ニュース

-

コンクリート・ブロックの製造に使用される機械とは?

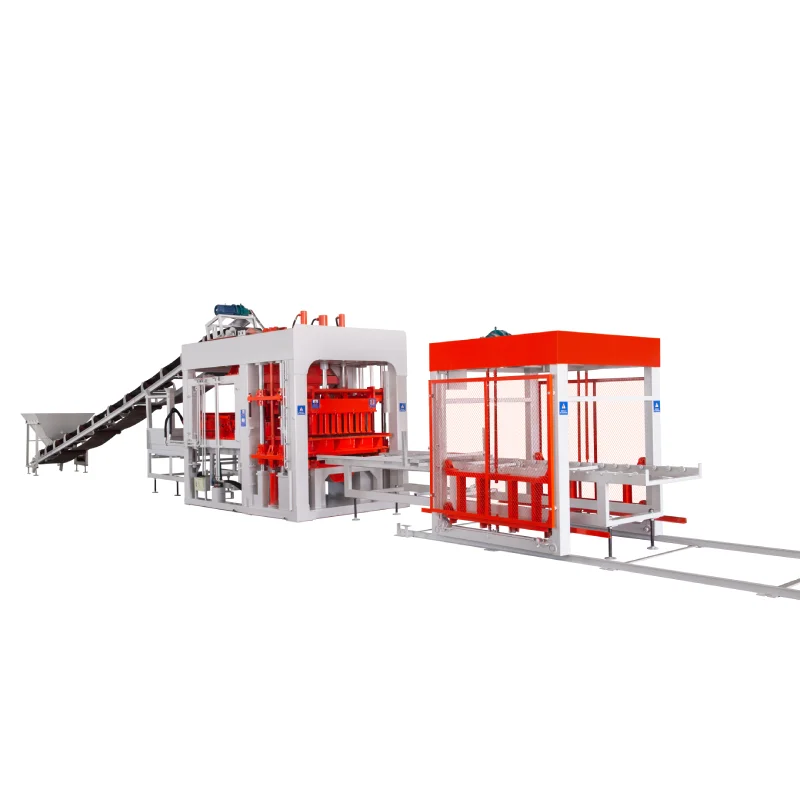

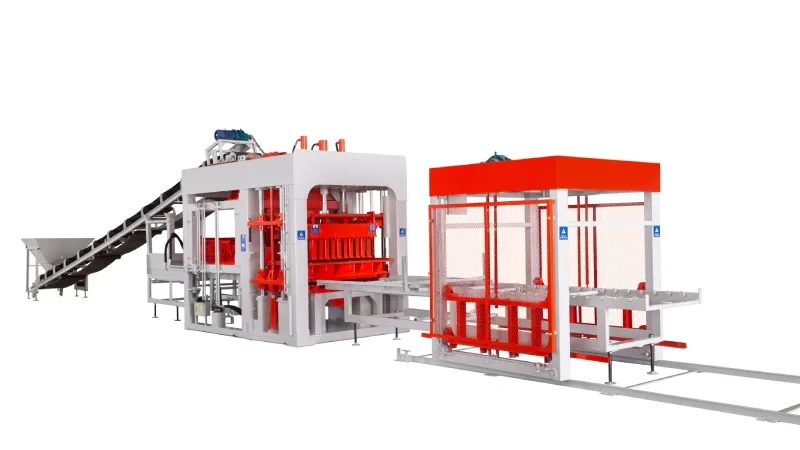

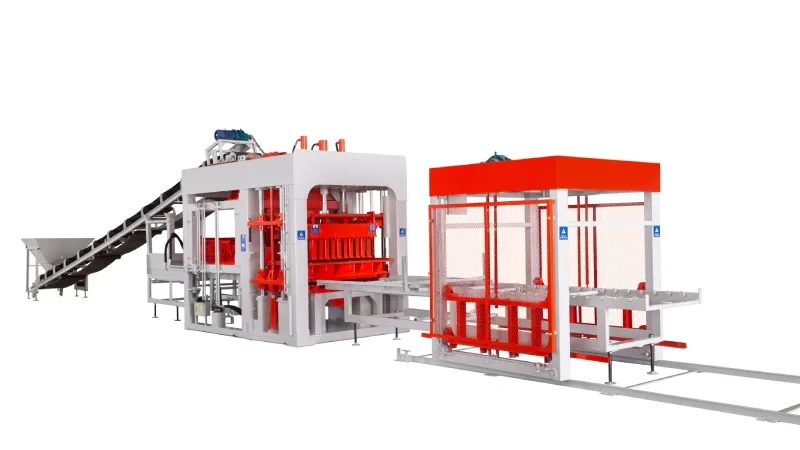

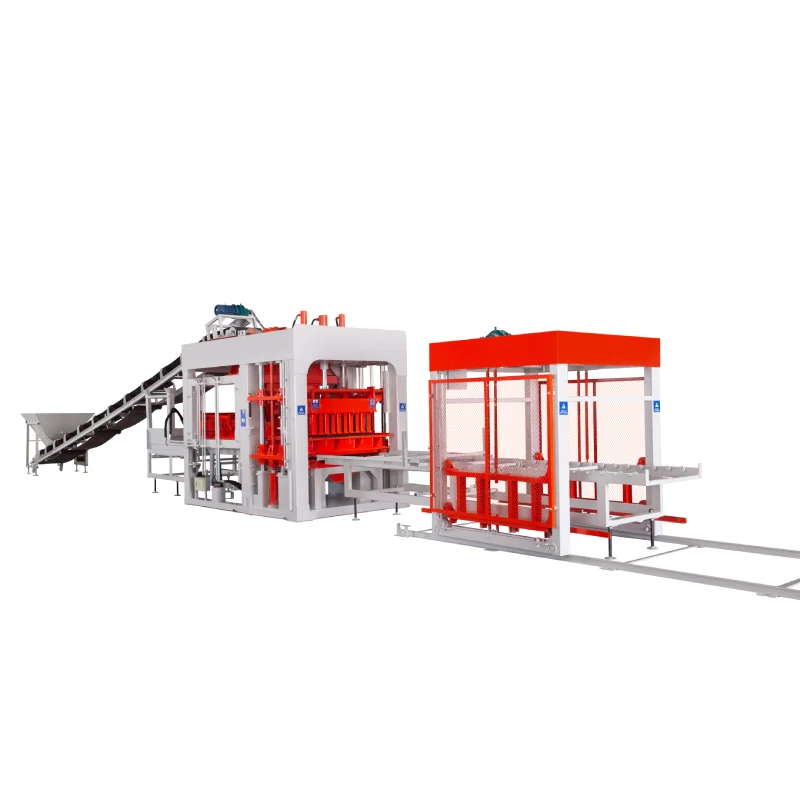

読む もっと読むConcrete blocks are indispensable in construction projects, known for their durability and cost-effectiveness. But do you know how they’re made? With a concrete block making machine, creating these vital materials is easier than ever. The Role of Concrete Block Making Machines These machines mix cement, sand, gravel, and water to form uniform blocks. They automate production, saving time and reducing labor costs while ensuring consistent quality. Benefits of Using High-Quality Concrete Blocks Using high-quality concrete blocks means investing in strength, versatility, and sustainability. Why Choose XINGXIN Machinery’s Concrete Block Making Machine? When it comes to selecting a Block Making Machine manufacturer, XINGXIN Machinery stands out. Their machines are designed to […]

-

コンクリートブロック製造機の仕組み

読む もっと読むコンクリートブロック製造機は、セメント、骨材(砂や砂利など)、および水を混合したものを型に成形することで、コンクリートブロック、レンガ、または舗装の製造を自動化します。この工程では、圧縮、振動、硬化を組み合わせて、緻密で耐久性のあるブロックを作ります。ここでは、その工程を順を追って説明する:1.材料の準備 2.機械への供給 3.圧縮と振動 4.成形 5.脱型 6.硬化 7.積み重ねと保管 機械の主なメカニズム 機械の種類とワークフローのバリエーション 効率的な理由 ブロック生産サイクルの例 主な検討事項 成形と硬化を自動化することで、これらの機械は、住宅からインフラ・プロジェクトまで、あらゆる用途の堅牢で標準化されたブロックを生産します。選択 [...]

