業界知識

-

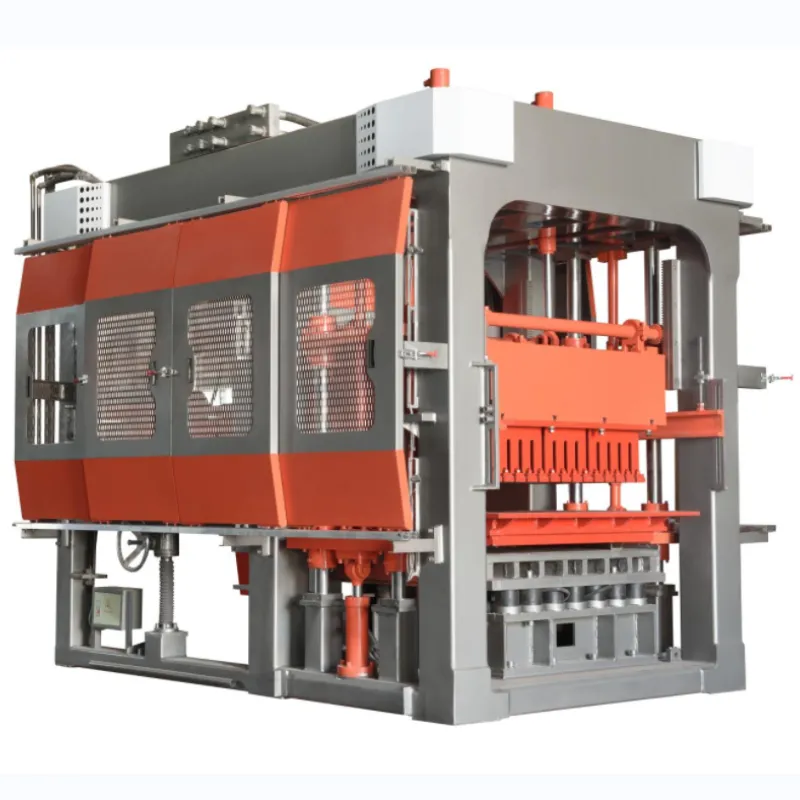

![QT12-15-BrickBlock-Making-Machine-1[1] A Proven Guide to Multi-size brick production capability: Boost Project ROI by 35% in 2026](https://www.kblmachinery.com/wp-content/uploads/2026/02/QT12-15-BrickBlock-Making-Machine-11.webp)

A Proven Guide to Multi-size brick production capability: Boost Project ROI by 35% in 2026

読む もっと読むAbstract The evolution of construction machinery reflects a broader industrial shift from rigid specialization towards dynamic versatility. This analysis examines the operational and economic implications of multi-size brick production capability in modern concrete block machines, particularly within the rapidly developing markets of Southeast Asia and the Middle East. It posits that the ability of a single machine to produce a diverse portfolio of concrete products—from hollow blocks and solid bricks to pavers and curbstones—is no longer a peripheral feature but a central pillar of competitive advantage and project profitability. By leveraging interchangeable mold technology and advanced hydraulic and control systems, manufacturers can significantly enhance their market responsiveness, optimize resource allocation, […]

-

How to Calculate Daily Brick Production Capacity and Scale a Profitable Brick Factory?

読む もっと読むThe short answer is that daily brick production capacity is determined by a combination of machine configuration, mold design, operating hours, labor efficiency, and curing logistics. For industrial investors and brick manufacturers, understanding this metric is essential because it directly impacts unit cost, return on investment, and market responsiveness. For example, two factories using similar raw materials may produce dramatically different daily outputs simply due to differences in automation level and production planning. This article explains how daily brick production capacity is calculated, what factors influence it, and how decision-makers can scale output sustainably. What Daily Brick Production Capacity Really Means in Industrial Terms In a B2B manufacturing context, daily […]

-

What Determines Brick Machine Output Capacity and How Can Manufacturers Optimize It?

読む もっと読むYes, brick machine output capacity is not determined by a single specification or machine parameter. Instead, it is the result of multiple interrelated technical, operational, and organizational variables working together across the entire production system. For brick manufacturers, investors, and plant managers, understanding brick machine output capacity factors is essential because output directly affects unit cost, delivery capability, and return on investment. For example, two factories using the same machine model may achieve very different daily production volumes due to differences in material preparation, automation level, or curing logistics. This article breaks down the core factors that influence output capacity and explains how B2B decision-makers can optimize production performance in […]

-

Fly Ash vs Concrete Brick Machine Differences: Which Technology Delivers Better Long-Term Value for Manufacturers?

