Expert Guide to Smart Manufacturing in Brick Production: 5 Key 2026 Trends for Buyers in Southeast Asia

31 de diciembre de 2025

Resumen

The transition toward smart manufacturing in brick production signifies a pivotal evolution for the construction materials industry, particularly within the rapidly developing economies of Southeast Asia and the Middle East. This analysis examines the integration of Industry 4.0 technologies—such as the Internet of Things (IoT), artificial intelligence (AI), robotics, and data analytics—into the block and brick manufacturing process. It investigates how these advancements are transforming traditional factories into highly efficient, interconnected, and autonomous systems. The discourse focuses on the tangible benefits, including enhanced productivity, superior product consistency, significant cost reductions through predictive maintenance and waste minimization, and improved workplace safety. By evaluating current trends and projecting future developments for 2026, this document provides a comprehensive framework for business owners and operations managers considering strategic investments in modern machinery, such as QT series fully auto concrete block making machines. The objective is to elucidate the practical pathway and compelling return on investment associated with adopting smart manufacturing principles.

Principales conclusiones

- Integrate IoT sensors for real-time monitoring and predictive maintenance, reducing costly downtime.

- Adopt full-scale automation to enhance production speed and ensure consistent block quality.

- Use AI-powered vision systems for automated quality control, minimizing defects and waste.

- Focus on smart manufacturing in brick production to optimize energy and raw material usage.

- Invest in upskilling your workforce to manage and operate new automated systems effectively.

- Choose a technology partner that provides comprehensive support for a smooth transition.

- Start with a pilot project to measure ROI before committing to a full-scale upgrade.

Índice

- The Dawn of a New Era: Understanding Smart Manufacturing in Brick Production

- A Comparative Lens: Traditional vs. Smart Brick Production

- Trend 1: The Rise of IoT-Integrated Block Making Machines

- A Closer Look: Comparing Modern QT Series Block Making Machines

- Trend 2: Full-Scale Automation from Raw Material to Cured Block

- Trend 3: Data Analytics and AI for Unprecedented Quality Control

- Trend 4: Sustainability as a Core Operational Metric

- Trend 5: Human-Centric Smart Factories and Upskilling the Workforce

- Making the Transition: A Strategic Roadmap for Your Business

- FAQs about Smart Manufacturing in Brick Production

- A Forward-Looking Perspective

- Referencias

The Dawn of a New Era: Understanding Smart Manufacturing in Brick Production

The world of construction is built, quite literally, on the humble brick. For centuries, its production was a craft defined by manual labor, elemental forces of fire and earth, and a certain acceptance of inconsistency. Today, as we stand in 2026, that paradigm is undergoing a profound and irreversible transformation. We are witnessing the rise of smart manufacturing in brick production, a movement that replaces the unpredictability of the past with the precision of the digital age. This is not merely an upgrade of machinery; it is a complete rethinking of the factory floor, turning it into a living, thinking ecosystem.

What is Smart Manufacturing, Really? (Beyond the Buzzword)

To grasp the essence of smart manufacturing, let us draw an analogy. Imagine a traditional orchestra where each musician plays their part from a sheet of music, relying on the conductor's cues. If one musician falters, the conductor must notice and correct them, but a slight delay is inevitable. Now, imagine a "smart" orchestra. Each instrument is interconnected, aware of the others. If a violin begins to drift out of tune, sensors detect it instantly and can even make micro-adjustments in real-time. The conductor, now more of a systems director, is not just reacting to problems but is analyzing data from the entire ensemble to predict potential issues and optimize the overall harmony for the next performance.

This is precisely what smart manufacturing in brick production accomplishes. It moves beyond simple automation, which is like having machines that can play their instruments perfectly but in isolation. Smart manufacturing connects these machines. A concrete mixer, a block molding machine, and a curing system are no longer separate islands of activity. They communicate. The mixer "knows" the exact moisture content of the sand and adjusts the water dosage. The block machine "knows" the batch is ready and that the curing chamber has space. This interconnectedness is achieved through a fusion of physical machinery and digital technology—the Internet of Things (IoT), artificial intelligence (AI), and big data analytics. It is a system designed not just to do a task, but to learn from it and optimize it continuously.

Why Now? The Driving Forces in Southeast Asia and the Middle East

The adoption of this advanced approach is not a matter of technological novelty; it is a response to powerful economic and social pressures converging in Southeast Asia and the Middle East. These regions are experiencing some of the most rapid urbanization in human history. Mega-projects, from sprawling new cities in the Saudi desert to extensive infrastructure upgrades in Vietnam and the Philippines, are creating an insatiable demand for high-quality construction materials. Meeting this demand with traditional, labor-intensive methods is becoming untenable.

First, there is the challenge of labor. The physically demanding nature of traditional brick making, coupled with rising wages and a shrinking pool of workers willing to perform such tasks, creates a significant operational bottleneck. Smart manufacturing directly addresses this by automating the most strenuous and repetitive jobs, re-envisioning the human role as one of oversight and technical management.

Second, the standards for quality have risen dramatically. Architects and engineers on these multi-billion-dollar projects demand uniformity and specified strength in every single block. A weak batch of bricks can compromise the integrity of an entire structure. Smart manufacturing in brick production provides a level of quality control that is simply impossible to achieve with human inspection alone. By monitoring every variable—from the grain size of the aggregate to the temperature of the curing process—the system ensures that every brick meets exact specifications.

