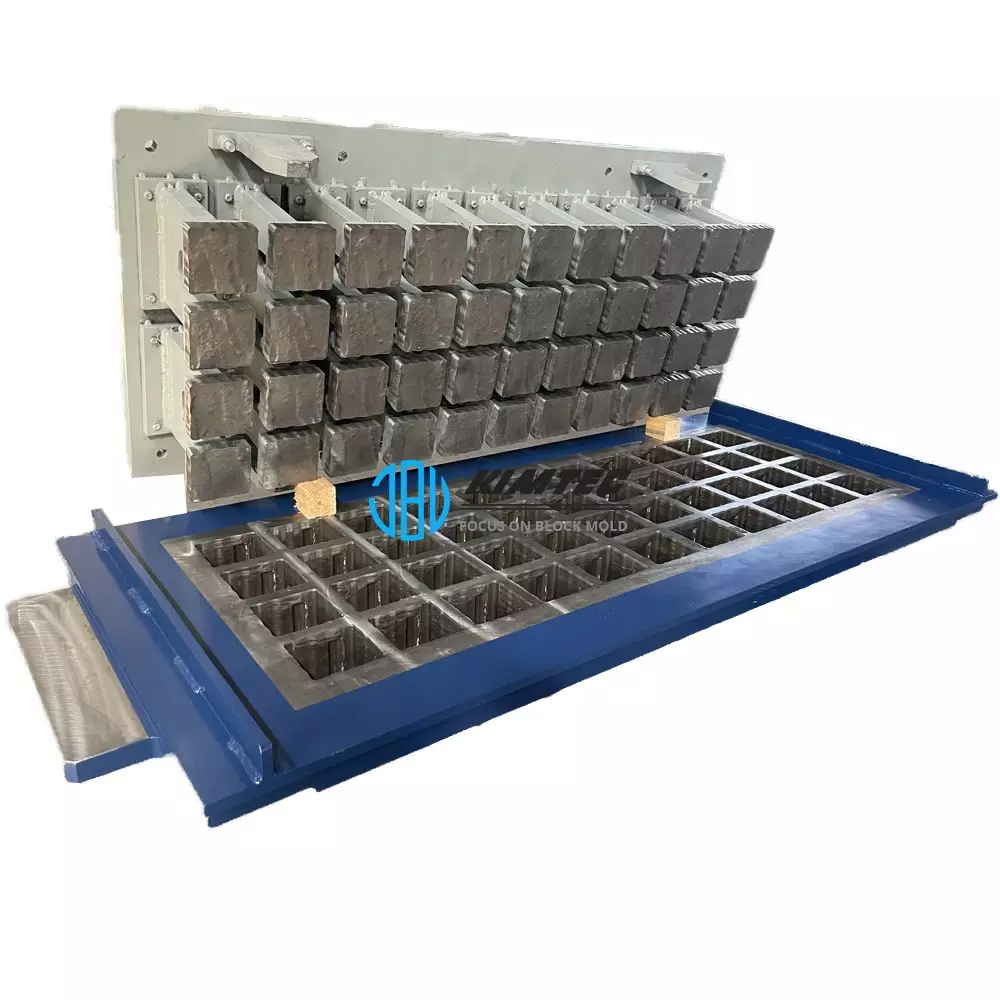

Moule à béton hexagonal Moule à briques à emboîtement

Moules à béton hexagonaux et à emboîtement

1. Types de blocs

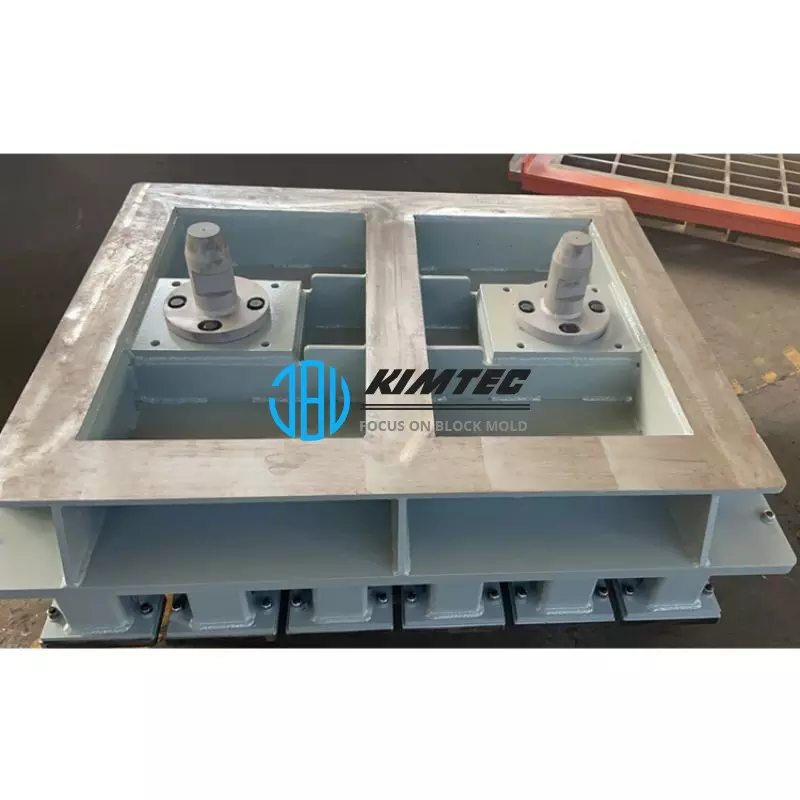

Nous concevons et fabriquons des moules en acier de haute qualité pour les pavés autobloquants, les dalles, les pavés perméables, les bordures, les murs de soutènement, les blocs creux et les blocs spéciaux. Nous répondons à toutes les exigences des clients et proposons des suggestions de conception innovantes.

2. Matières premières

Nos moules sont fabriqués à partir d'acier trempé et revenu de première qualité importé d'Italie, avec un traitement thermique pour améliorer la durabilité et la résistance à l'abrasion.

3. Expérience en matière de fabrication

Avec près de 30 ans d'expérience, nous servons des clients dans le monde entier. Grâce à l'utilisation d'un acier de première qualité et à un savoir-faire expert, nous fournissons des moules compatibles avec des marques telles que MASA, HESS, ZENITH, TIGER, Bessel, Ritu, et bien d'autres encore.

Détails techniques du moule

Caractéristiques des moules

1. Processus d'assemblage avancé

-

Précision : Le soudage avancé et le traitement de déstressage empêchent la déformation, garantissant des dimensions et des tolérances correctes.

-

