業界知識

-

A 7-Step Expert Guide to Launching Your Profitable Cement Block Plant in 2025

読む もっと読むAbstract The rapid urbanization and infrastructure development across Southeast Asia and the Middle East present a significant entrepreneurial opportunity in the manufacturing of construction materials. This analysis provides a comprehensive framework for establishing a profitable cement block plant in 2025. It meticulously details a seven-step process, beginning with in-depth market research and feasibility studies tailored to regional demands. A central focus is placed on the critical decision of selecting appropriate machinery, with a comparative examination of semi-automatic versus fully automatic systems, including the prevalent QT series of concrete block making machines. The guide further explores optimal plant layout design, sourcing of raw materials, and robust financial planning, encompassing capital expenditure, […]

-

A Data-Backed Guide: 5 Factors for Selecting the Right Brick Manufacturing Machine in 2025 for SEA & ME Markets

読む もっと読むAbstract The selection of an appropriate brick manufacturing machine represents a foundational investment for enterprises aiming to capitalize on the robust construction sectors of Southeast Asia and the Middle East in 2025. This document examines the pivotal factors influencing this decision, presenting a comparative analysis between fully automatic systems, such as the QT series, and static hydraulic presses. It explores the intricate relationship between machine type and the availability of regional raw materials, including sand, aggregates, and industrial byproducts like fly ash. The analysis extends to production capacity, levels of automation, and their direct implications on labor costs and operational efficiency. Furthermore, the versatility of different machines in producing a […]

-

Expert Buyer’s Guide: 7 Crucial Factors for Selecting Brick Making Machines for Sale in 2025

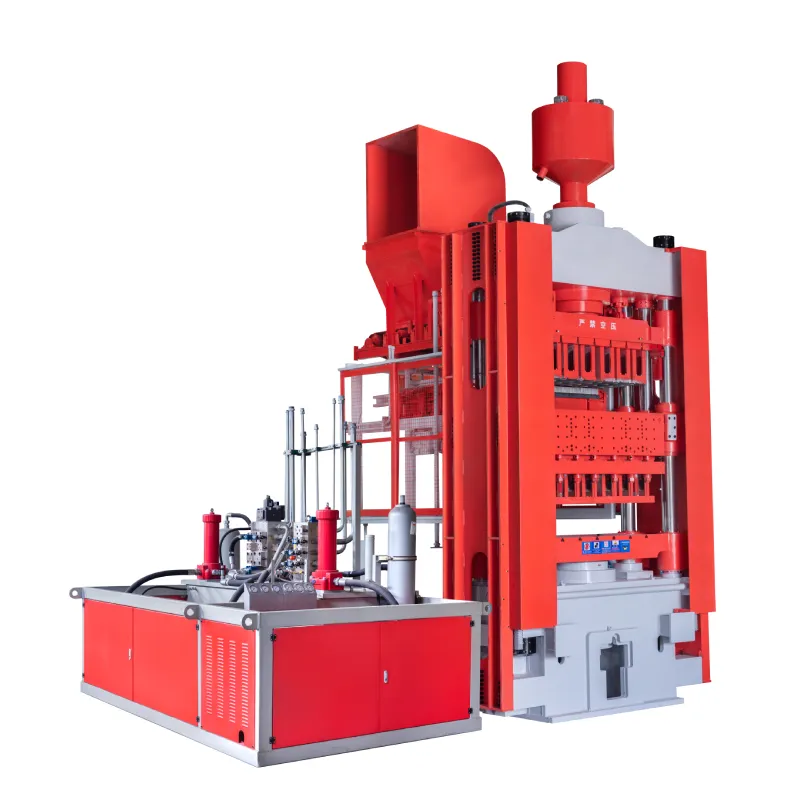

読む もっと読むAbstract The acquisition of brick making machinery represents a significant capital investment for entrepreneurs in the construction materials sector, particularly within the burgeoning markets of Southeast Asia and the Middle East. This guide examines the critical factors influencing the selection of appropriate brick making machines for sale in 2025. It provides a detailed analysis of two primary technologies: QT series fully automatic concrete block making machines, which utilize vibration and pressure, versus static hydraulic block pressing machines. The discourse extends to a comprehensive evaluation of production capacity, mold versatility, raw material compatibility, automation levels, total cost of ownership, supplier reliability, and infrastructural prerequisites. By synthesizing technical specifications from manufacturers with […]

-

An Expert’s 5-Point Checklist for Selecting Your 2025 Bricks Machine in the Middle East & SEA

読む もっと読むAbstract The selection of a bricks machine for construction projects in Southeast Asia and the Middle East represents a significant capital investment influenced by unique regional factors. This analysis examines the critical decision-making criteria for acquiring concrete block and hydraulic press machinery in 2025. It deconstructs the process into five core evaluative points: production capacity and scalability, levels of automation, local raw material compatibility, technological and build quality, and total cost of ownership, including supplier support. The study synthesizes technical specifications from contemporary models, such as the QT series, with the practical realities of operating in diverse economic and geological environments. It posits that a successful investment hinges not only […]

-

Brick Machine for Sale: An Expert’s 2025 Guide to 5 Critical Investment Factors

読む もっと読むAbstract The acquisition of a brick making machine represents a significant capital investment with far-reaching implications for a construction or manufacturing enterprise. This analysis examines the multifaceted considerations inherent in selecting an appropriate brick machine for sale, with a specific focus on the burgeoning markets of Southeast Asia and the Middle East in 2025. It delineates the fundamental technological distinctions between QT series vibration-based machines and static hydraulic presses, evaluating their respective applications in relation to production volume, product diversity, and end-product specifications. The inquiry extends to the critical role of automation levels, from semi-automatic to fully integrated production lines, and their correlation with labor costs, operational efficiency, and quality […]