Finally, sustainability is no longer a peripheral concern but a central pillar of modern development. Governments and investors are increasingly mandating green building standards. Smart manufacturing enables a far more efficient use of resources. Precision mixing reduces cement and water waste, optimized curing cycles cut energy consumption, and the ability to consistently incorporate recycled materials, such as fly ash and slag (hfblockmachine.com, 2026), turns industrial byproducts into valuable assets. This aligns production with the principles of a circular economy, a concept gaining significant traction across the globe.

The Core Components: A Look Inside a Smart Brick Factory

A smart brick factory is a symphony of four key technological components working in concert.

-

The Internet of Things (IoT): This is the nervous system of the factory. Countless sensors are embedded throughout the production line—in raw material silos, on mixer motors, within hydraulic presses, and inside curing chambers. They continuously collect data on temperature, pressure, vibration, humidity, and material flow. This data is transmitted wirelessly to a central control system.

-

Automation and Robotics: This is the muscle. It includes automated guided vehicles (AGVs) that transport materials, robotic arms that stack and palletize finished blocks, and sophisticated machinery like Máquinas de fabricación de bloques de hormigón totalmente automáticas de la serie QT that can operate continuously with minimal human intervention. These systems execute the physical tasks with speed and precision far beyond human capability.

-

Artificial Intelligence (AI) and Machine Learning: This is the brain. AI algorithms analyze the vast streams of data coming from the IoT sensors. They can identify patterns that a human might miss. For example, an AI might detect a subtle change in a motor's vibration that indicates a bearing is likely to fail in the next 72 hours, triggering a predictive maintenance alert. Machine learning models can also analyze images of freshly molded bricks to spot microscopic cracks, ensuring that only perfect products proceed to the next stage.

-

Data Analytics and The Cloud: This is the memory and consciousness of the system. All the operational data is stored and processed, often in the cloud, making it accessible from anywhere. This allows managers to view real-time production dashboards on a tablet, compare the efficiency of different shifts, and generate detailed reports on everything from energy usage per brick to overall equipment effectiveness (OEE). This historical data becomes an invaluable resource for long-term strategic planning and continuous process improvement.

Together, these elements create a virtuous cycle: sensors collect data, automation performs the work, AI analyzes the performance to find improvements, and the insights are fed back into the system to make it even smarter and more efficient tomorrow than it was today. This is the foundational promise of smart manufacturing in brick production.

A Comparative Lens: Traditional vs. Smart Brick Production

To fully appreciate the magnitude of this shift, a direct comparison is illuminating. The table below contrasts the key operational aspects of a traditional brick factory with those of a modern smart factory, highlighting the clear advantages of embracing Industry 4.0 principles.

| Característica | Traditional Brick Production | Smart Manufacturing in Brick Production |

|---|---|---|

| Quality Control | Manual, sporadic inspection; high variability. | Automated, 100% inspection with AI vision; high consistency. |

| Requisitos laborales | High; manual handling, mixing, and stacking. | Low; focus on system monitoring and technical oversight. |

| Material Usage | Inaccurate batching; significant material waste. | Precise, sensor-driven batching; minimal waste. |

| Eficiencia energética | High energy consumption; unoptimized processes. | Optimized energy usage; predictive load management. |

| Mantenimiento | Reactive; fix-when-broken approach leads to downtime. | Predictive; IoT sensors anticipate failures, minimizing downtime. |

| Velocidad de producción | Limited by manual labor; inconsistent cycle times. | High-speed, continuous operation; optimized cycle times. |

| Datos e informes | Manual logs; limited operational insight. | Real-time digital dashboards; deep data analytics. |

| Workplace Safety | High risk of injury from heavy lifting and machinery. | Significantly safer; automation handles dangerous tasks. |

| Adaptability | Difficult to change product types or specifications. | Flexible; software-driven adjustments for different products. |

Trend 1: The Rise of IoT-Integrated Block Making Machines

The heart of any brick production facility is the block making machine itself. For decades, these have been powerful but "dumb" pieces of equipment. They performed their mechanical function—vibrating and pressing a mix into a mold—reliably, but without any awareness of the materials they were using or their own operational health. The first and most significant trend in smart manufacturing is the infusion of these machines with intelligence through the Internet of Things (IoT). This transforms them from simple tools into active, data-generating nodes within the larger factory ecosystem.

From Mechanical to Intelligent: The Evolution of the QT Series

Let's consider the evolution of a popular line of equipment, the QT series. A traditional, older-generation machine, perhaps a semi-automatic model, relies heavily on operator skill. The operator controls the cycle, visually judges the material feed, and listens for mechanical noises that might signal a problem. The quality of the output is heavily dependent on the experience and attentiveness of that individual.

