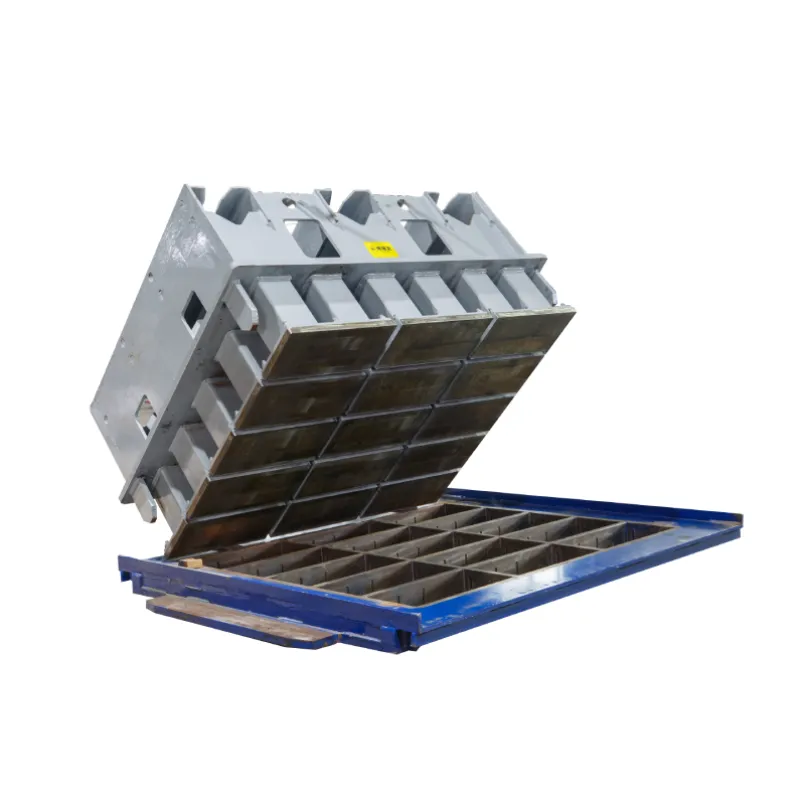

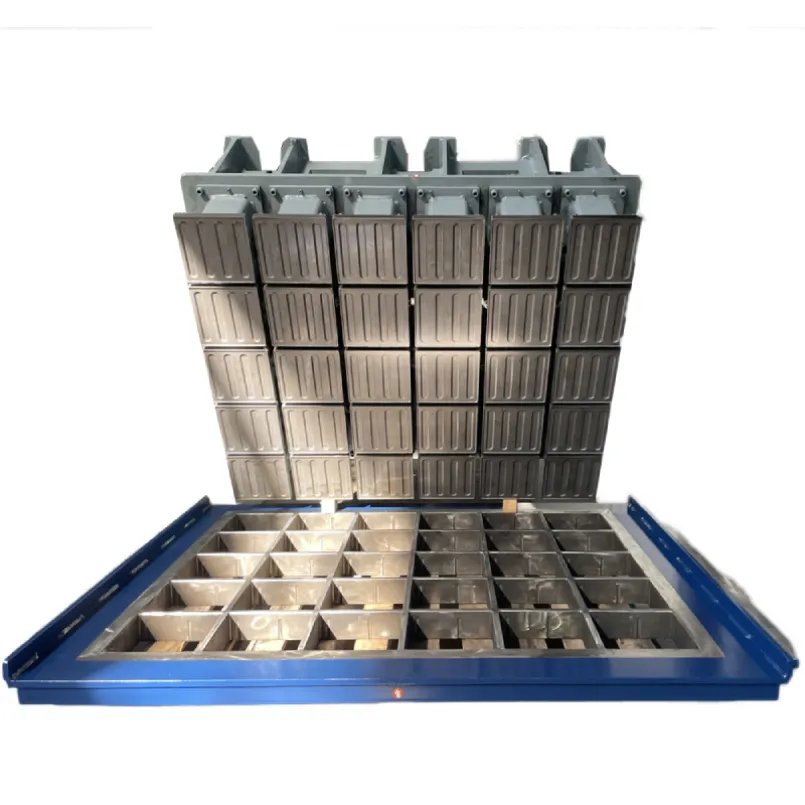

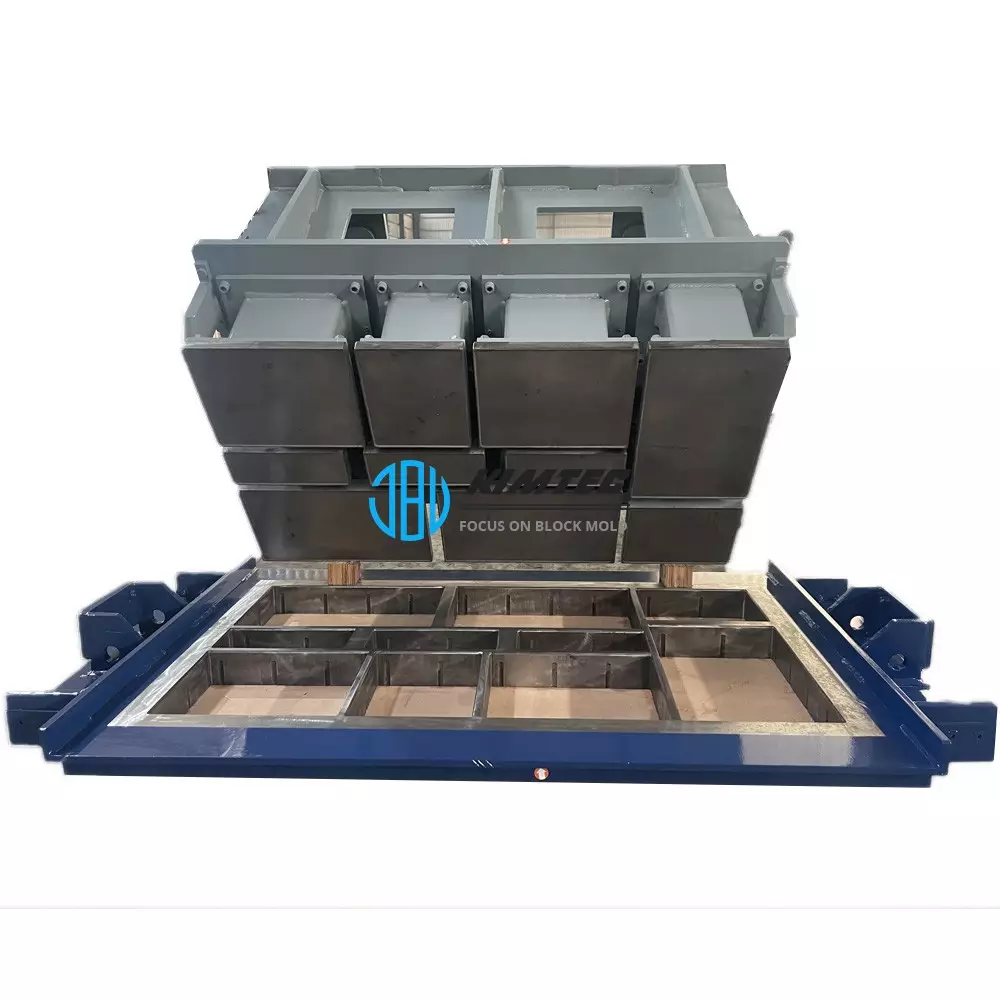

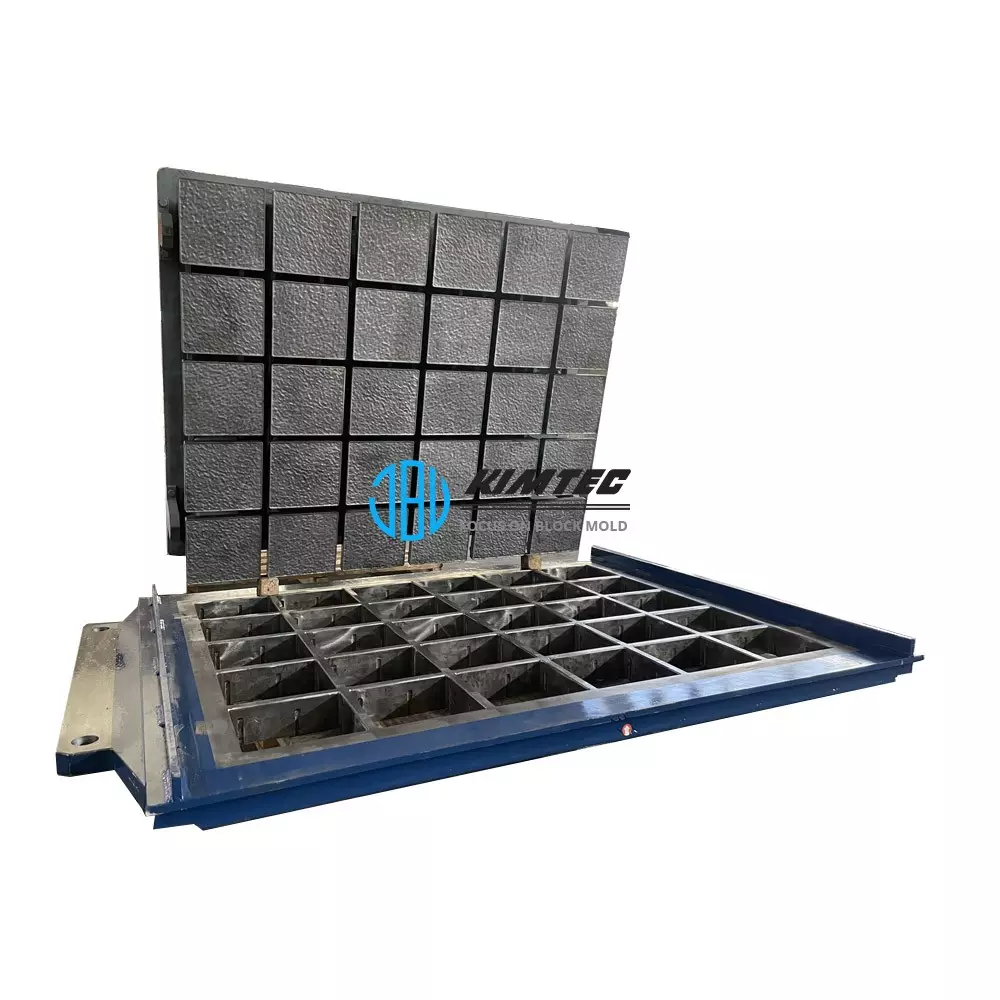

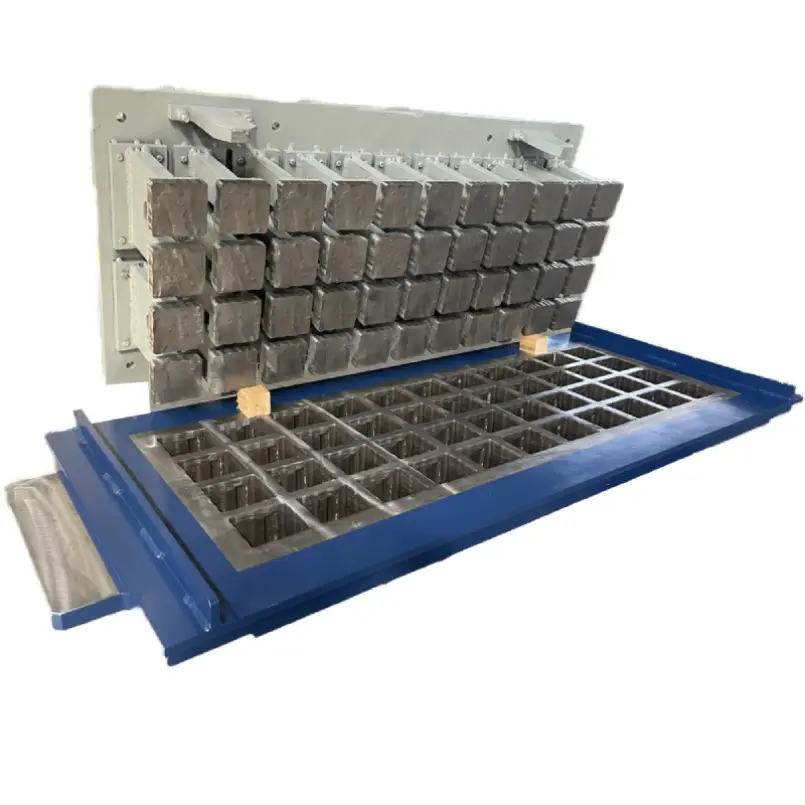

敷石金型天井ブロック金型多くの種類のブロックをカスタマイズすることができます。

敷石型、天井ブロック型-様々なブロックタイプにカスタマイズ可能

よくある質問 - キンバリー機械金型

1.見積もりはどのように入手できますか?

-

図面付き:必要なブロックの詳細図面をお送りいただければ、お客様の仕様に基づいてお見積もりをお出しします。

