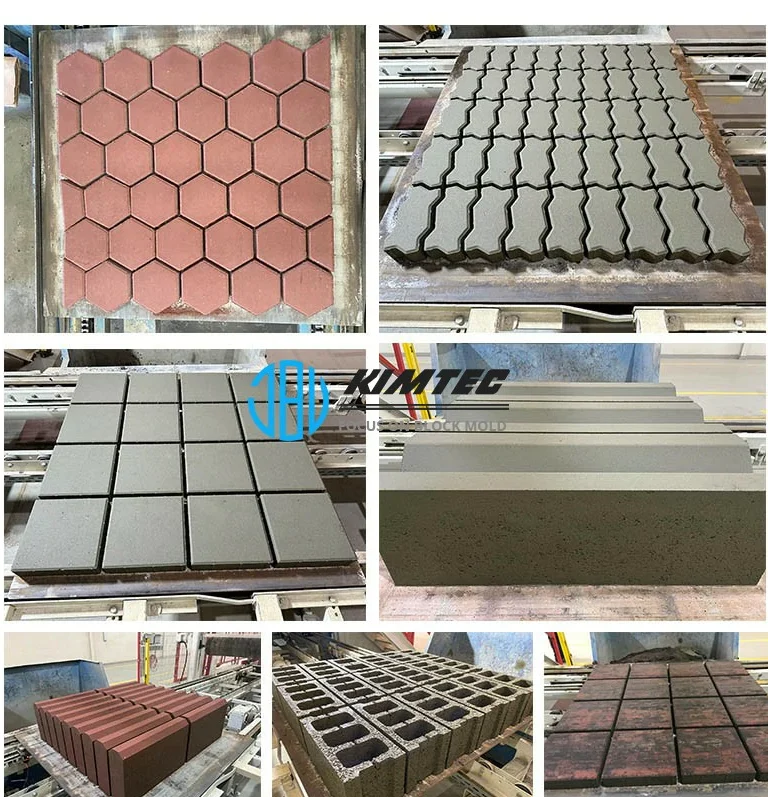

Moule à briques pour trottoirs Moule à blocs creux pour machines à blocs de béton Fabricant chinois de machines à blocs de béton

