強さの上に成り立つ信頼性の高い生産を実現する振動ブロック製造機

6月 4, 2025

KBL Machinery Delivers Efficiency, Durability, and Precision to Global Builders

Vibration Technology That Powers the Future of Construction

In the fast-growing construction sector, speed and structural integrity go hand in hand. Whether it’s low-rise housing, large-scale infrastructure, or urban paving solutions, the demand for consistent, high-quality blocks has never been greater. That’s where KBL Machinery steps in—with its innovative line of Vibration Type-Brick/Block Making Machines, built to optimize density, output, and cost-efficiency.

KBL’s machines are trusted by contractors and manufacturers across Asia, the Middle East, Africa, and Latin America for their ability to produce uniform, load-bearing blocks across a range of applications.

What Makes Vibration Type Machines Stand Out?

Unlike traditional compaction systems, Vibration Type-Brick/Block Making Machines use high-frequency mechanical vibration to eliminate air pockets and increase the density of concrete or cement mix. This results in stronger, longer-lasting bricks and blocks with a smoother surface finish.

主な利点は以下の通り:

- High compaction strength for structural-grade output

- Faster cycle times with reduced curing defects

- Lower cement-to-water ratio needed, improving sustainability

- Adaptable to a wide range of mould types and sizes

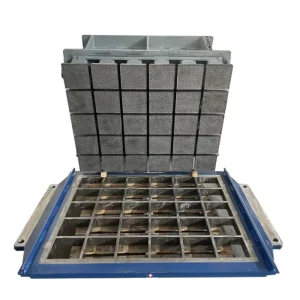

This method is particularly effective when paired with specialized ブロックモールド such as solid, interlocking, and ホローブロックモールド sets, all of which KBL Machinery supplies in-house for precise compatibility.

Integrated Block Mould Systems

A machine is only as versatile as the moulds it supports. KBL offers a full catalogue of ブロックモールド designed for durability and clean separation, allowing clients to switch between product types with minimal downtime.

Whether you’re producing interlocking pavement tiles, hollow bricks for low-cost housing, or custom-shaped blocks for decorative finishes, KBL’s mould systems provide:

- Hardened steel construction with anti-rust coating

- CNC-milled precision for uniform output

- Custom designs available for private projects or OEM branding

For example, the ホローブロックモールド range remains one of the best-selling series, thanks to its balance of strength, material efficiency, and insulation properties—especially suitable for hot-climate housing and lightweight construction.

Built for Automation, Designed for Longevity

KBL’s 振動式レンガ/ブロック製造機 lineup includes semi-automatic and fully automatic models that support continuous production with minimal manual labor. These machines integrate hydraulic feeding, PLC control systems, and real-time diagnostics to ensure smooth operation—even in challenging environments.

Each machine is:

- Tested under simulated field conditions

- Calibrated for multiple block formats

- Delivered with full documentation, training support, and spare part packages

In addition, energy efficiency is a core focus. Vibration frequency and amplitude can be adjusted based on the material type and mould, saving electricity while maintaining strength requirements.

A Trusted Export Brand in Block Machinery

As a global ブロックモールド and machinery manufacturer, KBL Machinery has earned a reputation for reliability and after-sales excellence. The company exports to over 60 countries and offers bilingual technical assistance, remote installation support, and localized training for production teams.

Buyers choose KBL because they get:

- Scalable production lines from 4,000–20,000 blocks/day

- Custom layout design and plant consultation

- CE/ISO-certified equipment and logistics-ready packaging

- Long-term access to original ホローブロックモールド replacements