究極の2025年版ブロック製造機器ガイド:成功のための7つのポイント

8月 21, 2025

要旨

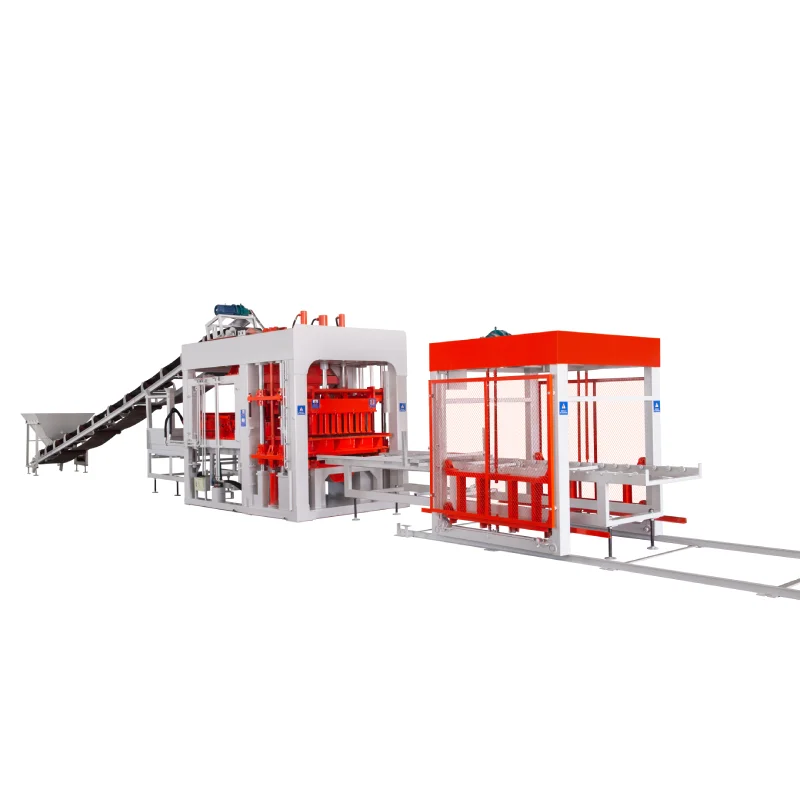

This comprehensive guide examines the multifaceted considerations involved in the acquisition of block making equipment, with a specific focus on the needs of construction enterprises in Southeast Asia and the Middle East. It provides a deep analytical framework for evaluating different machine types, including the QT series of fully automatic concrete block making machines and static hydraulic block pressing machines. The analysis extends beyond mere technical specifications to encompass the broader economic and operational ecosystem, including raw material sourcing, production scalability, total cost of ownership, and the critical importance of supplier reliability. By exploring seven fundamental factors, this discourse aims to equip professionals with the necessary knowledge to make an informed investment decision that aligns with long-term strategic goals. It posits that the selection of such foundational machinery is not merely a capital expenditure but a strategic choice that profoundly shapes a company’s production capabilities, market responsiveness, and ultimate profitability in the dynamic construction landscapes of 2025 and beyond.

要点

- Align machine type with your specific production volume and product diversity needs.

- Evaluate raw material availability in your region to ensure cost-effective operation.

- Choose the right block making equipment by considering both initial cost and long-term value.

- Supplier reliability and after-sales support are as vital as the machine’s mechanics.

- Understand how mold quality and variety directly impact your market opportunities.

- Calculate the total cost of ownership, including energy, labor, and maintenance.

- Future-proof your investment by considering automation and scalability from the start.

目次

- Understanding the Core Technology: What is Block Making Equipment?

- Factor 1: Aligning Machine Type with Production Needs (The Great Debate: Automatic vs. Hydraulic)

- Factor 2: Raw Material Compatibility and Sourcing Strategy

- Factor 3: Production Capacity, Scalability, and Project Scope

- Factor 4: Evaluating Build Quality, Durability, and Maintenance

- Factor 5: The Crucial Role of Molds in Product Diversification

- Factor 6: Navigating the Supplier Landscape: Choosing a Reliable Partner

- Factor 7: Calculating Total Cost of Ownership (TCO) Beyond the Sticker Price

- Operational Excellence: Best Practices for Your Block Making Plant

- The Future of Block Production: Innovations and Trends

- よくある質問(FAQ)

- A Final Consideration on Foundational Investments

- 参考文献

Understanding the Core Technology: What is Block Making Equipment?

To embark on an inquiry into the world of construction and infrastructure is to engage with the very foundations of human society. The structures we build—our homes, our public squares, our commercial centers—are not merely functional objects; they are the physical embodiment of our collective aspirations and the framework within which our lives unfold. At the heart of this constructive endeavor lies a humble yet profoundly significant component: the concrete block. And at the heart of the block’s creation, we find the machine. To ask “What is a block making machine?” is to ask a question that extends far beyond a simple mechanical definition. It is to probe into the engine of modern development, a tool that translates raw materials into the building blocks of civilization.

At its most elemental level, a block making machine is a piece of industrial equipment designed to manufacture concrete blocks in a consistent, efficient, and repeatable manner. The fundamental principle involves the compaction of a carefully proportioned mixture of cement, aggregate (such as sand, gravel, or crushed stone), water, and often other additives. This compaction is achieved through a combination of intense pressure and vibration, a process that expels air pockets and ensures the final product possesses the requisite density, strength, and durability. The machine is, in essence, an instrument of transformation, taking a semi-dry, granular mixture and, through the application of precise force, molding it into a solid, stable form. It is a testament to the power of controlled mechanics to create order and resilience from particulate matter.

However, to leave the definition there would be to overlook the rich tapestry of its variations and the nuanced logic that guides its design. The world of block making equipment is not monolithic. It is populated by a diverse family of machines, each with its own character, its own strengths, and its own ideal application. We encounter stationary machines, which form the heart of a dedicated production facility, and mobile units, which offer the flexibility of on-site production. We see distinctions in the degree of automation, from manual machines requiring significant human intervention to sophisticated, fully automatic block making machines that orchestrate the entire production cycle with minimal oversight. The method of force application also provides a key point of differentiation, with some machines relying on mechanical pressure and others employing the formidable and precise power of hydraulic systems.

Consider, for a moment, the philosophical weight of this technology. In regions undergoing rapid development, such as many parts of Southeast Asia and the Middle East, the availability of high-quality, affordable building materials is not a matter of mere convenience; it is a catalyst for social and economic progress. The ability to produce blocks locally, using indigenous raw materials, reduces reliance on expensive imports, creates local employment, and empowers communities to build their own futures. Therefore, the block making machine is more than a piece of capital equipment; it is a tool of empowerment, a mechanism for fostering self-sufficiency and resilience. The choice of a particular machine is thus laden with consequence, influencing not only the efficiency of a single construction project but also the broader economic trajectory of a region. It is a decision that demands a deep, empathetic understanding of the specific context—the available resources, the labor market, the scale of ambition—in which it will operate. This guide, then, is an invitation to engage in that deeper inquiry, to move beyond a superficial understanding and to appreciate the profound role this equipment plays in shaping our built environment.

Factor 1: Aligning Machine Type with Production Needs (The Great Debate: Automatic vs. Hydraulic)

The decision of which block making equipment to acquire is perhaps the most foundational choice a construction enterprise can make. It is not a simple matter of selecting the most powerful or the most advanced model available. Rather, it is an exercise in practical reason, requiring a deep and honest assessment of one’s own operational needs, market demands, and long-term strategic goals. The central tension in this decision often lies between different operational philosophies, most notably embodied in the distinction between fully automatic systems and static hydraulic presses. To navigate this choice with wisdom is to understand that each type of machine represents a different answer to the fundamental questions of production: how much, how fast, and with what degree of human involvement?

