ニュース

-

なぜメーカーは精密加工にXX200油圧プレス機を好むのか?

読む もっと読む今日の競争の激しい製造環境では、精度、効率、耐久性が成功の礎となっています。自動車部品から建設資材に至るまで、製品を正確に成形する能力は、品質と収益性の両方を決定します。先進的なツールの中でも、XX200油圧プレス機は、精度と多用途性を求めるメーカーに選ばれています。製造業における油圧プレスの役割 油圧プレス機械は、流体の力を利用して大きな力を発生させ、材料を高精度に成形、成型、圧縮することができます。XX200油圧プレス機は、パワーと洗練された制御を組み合わせることで、強度と正確な仕様の両方が要求される部品の製造に理想的です。XX200油圧プレスが選ばれる理由

-

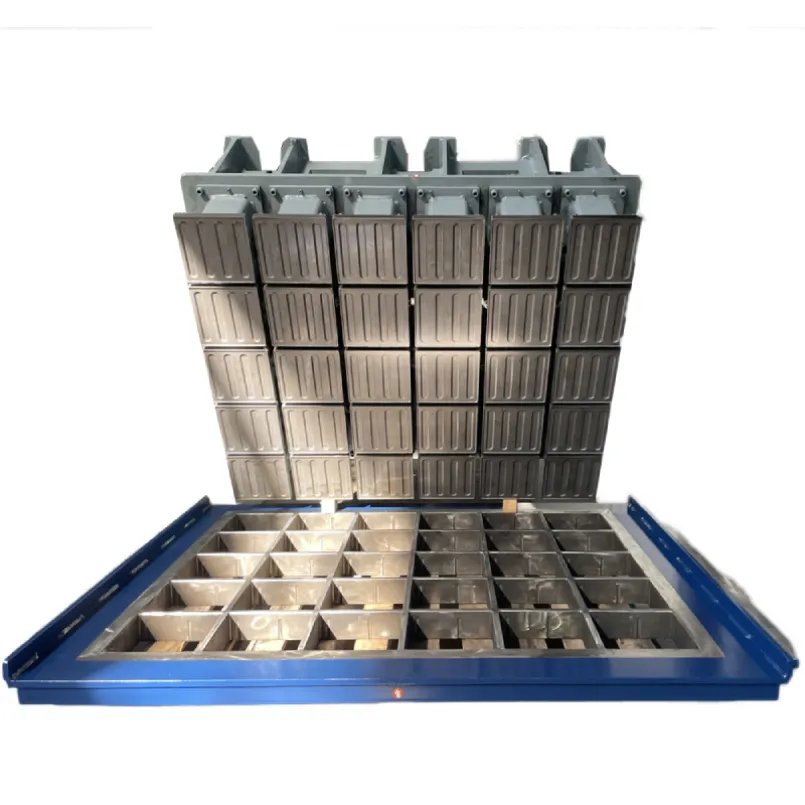

舗装用レンガ型を購入する前に知っておくべきこととは?

読む もっと読む舗装用レンガは、車道や歩道、屋外の路面に欠かせないもので、耐久性と美観の両方を兼ね備えています。製造業者にとって、適切な敷レンガ用金型を選択することは、一貫した品質、効率的な生産、長期的な収益性を達成するための鍵となります。適切な型があれば、企業は製品の幅を広げ、多様な市場の需要に応えることができます。金型の品質が重要な理由 金型は、各敷石レンガの形状、サイズ、表面の質感を決定します。金型の品質が悪いと、エッジの凹凸、表面のひび割れ、寸法の不揃いなどの欠陥が生じます。KBLマシナリーの高品質金型は、そのような事態を回避するように設計されています:耐久性のある金型に投資することで、メーカーはメンテナンスコストを削減し、生産効率を向上させることができます。コンクリートブロックマシンとの統合 [...]...

