ニュース

-

利益への7つのステップ:建設廃材からエコレンガを作るための究極の2025年ガイド

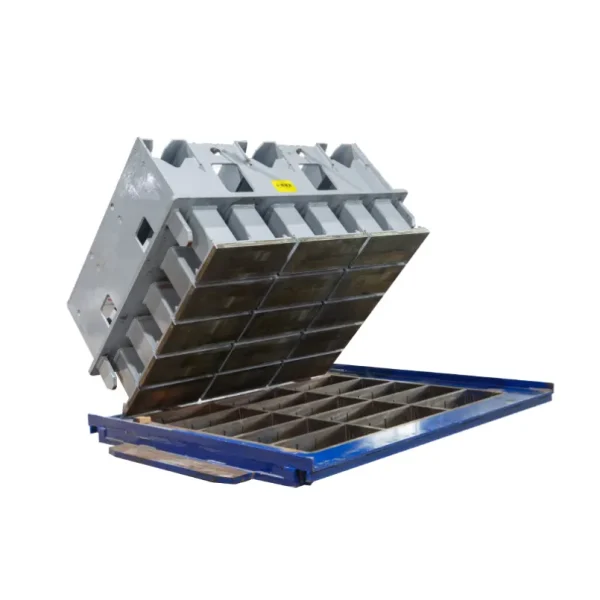

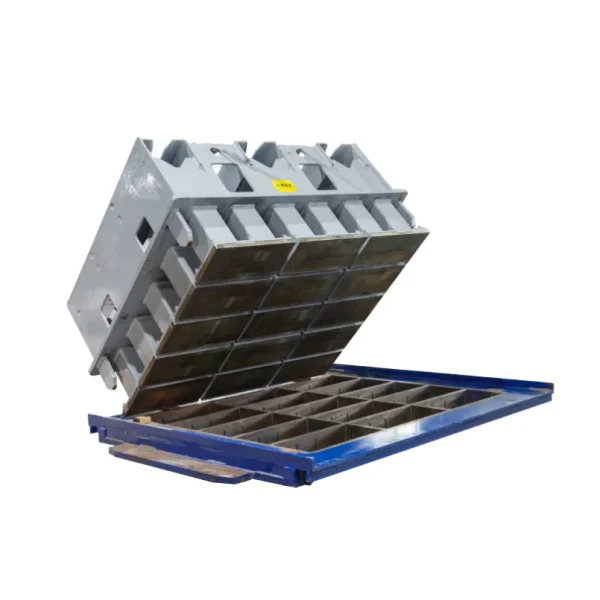

読む もっと読む要旨 特に東南アジアや中東のような急速に都市化が進む地域では、建設・解体廃棄物(C&D)の危機が深刻化しており、環境的にも経済的にも大きな課題となっている。本書では、C&D廃棄物を耐久性のある持続可能な建築材料に変える、建設廃棄物からの実行可能で収益性の高いエコレンガのソリューションについて検討する。分析では、廃棄物の特性評価と調達から始まり、処理、混合、製造の技術段階を経て、包括的な枠組みを概説している。最終製品の品質と一貫性を確保する上で、全自動コンクリートブロック製造機や静的油圧プレス機などの高度な機械が果たす極めて重要な役割に重点を置いている。[...]

-

2025年に省エネブロック生産技術をマスターする5つの究極の方法

読む もっと読む要旨 世界の建設業界、特に急速に発展している東南アジアや中東地域では、建築資材の需要増に対応すると同時に、環境と経済に対する緊急の圧力に対処するという、二重の課題に直面している。伝統的なブロック製造における高いエネルギー消費は、運用コストと生態系に大きな負担をもたらす。この分析では、戦略的解決策として、先進的な省エネルギーブロック製造技術の導入を検討する。QTシリーズの機械に見られる最新の油圧・振動システムの採用から始まり、効率向上のための5つの中核的方法論を検討する。調査は、フライアッシュのようなポゾラン代替物の使用を含む原材料配合の最適化、および革命 [...] にまで及ぶ。

-

2025年にハイテクブロック機械メーカーと提携する5つの理由

読む もっと読む要旨 世界の建設部門、特に急速に拡大する東南アジアや中東の市場では、著しい技術的変革が進行している。この進化には、従来の建材生産から、より高度で効率的かつ持続可能な方法への戦略的転換が必要である。本稿では、建設企業がハイテク・ブロック機械メーカーと提携することの説得力を検証する。このようなパートナーシップは、単なる調達の決定ではなく、オペレーションの卓越性、製品の優位性、長期的な市場競争力への基礎投資であるとする。この分析では、QTシリーズ全自動コンクリートブロック製造機や静的油圧式ブロックプレス機などの高度な設備から得られる具体的なメリットに焦点を当てている。

