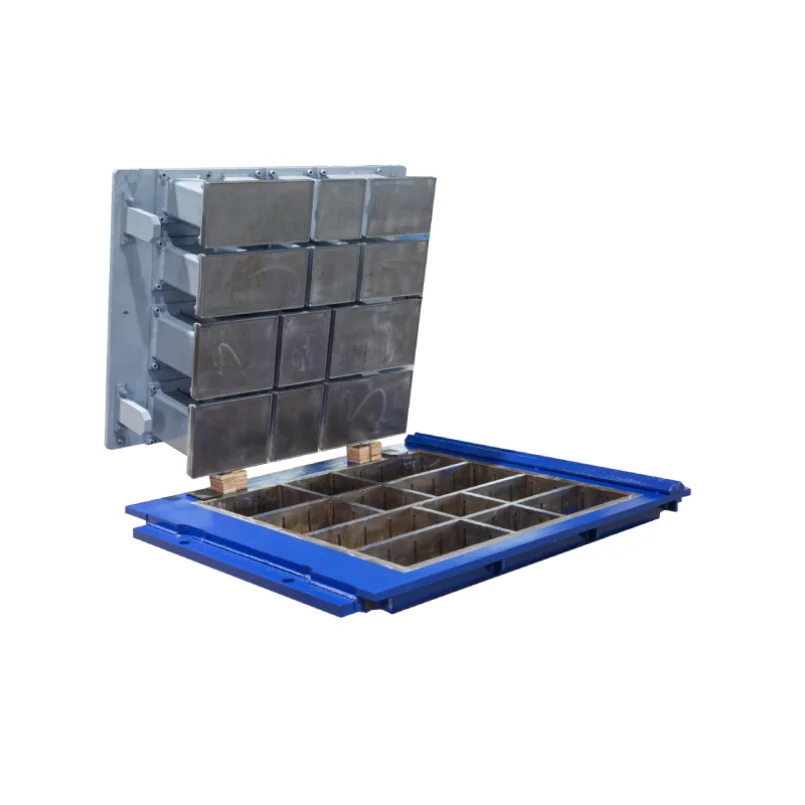

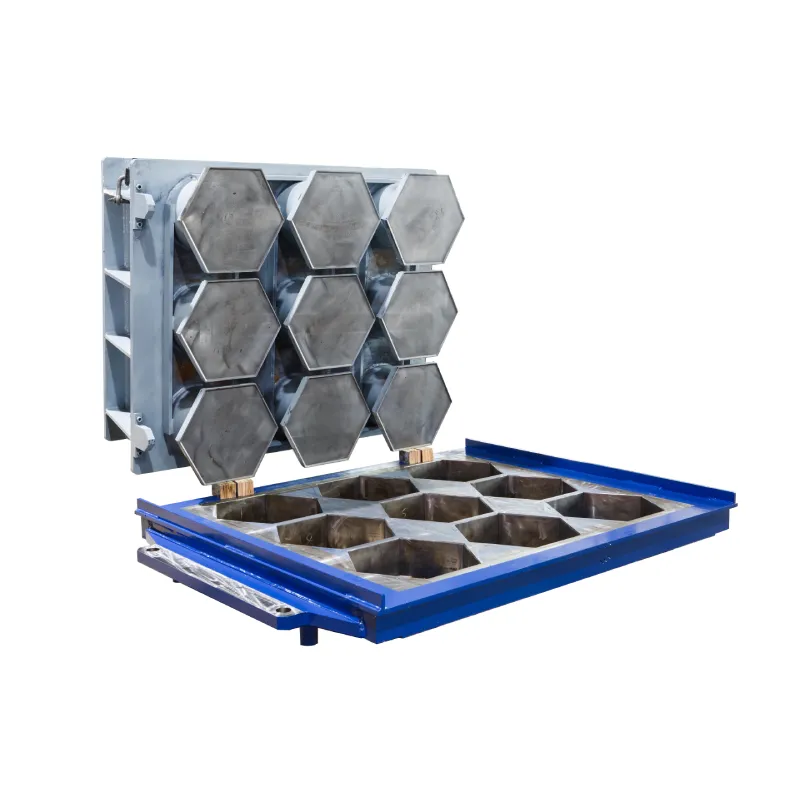

Design and Manufacture High Quality Steel Molds Interlocking Paving Stone Mold

Design and Manufacture of High-Quality for Interlocking Paving Stones

FAQ:

How Can I Get a Quotation?

