ニュース

-

レンガ製造マシンはいかにして建設の未来を形作るのか?

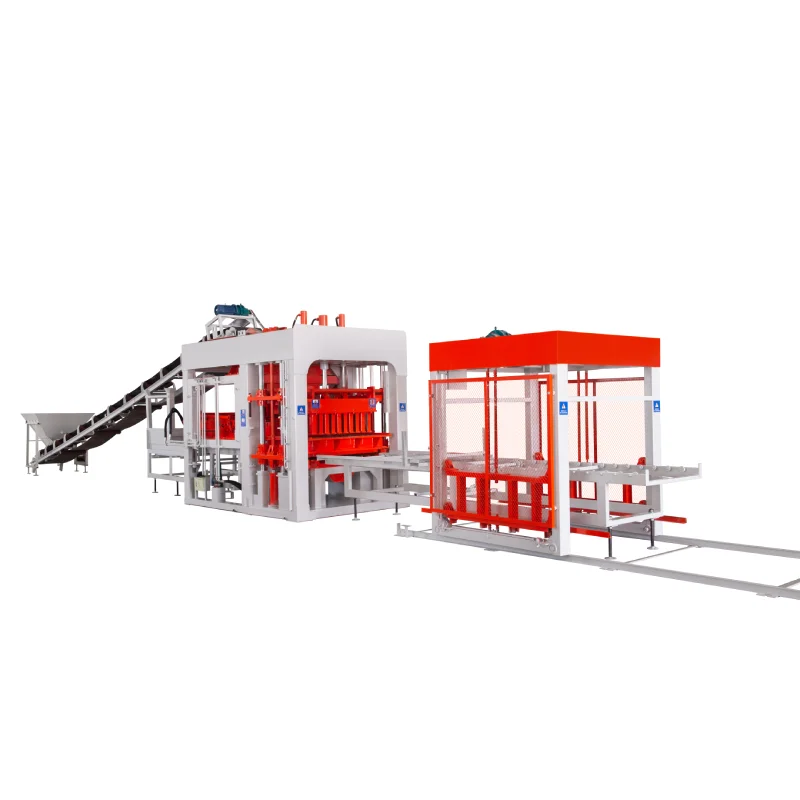

読む もっと読むはじめに現代建築におけるレンガの役割 レンガは長い間、耐久性、強度、多用途性を備えた建築の定番であった。近代建築では、レンガは構造的な完全性を提供するだけでなく、エネルギー効率やコスト削減にも貢献している。高品質なレンガへの需要が高まる中、業界では生産ニーズに応えるため、レンガ製造機械への注目が高まっています。これらの機械は、れんが製造工程を自動化し、効率性、一貫性、費用対効果を大幅に改善する。このシフトは、レンガ製造の状況を一変させ、大規模プロジェクトのニーズへの対応を容易にし、持続可能性を向上させている。レンガ製造機械の進化 手作業から完全自動化システムへ、レンガ製造機械の進化 [...]...

-

中空ブロック成形と機械の総合ガイド

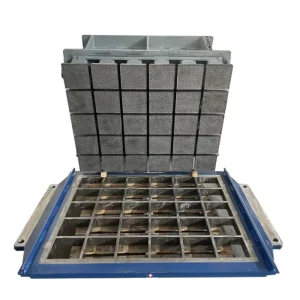

読む もっと読むはじめに中空ブロックの需要の高まり 中空ブロックは、その軽量性、断熱性、コストパフォーマンスの高さから、建設業界でますます人気が高まっている。セメント、骨材、水を混ぜて作られるこのブロックは、基礎から間仕切り壁まで、さまざまな建設用途に使用されている。これらのブロックの需要が高まるにつれ、製造業者は生産を合理化するために自動化されたソリューションに目を向けている。このシフトにより、中空ブロック成形機と自動中空ブロック製造機は、市場の拡大するニーズに対応するために不可欠なものとなっています。中空ブロック成形:効率的な生産の鍵 中空ブロック成形とは?中空ブロック成形とは、コンクリート混合物を[...]に成形するプロセスです。

-

What is the Best Way to Remove Concrete from Molds?

