How to Clean Mold Off Cinder Block Walls in Basement

July 31, 2025

Basements are prone to moisture, and when ventilation or waterproofing is lacking, mold growth on cinder block walls becomes a common issue. While the sight (and smell) of mold can be alarming, cleaning it effectively doesn’t require demolition—just the right process, tools, and prevention techniques.

But before addressing the cleaning method, it’s important to understand why cinder blocks are often affected. The porous nature of concrete makes them absorb and retain moisture, especially in humid or poorly drained basements. This creates an ideal environment for mold spores to thrive.

Step-by-Step: How to Remove Mold from Cinder Block Walls

Proper mold removal is not only about aesthetics—it’s about air quality and safety. Here’s how to do it safely and efficiently:

- Ventilate the area: Open windows and use fans to increase airflow.

- Wear protective gear: Gloves, goggles, and a respirator mask are essential.

- Prepare a cleaning solution: Mix water with detergent, white vinegar, or a diluted bleach solution.

- Scrub the surface: Use a stiff-bristle brush to scrub mold patches thoroughly.

- Rinse and dry: Wipe down the walls with clean water, then dry the area with fans or dehumidifiers.

After cleaning, it’s crucial to identify and fix the moisture source—whether it’s poor drainage, wall seepage, or high humidity.

Why Block Quality Matters in Mold Resistance

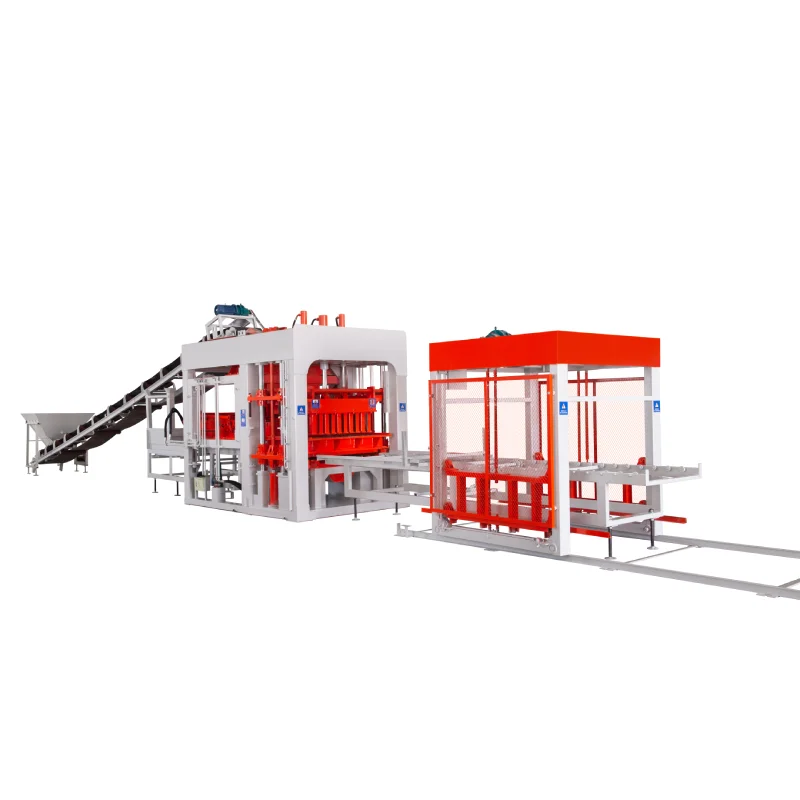

Not all cinder blocks are created equal. The durability and moisture resistance of the blocks themselves can significantly affect how mold-prone a wall becomes. That’s where manufacturers like KBL Machinery play a crucial role.

As a professional provider of cinder block making machines, KBL focuses on precision compaction, consistent curing systems, and mold engineering that reduce porosity in finished blocks. When blocks are better formed and denser, they absorb less water—making them more resistant to mold growth over time.

Investing in Better Block Manufacturing Equipment

For builders, developers, and producers of precast blocks, choosing the right machinery is a critical step toward long-term structural integrity. KBL offers advanced cinder block making machines for sale that incorporate:

- High-pressure vibration systems for optimal density

- Automated molding and demolding for consistency

- Customizable mold options from a leading China cement brick mold manufacturer

- Energy-efficient hydraulic systems for reduced production costs

These machines not only improve production speed but also elevate the quality of each block—ensuring durability from basement walls to exterior façades.

Why Choose KBL Machinery?

KBL Machinery combines engineering excellence with industry insight to deliver equipment tailored to modern construction needs. With a full range of cinder block making machines, the company serves small-scale producers and large-volume plants alike.

Clients choose KBL for:

- Durable steel frame construction across all machine models

- Precision-fit molds made by a trusted China cement brick mold manufacturer

- After-sales support, including mold customization and training

- Efficient automation, allowing operators to scale without compromising on quality

When paired with proper design and installation, blocks made by KBL’s systems create stronger, more moisture-resistant walls—reducing the risk of mold buildup in basement environments.

Prevention is Just as Important as Cleaning

Once mold is removed, take steps to prevent its return. These include:

- Installing dehumidifiers to keep humidity below 60%

- Applying concrete sealers to reduce wall permeability

- Improving exterior drainage to keep groundwater away from foundations

With the right tools—both in construction and maintenance—property owners can preserve indoor air quality and structural value. And with the right cinder block-making machines, builders can produce blocks that last longer and resist the challenges of moisture intrusion.