The Allure of Automation: Understanding Fully Automatic Concrete Block Making Machines

The fully automatic concrete block making machine, particularly models within the popular QT series, represents a paradigm of modern industrial efficiency. Its core appeal lies in the promise of integration and continuity. In such a system, the entire production process—from the precise dosing and mixing of raw materials to the conveying of the mixture, the molding of the blocks, and their subsequent transfer to the curing area—is orchestrated by a Programmable Logic Controller (PLC). Human intervention is minimized, relegated primarily to supervision, quality control, and maintenance. This high degree of automation brings with it a cascade of compelling advantages.

First and foremost is the matter of production volume and consistency. An automatic machine operates with a relentless, metronomic rhythm that a manually operated system can never hope to match. The cycle times are short and predictable, leading to a significantly higher output of blocks per shift. This makes it an ideal choice for large-scale commercial producers who serve a broad market or supply major construction projects where demand is high and deadlines are tight. Consistency is the twin sibling of volume. Because every parameter—mixing time, water content, vibration frequency, compaction pressure—is controlled by the PLC, the variation between individual blocks is virtually eliminated. Each block is a near-perfect replica of the last, ensuring uniform strength, size, and appearance. This level of quality control is not merely an aesthetic concern; it is crucial for structural integrity and for meeting the stringent standards often required in commercial and public works projects.

Furthermore, the reduction in labor requirements has profound economic implications. While the initial capital outlay for a fully automatic machine is substantial, the long-term operational savings can be significant. In regions where skilled labor is expensive or scarce, an automated system can drastically reduce payroll costs and the challenges associated with managing a large workforce. It also mitigates the risk of human error, which can lead to material wastage and product defects. The operational environment is often safer, as workers are removed from the most physically demanding and potentially hazardous aspects of the production process. The machine does the heavy lifting, the repetitive tasks, the precise measurements, leaving the human operator to function as a strategist and a guardian of quality.

The Power of Precision: Exploring Static Hydraulic Block Pressing Machines

In contrast to the continuous flow of an automatic system, the static hydraulic block pressing machine offers a different set of virtues, centered on power, precision, and versatility. As the name implies, these machines utilize hydraulic cylinders to exert immense, uniform pressure on the mold. This is often a “single” or “double” press system, where the focus is on the sheer force applied during the compaction phase. While they can also be automated to a high degree, their defining characteristic is the quality of the pressure they deliver.

What does this immense pressure achieve? It results in blocks of exceptionally high density and compressive strength. The hydraulic force is capable of compacting the concrete mixture more thoroughly than many vibration-based systems alone, squeezing out residual air and water to create a product that is less porous and more robust. This makes static hydraulic presses particularly well-suited for producing specialized, high-specification products. Think of heavy-duty paving stones designed to withstand constant vehicular traffic, dense curb stones that must resist weathering and impact, or solid, high-strength blocks required for critical load-bearing walls. The quality of the finish is often superior, with sharp, well-defined edges and a smooth surface texture.

The “static” nature of the press also lends itself to versatility. These machines are often designed to accommodate a wide range of mold sizes and shapes with relative ease. This flexibility allows a producer to pivot their product line in response to changing market demands. One week they might be producing interlocking pavers for a landscaping project; the next, they could be manufacturing custom-sized blocks for a unique architectural design. While their overall output in terms of blocks per hour might be lower than a top-of-the-line fully automatic machine, their strength lies in producing high-value, specialized items. This makes them an excellent choice for businesses that aim to carve out a niche in the premium segment of the market, where quality and customization command a higher price.

A Comparative Analysis for Informed Decision-Making

To choose between these two powerful options is to reconcile one’s ambitions with one’s resources. It requires a clear-eyed assessment of the intended market. Are you aiming to become a volume player, supplying a vast quantity of standard-sized hollow or solid blocks to a mass market? If so, the relentless efficiency and lower labor costs of a fully automatic machine like those in the QT series present a compelling case. Or is your vision to be a boutique producer of high-end, specialized concrete products, where superior strength and finish are your key differentiators? In that case, the focused power of a static hydraulic press might be the more prudent investment. The table below offers a structured comparison to aid in this critical deliberation.

| 特徴 | Fully Automatic Machine (e.g., QT Series) | 静油圧プレス機 |

|---|---|---|

| 主要メカニズム | Integrated system using vibration and moderate pressure, controlled by PLC. | Focused system using immense hydraulic pressure, often with supplementary vibration. |

| Production Volume | Very High. Designed for continuous, high-speed production of standard blocks. | Moderate to High. Cycle times may be longer, focusing on quality over sheer quantity. |

| 労働条件 | Low (typically 2-4 operators for supervision and palletizing). | Low to Moderate, depending on the level of automation in feeding and off-bearing. |

| Product Strength | Good to Excellent. Meets and exceeds standard requirements for construction. | Excellent to Superior. Ideal for high-density, high-compressive-strength products. |

| 製品の多様性 | High. Can produce a wide range of blocks, pavers, and curbstones by changing molds. | Very High. Excels at producing specialized, custom, and high-value items. |

| 初期投資 | High. Represents a significant capital outlay for the complete production line. | Moderate to High. Can be less than a full automatic line, but high-end models are costly. |

| Ideal Application | Large-scale commercial production, government housing projects, mass-market supply. | Premium pavers, architectural blocks, heavy-duty industrial elements, niche markets. |

Ultimately, the choice is not about which machine is “better” in an abstract sense, but which machine is “right” for your specific context. It is a reflection of your business philosophy. Do you pursue the path of scale and efficiency, or the path of specialized craftsmanship and premium value? The answer will determine the very heart of your production facility and set the course for your venture’s future.

Factor 2: Raw Material Compatibility and Sourcing Strategy

A block making machine, for all its mechanical sophistication, is fundamentally an instrument of transformation. It does not create substance from nothing; it gives form and strength to the materials it is fed. Therefore, a truly wise investment in such equipment cannot be made in a vacuum. It must be deeply rooted in a thorough understanding of the raw materials that will constitute its daily diet. The compatibility of the machine with locally available resources and the development of a resilient sourcing strategy are not secondary considerations; they are co-equal in importance to the specifications of the machine itself. This is particularly true in the diverse geological and economic landscapes of Southeast Asia and the Middle East, where the availability and cost of aggregates can vary dramatically from one region to another.

The Fundamental Ingredients: A Universal Recipe with Local Flavors

The basic recipe for a concrete block is deceptively simple: a binder (typically Portland cement), aggregates (fine and coarse), and water. However, the character and quality of the final product are profoundly influenced by the specific nature of these ingredients. The cement provides the chemical reaction that binds everything together, but the aggregates—which can constitute up to 75-80% of the block’s volume—are its very heart and soul. They determine its weight, its thermal properties, its texture, and a significant portion of its strength.

This is where a localized perspective becomes indispensable. While a manufacturer in one region might have easy access to abundant, high-quality river sand and crushed granite, another might be situated in an area rich in volcanic pumice, limestone, or industrial byproducts like fly ash or slag. A prudent investor must begin not by looking at machine catalogues, but by looking at the ground beneath their feet. What resources are locally abundant, and therefore, cost-effective? Can the business be built upon a foundation of readily available sand and gravel, or is there an opportunity to innovate by utilizing alternative materials?