-

図面なし:図面なし:ブロックの種類(例:中空または中実)を明記し、寸法(長さ×幅×厚さ(mm))を記載した写真を提出する。

-

追加情報:パレットの寸法、タンパーヘッドのサイズ、金型の高さを記載し、金型と機械の接続方法を説明してください。接続図面があればありがたい。

お客様の情報を受け取り次第、できるだけ早くお見積もりを作成いたします。

2.納期はどのくらいですか?

-

標準的な型: 沈殿物を受け取った後 20-25 仕事日

-

高級金型30~40営業日

3.輸送包装はどのように扱われますか?

私達はデフォルトでプラスチックフィルムが付いている木枠を使用するか、またはバイヤーの指定に従って包装をカスタマイズしてもいい。

4.新しい金型は私のマシンに合いますか?

私たちはさまざまなブランドの金型を製造しており、詳細な記録を保持しています。

保証のために、現在の金型を測定するか、または評価のために写真を送ることができます。私達は型があなたの機械と継ぎ目無く合うことを保障します。

5.支払い条件は?

50%をT/Tで前払いして生産を開始し、残金は出荷前に清算する。

6.連絡方法は?

WeChat/WhatsAppでご連絡ください:+86-1330506196 | +86-18960287187

キンバリーマシナリーについて

1990年代に設立されたKimberly Machineryは30年近い製造経験を持ち、2008年から輸出を行っています。MASA、HESS、ZENITHなど様々なブロック機械ブランドの高品質金型を専門に、国内外市場にサービスを提供しています。

生産能力は年間約1,000セットで、ブロックの種類は中空ブロック、多孔質レンガ、ソリッドレンガ、道路タイル、河川斜面保護レンガ、角レンガ、埠頭レンガ、断熱レンガ、芝生植栽レンガ、バイヤーの要望に合わせた特注形状など多岐にわたる。

私たちは、研究開発、製造、生産、販売に焦点を当てた一貫企業です。金型材料はQ345鋼からハイエンドの輸入イタリア鋼に及ぶ。私達の型は62 HRCの硬度および優秀な耐久性に達成する高度のCNCのワイヤーカットおよび真空の浸炭プロセス経る。サイクルタイムは80,000-120,000回に達することができます。

高度な技術、優れた職人技、信頼性の高い品質、競争力のある価格で、私たちの金型は、世界中のお客様に信頼され、支持されています。