-

With Detailed Drawings: Send us your block drawings for review, and we will provide a quote based on them.

-

Without Drawings: Let us know the block type (hollow or solid), and optionally send a photo along with dimensions (length × width × thickness in mm).

-

Pallet Size: Please specify your pallet dimensions.

-

Mold Details: Provide the size of your tamper head and the height of your down mold.

-

Connection Information: Explain how your mold connects to your machine. If available, share a connection drawing.

Once we receive this information, we will provide a quotation promptly.

What Is the Delivery Time?

-

Standard block molds: 20–25 working days after deposit

-

High-end block molds: 30–40 working days after deposit

How Is the Transport Packaging Handled?

We use wooden packaging with plastic film by default, or can customize packaging according to buyer specifications.

Will the Mold Be Compatible with My Machine?

We have extensive experience manufacturing molds for various block machine brands and maintain detailed records. Some molds may already fit your machine.

-

If necessary, you can invite an engineer to measure your machine.

-

Alternatively, we can guide you to send digital photos and measurements to ensure compatibility.

-

Once confirmed, the mold will fit your machine seamlessly.

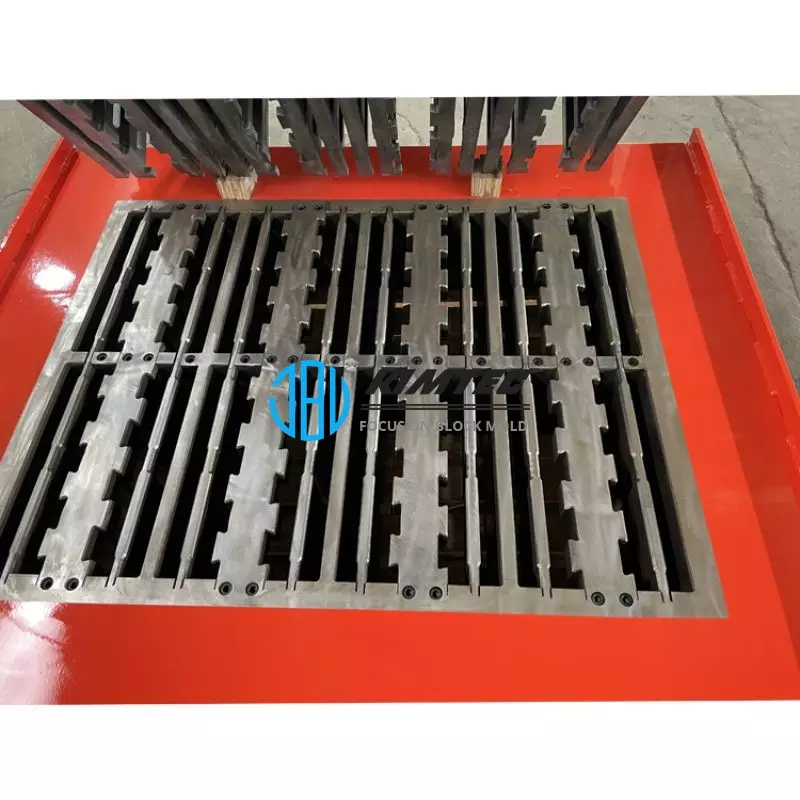

Mold Material & Performance

-

Made with high-end specialty alloy steel

-

Cycle options: 80,000 or 120,000 operations

-

Heat treatment: Increases hardness to 62–65 HRC for long-lasting durability

Payment Terms

A 50% advance via T/T is required to start production. The remaining balance must be paid before shipment.