For instance, in many parts of the Middle East, desert sand presents both a challenge and an opportunity. Its fine, rounded grains may not be ideal for high-strength concrete without blending with coarser, more angular aggregates. A sourcing strategy here might involve identifying a reliable quarry for crushed rock to create an optimal mix. Conversely, in parts of Southeast Asia, particularly in volcanic regions like Indonesia or the Philippines, lightweight aggregates like expanded clay or crushed volcanic rock are available. Using these materials can produce lightweight blocks with excellent insulating properties, a highly desirable feature in hot climates. The chosen block making equipment must be versatile enough to handle these different materials. The size of the hopper, the power of the mixer, and the design of the feeding system should be evaluated for their ability to process the specific aggregates you intend to use.

The Rise of Sustainable and Alternative Materials

The conversation around raw materials in 2025 is increasingly shaped by the imperatives of sustainability and the circular economy. The traditional reliance on virgin aggregates and cement has significant environmental costs, from the energy intensity of cement production to the ecological impact of quarrying. This has spurred a global movement towards incorporating recycled and waste materials into concrete production, a trend that offers both ecological benefits and significant economic advantages.

One of the most prominent alternative materials is fly ash, a byproduct of coal-fired power plants. When used to replace a portion of the Portland cement, fly ash not only diverts waste from landfills but also enhances the long-term properties of the concrete, improving its workability and increasing its resistance to chemical attack. Similarly, ground granulated blast-furnace slag (GGBS), a byproduct of steel manufacturing, can be used as a cementitious material, contributing to strength and durability. In agricultural regions, there is growing research into using processed organic waste, such as rice husk ash, as a pozzolanic material. The use of crushed recycled concrete as an aggregate is another cornerstone of the circular economy, turning construction demolition waste into a valuable resource.

An enterprise considering an investment in block making equipment must ask a critical question: is this machine capable of working with these alternative materials? Some materials, like fly ash, are very fine and may require specialized silos and more precise dosing systems. Others, like recycled aggregates, can be more variable in shape and size, which might challenge a machine’s feeding and compaction mechanisms. Investing in a machine with the flexibility to incorporate these sustainable materials is not just an environmental choice; it is a shrewd business strategy. It can lower raw material costs, create a “green” marketing advantage, and future-proof the operation against potential regulations on virgin material use or carbon emissions. Understanding the technical specifications of a state-of-the-art concrete block making machine is crucial to ensuring it can handle these innovative mixes.

Developing a Resilient Sourcing Strategy

Once you have identified the optimal raw material mix for your products and your region, the task shifts to securing a stable and cost-effective supply. A sourcing strategy is not a one-time task but an ongoing process of risk management and relationship building. It involves several key elements:

- Supplier Redundancy: Relying on a single supplier for a critical material like sand, gravel, or cement creates a significant vulnerability. What if their quarry is shut down for regulatory reasons? What if their equipment breaks down? What if they decide to raise their prices exorbitantly? A resilient strategy involves identifying and vetting at least two or three reliable suppliers for each key ingredient. This creates competition that helps control prices and ensures continuity of supply in case of a disruption with your primary source.

- Quality Control at the Source: The quality of your blocks can be no better than the quality of your raw materials. It is essential to establish clear quality specifications with your suppliers. This includes parameters like particle size distribution (gradation), cleanliness (absence of silt, clay, or organic matter), and, in the case of cement, freshness and conformity to standards. Regular testing of incoming materials should be a non-negotiable part of your operational procedure. A simple sieve analysis for aggregates, for example, can prevent major production problems down the line.

- Logistics and Storage: The cost of transporting raw materials from the source to your production site can be a major component of your operational budget. The sourcing strategy must therefore include a careful analysis of logistics. Is the supplier located nearby? Are the roads accessible to heavy trucks? You must also plan for adequate on-site storage to buffer against potential supply interruptions. This means designated, covered storage areas for cement and fly ash to protect them from moisture, and clean, well-drained stockpiles for aggregates to prevent contamination.

In essence, the selection of block making equipment and the development of a raw material strategy are two sides of the same coin. A machine is only as good as the materials it processes, and a brilliant material mix is useless without a machine capable of handling it. The truly successful enterprise is one that achieves a harmonious synergy between the two, creating a production ecosystem that is efficient, resilient, and perfectly adapted to its local environment.

Factor 3: Production Capacity, Scalability, and Project Scope

The question of capacity is one of the most immediate and tangible considerations in the selection of block making equipment. It is a quantitative measure that speaks directly to the potential revenue and market reach of the enterprise. However, viewing capacity merely as a number—blocks per hour or blocks per day—is a reductive approach that can lead to significant strategic errors. A more nuanced and insightful perspective understands capacity as a dynamic relationship between the machine’s potential, the company’s current needs, and its future aspirations. It is about matching the scale of the investment to the scale of the ambition, not just for today, but for the years to come. This requires a careful deliberation on three interconnected concepts: baseline production requirements, the logic of scalability, and the specific demands of your target projects.

Defining Your Baseline: Production for Today’s Market

Before one can even begin to contemplate future growth, there must be a rigorous and realistic assessment of the current market opportunity. This is the foundational step of defining your baseline production requirement. It is an exercise in market research and self-reflection. Who are your initial customers? Are you planning to supply a few local builders with a steady but modest stream of standard hollow blocks? Or are you targeting a large-scale government housing project that requires a massive volume of blocks delivered on a strict schedule? The answer to this question will dictate the minimum viable capacity for your operation.

Let’s consider two contrasting scenarios. An entrepreneur in a rural area of Southeast Asia might identify a consistent local demand for about 2,000 to 3,000 standard blocks per day. This demand is driven by individual home construction and small commercial buildings. For this context, investing in a massive, fully automatic line capable of producing 15,000 blocks per shift would be a catastrophic misallocation of capital. The machine would sit idle for much of the time, the high initial investment would be impossible to recoup, and the operational costs would be disproportionate to the revenue. A smaller, semi-automatic, or a more modest stationary machine would be a far more rational choice, perfectly aligning capacity with demand.

Now, imagine a well-capitalized company in a rapidly growing metropolitan area in the Middle East, like Riyadh or Dubai. They have secured a contract to supply a major real estate developer building a series of residential towers. The demand here is not 3,000 blocks a day, but potentially 20,000 or more. In this scenario, a smaller machine would be wholly inadequate. It would be unable to meet the project’s timeline, leading to contractual penalties and reputational damage. Here, a high-capacity, fully automatic block making machine is not a luxury; it is a necessity. The key is to avoid the twin pitfalls of over-equipping and under-equipping. The former wastes capital, while the latter forfeits opportunity. A careful analysis of your immediate, verifiable market is the only reliable guide.

The Logic of Scalability: Planning for Tomorrow’s Growth

While it is crucial to ground your decision in present realities, it is equally important to plan with an eye toward the future. A business is a living entity; it is meant to grow. The concept of scalability refers to the ability of your production system to grow in capacity without a disruptive and excessively costly overhaul. Choosing a piece of block making equipment with scalability in mind is one of the shrewdest moves a long-term thinker can make.

What does scalability look like in practice? It can take several forms. One approach is to invest in a machine that has a higher theoretical capacity than your immediate baseline needs. For example, if your current market demands 5,000 blocks per day, you might choose a machine capable of producing 8,000 blocks in a single shift. Initially, you might run the machine for only five or six hours a day. As your customer base expands, you can simply extend the operating hours to a full eight-hour shift, and later, add a second shift, effectively doubling your output without any new capital investment in the primary machine. This provides a clear and cost-effective path for growth.

Another approach to scalability involves a modular design. Some production lines are designed so that ancillary equipment can be added over time. You might start with a core block machine and manual palletizing. As revenue grows, you can invest in an automatic cuber or stacker, which increases efficiency and reduces labor costs. Later, you could add a more sophisticated batching plant or cement silo to automate the front end of the process. This modular approach allows you to scale your investment in lockstep with your revenue growth, minimizing initial financial risk while preserving a pathway to a fully automated, high-capacity line. When discussing potential equipment with a supplier, the question should not just be “What can it do now?” but also “How can it grow with me?” A forward-thinking manufacturer will be able to articulate a clear, phased upgrade path for their equipment.

