A 7-Step Expert Guide to Launching Your Profitable Cement Block Plant in 2025

12월 27, 2025

초록

The rapid urbanization and infrastructure development across Southeast Asia and the Middle East present a significant entrepreneurial opportunity in the manufacturing of construction materials. This analysis provides a comprehensive framework for establishing a profitable cement block plant in 2025. It meticulously details a seven-step process, beginning with in-depth market research and feasibility studies tailored to regional demands. A central focus is placed on the critical decision of selecting appropriate machinery, with a comparative examination of semi-automatic versus fully automatic systems, including the prevalent QT series of concrete block making machines. The guide further explores optimal plant layout design, sourcing of raw materials, and robust financial planning, encompassing capital expenditure, operational costs, and return on investment calculations. It addresses the human element of staffing and training, alongside the implementation of stringent quality control and safety protocols. The final stage outlines strategies for market entry, customer acquisition, and long-term business scaling, providing a holistic roadmap for aspiring investors in the cement block manufacturing sector.

주요 내용

- Conduct thorough market research to identify local demand for specific block types.

- Select machinery, like a QT series machine, that aligns with your production volume and budget.

- Design an efficient plant layout to optimize workflow from mixing to curing.

- Develop a detailed financial plan to accurately forecast your investment and profitability.

- Source high-quality raw materials to ensure the structural integrity of your products.

- Establish a successful cement block plant by implementing rigorous quality control measures.

- Build a strong customer base through targeted marketing and networking with local contractors.

목차

- Step 1: Foundational Market Research and Feasibility Analysis

- Step 2: Selecting the Core of Your Operation – The Block Making Machine

- Step 3: Designing the Optimal Plant Layout and Workflow

- Step 4: Sourcing High-Quality Raw Materials

- Step 5: Financial Planning, Budgeting, and Securing Investment

- Step 6: Assembling Your Team and Ensuring Operational Readiness

- Step 7: Launch, Marketing, and Scaling Your Cement Block Plant

- 자주 묻는 질문

- 결론

- 참조

Step 1: Foundational Market Research and Feasibility Analysis

Embarking on the venture of a cement block plant requires a profound understanding that the foundation of the business is not laid with concrete, but with data and diligent analysis. Before a single bag of cement is purchased or a piece of machinery is ordered, a rigorous examination of the market's terrain is paramount. This initial phase is an exercise in foresight, a process of mapping the currents of supply and demand, navigating the channels of regulation, and charting a course through the competitive waters. It is an intellectual endeavor that separates a speculative gamble from a calculated investment. The quality of this preparatory work directly correlates with the resilience and ultimate success of the enterprise. It involves asking difficult questions and seeking honest answers, delving into the specific economic and social fabric of your target region, be it the rapidly expanding suburbs of a Southeast Asian metropolis or the ambitious giga-projects of the Middle East.

Understanding Local Demand: What Blocks Are Needed?

The first line of inquiry must concern the product itself. What kind of blocks does your market truly need? A generic approach is a path to mediocrity. To truly serve a market, one must first listen to it. This involves more than a cursory online search; it demands direct observation and engagement. Consider spending time at local construction sites, not as a salesperson, but as a student of the industry. Observe the types of blocks being used. Are they predominantly hollow blocks for partition walls, dense solid blocks for structural elements, or intricately shaped interlocking pavers for driveways and public squares?

Engage in conversations with site foremen, small-scale contractors, and project managers. What are their primary concerns? Is it the compressive strength of the block, its dimensional accuracy, its thermal insulation properties, or simply its price? In many parts of Southeast Asia, for example, the demand for lightweight, thermally efficient blocks is rising due to increasing energy costs and a growing awareness of sustainable building practices. Conversely, in certain infrastructure projects in the Middle East, the emphasis might be on extremely high-strength blocks and curb-stones capable of withstanding heavy traffic and harsh environmental conditions.

Your research should be granular. Document the common sizes. A standard 400x200x200mm hollow block is ubiquitous, but are there regional variations? What about specialized products like hourdis blocks for slab construction or decorative screen blocks? By cataloging this information, you begin to build a profile of your potential product line. This data-driven approach allows you to tailor your initial machinery investment to produce what is already in demand, minimizing the risk of producing stock that nobody wants to buy. This is the empathetic first step: understanding the specific needs and pain points of the builders you intend to serve.

Analyzing the Competitive Landscape

Once you have a clear picture of what to produce, you must assess who else is producing it. An analysis of your competition is not an act of intimidation but of strategic positioning. Who are the existing players in your chosen area? Are they large, established factories with extensive distribution networks, or are they a collection of smaller, localized operators?