Dégagement du pied presseur : 0,3-0,8 mm pour une adaptation optimale à la machine.

-

Connexions durables : Boulons à haute résistance avec traitement anti-desserrage.

-

Assemblage standardisé : Remplacement facile des pièces.

-

Plaques d'acier résistant à l'usure : Moules à longue durée de vie.

-

Fonction d'amortissement : Réduit les vibrations pendant le fonctionnement.

-

Conception personnalisée : Conception numérique de la surface libre disponible.

2. Traitement de durabilité

-

Carbonitruration : Le cadre de la matrice et le pied de la presse sont trempés à 60-65 HRC.

-

Profondeur de trempe : Minimum 1,2 mm pour une meilleure résistance.

FAQ

1. Comment obtenir un devis ?

-

Avec les dessins : Envoyer les plans d'ensemble détaillés.

-

Sans dessins : Indiquer le type de bloc (creux/solide), la photo et les dimensions (L×L×H en mm).

-

Indiquez la taille de la palette, la taille de la tête d'inversion, la hauteur du moule et les détails de connexion. Les plans de raccordement sont utiles s'ils sont disponibles.

2. Délai de livraison

-

Moules standard : 20-25 jours ouvrables après le dépôt.

-

Moules haut de gamme : 30-40 jours ouvrables après le dépôt.

3. Emballage de transport

-

Caisses en bois avec film plastique, ou emballage personnalisé selon les exigences de l'acheteur.

4. Contact

-

WeChat / WhatsApp : +86-1330506196 | +86-18960287187