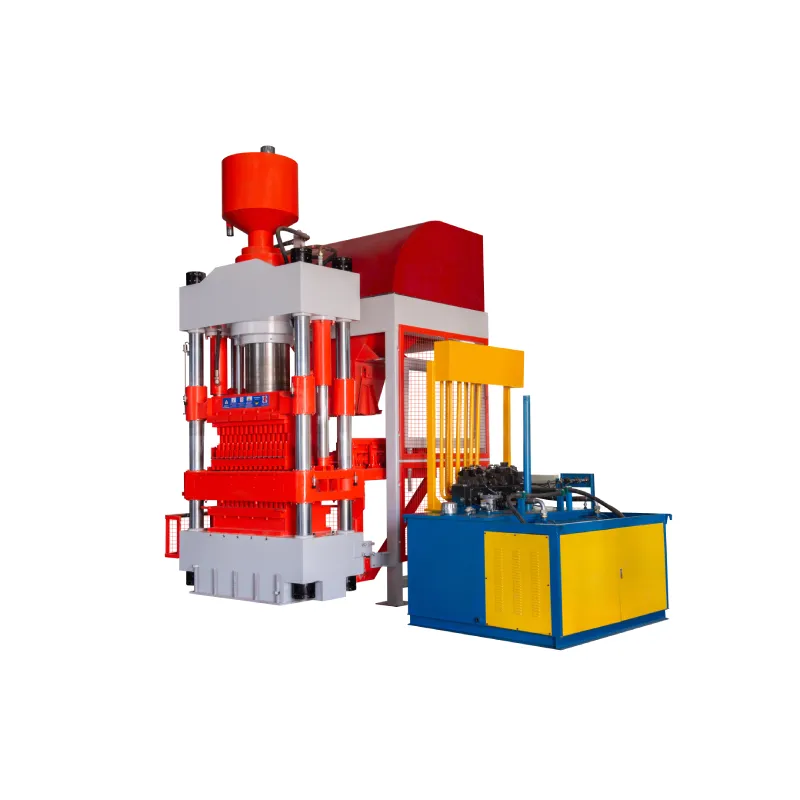

Now, fast forward to 2026 and look at the modern QT series fully auto concrete block making machines, such as the QT6-15 or the high-capacity QT12-15. These are not just more automated; they are fundamentally smarter. Manufacturers like Hongfa and QGM integrate advanced PLC (Programmable Logic Controller) systems, often from world-class brands like Siemens, which act as the machine's onboard brain (hfbrickmachine.com, 2026). But the real leap forward is the network of IoT sensors that now blankets the machine.

There are sensors in the material hopper measuring the volume and flow of the concrete mix. There are vibration sensors on the main motors that monitor frequency and amplitude in real-time, ensuring optimal compaction for every single cycle. Hydraulic pressure sensors confirm that the exact required force is applied, no more and no less. Temperature sensors monitor the motors and hydraulic systems to prevent overheating. A machine like the QT12-15, which can produce over 20,000 hollow blocks in an eight-hour shift (hfblockmachine.com, 2026), generates a colossal amount of data with every cycle. This data is no longer lost; it is captured, transmitted, and turned into actionable intelligence. The machine is no longer a black box; it is a transparent and communicative partner in production.

Real-Time Monitoring and Predictive Maintenance

Perhaps the most immediate financial benefit of an IoT-integrated machine is the shift from reactive to predictive maintenance. In a traditional factory, a critical motor might fail without warning, bringing the entire production line to a halt. The subsequent downtime could last for hours or even days, resulting in lost revenue, missed deadlines, and frustrated customers. The cost is not just in the repair itself, but in the lost opportunity.

In a smart manufacturing environment, this scenario is largely a relic of the past. The vibration sensor on that same motor continuously streams data to an AI algorithm. This algorithm has been trained on thousands of hours of operational data and knows the "healthy" vibration signature of that specific motor. Weeks before a potential failure, it might detect a minuscule, almost imperceptible change in that signature—a pattern that indicates early-stage bearing wear.

Instead of a catastrophic failure, the system generates a predictive alert. It might say: "Motor 3 on the main vibrator shows a 7% deviation in vibration signature. Probability of bearing failure within 150 operating hours is 95%. Recommended action: Schedule replacement during the next planned maintenance window." The maintenance team can then order the part in advance and perform the repair during a scheduled shutdown, resulting in zero unplanned downtime. This capability alone can deliver a massive return on investment, transforming maintenance from a costly, reactive fire-fight into a planned, efficient, and data-driven process. The application of smart manufacturing in brick production turns a liability into a manageable operational parameter.

Optimizing the Mix: Sensor-Driven Material Management

The quality of a concrete block is determined before it ever reaches the mold. It is determined in the mix. The ratio of cement, sand, aggregate, water, and any additives is a precise science. In traditional production, this is often a source of inconsistency. The moisture content of the sand can vary depending on the weather, a silo might not discharge material evenly, or an operator might make a small error in measurement. Any of these small deviations can result in a batch of blocks that are too weak, too brittle, or dimensionally unstable.

IoT-integrated systems bring scientific precision to this critical first step. Moisture sensors in the sand and aggregate bins provide real-time data to the batching controller. The system can then automatically adjust the amount of water added to the mix to achieve the perfect water-cement ratio every time, regardless of ambient conditions. Load cells on the silos and conveyors ensure that the exact weight of each raw material is dispensed for every batch, down to the gram.

Furthermore, these sensors can monitor the consistency of the concrete in the mixer itself. By measuring the torque on the mixer's motor, the system can "feel" the viscosity of the mix. If it's too thick or too thin, it can make micro-adjustments or alert the operator. This ensures that the material arriving at the advanced concrete block making machine is always in its optimal state for molding. The result is a dramatic reduction in rejected blocks and a consistently high-quality product that builds trust with your customers. This level of control is a cornerstone of smart manufacturing in brick production and a key differentiator in a competitive market.