Categorize your competitors. For each one, attempt to understand their strengths and weaknesses. Does a large competitor benefit from economies ofscale, allowing them to offer lower prices? Perhaps their weakness is a lack of flexibility or slow delivery times. Smaller operators might be more agile but may struggle with quality consistency or production volume. Where in this spectrum can your new cement block plant find its niche?

Consider their pricing structures, their reputation for quality, and their relationships with key buyers. A market saturated with low-cost, low-quality producers might present an opportunity for a new entrant focused on superior quality and reliability, even at a slightly higher price point. You could position your brand as the premium choice for developers who cannot afford to compromise on structural integrity. Conversely, if the market is dominated by a few high-cost players, a lean, efficient operation utilizing modern machinery could potentially disrupt the status quo by offering a better value proposition. This analysis is about finding the unoccupied space in the market, the unmet need that your business is uniquely positioned to fill.

Regulatory and Legal Frameworks in Your Region

The most brilliant business plan and the most advanced machinery are rendered useless if they operate outside the bounds of the law. Navigating the regulatory environment is a non-negotiable aspect of establishing your cement block plant. The requirements can vary significantly from one country to another, and even between different states or municipalities within the same country.

Your investigation must cover several key areas. First, business registration and licensing. What legal structure will your company take? What permits are required to operate a manufacturing facility? Second, zoning and land use regulations. Is your proposed site zoned for industrial activity? Overlooking this can lead to costly fines and forced relocation. Third, environmental regulations. Manufacturing cement products involves dust, noise, and water usage. What are the local standards for pollution control? You may need to invest in dust collection systems or water recycling facilities. Environmental impact assessments are often a prerequisite for obtaining a permit.

You should also research building codes and material standards. Your blocks must meet the minimum strength and quality requirements stipulated by national or regional standards organizations. Failing to do so not only exposes you to legal liability but also destroys your brand's reputation. It is often wise to engage a local legal consultant or business advisor who specializes in the construction sector. Their expertise can be invaluable in navigating the bureaucratic maze, ensuring that your cement block plant is built on a firm legal footing from day one.

Crafting a Comprehensive Business Plan

The culmination of your research is the business plan. This document is not merely a formality for securing loans; it is the architectural blueprint for your entire enterprise. It translates your vision into a concrete, actionable strategy. A well-crafted business plan serves as your guide, helping you to stay focused on your objectives and measure your progress.

Your business plan should synthesize all the elements of your feasibility study. It must begin with a clear executive summary, articulating your mission, your target market, and your competitive advantage. The marketing section will detail the demand you have identified and outline your strategy for reaching customers. The operations section will describe your proposed plant layout, your production process, the machinery you intend to purchase (such as specific models from the QT series), and your raw material sourcing plan.

The financial section is the heart of the document. Here, you will present detailed projections for startup costs, operational expenses, and revenue forecasts based on your market analysis and production capacity. This section should include a break-even analysis and a projected return on investment. The management section will outline your organizational structure and the key personnel you need to hire.

Think of the business plan as a living document. The market will change, new challenges will arise, and you will discover new opportunities. Your plan should be robust enough to provide direction, yet flexible enough to adapt. It is the disciplined expression of your entrepreneurial ambition, a testament to the rigorous thought that precedes successful action.

Step 2: Selecting the Core of Your Operation – The Block Making Machine

The block making machine is the veritable heart of your cement block plant. It is the engine that will drive your production, determine your output capacity, and significantly influence both your product quality and your operational costs. The selection of this single piece of equipment is arguably the most critical investment decision you will make. It is a choice that demands a careful balancing of technological capabilities, financial constraints, and long-term strategic goals. A hasty decision based on price alone can lead to perpetual maintenance headaches, inconsistent product quality, and a crippling inability to meet market demand. Conversely, a well-researched choice provides a reliable and efficient production core that can serve your business for decades. The landscape of available machinery is vast, ranging from basic semi-automatic models to highly sophisticated, fully automated production lines.

Semi-Automatic vs. Fully Automatic: A Comparative Analysis

The primary decision point for any new cement block plant entrepreneur is the level of automation. This choice has profound implications for your initial capital outlay, your labor requirements, and your production efficiency. Understanding the trade-offs is essential.

A semi-automatic machine requires more manual intervention. Typically, processes like material feeding, pallet feeding, and the transport of finished blocks to the curing area are handled by operators. A fully automatic line, often controlled by a Programmable Logic Controller (PLC), integrates these functions. A central computer manages the entire sequence from mixing to stacking, requiring minimal human oversight.