Matching Capacity to Project Scope: A Tale of Two Projects

The required capacity is also intimately tied to the nature of the projects you intend to supply. The demands of supplying a large, single project are very different from the demands of serving a diverse base of smaller customers. To illustrate this, let’s return to our two hypothetical projects.

The large residential tower project in the Middle East demands high volume and unwavering consistency. The builder needs tens of thousands of identical blocks delivered on a predictable schedule. A delay of even a few days can have cascading effects on the entire construction timeline, involving dozens of other subcontractors. For this scope, a high-capacity, automated system is the only logical choice. Its ability to produce a large volume of highly uniform blocks day in and day out is perfectly matched to the project’s needs.

Now consider a different kind of project: the restoration of a historic district or the construction of a high-end, architecturally unique boutique hotel. Here, the total volume of blocks required may be much smaller. However, the project might demand a wide variety of special products: custom-sized blocks, uniquely colored pavers, or blocks with a specific architectural finish. The key requirement is not sheer volume, but precision and versatility. A static hydraulic press, with its ability to produce high-strength, high-finish specialty items and its flexibility in changing molds, would be far better suited to this scope, even if its per-hour output of a single type of block is lower than an automatic line. The value here is generated not by volume, but by customization and quality.

The table below summarizes this relationship between project scope and ideal machine capacity.

| Project Type | Key Demands | Implied Capacity Requirement | Recommended Machine Type |

|---|---|---|---|

| Mass Housing / Government Projects | High Volume, High Speed, Consistency, Low Cost per Unit | Very High (e.g., 10,000-25,000+ blocks/shift) | Large Fully Automatic Production Line |

| Commercial Real Estate (Malls, Offices) | High Volume, Strict Quality Standards, Punctual Delivery | High (e.g., 8,000-15,000 blocks/shift) | Medium to Large Automatic Machine |

| General Contractor Supply (Mixed Small Projects) | Moderate Volume, Product Variety (blocks, pavers), Flexibility | Moderate (e.g., 4,000-8,000 blocks/shift) | Medium Semi-Automatic or Automatic Machine |

| Specialty Architectural / Landscaping Projects | Low Volume, High Quality Finish, Custom Shapes/Colors, High Strength | Low to Moderate (Focus on value, not volume) | Static Hydraulic Press / High-Quality Versatile Machine |

| Small-Scale Local/Rural Production | Low Volume, Simplicity of Operation, Low Initial Cost | Low (e.g., 1,000-4,000 blocks/shift) | Small Stationary or Mobile Machine |

In conclusion, the deliberation over capacity must transcend a simple numerical calculation. It is a strategic dialogue between the present and the future, between the demands of the market and the capabilities of the machine. By realistically assessing your baseline, thoughtfully planning for scalability, and clearly defining your target project scope, you can select a piece of block making equipment that is not just a tool for today, but a powerful engine for sustainable growth.

Factor 4: Evaluating Build Quality, Durability, and Maintenance

When one invests in a substantial piece of industrial machinery like a block making machine, one is not merely purchasing a collection of functions; one is entering into a long-term relationship with a physical object. This object will be subjected to immense and relentless forces: constant vibration, high pressure, and the abrasive action of sand and cement. Its ability to withstand these stresses over years, even decades, of service is what separates a wise investment from a costly mistake. Therefore, the evaluation of the machine’s physical constitution—its build quality, its durability, and the ease with which it can be maintained—is a matter of paramount importance. It requires a shift in perspective from that of a mere buyer to that of a discerning engineer, looking beyond the glossy paint to the very bones of the machine.

The Anatomy of a Robust Machine: Steel, Welds, and Components

The durability of a block making machine begins with the quality of its primary material: steel. The frame of the machine is its skeleton, providing the structural integrity required to absorb the intense forces of compaction and vibration without deforming. A prospective buyer must inquire, with specificity, about the type and thickness of the steel used. Is it standard structural steel, or a high-strength, manganese-alloy steel (like Q345 or its equivalent) known for its superior toughness and resistance to fatigue? A heavier, more robust frame is not a sign of outdated design; it is often a deliberate choice by the manufacturer to enhance longevity. A machine built with thicker steel plates will naturally be better equipped to dampen vibration, reducing wear and tear on all its components and leading to a longer operational life.

The quality of the welding is the next critical point of inspection. The welds are the ligaments that hold the steel skeleton together. Poorly executed welds, characterized by porosity, undercutting, or a lack of penetration, are points of weakness that can fail catastrophically under stress. A reputable manufacturer will employ certified welders and utilize advanced techniques like robotic welding for key structural joints to ensure consistency and strength. When examining a machine, or even photographs of it, one should look for clean, uniform weld beads. This attention to detail in the fabrication process is a powerful indicator of the manufacturer’s overall commitment to quality.

Beyond the frame, one must turn a critical eye to the key operational components. These are the moving parts that bear the brunt of the daily workload. Consider the hydraulic system in a static press or the vibration motors in an automatic machine. Are these components sourced from internationally recognized brands known for their reliability (e.g., Siemens for electronics, Bosch Rexroth or Parker for hydraulics)? While a machine built with premium components may have a higher initial price, the investment often pays for itself through reduced downtime and lower replacement costs. The same scrutiny should be applied to bearings, sensors, chains, and gears. A manufacturer who is proud of their component sourcing will be transparent about the brands they use. A reluctance to provide this information should be seen as a significant red flag.

The Logic of Maintenance: Designing for Serviceability

Even the most robustly built machine will require regular maintenance to perform at its peak. Durability is not just about resisting wear; it is also about being easy to repair and service when wear inevitably occurs. A machine that is designed with maintenance in mind is a machine that respects the operator’s time and the owner’s bottom line. This concept, known as serviceability, is a hallmark of intelligent engineering design.

What are the signs of good serviceability? One key feature is accessibility. Can a technician easily reach critical maintenance points like lubrication nipples, filters, and adjustment bolts? Or are they buried deep within the machine, requiring hours of disassembly just to perform a simple task? Look for logically placed access panels, centralized lubrication points (or even automatic lubrication systems), and components that can be replaced without having to dismantle the entire machine. For example, are the vibration motors mounted externally for easy access, or are they integrated into the vibration table in a way that makes replacement a major undertaking?

Another aspect of serviceability is the use of standardized, non-proprietary parts where possible. While some core components will inevitably be specific to the manufacturer, a good designer will use standard-sized bearings, seals, hydraulic fittings, and electrical components that can be sourced locally in most major markets. This is a critical consideration for buyers in Southeast Asia and the Middle East, as it means you are not held captive to the original manufacturer for every single spare part. The ability to source a common bearing or a hydraulic hose from a local supplier can turn a potentially week-long shutdown into a repair that takes only a few hours. When speaking with a supplier, ask for a critical spare parts list and investigate the availability of those parts in your local market.

The Supplier’s Role: After-Sales Support and Technical Guidance

The relationship with the manufacturer does not end when the machine is delivered and paid for. In fact, for a complex piece of equipment, this is just the beginning of a long-term partnership. The quality and responsiveness of the supplier’s after-sales support are an integral part of the machine’s overall value proposition. A machine, no matter how well-built, is only as good as the support structure that stands behind it.

Before committing to a purchase, one must probe deeply into the nature of this support. What does the warranty cover, and for how long? More importantly, what is the process for making a warranty claim? Will the supplier send technicians to your site for installation and commissioning? This is a crucial service, as improper installation is a common cause of premature failure. Do they provide comprehensive training for your operators and maintenance staff? A well-trained team is your first line of defense against downtime.