A Closer Look: Comparing Modern QT Series Block Making Machines

Choosing the right machine is a critical decision. The QT series offers a range of models tailored to different production scales and levels of automation. The table below provides a comparative overview of several popular models, based on specifications provided by leading manufacturers (hfblockmachine.com, 2026; qgmblockmachine.com, 2026), to help you understand their capabilities.

| Modelo | Nivel de automatización | Typical Cycle Time (s) | Productivity (8-hr shift, 400x200x200mm blocks) | Características principales | Ideal para |

|---|---|---|---|---|---|

| QT4-26 | Semi-Automatic | 26-35 | 3,840 – 4,400 | Electric push-pull mold, simple PLC control. | Start-ups and small-scale producers. |

| QT4-25 | Automático | 25-35 | 3,600 – 4,800 | PLC control, automatic plate supply, material distribution. | Growing businesses needing higher efficiency. |

| QT6-15 | Fully Automatic | 15-25 | 8,640 – 11,520 | Advanced PLC, Siemens motors, hydraulic system. | Medium to large-scale operations. |

| QT12-15 | Fully Automatic | 15-20 | 17,280 – 23,040 | High-capacity, Siemens PLC, Yuken hydraulics, advanced vibration. | Large-scale industrial production, major projects. |

Trend 2: Full-Scale Automation from Raw Material to Cured Block

While the block making machine is the heart of the operation, smart manufacturing is about orchestrating the entire production flow. The second major trend is the move toward full-scale, end-to-end automation. This means creating a seamless, "no-hands" process from the moment raw materials enter the site to the moment cured, palletized blocks are ready for shipment. This holistic approach to automation is where the most significant gains in efficiency, safety, and productivity are realized.

Automated Material Handling and Batching

The journey of a brick begins as separate piles of sand, cement, and aggregate. In a traditional plant, this stage involves front-end loaders, manual silo controls, and a significant amount of guesswork. It's labor-intensive, dusty, and prone to error. Full-scale automation completely revolutionizes this process.

Imagine a system where raw materials are delivered to designated intake hoppers. From there, a network of enclosed conveyors and bucket elevators takes over. Guided by the central PLC system, these conveyors transport the precise amount of each material to the batching plant. The batching plant itself is a marvel of precision. Instead of a worker pulling levers, the entire process is controlled by the software. Load cells under the weighing hoppers measure out each component of the recipe with digital accuracy. The system automatically accounts for material density and flow characteristics. Once the dry components are weighed, they are discharged into the mixer, where an automated system adds the exact amount of water and admixtures, as determined by the moisture sensors we discussed earlier.

This level of automation, often managed by robust control systems from brands like Siemens or Schneider (hfblockmachine.com, 2026), offers several profound advantages. It drastically reduces labor costs. It virtually eliminates the health risks associated with airborne dust (silicosis). Most importantly, it guarantees a perfectly consistent mix for every single batch, laying the foundation for a uniformly high-quality final product. This is a foundational step in implementing a true system of smart manufacturing in brick production.

The Role of Static Hydraulic Block Pressing Machines in Automation

Within this automated ecosystem, the choice of pressing technology is paramount. While vibratory machines are common, single and double static hydraulic block pressing machines play a crucial role, especially when precision and high density are required. Unlike purely vibratory systems, a static hydraulic press applies immense, controlled pressure to the concrete mix within the mold.

In an automated line, these machines are prized for their consistency. The hydraulic system, often featuring high-end components from brands like Yuken (hfblockmachine.com, 2026), can be programmed to deliver a precise pressure profile for every cycle. This means every block is compacted to the exact same density, resulting in superior strength and dimensional accuracy.

When integrated into a fully automated line, the static hydraulic press becomes a key station. An automated conveyor delivers the perfectly batched mix to the machine's feed box. The machine then executes its pressing cycle, ejects the "green" block onto a pallet, and signals the downstream system that the pallet is ready for removal. The entire operation is a smooth, continuous flow, with the hydraulic press acting as a guarantor of quality and consistency at the core of the process. For producers of high-specification products like architectural blocks or high-density pavers, these machines are an indispensable part of their smart manufacturing strategy.

Curing and Stacking Reimagined: Robotic Palletizing and Curing Chambers

Once the green blocks are formed, they are at their most vulnerable. The handling and curing process is critical to achieving their final strength. Traditional methods, involving manual stacking and open-air curing, are slow and expose the blocks to inconsistent environmental conditions, leading to variable quality.

Smart automation transforms this final, critical stage. As a pallet of green blocks is ejected from the block making machine, a signal is sent to a robotic palletizer. A robotic arm, capable of lifting heavy loads with delicate precision, picks up the entire pallet and places it onto a multi-level rack. This eliminates the back-breaking and dangerous manual labor of stacking.

Once a rack is full, an Automated Guided Vehicle (AGV)—a small, robotic cart that navigates using lasers or magnetic strips on the floor—arrives. It picks up the entire rack and transports it to the entrance of a smart curing chamber. These chambers are enclosed environments where temperature and humidity are precisely controlled by the central PLC system. Sensors inside the chamber monitor the conditions in real-time, ensuring the blocks cure at the optimal rate to achieve maximum strength and durability. The system can even be programmed with different "curing recipes" for different types of products.