-

Expert Buyer’s Guide 2025: 7 Critical Factors for Your hollow brick making machine in the Middle East & SEA

読む もっと読むAbstract The acquisition of a hollow brick making machine represents a significant capital investment for construction enterprises, particularly within the burgeoning markets of Southeast Asia and the Middle East. This decision-making process is contingent upon a nuanced evaluation of technical specifications, operational capabilities, and economic viability. An optimal selection requires a deep understanding of the machine's core components, such as the Programmable Logic Controller (PLC) and the hydraulic vibration system, which are determinative of block quality, production efficiency, and operational stability. The versatility of a machine, demonstrated by its capacity to produce various block types like pavers and curbstones through interchangeable moulds, is a primary driver of market adaptability and […]

-

Expert 2025 Guide: 7 Key Factors for Choosing a Bricks Making Machine in the Middle East & SEA

読む もっと読むAbstract The acquisition of a bricks making machine represents a significant capital investment for construction enterprises, particularly within the burgeoning markets of Southeast Asia and the Middle East. This document examines the multifaceted decision-making process involved in selecting an appropriate machine in 2025. It moves beyond a simple comparison of features to a holistic evaluation framework. The analysis focuses on seven pivotal factors: the level of automation, the specifications of the hydraulic and vibration systems, versatility in raw material usage, the diversity and durability of molds, effective production capacity, the total cost of ownership, and the quality of after-sales support. By exploring the interplay between technological capabilities, such as those […]

-

実用的な2025年バイヤーズ・ガイド:コンクリートブロック用機械を選ぶ7つの要素

読む もっと読むAbstract The selection of an appropriate machine for concrete blocks represents a pivotal capital investment for ventures in the construction materials sector, particularly within the burgeoning markets of Southeast Asia and the Middle East in 2025. This analysis examines the multifaceted decision-making process, moving beyond mere equipment pricing to a holistic evaluation of operational efficacy. It investigates the primary typologies of block-making technology, namely the fully automated QT series and static hydraulic pressing machines, contrasting their mechanisms, output capacities, and labor requirements. The study considers the profound influence of local raw material availability, such as fly ash and regional aggregates, on machine suitability and final product quality. Furthermore, it explores […]

-

Buyer’s Guide: 7 Expert Factors for Choosing a Cement Block Maker in 2025

読む もっと読むAbstract This analysis explores the multifaceted process of selecting a cement block maker in the context of 2025's construction industry, with a specific focus on the burgeoning markets of Southeast Asia and the Middle East. It posits that the decision transcends a mere capital expenditure, representing a strategic investment that shapes a business's productivity, market competitiveness, and environmental stewardship. The discourse provides a granular examination of seven pivotal factors, beginning with the foundational choice between high-frequency vibration technology, characteristic of QT series automatic machines, and the immense force of static hydraulic presses. It further investigates the imperatives of production capacity, raw material versatility, mold quality, manufacturer reliability, ancillary systems, and […]

-

Expert 2025 Guide: How Much is a Brick Making Machine? 7 Key Factors for SEA & Middle East Buyers

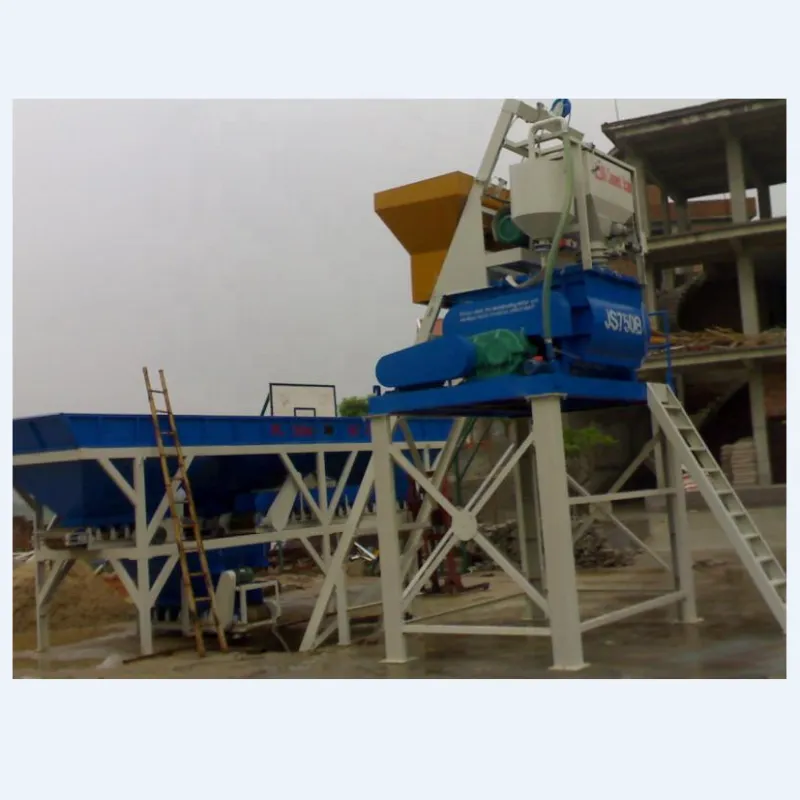

読む もっと読むAbstract An examination of the financial investment required for brick manufacturing equipment reveals a complex landscape where costs are contingent upon a multitude of interdependent variables. The initial purchase price of a brick making machine, while a primary consideration, represents only a fraction of the total expenditure. This analysis explores the integral factors that determine the overall cost, including the degree of automation—ranging from manual to fully automatic systems—production capacity, and the specific technology employed, such as hydraulic pressure versus mechanical vibration. Further consideration is given to the origin of manufacture, the quality of components utilized, the necessity of auxiliary equipment like mixers and batching plants, and the often-underestimated 'landed […]