-

コンクリートブロック製造機とは

読む もっと読むコンクリートブロック製造機とは、セメント、骨材(砂、砂利)、水を混合したものを型に圧縮して、コンクリートブロック、レンガ、舗装材などの建設資材を製造するための専用装置です。均一で高品質なブロックを効率よく製造するために、建設現場では欠かせない機械です。詳しい内訳は以下の通り:仕組み主な構成要素ブロック製造機械の種類用途利点考慮すべき点環境への影響

-

Fully Automated Concrete Mixing Machine: A New Era of Efficient Production

読む もっと読むFully automated concrete mixing machine technology is revolutionizing the construction industry, enhancing efficiency and precision in concrete production. KBL Machinery utilizes advanced robotics, sensors, and AI-driven controls to fully automate the concrete mixing process, from batching raw materials to mixing, pouring, and quality monitoring. This automation minimizes manual intervention, ensuring uniform consistency while reducing human error. By streamlining operations, a concrete mixing machine significantly increases output capacity while maintaining strict quality control over concrete strength, composition, and durability. One of the biggest advantages of fully automated concrete mixing machines is their ability to operate continuously with minimal downtime, boosting overall productivity. Equipped with real-time monitoring systems, these machines detect and […]

-

How PVC Board Enhances Durability and Versatility in Interior Design

読む もっと読むPVC board has become an essential material in modern interior design due to its exceptional durability and adaptability. Unlike traditional wood or plywood, PVC board is resistant to moisture, termites, and mold, making it an ideal choice for high-humidity environments such as kitchens and bathrooms. Its non-porous surface prevents water absorption, ensuring long-term stability and minimal maintenance. Additionally, its fire-resistant properties enhance safety, making it a reliable material for both residential and commercial interiors. Beyond durability, PVC board offers unmatched versatility in design applications. Available in various textures, colors, and finishes, it can mimic natural wood or other materials, providing aesthetic flexibility without the associated drawbacks. Designers use PVC board […]

-

完全なラインを作るマシンのブロックの未来:技術と自動化

読む もっと読む自動化とスマート製造の進歩により、ブロック製造機ライン技術の未来は急速に進化しています。最新のブロック製造機ラインソリューションは、よりインテリジェントで効率的、自動化されつつあり、優れた品質管理を確保しながら手作業を大幅に削減しています。KBLマシナリーは、AIと機械学習をブロック製造機のプロセスに統合する最前線にあり、機械が生産サイクルを最適化し、原材料の使用状況を監視し、メンテナンスの必要性を予測することを可能にしている。これらの技術革新は、効率を高めるだけでなく、製造されるブロックの品質と一貫性を向上させる。自動化はまた、環境負荷の低減においても重要な役割を果たしている。

-

持続可能な建設のための環境に優しい中空ブロック金型マシン

読む もっと読む今日の建設業界では、持続可能なソリューションに対する需要が急速に高まっており、KBLマシナリーは革新的な中空ブロック成形機で最前線に立っています。これらの機械は、生産工程における廃棄物の削減とエネルギー消費の低減により、環境への影響を最小限に抑えるように設計されています。KBLマシナリーの中空ブロック成形機は、高度な技術を活用することで、使用される原材料が責任を持って調達されることを保証しながら、高品質のブロックを製造します。このように持続可能性を重視することで、これらの機械はグリーンビルディングの実践に取り組む企業に選ばれています。KBLマシナリーの環境に優しい中空ブロック成形機の主な利点の1つは、二酸化炭素排出量を最小限に抑えてブロックを製造できることです。従来のブロック製造 [...]...

