MASA HESS Moule à pavé unipavé zigzag pour machines à blocs

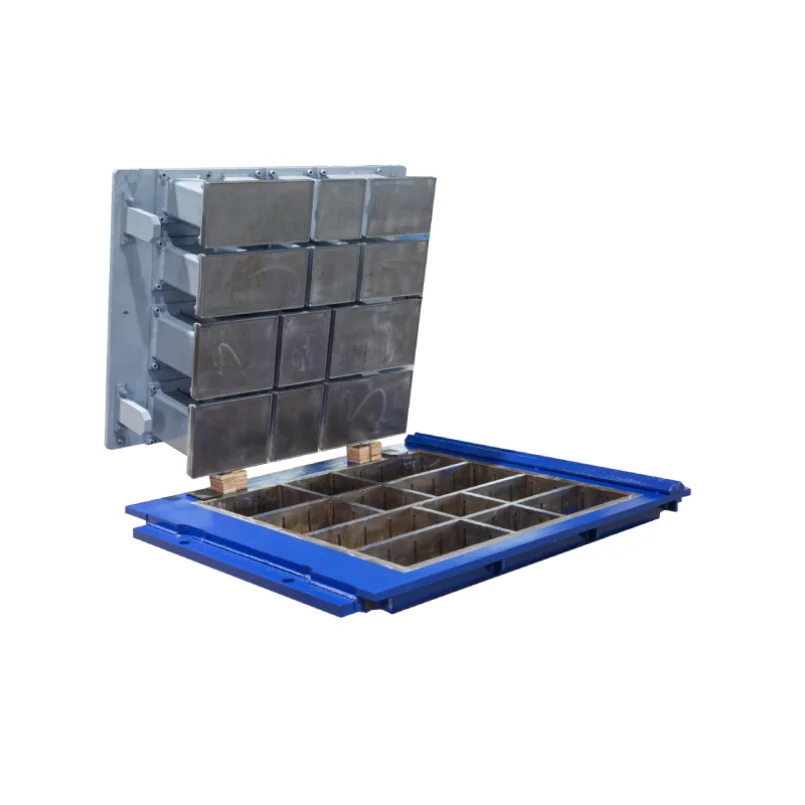

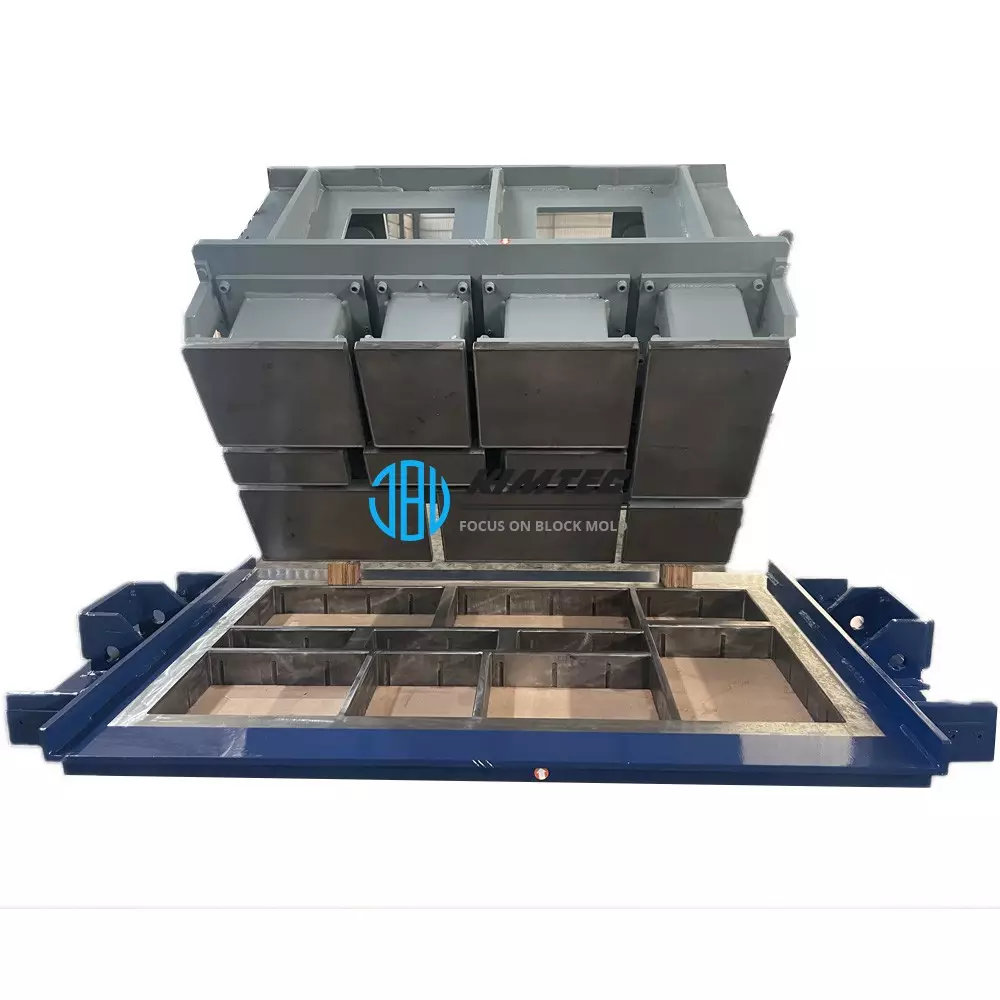

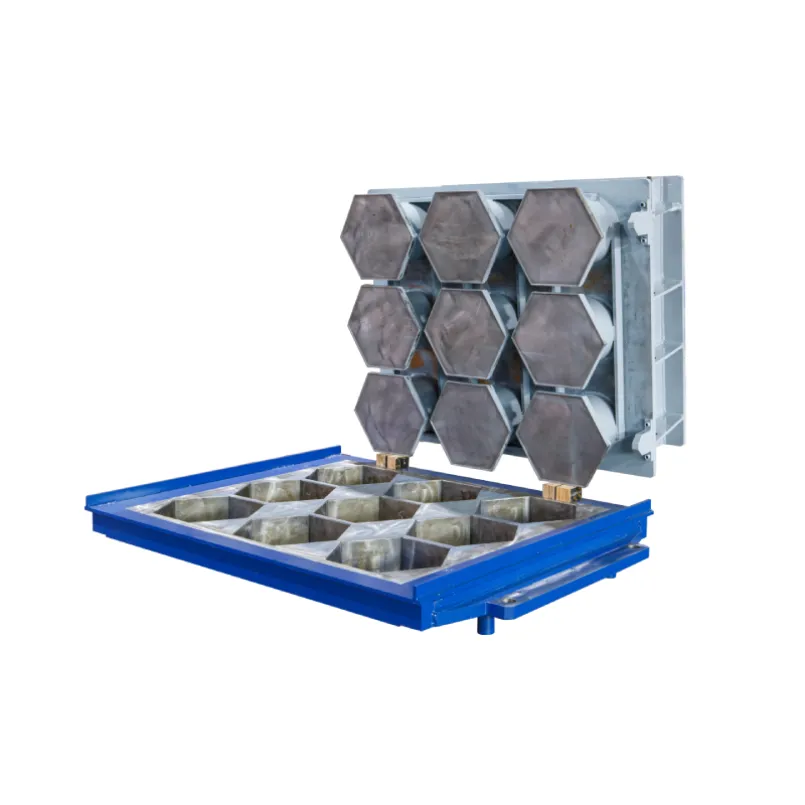

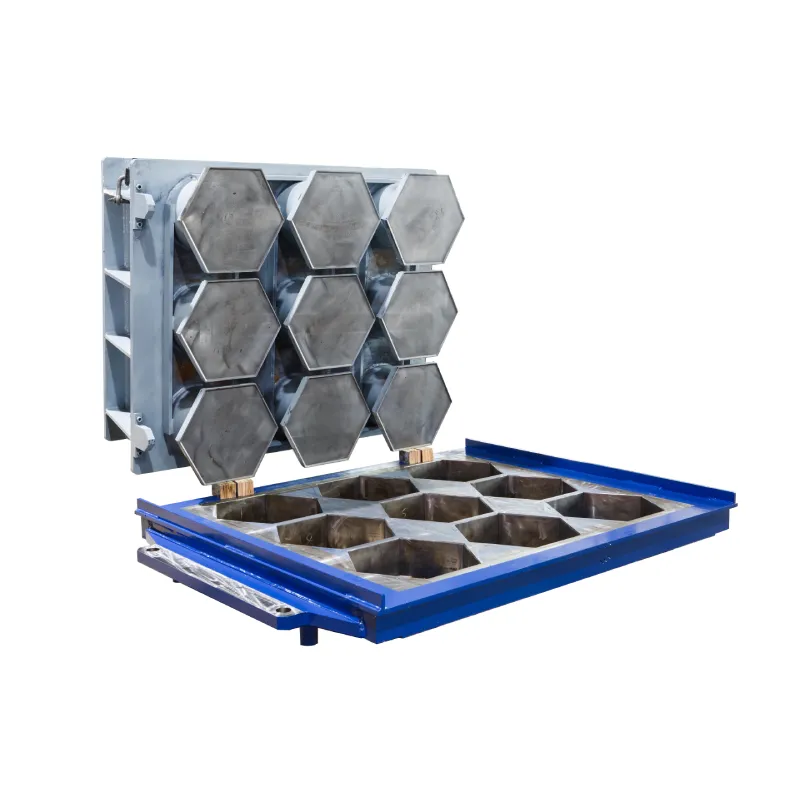

MASA HESS Interlocking Unipaver Zigzag Paver Mold for Block Machines

1.Types de blocs

We design and manufacture high-quality steel molds for interlocking paving stones, slabs, permeable paving stones, curbstones, retaining walls, hollow blocks, and special blocks. We meet customer requirements and provide innovative solutions.2. les matières premières

Our molds are made from high-end quenched and tempered steel imported from Italy, with heat treatment to enhance abrasion resistance and durability.3.Expérience en matière de fabrication

With nearly 30 years of experience, we serve customers worldwide. We combine expertise with premium materials to deliver top-quality molds compatible with brands like MASA, HESS, ZENITH, TIGER, Bessel, Ritu, and more.Spécifications des moules