読む もっと読むRemoving concrete from molds efficiently and without damage is a crucial step in block production. Whether you are working with concrete pavement moulds, concrete block making moulds, or concrete brick molds, understanding the best methods will ensure smooth operations and high-quality results. In this guide, we will explore proven techniques that improve mold removal while extending the lifespan of your equipment. Key Techniques for Efficient Mold Removal 1. Use of Proper Release Agents One of the most effective ways to remove concrete from molds is by using high-quality release agents. These agents reduce friction between the concrete and the mold, making it easier to remove the block after curing. When […]

-

自動インターロッキングレンガマシンによる建設効率の向上

読む もっと読む建設業界は大きな変化を遂げつつあり、自動化が効率向上の原動力となっている。自動フライアッシュれんが製造機、自動インターロッキングれんが製造機、全自動れんが製造機などの主要な技術革新は、れんが製造に変革をもたらしつつある。これらの機械は、生産量の増加、一貫性の向上、コストの削減を実現し、最終的に建設プロジェクトのタイムラインと収益性を向上させます。生産速度と効率の向上 自動フライアッシュれんが製造機は、サイクルタイムを短縮することで、生産速度を大幅に向上させます。これらの機械は、わずか12秒でレンガを生産することができ、生産プロセスをスピードアップし、大量注文をより迅速に完了することができます。主要な生産工程を自動化できることで、企業は、[...]を満たすことができます。

-

全自動レンガ生産ラインでビジネスを強化

読む もっと読むWhy Invest in a Fully Automated Brick Production Line? Investing in a fully automated brick production line offers significant advantages for businesses in the construction industry. As the demand for durable, sustainable, and high-quality building materials continues to rise, automated production lines provide a way to meet these needs efficiently. Key benefits include: Automation not only improves operational efficiency but also enhances competitiveness, positioning businesses to meet diverse market demands while maintaining sustainability. Key Features of KBL-TEC Block Making Machines KBL Machinery’s KBL-TEC block making machine is designed to optimize efficiency and reliability. These machines feature: Why Automation is Key to Modern Brick Production The adoption of automation in brick […]

-

What Are the Benefits of Starting a Brick Manufacturing Business?

読む もっと読むBricks are essential in construction and will continue to be in demand due to their durability and versatility. As cities expand and construction projects multiply, the brick manufacturing industry presents substantial opportunities. Moreover, with growing awareness of sustainability, brick manufacturing has evolved, offering new business prospects for entrepreneurs. High Market Demand The need for bricks is undeniable across various sectors. Key factors contributing to this demand include: As the construction industry expands, manufacturers who can produce quality products like paving bricks and concrete blocks will benefit from this high demand. Low Entry Barrier One of the primary reasons entrepreneurs choose brick manufacturing is the relatively low initial investment. Here’s why: […]

-

Why the QT4-15 is Ideal for Medium-Scale Concrete Production

読む もっと読むFor medium-scale concrete block production, businesses need a solution that strikes the perfect balance between efficiency, affordability, and quality. The QT4-15 hydraulic block making machine provides just that. Designed for producers seeking high output with manageable investment costs, the QT4-15 stands as a perfect choice for those looking to optimize their production without overcommitting on a large-scale machine. 1. Optimized Production Capacity The QT4-15 block making machine is built for medium-scale production with an output of up to 4,000 blocks per day. This makes it ideal for businesses that are growing but don’t yet require the high capacity of larger models. The QT4-15 ensures your production line operates at an […]

-

Future Trends in Interlocking Molds: What’s Next?