読む もっと読むFly ash vs concrete brick machine differences mainly come down to raw material behavior, production process control, equipment configuration, and long-term operating economics. Fly ash brick machines are designed to process fine, pozzolanic industrial by-products with lower cement content, while concrete brick machines focus on dense aggregate mixtures that prioritize compressive strength and dimensional stability. For construction material manufacturers, choosing between these two technologies is a strategic decision that affects capital investment, product positioning, sustainability goals, and market competitiveness. This article explains the fly ash vs concrete brick machine differences from a practical manufacturing perspective, using real production scenarios to help decision-makers choose the most suitable solution. Raw Material Characteristics […]

-

レンガ製造機の種類:建設生産戦略に最適なソリューションは?

読む もっと読むThe different Types of Brick Machines are designed to meet very different production goals, from small-scale local building projects to fully automated industrial manufacturing. Choosing the right type depends on output capacity, material availability, labor strategy, and long-term return on investment. For contractors, developers, and infrastructure suppliers, understanding these machine types is not just a technical exercise but a strategic business decision that directly affects cost control, quality consistency, and scalability. This article provides a practical, buyer-focused overview of the Types of Brick Machines, explaining how each category works, where it performs best, and how real production scenarios influence equipment selection. How Brick Machines Are Classified in Industrial Manufacturing The […]

-

What Materials Can Be Used in a Brick Machine? A Practical Guide for Industrial Buyers

読む もっと読むWhat materials can be used in a brick machine? In short, modern brick machines can process a wide range of raw materials, including cement, sand, aggregates, fly ash, slag, stone dust, recycled construction waste, and even certain industrial by-products. The exact material combination depends on the brick type, strength requirements, local regulations, and the machine’s design. For industrial buyers, understanding material compatibility is critical to controlling production cost, ensuring consistent quality, and maximizing return on investment. Core Raw Materials Used in Brick Machines The most common materials used in brick machines form the backbone of concrete and block production worldwide. These materials are widely available, cost-effective, and easy to control […]

-

What Types of Bricks Can a Brick Machine Produce? A Complete Guide for Industrial Buyers

読む もっと読むIn practice, a modern brick machine can produce a wide variety of concrete and masonry products, including solid bricks, hollow blocks, paving bricks, interlocking blocks, curbstones, and customized special-shaped units. The final product range depends on mold design, machine capacity, vibration and compaction technology, and the raw materials used. For industrial buyers, understanding these product types is essential for selecting the right equipment and planning a profitable production line. Solid Bricks for Structural and Load-Bearing Applications Solid concrete bricks are one of the most common products manufactured by brick machines. These bricks are widely used in load-bearing walls, foundations, and structural components where high compressive strength is required. Solid bricks […]

-

American Block Manufacturing vs. Chinese Machinery: A 5-Point Buyer’s Guide for 2026

読む もっと読むAbstract The global market for concrete block machinery in 2026 presents a complex decision for buyers, particularly those in rapidly developing regions like Southeast Asia and the Middle East. This analysis examines the comparative merits of machinery sourced from traditional American block manufacturing hubs versus the increasingly sophisticated and cost-competitive options from Chinese manufacturers. It undertakes a structured, five-point evaluation focusing on automation and control systems, material science and block quality compliance, total cost of ownership, supply chain logistics, and long-term scalability. The investigation reveals that while American machinery has a long-standing reputation for robustness, leading Chinese machines, such as the QT series, now integrate high-quality international components, offer comparable […]

-

Turn Waste into Profit: An Expert’s 2026 Guide to the Circular Economy in Building Materials

読む もっと読むAbstract The global construction industry, a significant contributor to resource depletion and waste generation, stands at a critical juncture in 2026. This analysis examines the transition from a linear "take-make-waste" paradigm to a circular economy in building materials, with a particular focus on its implementation within the rapidly developing regions of Southeast Asia and the Middle East. It investigates the principles of designing for disassembly, reuse, and high-value recycling, positing that such a shift is not merely an environmental imperative but a substantial economic opportunity. The document explores the practical application of circular principles through the utilization of industrial by-products and demolition waste, such as fly ash, slag, and crushed […]

-

Expert Guide to Smart Manufacturing in Brick Production: 5 Key 2026 Trends for Buyers in Southeast Asia

読む もっと読むAbstract The transition toward smart manufacturing in brick production signifies a pivotal evolution for the construction materials industry, particularly within the rapidly developing economies of Southeast Asia and the Middle East. This analysis examines the integration of Industry 4.0 technologies—such as the Internet of Things (IoT), artificial intelligence (AI), robotics, and data analytics—into the block and brick manufacturing process. It investigates how these advancements are transforming traditional factories into highly efficient, interconnected, and autonomous systems. The discourse focuses on the tangible benefits, including enhanced productivity, superior product consistency, significant cost reductions through predictive maintenance and waste minimization, and improved workplace safety. By evaluating current trends and projecting future developments for […]