Let's consider this through a practical lens. Imagine you are starting a small-scale plant in a region with relatively low labor costs. A semi-automatic machine might be an attractive option. The initial investment is lower, and the mechanical systems are often simpler, making maintenance and repair more straightforward for a less specialized team. However, the trade-off is a higher dependence on labor and potentially lower, less consistent output. The speed of production is often dictated by the efficiency of the human operators.

Now, picture a scenario where you aim to supply a large, demanding market, and labor costs are a significant concern. A fully automatic machine, such as a model from the QT series, becomes a much more compelling proposition. While the initial investment is substantially higher, the long-term benefits are considerable. These machines offer significantly higher production rates, superior consistency in block quality due to precise, repeatable actions, and a drastic reduction in labor requirements. A full line might only require a few supervisors instead of a large team of manual laborers.

| 기능 | Semi-Automatic Block Machine | Fully Automatic Block Machine (e.g., QT Series) |

|---|---|---|

| 초기 투자 | Lower | Higher |

| 노동 요구 사항 | High (5-8 workers) | Low (2-4 workers) |

| 생산 출력 | Moderate (e.g., 3,000-5,000 blocks/8hr) | High (e.g., 10,000-20,000+ blocks/8hr) |

| Product Consistency | Variable, depends on operator skill | High, controlled by PLC system |

| Operational Control | Manual buttons and levers | PLC with Touch Screen Interface |

| 유지 관리 | Simpler, more mechanical | More complex, requires electronic/hydraulic knowledge |

| 이상적인 대상 | Startups, small markets, low labor cost regions | Large-scale production, high labor cost regions |

Deep Dive into QT Series Fully Auto Concrete Block Making Machines

The "QT" series has become a benchmark in the industry for reliable and efficient automatic block production. These machines, offered by numerous reputable Chinese manufacturers like Hongfa and Huatong, are hydraulic-based systems renowned for their versatility and robustness (). Let's dissect what makes these machines so effective.

The core technology combines a powerful hydraulic system with a high-frequency vibration system. Here is how it works: a precisely measured batch of semi-dry concrete mix is fed into a mold. The hydraulic system then applies immense pressure from above, while the vibration system, often consisting of motors on the mold and the vibration table, agitates the mix. This combination of pressure and vibration expels air pockets and forces the concrete particles into a dense, tightly packed arrangement. The result is a block with high compressive strength, excellent dimensional accuracy, and a smooth finish.

Different models within the series offer varying capacities. For instance, a QT4-25 model might be a good entry-point into automatic production, capable of producing around 4,000-5,000 standard hollow blocks in an 8-hour shift (). As you move up the range to a QT10-15 or QT12-15, the machine size, hydraulic power, and pallet size increase, allowing for the production of more blocks per cycle. A large QT10-15 machine can easily produce over 14,000 hollow blocks in a single shift ().

One of the greatest advantages of the QT series is its versatility. By simply changing the mold, the same machine can produce a vast array of products: hollow blocks of various sizes, solid bricks, interlocking pavers, curb-stones, and more. This flexibility allows a cement block plant to adapt to changing market demands without needing to purchase entirely new machinery. The use of high-quality components from international brands like Siemens for PLCs and touch screens further enhances their reliability and ease of operation for a global audience ().

Understanding Static Hydraulic Block Pressing Machines

While vibration-based machines like the QT series are excellent for producing a wide range of standard blocks and pavers, another category of machine deserves consideration: the static hydraulic press. These machines operate on a different principle. Instead of relying heavily on vibration, they use extremely high hydraulic pressure to compact the concrete mix.

Static presses are particularly well-suited for producing high-density, specialized products. Think of large curb-stones, high-strength paving slabs, or terrazzo tiles. The immense pressure creates a product with very low porosity and exceptional strength and durability. Some dual-purpose machines offer both static pressing and vibration, providing the best of both worlds.

For a new cement block plant, a static hydraulic press might be considered as a second-phase investment. Initially, a versatile QT series machine can cover the bulk of the market demand for standard blocks and pavers. As the business grows and seeks to diversify into more premium, high-margin products, adding a static press can open up new revenue streams. It allows the plant to cater to specialized architectural or civil engineering projects that demand the superior characteristics of pressed concrete products.

Choosing a Reliable Chinese Supplier: Key Due Diligence

The globalization of manufacturing has made high-quality machinery from China accessible and affordable. However, the sheer number of suppliers can be overwhelming. Performing thorough due diligence is essential to avoid purchasing substandard equipment.