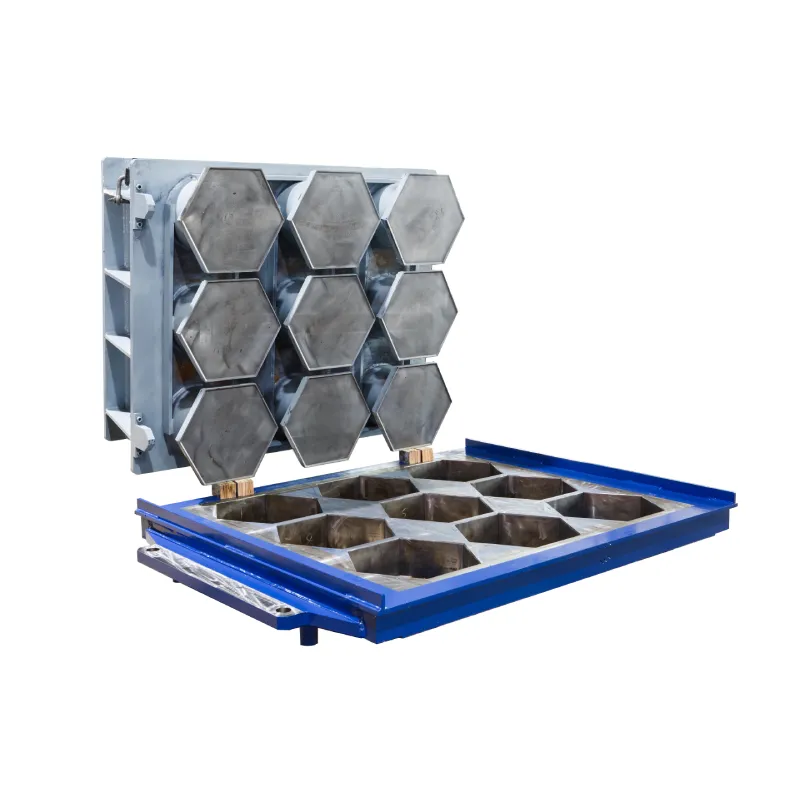

読む もっと読むInterlocking molds play an increasingly important role in concrete block production. As industries strive for higher efficiency, customization, and sustainability, these molds are evolving to meet these demands. The future of interlocking molds looks promising. Several key trends are emerging that will shape their development in the coming years. 1. Advanced Materials for Better Durability Manufacturing processes are becoming more sophisticated. The materials used in interlocking molds are also improving. New composite materials and high-performance alloys are making molds more durable, reliable, and cost-effective. With these advancements, interlocking molds can withstand harsher conditions. They offer higher durability and lower overall production costs. 2. Customization with CAD and 3D Printing Customization […]

-

How to Choose the Right Hollow Block Mould for Your Production Line

読む もっと読むSelecting the right hollow block mould is crucial for ensuring the efficiency and quality of your concrete block production line. With so many options available, understanding the types, materials, and features of hollow block moulds will help you make an informed decision. Important factors to consider include hollow block mould design, material selection, price, and choosing the right supplier to meet your specific requirements. Types of Hollow Block Moulds There are several types of hollow block moulds, each designed for specific production scales and project needs: Choosing the right type of mould depends on your production scale, budget, and specific project requirements. The Importance of Hollow Block Mould Design The hollow block mould design has a direct impact […]

-

プレキャストコンクリートブロック型の使用後の清掃方法

読む もっと読むPrecast concrete block moulds play a crucial role in concrete block production, and maintaining their quality is essential for smooth and efficient manufacturing. At KBL Machinery, we specialize in precast concrete block moulds made from high-quality materials such as Q355 steel and premium Italian steel, ensuring both durability and reliability. These materials help our moulds withstand repeated use while maintaining the shape and quality of the blocks they create.. Proper cleaning of these moulds is vital to prevent concrete build-up and preserve the moulds’ structural integrity. Over time, hardened concrete left in the moulds can become difficult to remove and may lead to defects in the final product. Regular cleaning not only ensures […]