After the specified curing time (typically 24-48 hours), another AGV retrieves the rack and transports it to a de-stacking station. Here, another robot gently separates the cured blocks, stacks them into the final shipping cubes, and applies banding. The finished, perfectly formed cubes of blocks are then ready for inventory or direct shipment. This end-to-end automation minimizes handling damage, guarantees optimal curing, and creates a production flow that is fast, efficient, and almost entirely independent of manual intervention. It's the final piece of the puzzle in creating a truly intelligent system for smart manufacturing in brick production.

Trend 3: Data Analytics and AI for Unprecedented Quality Control

If automation is the muscle of the smart factory, then data and artificial intelligence are its senses and intellect. The third major trend is the move away from manual, spot-checking quality control toward a system of 100% automated inspection and process optimization driven by AI. This allows for a level of quality assurance that was unimaginable a decade ago, catching microscopic flaws and predicting process deviations before they result in defective products.

The Power of the Digital Twin: Creating a Virtual Factory

One of the most powerful concepts in smart manufacturing is the "digital twin." Imagine creating a perfect, one-to-one virtual replica of your entire brick production line inside a computer. This is not just a 3D drawing; it is a living, dynamic simulation that is fed real-time data from the IoT sensors on your actual factory floor. The virtual block machine in the simulation behaves exactly like the physical one because it is receiving its operating parameters—vibration, pressure, temperature—from it every second.

What is the purpose of such a creation? Its applications are transformative. First, it allows for risk-free experimentation. Suppose you want to know what would happen if you increased the vibration frequency of your QT series fully auto concrete block making machines by 5% to try and reduce the cycle time. In a real factory, this could be a risky experiment, potentially damaging the machine or producing a batch of bad blocks. With a digital twin, you can run the simulation. The model, using physics-based algorithms, will predict the effect on block density, potential stress on the machine's components, and the impact on energy consumption. You can test dozens of "what-if" scenarios virtually to find the optimal settings before ever touching the real equipment.

Second, it is an incredible tool for troubleshooting. If production quality suddenly drops, you can look at the digital twin to see exactly where and when the process deviated from its normal parameters. It's like having a perfect recording of your factory's entire operation. This drastically reduces the time it takes to diagnose and fix problems. For any business serious about smart manufacturing in brick production, the digital twin is the ultimate tool for process understanding and optimization.

AI-Powered Vision Systems for Defect Detection

Human inspection is fallible. An inspector might be tired, distracted, or simply unable to see a hairline crack. In a high-speed production line where thousands of blocks are produced per hour, it is statistically impossible to inspect every single one thoroughly.

AI-powered vision systems solve this problem with superhuman accuracy and endurance. At a key point on the conveyor line, after the blocks are molded, they pass under a high-resolution camera. This camera captures an image of every block. The image is then instantly analyzed by an AI algorithm. This algorithm has been trained on tens of thousands of images of both "good" and "bad" blocks. It can identify a vast range of defects in a fraction of a second:

- Dimensional Inaccuracies: Is the block the correct height, width, and length to within a fraction of a millimeter?

- Surface Defects: Are there any chips, cracks, or air pockets on the surface?

- Color Inconsistency: For colored pavers, is the color and texture uniform across the block and consistent with the master sample?

If the AI detects a defective block, it can trigger a small pneumatic arm to gently push it off the line into a recycling bin. This 100% automated inspection ensures that not a single sub-standard product makes it to the curing stage, let alone to a customer. This not only protects your brand's reputation for quality but also saves the energy and resources that would have been wasted on curing a defective product.

From Reactive to Proactive: Using Data to Refine the Entire Process

The true power of data analytics in smart manufacturing in brick production is not just in catching errors, but in preventing them. Every piece of data collected—from motor temperatures to batch mix proportions to the reasons for AI-detected rejects—is stored in a central database. Over time, this creates an incredibly rich historical record of your factory's performance.

Machine learning algorithms can then be applied to this big data to uncover subtle, long-term trends and correlations. The analysis might reveal, for example, that a slight increase in the ambient humidity on rainy days correlates with a 2% increase in surface defects in blocks produced between 10 AM and 1 PM. Why? Perhaps the uncovered aggregate pile absorbs moisture, affecting the mix. Armed with this insight, you can take proactive steps, such as covering the aggregate pile or programming the batching system to automatically reduce its water addition by a tiny amount on high-humidity days.

This is the shift from a reactive to a proactive, data-driven culture. You are no longer just fixing problems as they occur. You are using data to understand the deep physics of your process and continuously refine it to achieve new levels of efficiency and quality. This continuous improvement loop is the engine of smart manufacturing, ensuring that your operation becomes more efficient, more profitable, and more competitive with each passing month.

Trend 4: Sustainability as a Core Operational Metric

In the 21st-century economy, sustainability is not just an ethical ideal; it is a business imperative. For construction material producers in Southeast Asia and the Middle East, where environmental regulations are tightening and clients are demanding greener buildings, demonstrating a commitment to sustainability is key to long-term success. The fourth trend, smart manufacturing, is intrinsically linked with sustainability, providing the tools to build a more efficient and less wasteful operation from the ground up.