First, look for experience and reputation. A company that has been in operation for decades, like Hongfa Machinery which was established in 1990, likely has a proven track record (). Look for evidence of a global footprint. Have they exported to your region before? Can they provide case studies or references from customers in nearby countries?

Second, scrutinize the technical specifications. Do not be swayed by glossy brochures alone. Compare the key parameters: hydraulic pressure, vibration force (measured in KN), cycle time, and motor power. Pay close attention to the brands of the key components. The use of reputable international brands for PLCs, hydraulic valves, and sensors is a strong indicator of quality.

Third, evaluate the after-sales support. A machine is only as good as the support behind it. What kind of warranty is offered? Do they provide installation and training services? The ability to send an engineer to your site for commissioning is a huge advantage. What is their process for supplying spare parts? A machine sitting idle for weeks while waiting for a part from overseas can be disastrous for your business.

Finally, if possible, arrange a factory visit or, at the very least, a detailed video call to see the manufacturing process. A transparent and professional supplier will be proud to show you their facilities and their quality control processes. This investment in due diligence before the purchase will pay immense dividends in the long-term reliability and profitability of your cement block plant.

Step 3: Designing the Optimal Plant Layout and Workflow

The physical arrangement of your cement block plant is a critical factor that directly impacts its efficiency, safety, and profitability. A poorly designed layout can create bottlenecks, increase material handling costs, waste valuable time, and even pose safety risks to your workers. Conversely, a thoughtfully planned layout streamlines the entire production process, creating a seamless flow from the moment raw materials arrive to the moment finished blocks are ready for delivery. Think of your plant layout as a form of choreography, where every machine, every stockpile, and every worker's movement is orchestrated to achieve maximum harmony and productivity. The goal is to minimize unnecessary movement and ensure that each stage of the process logically follows the last, creating a lean and efficient manufacturing ecosystem.

Raw Material Storage and Handling

The production journey begins with the raw materials: cement, sand, gravel (aggregates), and water. The storage and handling of these materials must be planned with both accessibility and protection in mind.

Aggregates, such as sand and crushed stone, are typically stored in open-air bays. These bays should be constructed with sturdy retaining walls (often made of concrete blocks themselves) to keep the different types of aggregates separate and prevent contamination. The storage area should be located in a position that allows for easy unloading from delivery trucks while also being close to the batching machine's loading hoppers to minimize the travel distance for your front-end loader. A paved or compacted surface in this area is advisable to reduce mud and dust, which can contaminate your raw materials.

Cement, being a fine powder that reacts with moisture, requires more careful handling. It is typically stored in a vertical cement silo. A silo protects the cement from the elements, prevents wastage, and allows for precise, automated dispensing into the mixer. The size of the silo should be chosen based on your projected daily consumption and the reliability of your cement supply. Having enough storage to cover several days of production provides a buffer against potential delivery delays. A screw conveyor is used to transport the cement from the silo to the weighing hopper of the batching plant, an enclosed system that minimizes dust and material loss.

