レンガ製造機

-

How to Choose the Right Hollow Block Mould for Your Production Line

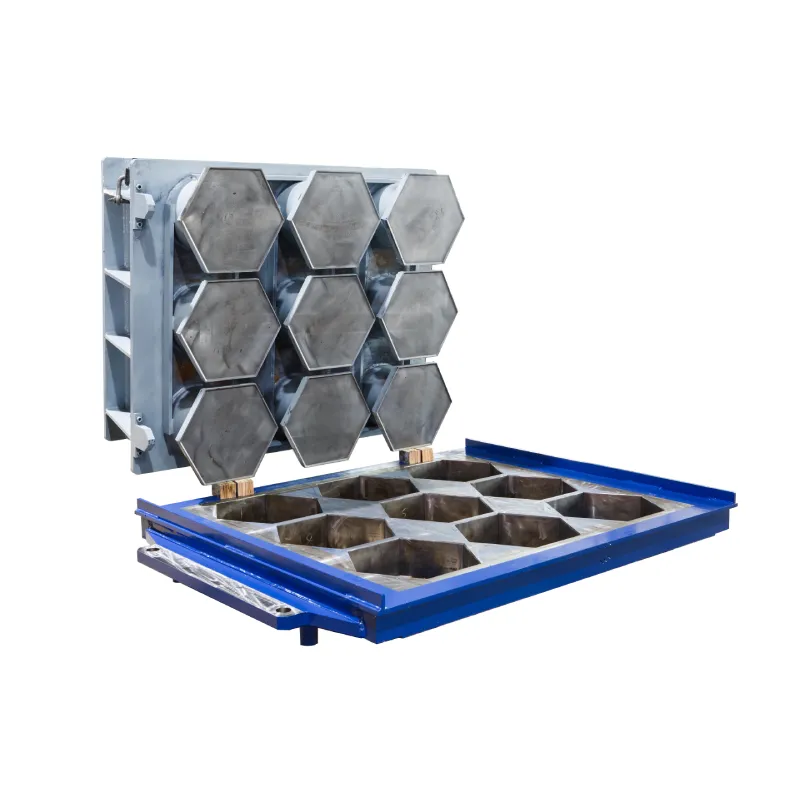

読む もっと読むSelecting the right hollow block mould is crucial for ensuring the efficiency and quality of your concrete block production line. With so many options available, understanding the types, materials, and features of hollow block moulds will help you make an informed decision. Important factors to consider include hollow block mould design, material selection, price, and choosing the right supplier to meet your specific requirements. Types of Hollow Block Moulds There are several types of hollow block moulds, each designed for specific production scales and project needs: Choosing the right type of mould depends on your production scale, budget, and specific project requirements. The Importance of Hollow Block Mould Design The hollow block mould design has a direct impact […]

-

プレキャストコンクリートブロック型の使用後の清掃方法

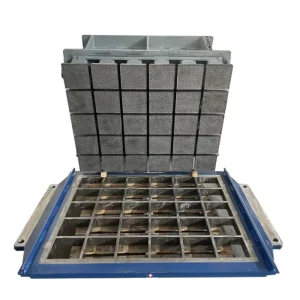

読む もっと読むPrecast concrete block moulds play a crucial role in concrete block production, and maintaining their quality is essential for smooth and efficient manufacturing. At KBL Machinery, we specialize in precast concrete block moulds made from high-quality materials such as Q355 steel and premium Italian steel, ensuring both durability and reliability. These materials help our moulds withstand repeated use while maintaining the shape and quality of the blocks they create.. Proper cleaning of these moulds is vital to prevent concrete build-up and preserve the moulds’ structural integrity. Over time, hardened concrete left in the moulds can become difficult to remove and may lead to defects in the final product. Regular cleaning not only ensures […]

-

How to Operate the QT4-15 Block Making Machine

読む もっと読むA block making machine is a vital piece of equipment used in the construction industry to produce concrete blocks. These blocks are essential for building walls, pavements, and various other structures. By automating the production process, block making machines enhance efficiency, reduce labor costs, and improve the consistency of the final products. Among all available models, the QT4-15 Block Making Machine stands out due to its fully automated system, high production capacity, and versatility in producing various block types. What is a Block Making Machine? A block making machine is designed to combine raw materials such as cement, sand, and water, which are then mixed and molded into concrete blocks […]

-

インターロッキングブロック型はどのように施工効率を向上させるのか?

読む もっと読むInterlocking block molds are a key tool in modern construction, offering many advantages that can enhance overall project efficiency. These molds are designed to create blocks that interlock seamlessly, improving both the speed and strength of construction projects. Whether you’re working on a small-scale residential build or a large commercial project, using interlocking bricks mould can dramatically increase productivity and reduce costs. Faster Production and Reduced Labor Costs One of the primary benefits of interlocking block molds is the speed at which they can produce blocks. This reduces labor costs and allows companies to scale their operations quickly. The increased speed and reduced labor requirements directly translate into cost savings […]