ニュース

-

What Materials Can Be Used in a Brick Machine? A Practical Guide for Industrial Buyers

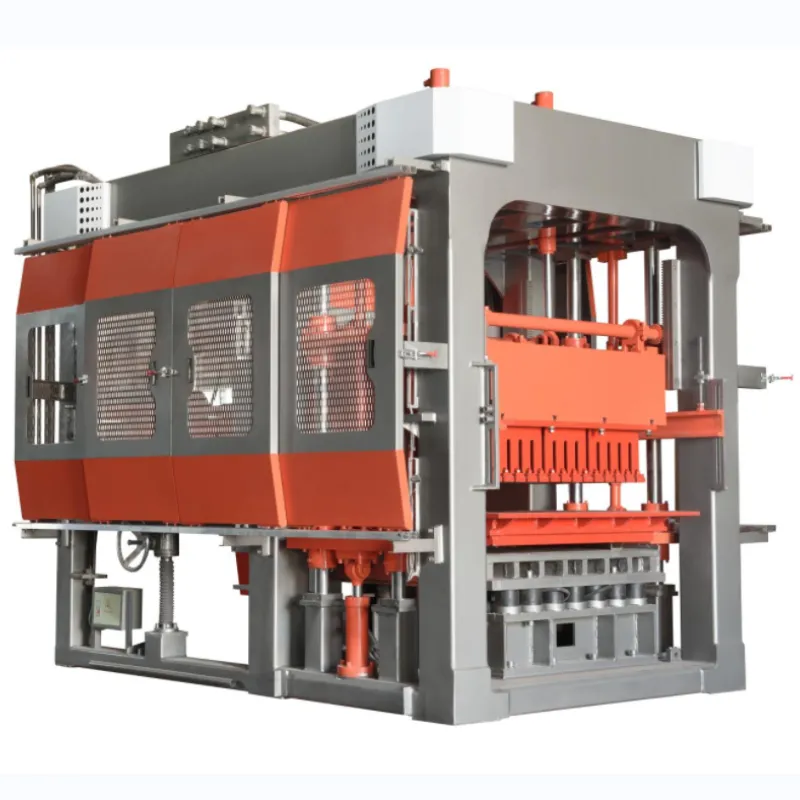

読む もっと読むWhat materials can be used in a brick machine? In short, modern brick machines can process a wide range of raw materials, including cement, sand, aggregates, fly ash, slag, stone dust, recycled construction waste, and even certain industrial by-products. The exact material combination depends on the brick type, strength requirements, local regulations, and the machine’s design. For industrial buyers, understanding material compatibility is critical to controlling production cost, ensuring consistent quality, and maximizing return on investment. Core Raw Materials Used in Brick Machines The most common materials used in brick machines form the backbone of concrete and block production worldwide. These materials are widely available, cost-effective, and easy to control […]

-

What Types of Bricks Can a Brick Machine Produce? A Complete Guide for Industrial Buyers

読む もっと読むIn practice, a modern brick machine can produce a wide variety of concrete and masonry products, including solid bricks, hollow blocks, paving bricks, interlocking blocks, curbstones, and customized special-shaped units. The final product range depends on mold design, machine capacity, vibration and compaction technology, and the raw materials used. For industrial buyers, understanding these product types is essential for selecting the right equipment and planning a profitable production line. Solid Bricks for Structural and Load-Bearing Applications Solid concrete bricks are one of the most common products manufactured by brick machines. These bricks are widely used in load-bearing walls, foundations, and structural components where high compressive strength is required. Solid bricks […]

-

American Block Manufacturing vs. Chinese Machinery: A 5-Point Buyer’s Guide for 2026