-

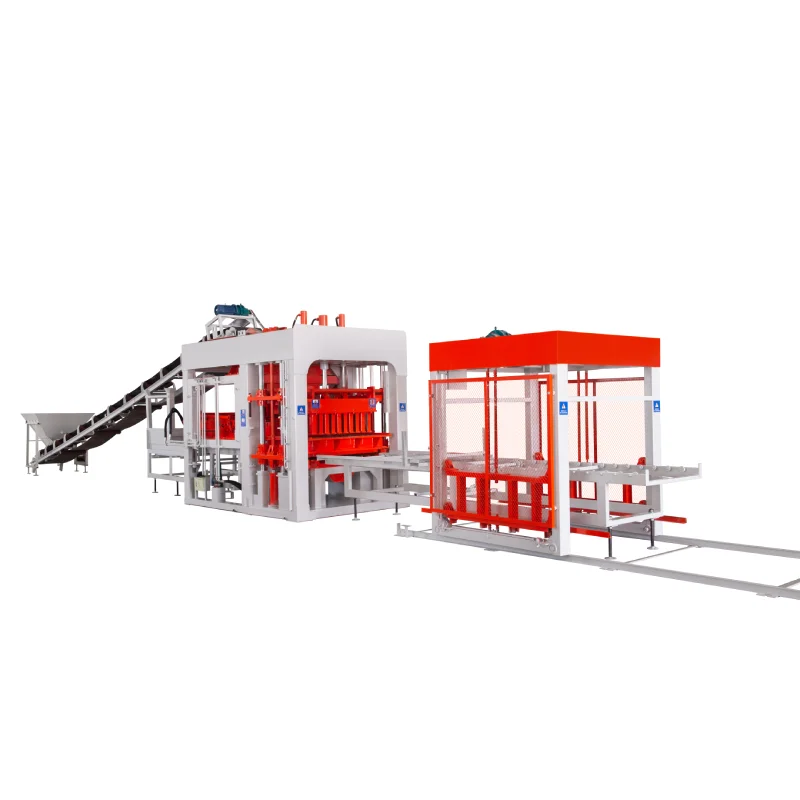

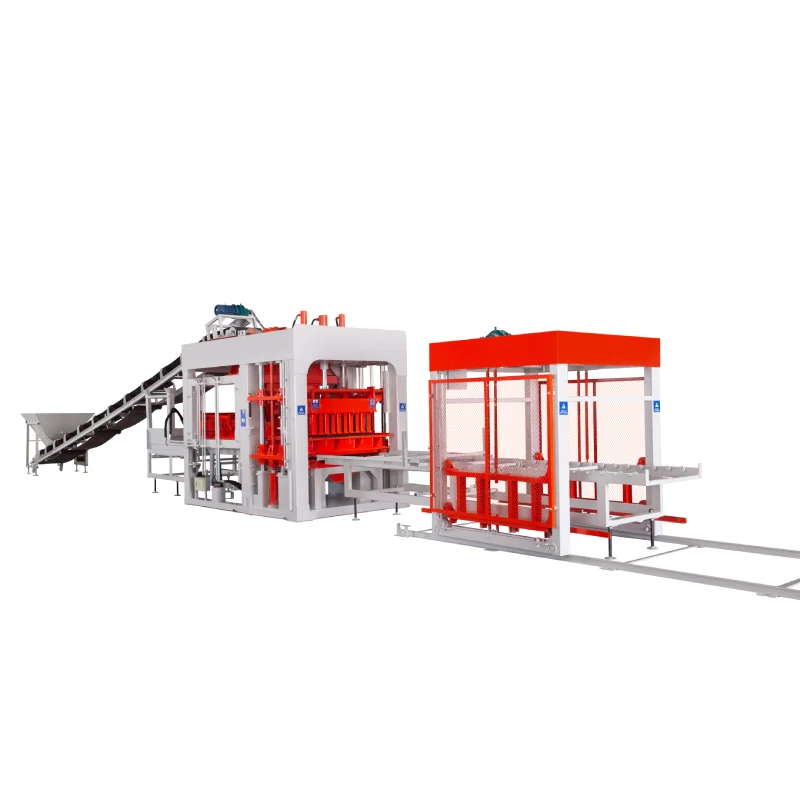

コンクリートブロックモルダーとは?

読む もっと読む建設業界では、スピード、品質、コスト効率が重要です。この3つに対応する機器のひとつがコンクリートブロックモルダーです。均一で耐久性のあるコンクリートブロックを製造するために設計されたこの機械は、品質に妥協することなく高い需要を満たすことを目指す建設業者、建築業者、製造業者にとって必要不可欠なものとなっています。コンクリート・ブロック・モルダーを理解する コンクリート・ブロック・モルダーは、コンクリートを一定の大きさと強度を持つブロックやレンガに成形し、圧縮する専用の機械です。機種によって、標準的な中空ブロック、ソリッドブロック、特注の舗装用レンガを製造できます。サイズと密度が均一であるため、各ブロックが建築基準を満たし、廃棄物が削減され、[...]が改善されます。

-

セメントブロック塀からカビを除去する方法

読む もっと読むセメントブロックの壁は、その強度と手頃な価格から、地下室やガレージ、ユーティリティ構造などによく使われている。しかし、これらの多孔質の表面は、湿気の多い環境や換気の悪い環境ではカビが繁殖しやすい。セメントブロック壁のカビは、見た目が悪いだけでなく、室内の空気の質や長期的な構造的完全性を損なう可能性があります。この記事では、KBL Machineryがカビを除去する実践的なステップを紹介し、最新のセメントブロック製造機技術がカビのリスクを元から減らすのに役立つことを説明します。セメントブロック塀にカビが生える理由 セメントブロックは、特に密閉されていない場合、空気、地面、または近くの雨漏りから湿気を吸収する可能性があります。この湿気はカビの胞子にとって理想的な環境を作り出します。

-

シンダーブロックの壁からカビを除去するには?