Waste Reduction Through Precision Manufacturing

Traditional manufacturing is often a story of waste. Over-batching of concrete "just in case," spills during transport, and a high percentage of rejected products all contribute to a significant loss of valuable raw materials like cement, sand, and water. Each rejected brick represents not just lost material, but also wasted energy and labor.

Smart manufacturing tackles waste at its source. As we have explored, sensor-driven batching systems ensure that the exact amount of each material is used for every mix, eliminating the "little extra" that adds up to tons of waste over a year. The precision of automated systems like the QT series fully auto concrete block making machines ensures a dramatically lower rejection rate. When combined with AI-powered quality control that removes defects early, the result is a production process with a near-zero waste output. This not only has a positive environmental impact but also directly improves your bottom line by reducing raw material costs. Effective smart manufacturing in brick production is, by its very nature, lean manufacturing.

Optimizing Energy Consumption: Smart Grids and Efficient Machinery

Brick and block production is an energy-intensive process. Large motors for vibration and mixing, as well as hydraulic systems, consume a significant amount of electricity. In a traditional plant, this energy usage is often unmanaged and inefficient.

A smart factory treats energy as a key resource to be optimized. Modern machines are designed with energy efficiency in mind, featuring high-efficiency motors (often from brands like Siemens, as noted by hfblockmachine.com, 2026) and hydraulic systems that only draw power when needed. But the "smart" aspect goes a step further. The central control system can be connected to the local energy grid. It can be programmed to understand peak and off-peak electricity pricing.

The system can then intelligently schedule its operations. For example, it might run the large, energy-intensive mixers to prepare batches of concrete during the middle of the night when electricity rates are lowest. The block making machine can then run continuously during the day, drawing from the prepared material. The smart curing chambers can be programmed to use their heating elements primarily during off-peak hours. This load-shifting strategy can lead to substantial savings on utility bills, turning energy from an uncontrollable expense into a managed operational variable.

The Circular Economy in Brick Production: Integrating Recycled Materials

The concept of a circular economy—where waste from one process becomes a resource for another—is central to modern sustainability. The construction industry is a prime candidate for this approach. Industrial byproducts like fly ash (from coal power plants), slag (from steel manufacturing), and crushed recycled concrete are often sent to landfills, yet they possess valuable cementitious properties.

The challenge in using these materials has always been consistency. Their chemical and physical properties can vary, and incorporating them into a mix using traditional methods can lead to unpredictable results in the final product. Smart manufacturing solves this problem. Advanced batching systems can be programmed to handle multiple, variable inputs. Sensors can analyze the properties of the incoming recycled material, and the system can adjust the rest of the mix in real-time to compensate and ensure the final product meets its strength and durability specifications.

This allows a block producer to confidently and consistently manufacture high-quality, eco-friendly "green bricks" that might contain 20-30% recycled content. This not only reduces the amount of virgin material (especially costly cement) that needs to be purchased but also creates a new revenue stream by turning low-cost or even free industrial waste into a premium, environmentally friendly product. This is smart manufacturing in brick production at its most innovative, aligning profitability directly with environmental stewardship.

Trend 5: Human-Centric Smart Factories and Upskilling the Workforce

The rise of the smart factory often sparks fears of mass unemployment, with robots replacing human workers. While it is true that the nature of work is changing, the fifth key trend is the emergence of a human-centric approach to smart manufacturing. The goal is not to eliminate people but to elevate their roles, moving them away from dull, dangerous, and dirty tasks toward more skilled, engaging, and safer positions. This requires a conscious effort to upskill the workforce and design systems that augment, rather than replace, human capabilities.

Shifting Roles: From Manual Laborer to System Operator

In a traditional brick plant, the majority of the workforce is engaged in manual labor: shoveling materials, lifting heavy blocks, and manually operating machinery. The work is physically taxing and often carries a high risk of injury. In a smart factory, these roles largely disappear, but they are replaced by new ones.

The new factory floor needs "system operators" or "production technicians." These are individuals who monitor the automated production line from a central control room. They don't lift the blocks, but they watch the digital dashboards that display the health of the entire system. They are trained to interpret data, spot anomalies, and make high-level adjustments to the process. Their job is not one of physical strength but of mental acuity and technical understanding.

Another new role is the "robotics and maintenance technician." This person is not just a mechanic with a wrench; they are trained to diagnose and service complex electromechanical systems, including robotic arms, AGVs, and the sophisticated single/double static hydraulic block pressing machines. Their work is highly skilled and critical to keeping the entire smart manufacturing system running smoothly. The transition requires a commitment from employers to invest in training and development, transforming their workforce into a team of skilled technicians who can effectively manage the advanced technology.

Augmented Reality (AR) for Maintenance and Training

One of the most exciting developments supporting this human-centric approach is the use of Augmented Reality (AR). Imagine a maintenance technician who needs to service a complex hydraulic valve on a QT12-15 block machine. In the past, they would need to consult a thick paper manual or rely on memory.

With AR, they can put on a pair of smart glasses. The glasses, connected to the factory's central system, recognize the machine and the specific valve. They then overlay digital information directly onto the technician's field of view. Step-by-step instructions might appear, floating in space next to the component. A 3D animation could show exactly how to disassemble the valve. Real-time data from the machine's sensors, such as pressure and temperature readings, could be displayed right next to the physical gauge.