読む もっと読むAbstract The global market for concrete block machinery in 2026 presents a complex decision for buyers, particularly those in rapidly developing regions like Southeast Asia and the Middle East. This analysis examines the comparative merits of machinery sourced from traditional American block manufacturing hubs versus the increasingly sophisticated and cost-competitive options from Chinese manufacturers. It undertakes a structured, five-point evaluation focusing on automation and control systems, material science and block quality compliance, total cost of ownership, supply chain logistics, and long-term scalability. The investigation reveals that while American machinery has a long-standing reputation for robustness, leading Chinese machines, such as the QT series, now integrate high-quality international components, offer comparable […]

-

Turn Waste into Profit: An Expert’s 2026 Guide to the Circular Economy in Building Materials

読む もっと読むAbstract The global construction industry, a significant contributor to resource depletion and waste generation, stands at a critical juncture in 2026. This analysis examines the transition from a linear "take-make-waste" paradigm to a circular economy in building materials, with a particular focus on its implementation within the rapidly developing regions of Southeast Asia and the Middle East. It investigates the principles of designing for disassembly, reuse, and high-value recycling, positing that such a shift is not merely an environmental imperative but a substantial economic opportunity. The document explores the practical application of circular principles through the utilization of industrial by-products and demolition waste, such as fly ash, slag, and crushed […]

-

Expert Guide to Smart Manufacturing in Brick Production: 5 Key 2026 Trends for Buyers in Southeast Asia

読む もっと読むAbstract The transition toward smart manufacturing in brick production signifies a pivotal evolution for the construction materials industry, particularly within the rapidly developing economies of Southeast Asia and the Middle East. This analysis examines the integration of Industry 4.0 technologies—such as the Internet of Things (IoT), artificial intelligence (AI), robotics, and data analytics—into the block and brick manufacturing process. It investigates how these advancements are transforming traditional factories into highly efficient, interconnected, and autonomous systems. The discourse focuses on the tangible benefits, including enhanced productivity, superior product consistency, significant cost reductions through predictive maintenance and waste minimization, and improved workplace safety. By evaluating current trends and projecting future developments for […]