読む もっと読むシンダーブロックの壁は、その強度と耐久性から、地下室やガレージ、工業スペースによく使われる。しかし、シンダーブロックは多孔質であるため、湿気の多い場所や風通しの悪い場所ではカビが生えやすくなります。カビを放置しておくと、構造の健全性に影響を及ぼすだけでなく、深刻な健康被害をもたらすこともあります。この記事では、KBL Machineryがシンダーブロックの壁からカビを除去する効果的な方法と、シンダーブロック製造機で作られたようなブロックの背後にある材料を理解することが予防に役立つ方法について説明します。シンダーブロックにカビが発生する理由 シンダーブロックは、特に地下や湿気の多い場所で使用されると、周囲の環境から湿気を吸収します。一旦湿気を帯びると、 [...] 続きを読む

-

コンクリートミキサーの選び方

読む もっと読む建設プロジェクトを始めるにせよ、ブロック生産ラインを拡張するにせよ、適切なコンクリートミキシングマシンを選択することは、効率性、一貫性、そして長期的な成功に向けた重要なステップです。非常に多くのモデルや構成があるため、ミキサーを選択することは、特に予算、出力ニーズ、生産品質のバランスを取る場合には、圧倒されることがあります。建設機械の大手プロバイダーであり、信頼できるコンクリートブロック製造機サプライヤーであるKBL Machineryは、コンクリートミキサーがお客様の特定の作業にとって真に効果的である理由についての専門的な洞察を提供します。コンクリートミキサーの役割を理解する コンクリートミキサーは、セメント、骨材、水、添加物を均一なコンクリートミックスにブレンドします。適切なミキサーは一貫した品質を保証し、労働力を節約します。

-

地下室のシンダーブロックの壁からカビを除去する方法

読む もっと読む地下室は湿気がこもりやすく、換気や防水が不足すると、シンダーブロックの壁にカビが生えることがよくあります。カビを見ると(そして臭いを嗅ぐと)心配になりますが、カビを効果的に掃除するには、解体する必要はありません。しかし、洗浄方法を説明する前に、なぜシンダーブロックがよく影響を受けるのかを理解することが重要だ。コンクリートは多孔質であるため、特に湿気の多い地下室や水はけの悪い地下室では湿気を吸収・保持します。これは、カビの胞子が繁殖するための理想的な環境を作成します。ステップバイステップ:シンダーブロックの壁からカビを除去する方法 適切なカビの除去は、美観だけではありません-それは空気の質と安全性についてです。ここでは、その方法をご紹介します。

-

ブロック製造のニーズに合ったコンクリートミキサーの選び方

読む もっと読む適切なコンクリートミキサーを選択することは、信頼性が高く効率的なレンガやブロックの生産ラインを構築する上で非常に重要なステップです。建設資材市場への参入を目指す新興企業であれ、設備をアップグレードする既存メーカーであれ、選択するミキサーは事業の品質、スピード、収益性に直接影響します。KBLマシナリーでは、ミキサーだけでなく、高性能のレンガ製造機や耐久性のあるコンクリートブロック型など、あらゆる生産規模のニーズに応える統合ソリューションの提供を専門としています。適切なコンクリートミキサーが重要な理由 コンクリートミキサーはブロックやレンガ製造の最前線に位置し、[...]を提供するだけではありません。

-

ナイジェリアにおけるコンクリートブロック製造機の価格は?

読む もっと読むナイジェリアの建設部門は活況を呈しており、手頃な価格で耐久性があり、効率的な建築資材に対する高い需要が生まれている。その中でもコンクリートブロックは、住宅・商業プロジェクトの定番として際立っている。起業家や請負業者にとって、レンガ製造機への投資は賢い選択ですが、ナイジェリアにおける現在のコンクリートブロック製造機価格を理解することが、正しい投資を行うための鍵となります。価格が変動する理由 ナイジェリアにおけるコンクリートブロック製造機の価格には、多くの要因が大きく影響しています:2025年までに、基本的な手動レンガ製造機の価格は₦50万円、半自動モデルは₦200万円から₦500万円の範囲に収まるかもしれません。高出力の全自動機械は、[...]を行くことができます。

-

なぜケニアでデュアル・ドアブロック浸漬機が人気を博しているのか?

読む もっと読むケニアで最も急成長している分野のひとつが建設業であり、このような環境では、信頼性が高く効率的なレンガ養生機が必要とされています。KBLマシナリーのデュアル・ドアブロック浸漬機は、石工工程の波を非常に効率的に、あまり考慮することなく受けており、正しい選択としてマークされています。この機械が注目されるには、それなりの理由があるはずだ。ケニアの耐久レンガ需要に応える ケニアの建設業界は急速に変化している。デベロッパー、請負業者、政府関係者がこの革命の主役であり、彼らの注目は [...]...