The availability of technical support and spare parts is perhaps the most critical long-term consideration. If a critical sensor fails or a PLC program becomes corrupted, how quickly can you get help? Does the supplier offer remote diagnostic support via the internet? Can they have a technician on a plane to your site within 48 or 72 hours if necessary? How large is their spare parts inventory, and how quickly can they ship a part to your country? A supplier with a dedicated international service team and a well-stocked parts warehouse offers a level of security that cannot be overstated. It is worth paying a premium for a machine from a supplier with a proven track record of excellent global support. Investigating the history and reputation of a firm, for instance by learning more about a professional block machine supplier with deep roots in the industry, can provide a great deal of confidence in their ability to provide this long-term support.

In sum, the physical integrity of the block making equipment is a direct reflection of the manufacturer’s philosophy. A commitment to high-quality materials, meticulous fabrication, and thoughtful design for serviceability is the hallmark of a machine built to last. By adopting the mindset of an engineer and thoroughly investigating the machine’s construction and the support system behind it, you can make an investment that will serve as a reliable and productive cornerstone of your business for many years to come.

Factor 5: The Crucial Role of Molds in Product Diversification

A block making machine, in its essence, is a vessel of potential. Its frame, its motor, and its hydraulic systems provide the force and the rhythm, but it is the mold that gives this potential its final, marketable form. The mold is the interface between the machine’s power and the product’s identity. To overlook the significance of the mold is to see only the engine and ignore the steering wheel. A sophisticated understanding of block production recognizes that the strategic acquisition and management of molds is the very key to product diversification, market adaptation, and ultimately, enhanced profitability. The machine creates the block, but the mold creates the opportunity.

More Than Just a Box: The Engineering of a High-Quality Mold

At first glance, a block mold may appear to be a simple steel box with cavities. This perception is profoundly misleading. A high-quality mold is a precision-engineered tool, designed to withstand extraordinary abuse while maintaining exacting dimensional tolerances. The quality of the mold has a direct and immediate impact on the quality of the final product and the efficiency of the entire operation.

The material and treatment of the mold are of primary importance. Molds are typically fabricated from high-strength, wear-resistant steel. However, the most critical areas—the surfaces that come into direct contact with the abrasive concrete mix—undergo specialized treatment to enhance their hardness and lifespan. A common and highly effective process is carburizing and quenching, also known as case hardening. This heat treatment process involves infusing the surface layer of the steel with carbon and then rapidly cooling it, creating an outer “case” that is extremely hard and wear-resistant, while the inner core of the steel remains tough and ductile, able to absorb shock without fracturing. A mold with a properly carburized surface, often reaching a hardness of over 60 HRC (Rockwell Hardness Scale), will last significantly longer, produce more blocks before needing replacement, and maintain sharp, clean edges on the product for a greater period.

The precision of the manufacturing process is equally vital. The clearance, or the gap between the tamper head (the part that presses down) and the mold box walls, is a critical parameter. If the clearance is too large, a “fin” or “burr” of cement paste will be squeezed out around the top edge of the block, creating a messy, unprofessional appearance and wasting material. If the clearance is too small, the tamper head can bind in the mold box as it moves, leading to excessive wear, jamming, and potential damage to both the mold and the machine. A top-tier manufacturer will use CNC (Computer Numerical Control) machining and wire-cutting techniques to ensure that these clearances are precise and consistent, typically within a fraction of a millimeter. This precision is what separates a professional-grade mold from a cheap imitation.

The Mold as a Gateway to New Markets

The true strategic value of the mold lies in its power to diversify your product portfolio. A block making business that produces only one type of standard hollow block is vulnerable. It competes on price alone in a commoditized market. A business that can offer a wide range of products, however, can serve multiple market segments and command higher prices for specialized items. Every new mold is, in effect, a key that unlocks a new market.

Consider the possibilities. With the right set of molds, a single block making machine can become a comprehensive production hub for a variety of construction and landscaping needs:

- Standard Blocks: The foundation of the business, including various sizes of hollow blocks for partition walls and solid blocks for load-bearing structures.

- 敷石(ペイバー): This is a vast and lucrative market. Molds for interlocking pavers in various shapes (I-shape, S-shape, rectangular, hexagonal) and thicknesses can supply projects for driveways, pedestrian walkways, public plazas, and industrial yards. Colored pavers, made by using a secondary “face mix” system on the machine, open up even more decorative possibilities.

- Curbstones (Kerbs): Essential for road construction, parking lots, and landscaping, curbstone molds allow you to supply a critical component for civil infrastructure projects.

- Specialty Architectural Blocks: This category includes decorative screen blocks (breeze blocks), split-face blocks that mimic natural stone, and other textured blocks used to create visually interesting facades. These are high-value products that appeal to architects and designers.

- Grid Pavers and Grass Pavers: These open-celled pavers are used for environmentally friendly parking areas and access roads, allowing grass to grow through them and rainwater to permeate the ground. They are increasingly popular in sustainable construction projects.

The ability to quickly and easily change molds is therefore a critical feature of the block making equipment itself. A well-designed machine will have a system for rapid mold changes, often using hydraulic clamps and quick-release connections. A mold change that takes several hours is a significant source of downtime and lost production. A system that allows a trained crew to swap molds in under 30 minutes dramatically increases the operational flexibility of the plant, allowing you to produce small batches of different products to meet specific customer orders without sacrificing overall efficiency.

Managing Your Mold Inventory: A Strategic Asset

A successful block producer thinks of their molds not as consumables, but as a strategic inventory of assets. This requires a proactive approach to their management, maintenance, and acquisition.

- Regular Inspection and Maintenance: Molds should be cleaned thoroughly at the end of every shift to prevent the buildup of hardened concrete, which can affect block dimensions and surface finish. They should be regularly inspected for signs of wear, particularly on the corners and top edges. Minor repairs and maintenance, such as touching up welds or ensuring all bolts are tight, can significantly extend a mold’s life.

- Systematic Rotation: If you have multiple molds for the same product, they should be rotated in and out of service systematically. This ensures even wear across your entire inventory and prevents a situation where all your high-volume molds wear out at the same time.

- Strategic Acquisition: Don’t wait for a customer to ask for a product you can’t make. Proactively research market trends in your region. Are architects starting to specify a new style of decorative block? Is there a large road-building project planned nearby that will require huge quantities of curbstones? Acquiring the necessary molds before the demand peaks positions you as a market leader rather than a follower.

In conclusion, the mold is the creative heart of the block making operation. By investing in high-quality, precision-engineered molds and viewing them as the key to product diversification, a business can elevate itself from a simple manufacturer to a versatile solution provider. The ability to offer a rich and varied catalogue of products, from the most basic hollow block to the most sophisticated architectural paver, is what builds a resilient, adaptable, and highly profitable enterprise in the competitive construction market.

Factor 6: Navigating the Supplier Landscape: Choosing a Reliable Partner

The act of purchasing block making equipment is far more than a simple transaction; it is the initiation of a long-term, high-stakes partnership. The supplier you choose is not just a vendor of machinery. They become your collaborator in production, your first point of contact in a crisis, and a critical resource for the knowledge needed to operate and maintain your investment effectively. In the globalized marketplace of 2025, where options may seem limitless and claims of quality are ubiquitous, the task of discerning a truly reliable partner from a mere seller of hardware is perhaps the most challenging, and most crucial, factor of all. This decision requires a form of due diligence that extends beyond technical specifications and price lists into the very character and capabilities of the supplying company.

Beyond the Brochure: Vetting a Supplier’s Credentials

The journey to finding a trustworthy supplier begins with a healthy skepticism toward marketing materials. A glossy brochure and a sleek website are easily produced. True reliability is built on a foundation of experience, expertise, and a verifiable track record. Your investigation should be forensic in its detail.

