How Does a Concrete Batching Plant Work? A Look Inside Modern Construction Efficiency

May 29, 2025

In the always evolving construction industry with the building of big construction projects, such as skyscrapers, the use of a concrete batching plant is very important to get high-quality concrete.

The batching plant is the initial place where you are to start if the stone blocks are manufactured by block making machines, and whether maximum productivity is needed throughout the entire process.

Being the leader in the construction equipment suppliers’ market, KBL Machinery provides the latest machinery and tools to builders and developers as well as creates global partnerships with companies like Kimberly Machinery.

But the main question is, how does a concrete batching plant function? To uncover the process.

What Is a Concrete Batching Plant?

A concrete batching plant is a system that combines various ingredients—such as sand, water, cement, and aggregates—to form concrete. These components are measured precisely, batched, and mixed automatically to produce consistent concrete quality for various construction projects.

There are two main types of batching plants:

- Dry Mix Plants: Ingredients are weighed and fed into trucks, where mixing occurs during transport.

- Wet Mix Plants: All materials are mixed within the plant before being loaded into transporters.

Key Components and Their Functions

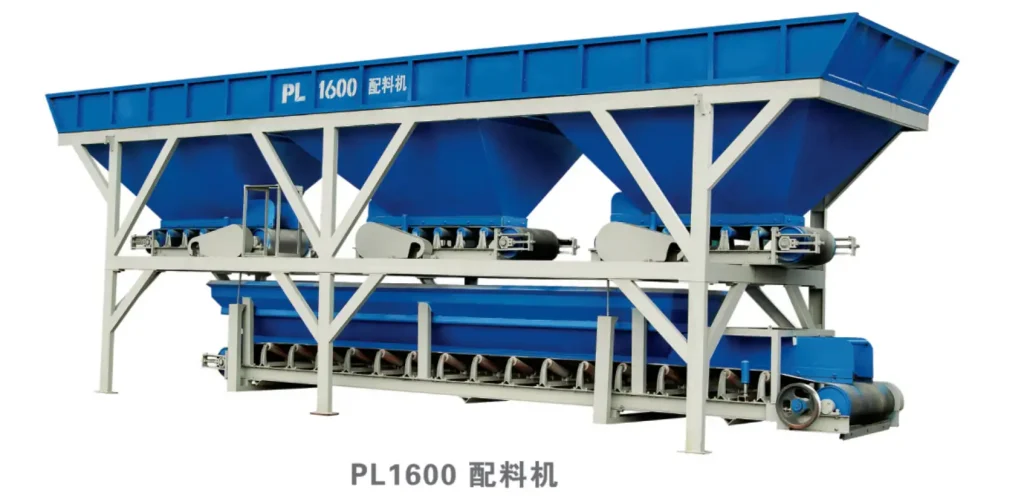

- Aggregate Bins

Store and separate different types of sand, gravel, or crushed stone. - Weighing System

Ensures each material is measured with high accuracy to meet specific mix designs. - Conveyor Belt or Skip Hoist

Transports aggregates to the mixer or storage silo. - Cement Silos

Store cement powder in a dry, controlled environment. - Mixing Unit

Combines all materials together—wet or dry—to create a uniform concrete batch. - Control Panel or PLC System

Operators can automate the entire batching process and monitor performance in real time.

The Batching Process: Step-by-Step

- Loading Raw Materials

Aggregates are loaded into bins, while cement is stored in silos. - Weighing & Dosing

The plant’s computer system calculates the required quantities for each batch. - Mixing

Depending on the plant type, mixing occurs either in the plant or inside the transit mixer. - Discharge & Transport

Once ready, the fresh concrete is discharged into mixers or mold systems like a brick making machine for block production.

This automated process reduces material waste, human error, and downtime—essential for fast-paced construction sites.

Integration with Brick Making and Precast Systems

For manufacturers focused on prefabricated systems or paving materials, pairing a concrete batching plant with a modern brick making machine can create a seamless production line.

KBL Machinery offers turnkey solutions where concrete produced on-site feeds directly into automated block molders—greatly enhancing speed and consistency for large-scale brick or tile production.

Why the Right Construction Equipment Supplier Matters

Choosing a reputable construction equipment supplier is just as important as selecting the right machinery. KBL Machinery has partnered with innovators like Kimberly Machinery to deliver:

- Scalable batching plants from 30m³ to 240m³/hour

- Modular designs for easy installation and relocation

- Full automation and remote monitoring capabilities

- Integration with mixers, conveyors, and forming lines

With technical support and export expertise, KBL ensures each plant fits local regulatory and performance requirements—whether in Asia, Africa, or South America.

Sustainability and Smart Features

Today’s batching plants also address sustainability through:

- Recycled water systems

- Dust collection units

- Energy-efficient motors and drives

- Real-time production monitoring

These features not only reduce the environmental footprint but also improve profitability through better resource management.