Curbside Sidewalk Brick Mold for Concrete Block Machinery - Made in China

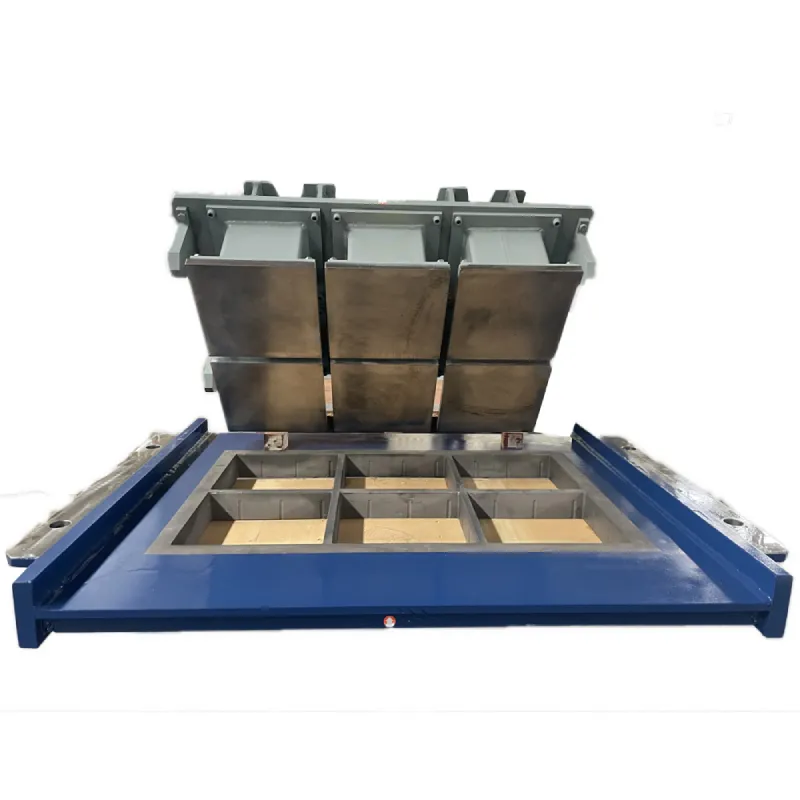

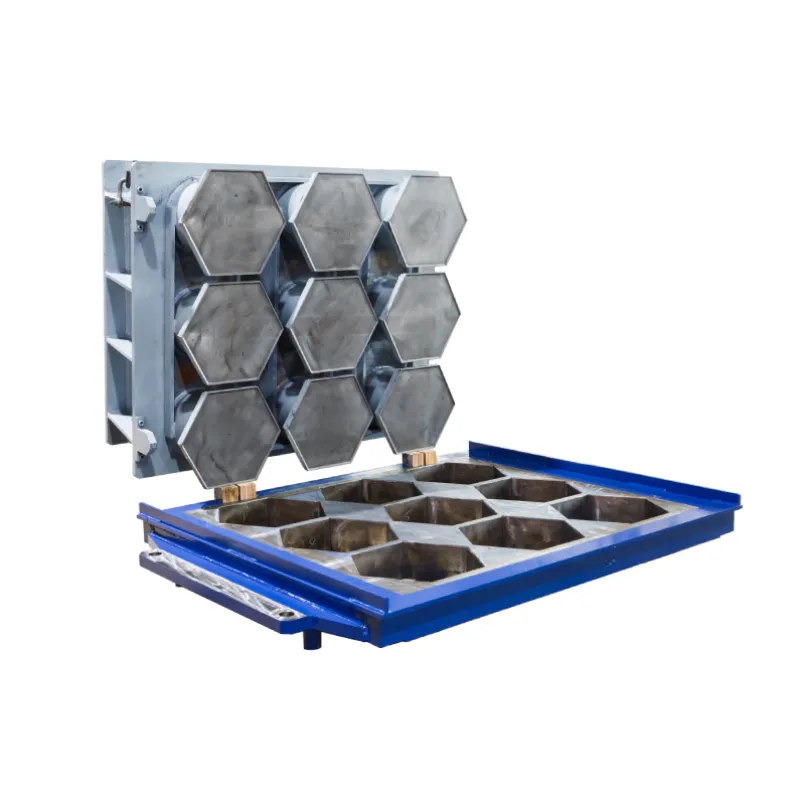

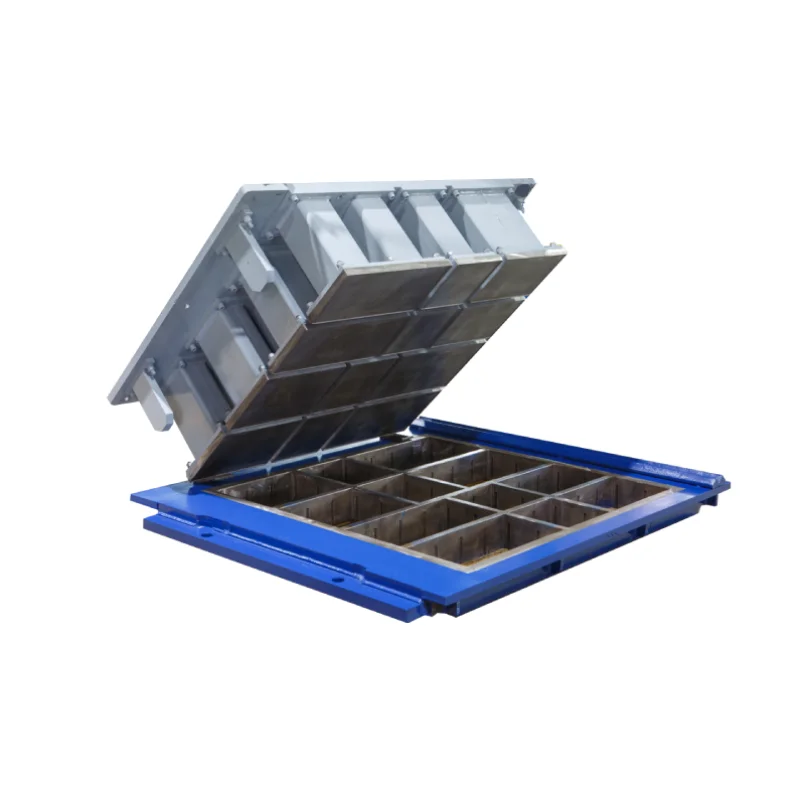

Caractéristiques des moules

Processus d'assemblage avancé

-

Precision Welding & De-Stress Treatment: Ensures minimal deformation during heat treatment; tempering after quenching eliminates internal stress for reliable mold function.

-

Press Foot Clearance: 0.3–0.8mm for machine compatibility.

-

Durable Fasteners: High-strength connection bolts with standard parts and anti-loosening treatment.

-

Standardized Assembly: Easy replacement of parts.

-

Wear-Resistant Steel Plates: High-quality steel for longevity.

-

Fonction d'amortissement : Réduit les vibrations pendant le fonctionnement.

-

Customizable Design: Supports digital free surface designs.

Heat Treatment for Durability

-

Carbonitruration : Le cadre de la matrice et le pied de la presse sont trempés à 60-65 HRC.

-

Hardening Depth: Minimum 1.2mm for enhanced strength.

FAQ

Comment obtenir un devis ?

-

Send detailed drawings of the block for a precise quote.

-

Without drawings, specify the block type (hollow, solid, etc.), provide a photo, and dimensions (length × width × thickness in mm).

-

Provide pallet size.

-

Indiquer la taille de la tête de tamper et la hauteur du moule de descente.

-

Explain how the mold connects to your machine, and share connection drawings if available.

We will provide a quote promptly once we receive this information.

Quel est le délai de livraison ?

-

Moules standard : 20-25 jours ouvrables après le dépôt.

-

Moules haut de gamme : 30-40 jours ouvrables.

Comment l'emballage de transport est-il géré ?

-

Wooden packing with plastic film, or customized per buyer requirements.

Will the mold fit my machine?

-

We manufacture molds for many block machine brands and maintain records. Some molds may already be compatible.

-

Measurements can be taken on-site by engineers, or digitally with photos.

-

Once confirmed, the mold will fit your machine perfectly.

Quelles sont les conditions de paiement ?

-

50% advance via T/T, remaining balance before shipment.

Comment puis-je vous contacter ?

-

WeChat/WhatsApp : +86-1330506196 ou +86-18960287187