Caractéristiques des moules

Processus d'assemblage avancé

-

Precision Manufacturing: Advanced welding and de-stress treatments prevent cavity/core deformation and ensure accurate dimensions and tolerances.

-

Press Foot Clearance: Maintained at 0.3–0.8mm for perfect machine compatibility.

-

Connexions durables : Boulons à haute résistance avec traitement anti-desserrage.

-

Standardized Assembly: Easy replacement of parts.

-

Wear-Resistant Steel Plates: Extend mold lifespan.

-

Damping Function: Smooth operation during production.

-

Conception sur mesure : La conception numérique de la surface libre est disponible pour les moules sur mesure.

Durabilité des moules

-

Carbonitriding Heat Treatment: Die frame and press foot hardened to 60–65 HRC.

-

Profondeur de trempe : Minimum 1,2 mm pour une meilleure résistance et des performances durables.

FAQ

1. Comment obtenir un devis ?

-

Avec les dessins : Envoyer les plans d'ensemble détaillés pour examen.

-

Sans dessins : Fournir le type de bloc (creux/solide), une photo et les dimensions (L×L×H en mm).

-

Indiquez la taille de la palette, la taille de la tête d'inversion, la hauteur du moule et les détails de connexion. Les plans de raccordement sont utiles s'ils sont disponibles.

-

Nous vous fournirons un devis dans les plus brefs délais dès réception de vos informations.

2. Délai de livraison

-

Moules standard : 20-25 jours ouvrables après le dépôt.

-

Moules haut de gamme : 30-40 jours ouvrables après le dépôt.

3. Emballage de transport

-

Caisses en bois avec film plastique, ou emballage personnalisé selon les exigences de l'acheteur.

4. Mold Compatibility

-

Molds are compatible with various block machine brands, and we maintain detailed records.

-

Measurements or digital photos can be provided to ensure perfect fit.

5. Payment Terms

-

50% avance par T/T pour démarrer la production ; solde avant expédition.

6. Contact

-

WeChat / WhatsApp : +86-1330506196 | +86-18960287187