This technology acts as a powerful cognitive assistant. It dramatically reduces the time it takes to perform complex repairs, minimizes the chance of error, and serves as an incredible on-the-job training tool. A less experienced technician can perform a complex task with the confidence of an expert because they have a digital expert guiding them every step of the way. AR is a perfect example of how technology can augment human skill, making workers more effective and capable.

Safety by Design: How Automation Creates a Safer Work Environment

The factory floor can be a dangerous place. The most common injuries in traditional brick plants are related to manual handling (back injuries from lifting), being struck by moving equipment, and exposure to dust and noise. Smart manufacturing in brick production inherently designs out many of these hazards.

Robots and automated conveyors take over the repetitive heavy lifting, virtually eliminating the risk of musculoskeletal injuries. The use of AGVs that follow predefined paths is far safer than having manually operated forklifts moving around the plant. Enclosed mixing and conveying systems drastically reduce the amount of airborne dust, protecting workers from respiratory illnesses. Modern machinery, like the latest QT series models, is also designed to operate with lower noise levels and comes equipped with comprehensive safety guards and emergency-stop systems that are integrated into the central control network (hfblockmachine.com, 2026).

By automating the most dangerous tasks, the smart factory becomes a fundamentally safer place to work. This not only fulfills an employer's ethical responsibility to protect their workers but also has a direct financial benefit by reducing accidents, lowering insurance premiums, and improving employee morale and retention. A safe worker is a productive worker, and a safe factory is an efficient factory.

Making the Transition: A Strategic Roadmap for Your Business

Embracing smart manufacturing can feel like a monumental task, but it does not have to be an "all or nothing" proposition. A phased, strategic approach can allow your business to reap the benefits of Industry 4.0 without overwhelming your budget or your team. Here is a practical, step-by-step roadmap to guide your transition.

Step 1: Assessing Your Current Operations: A Self-Audit

Before you can plan your journey, you need to know your starting point. Conduct a thorough and honest assessment of your current production process. The goal is to identify the biggest "pain points" and the areas with the most potential for improvement. Ask yourself critical questions:

- Where are our biggest bottlenecks? Is it the mixing process? The block machine's cycle time? The curing and handling stage?

- What is the primary cause of product defects or rejects? Is it inconsistent mixing? Operator error? Damage during handling?

- Where is our highest labor cost concentrated? Is it in material handling? Stacking and palletizing?

- What are our most frequent causes of unplanned downtime? Is it a specific machine failure? Waiting for materials?

- Where are we wasting the most material and energy? By quantifying these issues (e.g., "We have a 7% reject rate due to dimensional inaccuracies," or "Machine X was down for 40 hours last month due to hydraulic failures"), you can identify the areas where an investment in smart technology will have the most immediate and significant impact.

Step 2: Starting Small – The Pilot Project Approach

Instead of attempting to overhaul your entire factory at once, select one key problem area identified in your audit and launch a pilot project. This allows you to test a new technology on a smaller scale, measure its effectiveness, and gain valuable experience before making a larger commitment.

For example, if your audit revealed that inconsistent mixing is your biggest quality issue, your pilot project could be to upgrade your batching plant with automated weighing and moisture sensors. If unplanned downtime on your main block machine is the problem, you could pilot a predictive maintenance system by installing IoT vibration and temperature sensors on its critical motors.

The key is to define clear success metrics for your pilot project. What is the target reduction in reject rate or downtime? What is the expected return on investment (ROI)? By running a successful pilot, you not only solve a specific problem but also build a powerful business case to justify further investment in smart manufacturing.

Step 3: Choosing the Right Technology Partner and Machinery

The success of your transition depends heavily on the partners and equipment you choose. This is not just about buying a machine; it is about building a long-term relationship with a supplier who understands the technology and is committed to your success. When evaluating potential suppliers of equipment like QT series fully auto concrete block making machines or single/double static hydraulic block pressing machines, consider the following:

- Proven Expertise: Do they have a track record of successful installations in your region? Can they provide case studies or references? Companies with decades of experience, like those established since 1990 (hfbrickmachine.com, 2026), often have a deep well of practical knowledge.

- Quality of Components: Look for machines built with components from reputable international brands like Siemens, Schneider, Omron, and Yuken (qgmblockmachine.com, 2026). This is often an indicator of the machine's overall quality, reliability, and service life.

- Integration Support: Can the supplier help you integrate the new machine into your existing production line? Do they offer support for PLC programming and data connectivity? A true partner will help you make the new technology "talk" to your other systems.

- Training and After-Sales Service: What level of training do they provide for your operators and maintenance staff? Do they have a responsive after-sales support system to help you with troubleshooting and spare parts? This is a critical factor for long-term operational success.

Step 4: Measuring ROI and Scaling Up

Throughout your pilot project and as you begin to scale, continuously measure your performance against the baseline you established in your initial audit. Track key performance indicators (KPIs) such as Overall Equipment Effectiveness (OEE), reject rates, energy consumption per block, and labor cost per block.

Use this data to calculate the tangible ROI of your investments. When you can clearly demonstrate that the new automated batching plant paid for itself in 18 months through material savings and reduced rejects, it becomes much easier to secure the budget for the next phase of your smart manufacturing journey—perhaps investing in a new robotic palletizer or an AI-powered quality control system.

This data-driven, phased approach allows you to scale up your smart factory in a financially responsible and manageable way. Each successful step builds momentum and expertise, gradually transforming your entire operation into a highly efficient, competitive, and future-proof enterprise.