First, consider the supplier’s history and specialization. How long have they been in the business of manufacturing block making equipment? A company with decades of experience has likely encountered and solved a vast range of engineering challenges. They have weathered economic cycles and have a legacy to protect. Their longevity is, in itself, a testament to the quality of their products and their ability to satisfy customers. Conversely, a new company may offer innovative features, but they lack a proven track record of long-term machine performance and support. You must also ask: do they specialize in this type of machinery? A company that focuses exclusively on concrete block and paver machines will possess a depth of knowledge that a generalist manufacturer of various types of construction equipment simply cannot match. This specialized focus often translates into more thoughtful design, better problem-solving, and more relevant advice.

Second, seek out evidence of their manufacturing prowess. Do not be afraid to ask for a virtual or, if possible, a physical tour of their factory. A proud manufacturer will be eager to show you their facilities. Look for signs of a professional and well-organized operation: modern CNC machining centers, robotic welding stations, a clean and orderly assembly area, and a dedicated quality control department. The physical environment of the factory is a powerful reflection of the company’s culture and its commitment to precision. A supplier who is reluctant to show you their production process may have something to hide.

Third, and perhaps most importantly, ask for references. And not just any references—ask for references in your region or in a country with a similar climate and operational context. A supplier who has successfully installed machines in Southeast Asia or the Middle East has demonstrated their ability to handle the specific logistical, environmental, and support challenges of that region. Contact these references. Ask them candid questions: How was the installation process? How has the machine performed? What has been your experience with their after-sales service and spare parts availability? Have they been responsive and helpful when you’ve had a problem? The testimony of a fellow business owner who has already walked the path you are considering is an invaluable source of unvarnished truth.

The Language of Trust: Communication and Transparency

The quality of your communication with a potential supplier during the sales process is often a strong predictor of the quality of your relationship after the sale. A reliable partner communicates with clarity, honesty, and a genuine desire to understand your specific needs.

Pay close attention to how they answer your questions. Are their answers specific and technical, or are they vague and evasive? When you ask about the grade of steel used in the frame, do they give you a precise designation, or do they just say “high-quality steel”? When you ask about the brand of the hydraulic pump, do they name a reputable international manufacturer, or do they deflect the question? A trustworthy supplier will be transparent about their specifications and their component sourcing because they are confident in the quality of what they offer.

The nature of the sales negotiation itself can be revealing. Is the salesperson focused solely on closing the deal and pushing the most expensive model? Or are they taking the time to function as a consultant, asking you detailed questions about your raw materials, your production goals, your labor situation, and your site layout? A true partner is interested in selling you the right machine for your business, not just a machine. They understand that their long-term success is tied to your long-term success. They should be able to explain why a particular model or configuration is the best fit for you, grounding their recommendation in a clear analysis of your stated needs. This consultative approach is a hallmark of a customer-centric company, one that views the relationship as more than just a single transaction. This philosophy is often deeply embedded in the company’s identity, which is why understanding the history and values of a long-standing equipment manufacturer can be so enlightening.

The Global-Local Nexus: Support in Your Region

For a business in Southeast Asia or the Middle East purchasing equipment from a supplier in China or elsewhere, the question of local or regional support is paramount. A machine is a complex system, and issues can arise. The distance between your plant and the manufacturer’s headquarters can feel vast in a moment of crisis. A superior supplier mitigates this distance through a well-thought-out global support strategy.

Inquire about their network of agents or technical partners. Do they have an established presence in your country or a neighboring one? An agent can provide on-the-ground support, facilitate communication across language barriers, and assist with logistics and importation. Even without a local office, a top-tier supplier will have a dedicated team of international service engineers who are experienced in traveling to customer sites for installation, training, and complex repairs. Ask about their standard response time for sending a technician to your region.

The logistics of spare parts is another critical element of this support structure. A reliable supplier will provide you with a recommended spare parts list for the first one or two years of operation, allowing you to keep critical components on hand at your site. They should also have a streamlined process for international shipping of parts from their main warehouse. Inquire about their typical delivery times to your country for both standard and emergency parts orders. The ability to get a replacement part quickly can be the difference between a minor inconvenience and a costly, extended shutdown. The entire ecosystem of a company, from its manufacturing floor to its global logistics network, contributes to its reliability. A comprehensive view of the entire block making equipment operation reveals this interconnectedness.

In conclusion, the selection of a supplier is an act of judgment about character and competence. It requires moving beyond the surface of marketing and engaging in a deep investigation of a company’s history, manufacturing capabilities, communication style, and, most importantly, its demonstrated commitment to long-term customer support. By choosing a true partner, you are not just buying a machine; you are investing in a relationship that will provide a foundation of stability and expertise for your business’s journey.

Factor 7: Calculating Total Cost of Ownership (TCO) Beyond the Sticker Price

In the calculus of a major capital investment, the initial purchase price, or “sticker price,” often commands a disproportionate amount of attention. It is a concrete, easily comparable number that can dominate the decision-making process. This narrow focus, however, is a classic cognitive trap that can lead to profoundly poor long-term outcomes. A more enlightened and sustainable approach requires a shift in perspective from initial cost to Total Cost of Ownership (TCO). TCO is a comprehensive accounting framework that considers not only the upfront acquisition cost but all direct and indirect costs associated with the block making equipment over its entire operational lifespan. It is only by undertaking this holistic analysis that one can truly understand the long-term economic implications of their choice and identify the machine that offers the best overall value, not just the lowest initial price.

Deconstructing the Iceberg: The Hidden Costs of Ownership

The concept of TCO is often illustrated using the metaphor of an iceberg. The sticker price is the visible tip, but the vast, hidden mass of the iceberg below the waterline represents the ongoing operational and maintenance costs that can, over time, dwarf the initial investment. A responsible financial analysis must diligently map out and quantify these submerged costs.

These costs can be broken down into several key categories:

- Pre-Operational Costs: These are the expenses incurred after the purchase but before the machine produces its first block. This includes international shipping and freight, import duties and taxes (which can be substantial and vary greatly by country), marine insurance, and the cost of inland transportation from the port to your factory site. Furthermore, one must account for site preparation costs, such as the construction of a suitable concrete foundation for the machine and the installation of necessary utilities like a high-capacity electrical supply and a water source.

- インストールとコミッショニング: While some suppliers include this in the purchase price, others charge for it separately. This can involve the cost of sending one or two of the manufacturer’s engineers to your site for several weeks, including their flights, accommodation, and daily allowances. This is a critical investment to ensure the machine is set up correctly, but it must be factored into the total cost.

- エネルギー消費: A block making machine is an energy-intensive piece of equipment. The combined power consumption of its motors—for the hydraulic pump, the vibration table, the mixer, and the conveyors—can represent a significant ongoing operational expense. When comparing two machines, one must look at their total installed power rating (in kilowatts) and estimate the annual electricity cost based on your local utility rates and planned operating hours. A more energy-efficient machine, even with a higher purchase price, can generate substantial savings year after year.

- 人件費: The level of automation has a direct impact on labor costs. A fully automatic line may require only three people to supervise, while a semi-automatic or manual system could require eight or more. You must calculate the fully loaded cost of this labor—including salaries, benefits, and training—over the life of the machine. The savings in labor from a more automated system can often provide a rapid return on the higher initial investment.

