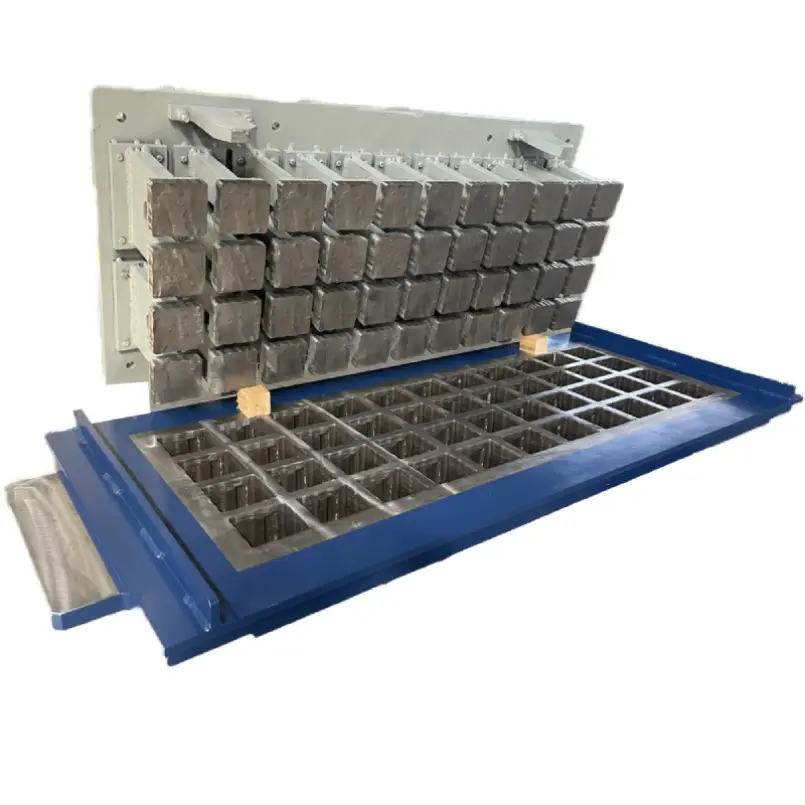

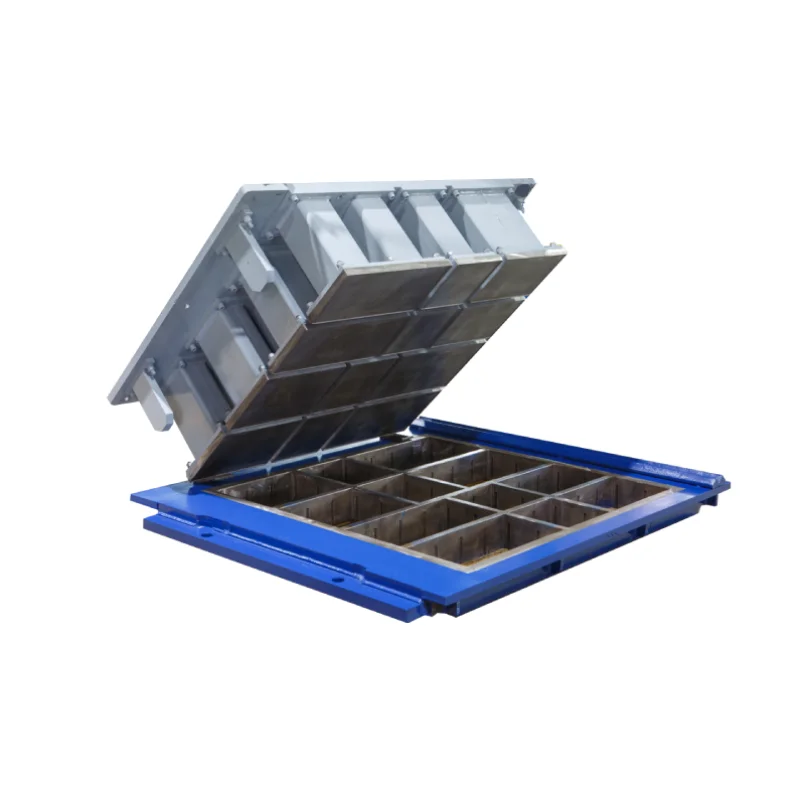

マス・ヘス・タイガー・ゼニス ETC のための上限の空煉瓦ブロックの天井の敷石の連結の雨どいの平板そして特別な型

機械を作るブロックのための具体的なブロック及び煉瓦型の中国の一流の製造業者

1.ブロックの種類

インターロッキング敷石、スラブ、透水性敷石、縁石、擁壁、中空ブロック、特殊ブロック用の高品質スチール金型を設計・製造しています。当社の金型は、多様なブロックの形状やサイズに対応する革新的なソリューションを提供しながら、お客様の仕様を満たしています。

2.原材料

当社の金型は、イタリアから輸入した高級焼入れ・焼戻し鋼から作られています。熱処理は鋼鉄強さおよび耐久性を高め、長続きがする性能を保障する。

3.製造経験

30年近い経験を持つ当社は、世界中のお客様にサービスを提供しています。専門知識と高品質の素材を組み合わせ、Masa、Hess、Zenith、Tiger、Besser、Rituなどの主要なブロック機械ブランドと互換性のある耐久性のある金型をお届けしています。

金型の特徴

-

高度な組立工程:精密溶接とデストレス処理により、キャビティとコアの変形を防ぎ、寸法精度とスムーズな動作を保証します。

-

プレスフットクリアランス:0.3~0.8mmでマシンに最適に適合。

-

耐久性のある構造:緩み止め処理を施した高強度ボルト、部品交換が容易な標準化されたアセンブリ、耐摩耗性鋼板。

-

パフォーマンスの向上:金型減衰が振動を低減し、デジタル自由曲面設計が精密なカスタマイズを可能にします。

-

熱処理:炭窒化処理:60~65HRC、硬化深さ1.2mm以上で長期耐久性を実現。