ブロック製造機

-

コンクリート・ブロック・マシンの利点

読む もっと読むスマートなビルダーが品質、スピード、節約のためにKBLマシナリーを選ぶ理由 建設スピード、構造の完全性、コスト効率がこれまで以上に重要視される時代において、コンクリートブロック製造マシンは世界中のビルダーにとって必需品となっています。小規模な製造現場を運営している場合でも、大規模なプロジェクトを手がけている場合でも、ブロック製造マシンに投資することで、労働集約的な作業から完全自動化へ、そして一貫性のない作業から工業的な精密さへと、オペレーションを変えることができます。では、コンクリートブロック製造機を使用する本当のメリットは何でしょうか?生産能力と収益をどのように向上させることができるかを探ってみましょう。より高い生産量、より速い施工 スピードこそが建設活動の本質です。最新のコンクリートブロック製造装置 [...]...

-

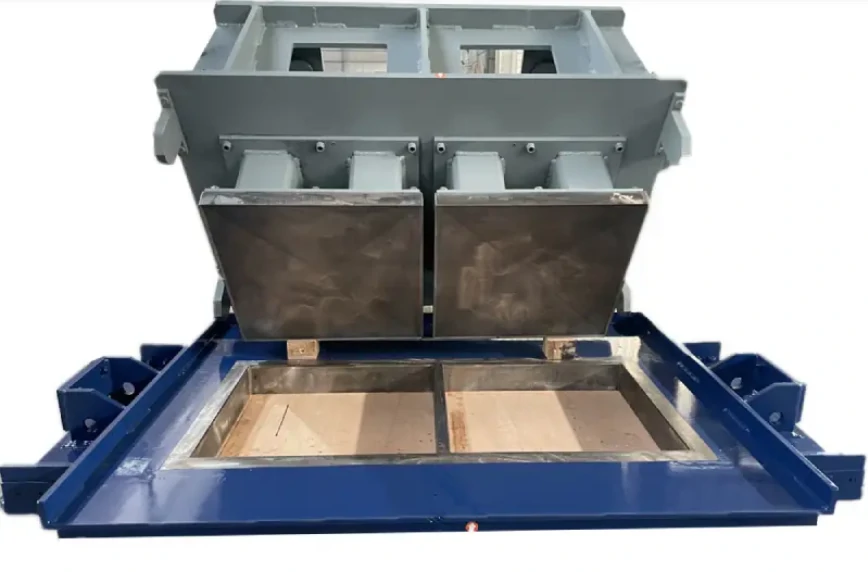

コンクリートブロック製造機とは

読む もっと読むKBL機械で現代建設における自動化の力を引き出す 現代の建設はコンクリート・ブロック製造の初期段階に大きく依存しており、ここで重要な要素は非常に効果的で精密なコンクリート・ブロック製造機械である。さらに、都市が発展し、住宅が一定の水準で建設されるようになったため、これは必然となっている。建設業界の投資家は、さまざまな機器の選択肢を検討しているが、コンクリートブロック製造機の需要は高い。この分野では、ブロックの品質を高め、それに対応してバリューチェーン全体を改善するために、高性能ブロック機械の調達を検討している。より詳しく [...] を見る

-

レンガ製造機の一般的な修理方法は?

読む もっと読むブロック製造機が故障したらどうすればいい?ご心配なく、どんな故障にも理由と症状があります。レンガ製造機の修理方法を見てみましょう!機械システムの故障 1.伝動部品の異常 故障現象:ベルトの滑り、破損、歯車の噛み合い異常音、チェーンの緩みや詰まり。メンテナンス方法:ベルトの張りをチェックし、プーリーの位置を調整するか、老朽化したベルトを交換する;ギアに注油し、摩耗がひどい場合はギアを交換する;チェーンテンショナーを調整し、切れたチェーンを交換し、定期的に注油する。2.2.ベアリングの損傷または潤滑不良 故障現象:ベアリング部の発熱、異音、装置運転中の揺れ。メンテナンス方法機械を停止し、ベアリングのグリースが不足していないか確認し、グリースを追加する。