-

Why Investing In A Quality QT12-15 Brick Making Machine Pays Off

読む もっと読むInvesting in a quality QT12-15 Brick Making Machine, such as those provided by XINGXIN Machinery, offers significant long-term benefits for businesses in the construction industry. A high-quality machine ensures consistent production of strong and durable bricks, reducing the risk of product defects and wastage. With precise engineering and cutting-edge technology, XINGXIN Machinery’s QT12-15 Brick-Making Machine delivers superior performance, enabling companies to meet large-scale demand without compromising on brick quality. This consistency in output not only improves operational efficiency but also strengthens the business’s reputation for reliability in the market. In addition to enhancing productivity, the QT12-15 Brick-Making Machine from XINGXIN Machinery is designed with advanced automation and hydraulic systems, ensuring […]

-

Understanding The Technology Behind Modern Flyash Bricks Machine

読む もっと読むModern flyash bricks machines have transformed the construction industry by incorporating advanced technologies to improve efficiency, precision, and sustainability. XINGXIN Machinery leads the market by integrating cutting-edge automation and control systems into their flyash bricks machines, enabling manufacturers to produce high-quality bricks with minimal manual intervention. These machines are designed to optimize material usage, minimize waste, and ensure consistent brick size and strength. Automation allows faster production cycles, enabling businesses to meet growing demands while maintaining superior quality standards. One of the most notable advancements in fly ash bricks machines is integrating hydraulic systems. XINGXIN Machinery’s automatic fly ash bricks machines utilize hydraulic pressure to create denser and stronger bricks, […]

-

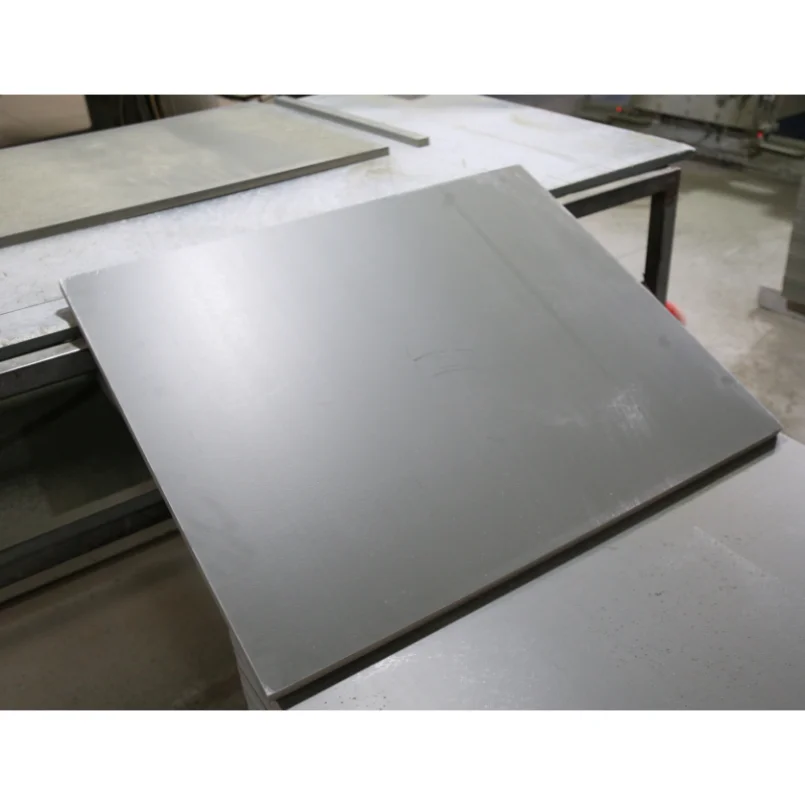

最新のコンクリート・ブリック・モールド・ローラーを支える技術を理解する

読む もっと読む最新のコンクリートレンガ型ローラーは、効率、精度、持続可能性を向上させる高度な技術を活用することで、建設業界を変革してきました。XINGXIN Machineryは、最先端の自動化および制御システムをコンクリートレンガ型ローラーに組み込み、製造業者が最小限の手作業で高品質のブロックやレンガを製造できるようにしています。これらのシステムは、材料の使用を最適化し、廃棄物を最小限に抑え、一貫したブロック寸法と強度を保証します。この自動化により、生産サイクルが加速されるだけでなく、企業は優れた品質基準を維持しながら高い需要に応えることができます。コンクリートレンガ型ローラーの重要な技術的進歩は、油圧システムの統合です。XINGXIN Machineryのソリューションは、油圧を利用してより強く高密度のブロックを製造し、その耐久性を確保 [...]...