-

A 7-Step Expert Guide to Launching Your Profitable Cement Block Plant in 2025

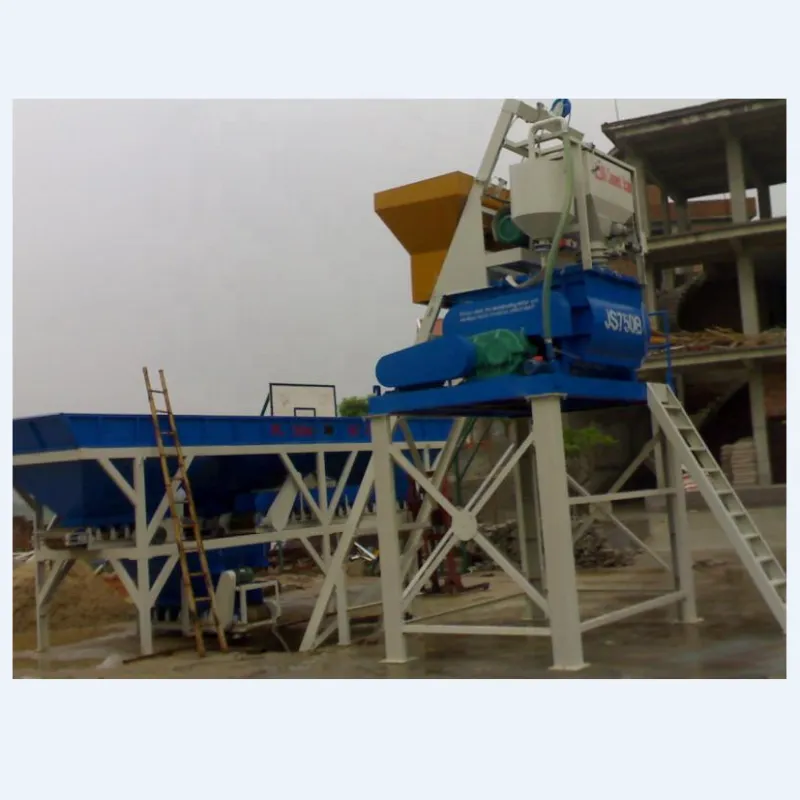

読む もっと読むAbstract The rapid urbanization and infrastructure development across Southeast Asia and the Middle East present a significant entrepreneurial opportunity in the manufacturing of construction materials. This analysis provides a comprehensive framework for establishing a profitable cement block plant in 2025. It meticulously details a seven-step process, beginning with in-depth market research and feasibility studies tailored to regional demands. A central focus is placed on the critical decision of selecting appropriate machinery, with a comparative examination of semi-automatic versus fully automatic systems, including the prevalent QT series of concrete block making machines. The guide further explores optimal plant layout design, sourcing of raw materials, and robust financial planning, encompassing capital expenditure, […]

-

A Data-Backed Guide: 5 Factors for Selecting the Right Brick Manufacturing Machine in 2025 for SEA & ME Markets