FAQs about Smart Manufacturing in Brick Production

1. Is smart manufacturing only for large, new factories? Not at all. While a new factory is a blank slate, many principles of smart manufacturing can be retrofitted into existing plants. The key is the phased approach. You can start by upgrading a single, critical piece of equipment, like installing a new automated block machine, or by implementing an IoT-based predictive maintenance system on your current machinery. These incremental upgrades can provide a significant ROI and serve as stepping stones toward a smarter operation.

2. What is the typical return on investment (ROI) for this technology? The ROI varies widely depending on the specific project, local labor costs, and material prices. However, it is often faster than many business owners expect. Savings come from multiple areas simultaneously: reduced labor costs, lower material waste, decreased energy consumption, and, most significantly, increased uptime and production output. A well-planned pilot project can often demonstrate a payback period of 18-36 months.

3. How much training will my staff need? There is a learning curve, but it is manageable. The roles shift from manual labor to technical oversight. Your staff will need training on how to operate the new control interfaces (which are often user-friendly touch screens) and how to interpret the data from the system dashboards. Reputable machinery suppliers provide comprehensive training as part of the installation package. The goal is to empower your existing workforce with new, more valuable skills.

4. Can my older block making machine be upgraded to be "smarter"? Yes, to an extent. While you may not be able to get all the features of a brand-new machine, you can often add significant "smart" capabilities to older equipment. This could involve retrofitting it with IoT sensors for temperature, vibration, and pressure to enable predictive maintenance. You could also upgrade the control system to a more modern PLC. This can be a cost-effective way to begin your journey into smart manufacturing.

5. What is the main difference between "automation" and "smart manufacturing"? This is a crucial distinction. Automation is about making a machine or process perform a task without human assistance. For example, an automated block machine can run its cycle automatically. Smart manufacturing is about connecting those automated processes and using data to make them intelligent. A smart factory doesn't just have automated machines; it has a system where the mixer, the block machine, and the curing chamber all communicate with each other and use data to optimize the entire production flow in real-time. Automation makes things happen; smart manufacturing makes things happen better.

6. How does smart manufacturing improve the quality of concrete blocks? It improves quality through consistency. Every step is precisely controlled by data. The mix composition is identical in every batch. The vibration and pressure in the block machine are the same for every cycle. The curing temperature and humidity are perfectly maintained for every block. This removes the human and environmental variables that cause defects, resulting in blocks with consistently superior strength, dimensional accuracy, and finish.

7. What are the first steps my company should take to explore this? The first step is education and assessment. Read resources like this guide to understand the concepts. Then, perform the internal audit described in the roadmap to identify your specific pain points. The next step is to reach out to a knowledgeable technology partner or machinery supplier. Have a discussion with them about your findings and explore what specific solutions might be the best fit for your initial pilot project.

A Forward-Looking Perspective

The path of industrial progress is clear. Just as the steam engine and the assembly line defined previous eras of manufacturing, the fusion of digital intelligence and physical machinery defines this one. For businesses in the construction materials sector of Southeast Asia and the Middle East, the adoption of smart manufacturing in brick production is not a question of "if," but "when." The pressures of rapid urbanization, the demand for higher quality and sustainability, and the challenges of a competitive labor market all point in the same direction.

To hesitate is to risk being left behind, operating with higher costs, lower quality, and less efficiency than your competitors. To embrace this transformation, however, is to open the door to a new realm of possibility. It is to build a business that is not only more profitable and efficient but also safer for its employees and more responsible in its use of our planet's resources. The journey begins with a single step: a commitment to understanding the technology, assessing your operation, and choosing the right partners to guide you into the future of manufacturing. The smart factory is no longer a distant vision; it is a present reality, and its tools are ready for you to build a stronger foundation for your business.

Referencias

- Hongfa Machinery. (2026). Concrete block and brick making machine manufacturer. hfbrickmachine.com.

- Hongfa Machinery. (2026). QT12-15. hfblockmachine.com.

- Hongfa Machinery. (2026). QT4-25. hfblockmachine.com.

- Hongfa Machinery. (2026). QT4-26 block machine. hfblockmachine.com.

- Hongfa Machinery. (2026). QT6-15. hfblockmachine.com.

- Kadam, S., & Bhalerao, S. (2010). A review on the fly ash-based geopolymer concrete. International Journal of Advanced Engineering Research and Studies, 1(1), 19-25.

- Kang, H. S., Lee, J. Y., Choi, S., Kim, H., & Park, J. H. (2016). Smart manufacturing: Past research, present findings, and future directions. International Journal of Precision Engineering and Manufacturing-Green Technology, 3(1), 111–128.

- Lu, Y., Liu, C., Wang, K. I. K., Huang, H., & Xu, X. (2020). Digital Twin-driven smart manufacturing: Connotation, reference model, and applications. Robotics and Computer-Integrated Manufacturing, 61, 101837.

- QGM Quangong Machinery Co.,Ltd. (2026). China block machine, brick making machine suppliers & manufacturers & factory. qgmblockmachine.com.

- Zhong, R. Y., Xu, X., Klotz, E., & Newman, S. T. (2017). Intelligent manufacturing in the context of Industry 4.0: A review. Engineering, 3(5), 616-630.