-

2025年に省エネブロック生産技術をマスターする5つの究極の方法

読む もっと読む要旨 世界の建設業界、特に急速に発展している東南アジアや中東地域では、建築資材の需要増に対応すると同時に、環境と経済に対する緊急の圧力に対処するという、二重の課題に直面している。伝統的なブロック製造における高いエネルギー消費は、運用コストと生態系に大きな負担をもたらす。この分析では、戦略的解決策として、先進的な省エネルギーブロック製造技術の導入を検討する。QTシリーズの機械に見られる最新の油圧・振動システムの採用から始まり、効率向上のための5つの中核的方法論を検討する。調査は、フライアッシュのようなポゾラン代替物の使用を含む原材料配合の最適化、および革命 [...] にまで及ぶ。

-

2025年にハイテクブロック機械メーカーと提携する5つの理由

読む もっと読む要旨 世界の建設部門、特に急速に拡大する東南アジアや中東の市場では、著しい技術的変革が進行している。この進化には、従来の建材生産から、より高度で効率的かつ持続可能な方法への戦略的転換が必要である。本稿では、建設企業がハイテク・ブロック機械メーカーと提携することの説得力を検証する。このようなパートナーシップは、単なる調達の決定ではなく、オペレーションの卓越性、製品の優位性、長期的な市場競争力への基礎投資であるとする。この分析では、QTシリーズ全自動コンクリートブロック製造機や静的油圧式ブロックプレス機などの高度な設備から得られる具体的なメリットに焦点を当てている。

-

利益への7つのステップ:建設廃材からエコレンガを作るための究極の2025年ガイド

読む もっと読む要旨 特に東南アジアや中東のような急速に都市化が進む地域では、建設・解体廃棄物(C&D)の危機が深刻化しており、環境的にも経済的にも大きな課題となっている。本書では、C&D廃棄物を耐久性のある持続可能な建築材料に変える、建設廃棄物からの実行可能で収益性の高いエコレンガのソリューションについて検討する。分析では、廃棄物の特性評価と調達から始まり、処理、混合、製造の技術段階を経て、包括的な枠組みを概説している。最終製品の品質と一貫性を確保する上で、全自動コンクリートブロック製造機や静的油圧プレス機などの高度な機械が果たす極めて重要な役割に重点を置いている。[...]

-

2025年に省エネブロック生産技術をマスターする5つの究極の方法

読む もっと読む要旨 世界の建設業界、特に急速に発展している東南アジアや中東地域では、建築資材の需要増に対応すると同時に、環境と経済に対する緊急の圧力に対処するという、二重の課題に直面している。伝統的なブロック製造における高いエネルギー消費は、運用コストと生態系に大きな負担をもたらす。この分析では、戦略的解決策として、先進的な省エネルギーブロック製造技術の導入を検討する。QTシリーズの機械に見られる最新の油圧・振動システムの採用から始まり、効率向上のための5つの中核的方法論を検討する。調査は、フライアッシュのようなポゾラン代替物の使用を含む原材料配合の最適化、および革命 [...] にまで及ぶ。

-

2025年にハイテクブロック機械メーカーと提携する5つの理由

読む もっと読む要旨 世界の建設部門、特に急速に拡大する東南アジアや中東の市場では、著しい技術的変革が進行している。この進化には、従来の建材生産から、より高度で効率的かつ持続可能な方法への戦略的転換が必要である。本稿では、建設企業がハイテク・ブロック機械メーカーと提携することの説得力を検証する。このようなパートナーシップは、単なる調達の決定ではなく、オペレーションの卓越性、製品の優位性、長期的な市場競争力への基礎投資であるとする。この分析では、QTシリーズ全自動コンクリートブロック製造機や静的油圧式ブロックプレス機などの高度な設備から得られる具体的なメリットに焦点を当てている。

-

利益への7つのステップ:建設廃材からエコレンガを作るための究極の2025年ガイド

読む もっと読む要旨 特に東南アジアや中東のような急速に都市化が進む地域では、建設・解体廃棄物(C&D)の危機が深刻化しており、環境的にも経済的にも大きな課題となっている。本書では、C&D廃棄物を耐久性のある持続可能な建築材料に変える、建設廃棄物からの実行可能で収益性の高いエコレンガのソリューションについて検討する。分析では、廃棄物の特性評価と調達から始まり、処理、混合、製造の技術段階を経て、包括的な枠組みを概説している。最終製品の品質と一貫性を確保する上で、全自動コンクリートブロック製造機や静的油圧プレス機などの高度な機械が果たす極めて重要な役割に重点を置いている。[...]

-

2025年に省エネブロック生産技術をマスターする5つの究極の方法

読む もっと読む要旨 世界の建設業界、特に急速に発展している東南アジアや中東地域では、建築資材の需要増に対応すると同時に、環境と経済に対する緊急の圧力に対処するという、二重の課題に直面している。伝統的なブロック製造における高いエネルギー消費は、運用コストと生態系に大きな負担をもたらす。この分析では、戦略的解決策として、先進的な省エネルギーブロック製造技術の導入を検討する。QTシリーズの機械に見られる最新の油圧・振動システムの採用から始まり、効率向上のための5つの中核的方法論を検討する。調査は、フライアッシュのようなポゾラン代替物の使用を含む原材料配合の最適化、および革命 [...] にまで及ぶ。