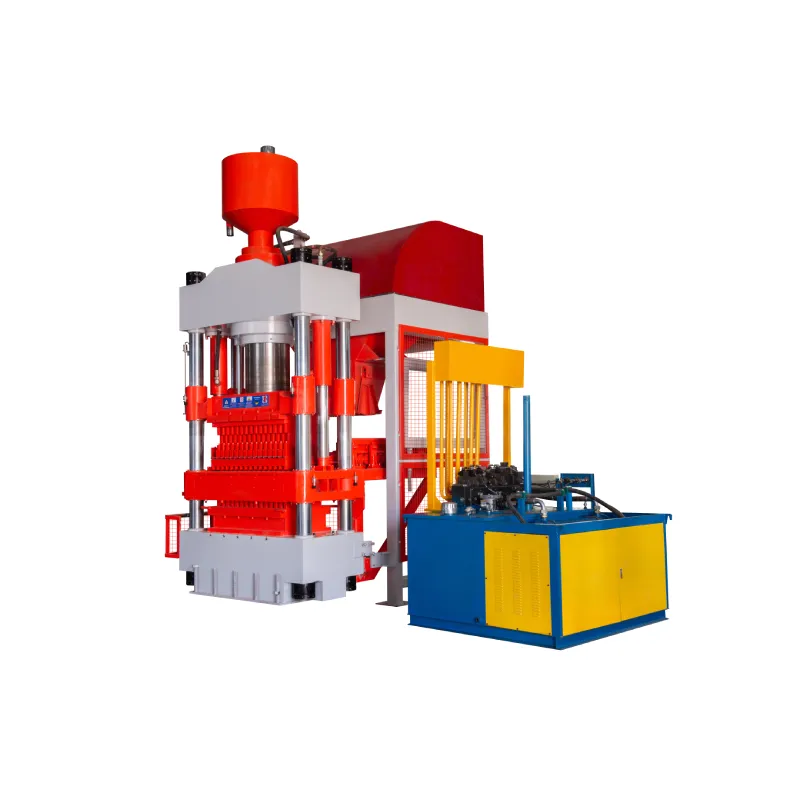

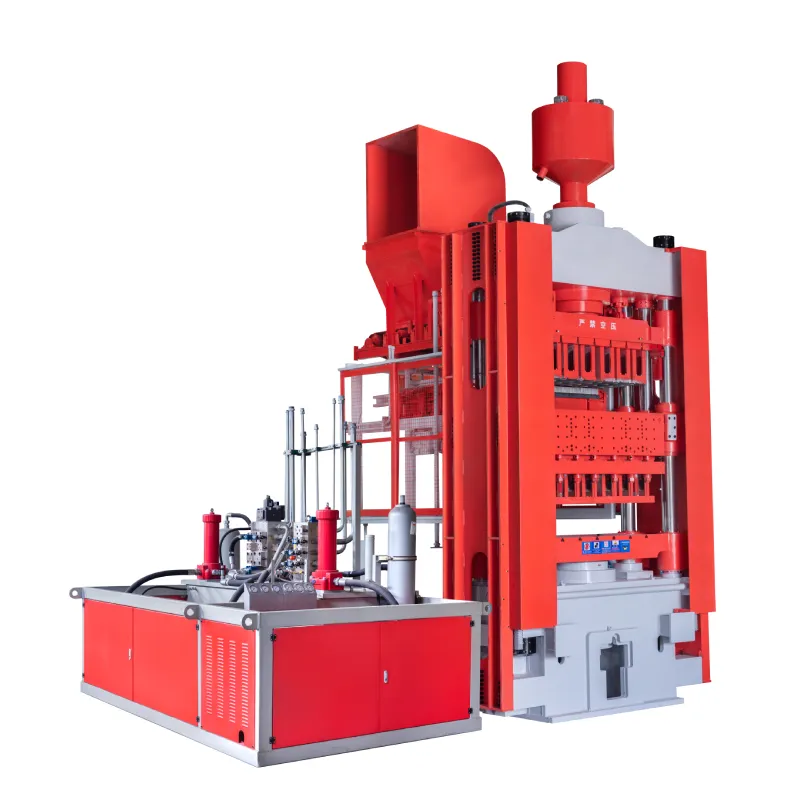

読む もっと読むAbstract The selection of an appropriate brick manufacturing machine represents a foundational investment for enterprises aiming to capitalize on the robust construction sectors of Southeast Asia and the Middle East in 2025. This document examines the pivotal factors influencing this decision, presenting a comparative analysis between fully automatic systems, such as the QT series, and static hydraulic presses. It explores the intricate relationship between machine type and the availability of regional raw materials, including sand, aggregates, and industrial byproducts like fly ash. The analysis extends to production capacity, levels of automation, and their direct implications on labor costs and operational efficiency. Furthermore, the versatility of different machines in producing a […]

-

Expert Buyer’s Guide: 7 Crucial Factors for Selecting Brick Making Machines for Sale in 2025

読む もっと読むAbstract The acquisition of brick making machinery represents a significant capital investment for entrepreneurs in the construction materials sector, particularly within the burgeoning markets of Southeast Asia and the Middle East. This guide examines the critical factors influencing the selection of appropriate brick making machines for sale in 2025. It provides a detailed analysis of two primary technologies: QT series fully automatic concrete block making machines, which utilize vibration and pressure, versus static hydraulic block pressing machines. The discourse extends to a comprehensive evaluation of production capacity, mold versatility, raw material compatibility, automation levels, total cost of ownership, supplier reliability, and infrastructural prerequisites. By synthesizing technical specifications from manufacturers with […]

-

An Expert’s 5-Point Checklist for Selecting Your 2025 Bricks Machine in the Middle East & SEA

読む もっと読むAbstract The selection of a bricks machine for construction projects in Southeast Asia and the Middle East represents a significant capital investment influenced by unique regional factors. This analysis examines the critical decision-making criteria for acquiring concrete block and hydraulic press machinery in 2025. It deconstructs the process into five core evaluative points: production capacity and scalability, levels of automation, local raw material compatibility, technological and build quality, and total cost of ownership, including supplier support. The study synthesizes technical specifications from contemporary models, such as the QT series, with the practical realities of operating in diverse economic and geological environments. It posits that a successful investment hinges not only […]

-

Brick Machine for Sale: An Expert’s 2025 Guide to 5 Critical Investment Factors

読む もっと読むAbstract The acquisition of a brick making machine represents a significant capital investment with far-reaching implications for a construction or manufacturing enterprise. This analysis examines the multifaceted considerations inherent in selecting an appropriate brick machine for sale, with a specific focus on the burgeoning markets of Southeast Asia and the Middle East in 2025. It delineates the fundamental technological distinctions between QT series vibration-based machines and static hydraulic presses, evaluating their respective applications in relation to production volume, product diversity, and end-product specifications. The inquiry extends to the critical role of automation levels, from semi-automatic to fully integrated production lines, and their correlation with labor costs, operational efficiency, and quality […]