- Maintenance and Spare Parts: This is one of the largest and most critical components of TCO. It includes the cost of routine consumables like hydraulic oil, lubricants, and filters. More significantly, it includes the cost of replacing wear parts like the mold, tamper head, conveyor belts, and bearings. A machine built with higher-quality, more durable components will have longer service intervals and lower replacement costs. When evaluating a supplier, ask for their recommended spare parts list and the prices for those parts. A low-cost machine may be built with inferior components that wear out quickly, leading to high long-term maintenance bills and excessive downtime.

- Downtime Costs: This is an indirect but critically important cost. Every hour that the machine is not running due to a breakdown is an hour of lost production and lost revenue. A cheaper, less reliable machine that experiences frequent downtime can quickly become far more expensive than a robust, well-supported machine that runs consistently. The TCO calculation must attempt to quantify the cost of this lost opportunity.

A Tale of Two Machines: A TCO Case Study

To illustrate the power of TCO analysis, let’s imagine a choice between two machines. Machine A has a sticker price of $80,000. Machine B, from a more reputable manufacturer with higher-quality components, has a sticker price of $110,000. On the surface, Machine A seems like the better deal.

Now, let’s apply a TCO analysis over a five-year period.

- Machine A (Lower Initial Cost): Its less efficient motors lead to higher energy consumption, costing an extra $3,000 per year. Its lower level of automation requires two additional workers, costing $15,000 per year in labor. Its molds and wear parts are made from lower-grade steel and need to be replaced more frequently, averaging $8,000 per year in parts. Its lower reliability leads to an average of 10 days of unscheduled downtime per year, representing $10,000 in lost revenue.

- Machine B (Higher Initial Cost): Its energy-efficient design saves $3,000 annually. Its higher automation saves $15,000 in labor. Its durable, high-quality wear parts only require $4,000 per year in replacements. Its superior reliability results in only 2 days of downtime per year, a lost revenue of just $2,000.

Over five years, the additional operating costs for Machine A amount to ($3,000 + $15,000 + $8,000 + $10,000) 5 = $180,000. Its total cost is $80,000 + $180,000 = $260,000. The additional operating costs for Machine B amount to ($4,000 + $2,000) 5 = $30,000 (note that energy and labor are savings, not costs, relative to A). Its total cost is $110,000 + $30,000 = $140,000. Despite being $30,000 more expensive upfront, Machine B is actually $120,000 cheaper over a five-year period. This simple example demonstrates how a narrow focus on the purchase price can be deeply misleading. The “cheaper” machine is, in fact, the far more expensive proposition.

TCO as a Strategic Tool

Thinking in terms of TCO is more than just an accounting exercise; it is a strategic discipline. It forces a long-term perspective and encourages decisions based on value and reliability rather than just initial price. It aligns the purchasing decision with the overall financial health and operational stability of the enterprise. When you engage with suppliers, frame your questions around TCO. Ask them to provide data on energy consumption, recommended maintenance schedules, and the expected lifespan of key wear parts. A supplier who understands and can intelligently discuss TCO is likely a supplier who has engineered their machine for long-term value.

Ultimately, the investment in block making equipment is an investment in your company’s productive capacity for years to come. By looking beyond the sticker price and embracing the comprehensive wisdom of the Total Cost of Ownership, you can ensure that this foundational investment is not only sound but also a powerful driver of sustainable, long-term profitability.

Operational Excellence: Best Practices for Your Block Making Plant

The acquisition of a high-quality piece of block making equipment is a momentous step, but it is not the final destination. It is, rather, the beginning of a journey towards operational excellence. The machine itself, no matter how advanced, is a tool. Its ultimate productivity, efficiency, and the quality of its output are profoundly dependent on the systems, processes, and human expertise that surround it. Achieving excellence in a block production facility is a holistic endeavor, an orchestration of plant layout, material handling, quality control, and a deep commitment to the craft of concrete technology. It is in the daily execution of these best practices that the true potential of the machinery is unlocked.

The Grammar of Production: Plant Layout and Workflow

A well-designed plant layout is like a well-structured sentence: it allows for a clear, logical, and efficient flow of action. A poorly designed layout, conversely, creates bottlenecks, inefficiencies, and safety hazards. The goal is to create a seamless workflow, from the moment raw materials arrive on site to the moment finished, cured blocks are dispatched to the customer. This requires thinking about the entire production process as an integrated system.

The layout should begin with the reception and storage of raw materials. Aggregates should be stored in clean, separated bays to prevent cross-contamination. Cement and other fine powders must be stored in weather-proof silos or warehouses to protect them from moisture, which can cause premature hydration and ruin the material. The location of these storage areas should allow for easy access by delivery trucks while being strategically close to the batching plant to minimize transport distance.

The batching and mixing station is the heart of the plant’s quality control. This area should be positioned to efficiently feed the block machine’s hopper. The workflow should then follow a linear path: the block machine molds the blocks, which are then ejected onto pallets. These fresh, or “green,” blocks are extremely fragile and must be transported smoothly to the curing area. The path from the machine to the curing area should be short, level, and free of obstructions. A finger cart or an automated transport system is essential for this task. After curing, the blocks are moved to a cubing station (where they are stacked into transportable cubes) and then to a stockyard. The stockyard itself should be well-organized, with clear separation between different types of products and a “first-in, first-out” (FIFO) system to ensure that older stock is sold first. This entire layout should be designed to minimize travel distances, avoid cross-traffic between forklifts and workers, and ensure a safe and orderly environment.

The Art and Science of Curing

The moment a block is ejected from the machine, its journey is only halfway complete. The strength of a concrete block does not come from the pressure of the machine, but from a chemical reaction known as hydration, where the cement particles react with water to form a hard, crystalline matrix that binds the aggregates together. This process, known as curing, is absolutely critical to achieving the desired strength and durability. Improper curing can ruin even the most perfectly molded blocks.

The primary goal of curing is to maintain sufficient moisture and a favorable temperature within the block for the hydration reaction to proceed to completion. For the first 24 to 48 hours, the green blocks are at their most vulnerable. They must be protected from the drying effects of wind and direct sunlight. In the hot, arid climates of the Middle East or the hot, humid conditions of Southeast Asia, this is a particularly acute challenge. A dedicated curing area is not a luxury; it is a necessity.

A common and effective method is to create a curing chamber or enclosure where the blocks can be stored and the environment can be controlled. In this chamber, a fine mist or fog can be used to maintain high humidity, ensuring the blocks do not dry out prematurely. Covering the stacks of green blocks with plastic sheeting is another simple but effective technique to trap moisture. The curing process should continue for several days. While a block may feel hard to the touch after 24 hours, it has only achieved a fraction of its potential strength. Standard practice often calls for a 7-day curing period to achieve approximately 65-75% of the final design strength, with the full 28-day strength being the benchmark for quality control testing.

A Culture of Quality Control

Quality control (QC) is not a single action but a continuous process, a culture of diligence that must permeate every stage of production. It begins before the first block is made and ends only when the product is delivered to a satisfied customer. A robust QC program is built on three pillars: material testing, process monitoring, and product testing.

- Material Testing: As discussed earlier, the quality of your inputs determines the quality of your output. Your QC program must include regular testing of incoming raw materials. This can be as simple as a visual inspection for contaminants and a “jar test” for silt in the sand, or as sophisticated as sending regular samples of your cement and aggregates to a laboratory for analysis. The key is consistency.

- Process Monitoring: This involves paying close attention to the production process itself. Are the batch weights consistently accurate? Is the water content in the mix correct? (A simple “slump test” or even a “hand-squeeze test” by an experienced operator can provide a good indication). Is the machine’s vibration and pressure set correctly for the product being made? These parameters should be documented on a production sheet for every batch, creating a record that can be invaluable for troubleshooting any quality issues that arise later.

