High-End Hollow Brick Block Ceiling Paving Stone Interlock Rain-Gutter Slab And Special Molds for MASS HESS TIGER ZENITH ETC

China Leading Manufacturer of Concrete Block & Brick Molds for Block Making Machines

1.Block Types

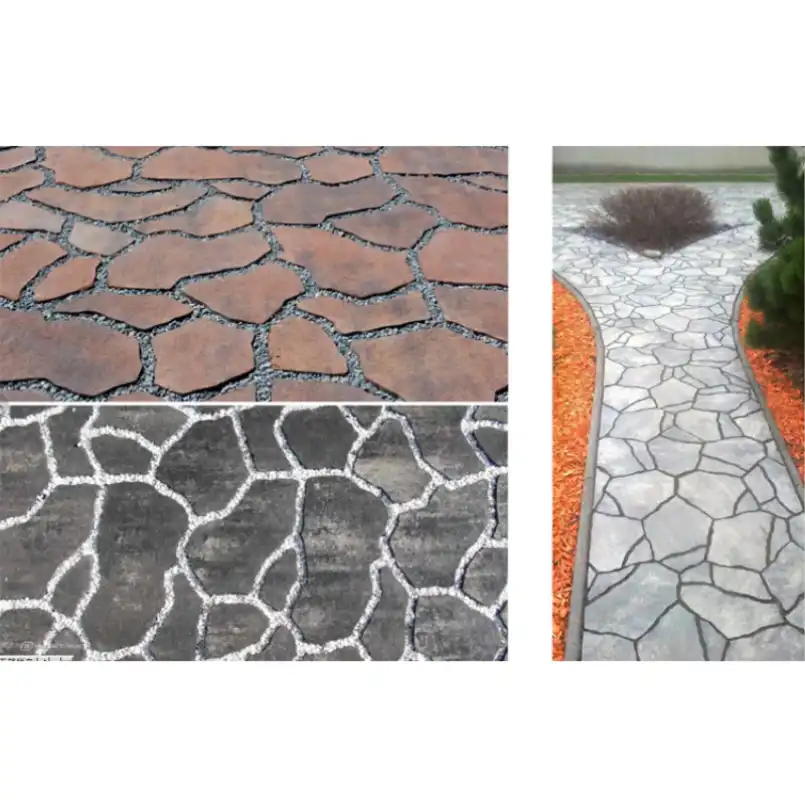

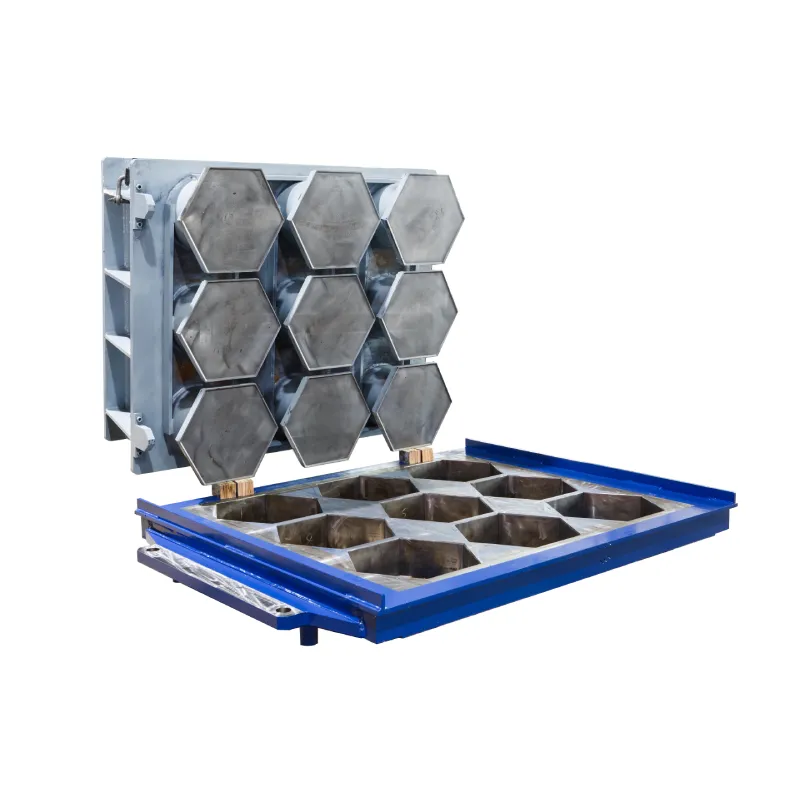

We design and manufacture high-quality steel molds for interlocking paving stones, slabs, permeable paving stones, curbstones, retaining walls, hollow blocks, and special blocks. Our molds meet customer specifications while offering innovative solutions for diverse block shapes and sizes.

2.Raw Materials

Our molds are made from premium quenched and tempered steel imported from Italy. Heat treatment enhances steel strength and wear resistance, ensuring long-lasting performance.

3.Manufacturing Experience

With nearly 30 years of experience, we serve clients worldwide. Combining expertise with high-quality materials, we deliver durable molds compatible with leading block machine brands such as Masa, Hess, Zenith, Tiger, Besser, and Ritu.

Mold Features:

-

Advanced Assembly Process: We use precision welding and de-stress treatments to prevent deformation of cavities and cores, ensuring dimensional accuracy and smooth operation.

-

Press Foot Clearance: 0.3–0.8 mm for optimal machine compatibility.

-

Durable Construction: High-strength bolts with anti-loosening treatment, standardized assembly for easy part replacement, and wear-resistant steel plates.

-

Enhanced Performance: Mold damping reduces vibrations, and digital free surface designs allow precision customization.

-

Heat Treatment: Carbonitriding to 60–65 HRC with a minimum hardening depth of 1.2 mm for long-term durability.