- Product Testing: This is the final verification of your quality. A sample of blocks from each day’s production should be set aside for testing. After they have cured for the specified period (typically 7 and 28 days), they should be tested for their compressive strength using a compression testing machine. This provides quantitative, objective data on the quality of your product and ensures you are meeting the required engineering standards. Other tests, such as water absorption and dimensional accuracy, should also be performed regularly. This rigorous testing is not just about catching defects; it is about building a reputation for reliability and quality that will set you apart from your competitors.

By embracing these best practices—by designing a logical plant, mastering the science of curing, and instilling a deep culture of quality control—a block producer can transform their facility from a simple factory into a center of excellence. This commitment to operational discipline is what ensures that the significant investment in high-quality block making equipment yields the highest possible return in the form of superior products, satisfied customers, and a thriving, sustainable business.

The Future of Block Production: Innovations and Trends

The world of construction, often perceived as traditional and slow to change, is on the cusp of a significant transformation. Driven by the twin pressures of environmental responsibility and the relentless pursuit of efficiency, the technology and methodology of block production are evolving. For an enterprise investing in block making equipment in 2025, it is not enough to understand the technologies of today; one must also have a view towards the horizon, anticipating the trends that will shape the industry of tomorrow. Engaging with these future trends is not merely an academic exercise; it is a strategic necessity for ensuring that an investment made today remains relevant, competitive, and profitable in the decade to come.

The Intelligence Revolution: Automation, Robotics, and IoT

The trend towards automation, already well-established with PLC-controlled machines, is set to deepen and expand in profound ways. The future is not just about automating the block machine itself, but about automating the entire production ecosystem. We are moving from automated machines to truly autonomous plants.

- Robotic Integration: While automatic cubers and stackers already exist, the next generation of robotics will handle an even wider range of tasks. Imagine robots capable of performing routine maintenance, cleaning molds, or even conducting quality control inspections using machine vision. Robotic arms could offer unparalleled flexibility in stacking and packaging custom orders, moving beyond simple cubes to create mixed pallets ready for specific job sites.

- The Internet of Things (IoT): The integration of IoT sensors into block making equipment will revolutionize maintenance and operational oversight. Sensors embedded in motors, bearings, and hydraulic systems will continuously monitor performance parameters like temperature, vibration, and pressure. This data will be fed into a central system that can predict potential failures before they happen. This shift from reactive maintenance (fixing things after they break) to predictive maintenance will drastically reduce unscheduled downtime and extend the life of the machine. Plant managers will be able to monitor their entire operation in real-time from a tablet or smartphone, receiving alerts about material levels, production targets, and potential maintenance needs.

- Data-Driven Optimization: A fully connected plant generates a massive amount of data. The future lies in using artificial intelligence (AI) and machine learning algorithms to analyze this data to find hidden efficiencies. An AI could analyze data from thousands of production runs to determine the absolute optimal mix of raw materials for a given strength requirement, or the perfect vibration frequency to minimize cycle time without compromising quality. This data-driven approach will move block production from a craft based on experience to a science based on empirical evidence.

The Green Imperative: Sustainable Materials and Carbon Capture

The global construction industry is a massive contributor to carbon emissions, with cement production alone accounting for a significant percentage. This reality is driving an intense search for more sustainable ways to build. The block of the future will be a “green” block, and the machinery must be ready to produce it.

- Cement-Free and Low-Carbon Binders: The most significant frontier is the development of alternatives to Ordinary Portland Cement (OPC). Research into geopolymers is showing immense promise. Geopolymers are binders formed by reacting aluminosilicate source materials (like fly ash or slag) with an alkaline solution. They can produce concrete with strength and durability comparable or even superior to OPC-based concrete, but with a carbon footprint that is up to 80% lower. Block making equipment of the future will need to be adapted to handle these new types of binders, which may have different mixing requirements and curing characteristics.

- Carbon-Capturing Concrete: An even more revolutionary concept is concrete that actively removes CO2 from the atmosphere. Several companies are developing technologies where CO2 is injected into the concrete mix during the production process. The CO2 reacts with the calcium ions in the cement to form a stable mineral, effectively sequestering the carbon permanently within the block. This turns a block from a source of emissions into a carbon sink. Block machines will need to be designed with integrated systems for the safe and efficient injection of CO2 during the mixing or molding phase.

- Hyper-Local and Waste-Based Materials: The trend of using local and recycled materials will intensify. The future will see the use of an even wider range of waste products, from crushed glass and recycled plastic to processed agricultural waste. This will require block machines with even greater versatility and more robust mixing and compaction systems capable of handling these non-traditional and often variable feedstocks.

A Glimpse of 2035: The Autonomous, Green Block Plant

Let us imagine a state-of-the-art block plant in the year 2035. Raw materials, many of them recycled or locally sourced byproducts, are delivered and automatically sorted into smart silos. An AI system, constantly monitoring market prices and material specifications, determines the optimal, lowest-carbon mix for the day’s production run. The materials are batched and mixed in a closed-loop system where captured CO2 is injected to create carbon-negative concrete. The mix is transported to a fully autonomous block machine, which adjusts its own vibration and pressure settings in real-time based on feedback from sensors in the mold.

The finished blocks are handled by a fleet of quiet, electric robots that transport them to a smart curing chamber where humidity and temperature are perfectly optimized. Other robots conduct quality control, tapping each block and using acoustic analysis to check for internal flaws. The entire plant is managed by a single technician in a control room, overseeing the operation on a series of holographic displays. This vision may seem futuristic, but all the component technologies are already in development. For the investor in 2025, the key is to choose a supplier and a machine that are on this technological trajectory. A modular machine that allows for future upgrades and a supplier who is actively engaged in research and development are the best hedge against obsolescence. The future of block production will be intelligent, sustainable, and highly efficient, and the time to prepare for it is now.

よくある質問(FAQ)

- 1. What is the typical lifespan of a well-maintained block making machine?

- A high-quality, robustly built block making machine from a reputable manufacturer, when subjected to a rigorous schedule of preventative maintenance and operated correctly, can have a remarkably long operational life. It is reasonable to expect a primary service life of 15 to 20 years. However, this is highly dependent on the quality of the initial build, particularly the frame’s steel quality and the durability of key components like the hydraulic system and vibration motors. The most critical factor is maintenance. Regular lubrication, timely replacement of wear parts like molds and tamper heads, and keeping the machine clean from concrete buildup are essential. Many machines older than 20 years are still in productive service around the world, a testament to the fact that a well-cared-for machine is a multi-decade investment.

- 2. How much space do I need to set up a complete block production line?

- The required space depends significantly on the scale and type of machine. A small, simple stationary machine might only require a covered area of 100-200 square meters. However, for a complete, medium-sized automatic production line, a much larger area is necessary to accommodate the entire workflow. A good rule of thumb is to plan for a minimum of 2,000 to 3,000 square meters. This provides adequate space for raw material storage (separate bays for sand and different sized aggregates), a cement silo, the batching plant, the main machine area, a sufficiently large curing area for several days’ worth of production, a stockyard for finished products, and maneuvering space for forklifts and delivery trucks.

- 3. Can I use desert sand to make concrete blocks?

- This is a critical question for producers in the Middle East and other arid regions. While it is possible to use desert sand, it presents challenges that must be managed. Desert sand particles are typically very fine and rounded by wind erosion. This shape is not ideal for creating strong concrete, as the particles do not interlock well, leading to a weaker paste-aggregate bond and requiring more cement and water to achieve workability. The solution is almost always to blend the desert sand with a high-quality, manufactured sand (crushed rock) which has the angular particles needed for good interlocking and strength. A typical blend might be 60-70% coarse, manufactured sand and 30-40% fine desert sand. A thorough mix design and testing are essential to find the optimal ratio for your specific materials.

- 4. What are the most important spare parts I should keep in stock?