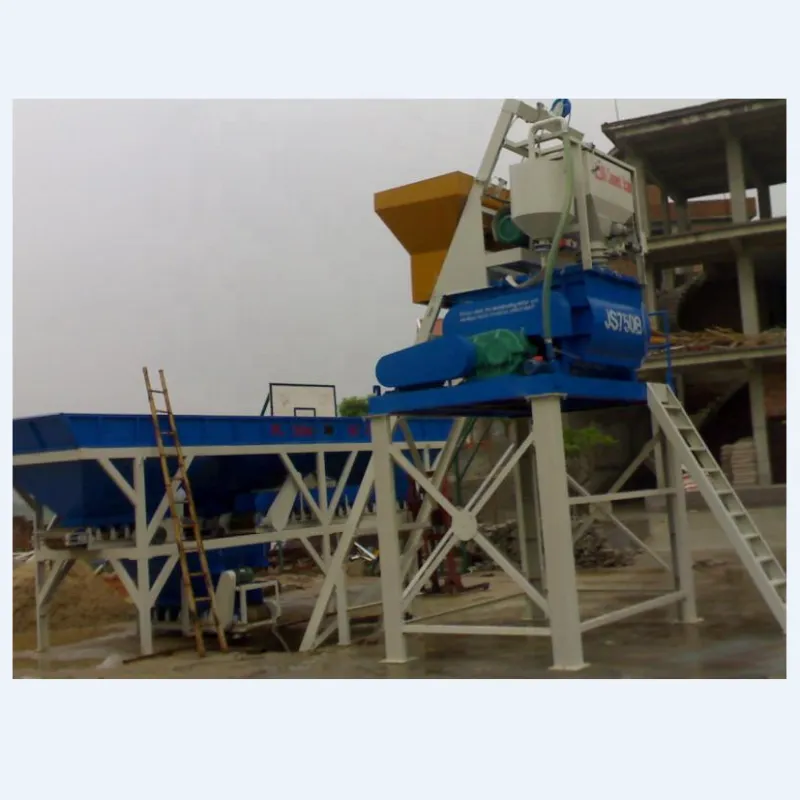

The Crucial Role of the Concrete Batching Plant

If the block machine is the heart of the operation, the 콘크리트 혼합 시스템 or batching plant is the brain that ensures the quality of the "blood" that flows to it. The consistency and strength of your concrete blocks are directly determined by the accuracy of your concrete mix. A batching plant is a system designed to precisely measure and combine all the raw materials according to a pre-programmed recipe before they enter the mixer.

A typical batching plant consists of aggregate storage bins, weighing hoppers for aggregates, cement, and water, and a control system. The process is automated: the front-end loader fills the aggregate bins. When a batch is required, the control system opens gates at the bottom of the bins, allowing the correct weight of each aggregate to fall onto a conveyor belt, which transports them to the mixer. Simultaneously, the system weighs the required amount of cement from the silo and water from the tank.

Investing in a reliable batching plant is not an area to cut corners. The accuracy of its weighing systems is paramount. An inconsistent mix, with too much water or not enough cement, will result in blocks that fail to meet strength requirements, leading to waste and a damaged reputation. Modern batching plants use electronic load cells and PLC controls to achieve a very high degree of accuracy, ensuring that every single batch of concrete is identical. This consistency is the bedrock of quality control in a modern cement block plant.

Production Line Flow: From Mixing to Curing

With the layout of your raw material storage and batching plant established, you can now map the flow of the main production line. The objective is to create a linear, unidirectional path.

-

믹싱: The precisely weighed raw materials from the batching plant are discharged into a concrete mixer. For the semi-dry mix used in block production, a planetary or twin-shaft mixer is ideal. These mixers are designed to create a homogenous mix quickly and efficiently. The mixer is typically positioned on an elevated platform, allowing it to discharge the mixed concrete directly into the hopper of the block making machine below.

-

Block Forming: The block making machine (e.g., a QT series model) receives the concrete mix. It automatically feeds the mix into the mold, forms the blocks through vibration and hydraulic pressure, and then ejects the freshly molded blocks onto a steel or GMT pallet.

-

Wet Block Transport: As a pallet of fresh, "green" blocks exits the machine, it needs to be transported to the curing area. In a fully automatic line, this is handled by a block conveyor and a stacker machine. The stacker automatically lifts the pallets and stacks them onto a rack, typically 8-12 layers high. This automated system is fast, gentle on the fragile green blocks, and eliminates the need for manual lifting.

-

Curing: A forklift or a manual cart then transports the entire rack of stacked pallets to the designated curing area. This movement should be a short, direct trip from the end of the production line to the start of the curing yard to maintain efficiency.

This linear flow—from raw materials, to batching, to mixing, to forming, to curing—prevents different stages of the process from interfering with one another and creates a safe, organized, and highly productive environment.

Curing Area Design: Natural vs. Steam Curing

Curing is the chemical process through which concrete gains its strength. It is not simply drying; it requires adequate moisture and temperature for the hydration of cement to occur effectively. The design of your curing area is a critical component of your plant layout.

The most common and cost-effective method is natural curing, also known as air curing. In this method, the racks of green blocks are stored in a covered, sheltered area for a period of 24 to 48 hours. During this initial, critical phase, they must be protected from direct sunlight, wind, and rain, which can cause them to dry out too quickly and crack. After this initial set, the blocks are typically de-stacked from the pallets and arranged in large cubes in an open yard for the remainder of the curing period, which can last up to 28 days for the blocks to reach their full design strength. Sprinkling the stacked blocks with water periodically, especially in hot, dry climates like those in the Middle East, is essential to ensure proper hydration. Your curing yard needs to be large enough to hold several weeks' worth of production.

For businesses that need to achieve high early strength or a faster production turnover, steam curing is an option. In this method, the green blocks are placed in an enclosed chamber or kiln, into which low-pressure steam is introduced. The high temperature and humidity accelerate the hydration process, allowing blocks to reach a significant portion of their final strength in less than 24 hours. This allows for faster pallet turnover and can be beneficial in cold climates. However, steam curing involves a significant additional investment in a boiler, piping, and the construction of curing chambers. For most new startups in the warm climates of Southeast Asia and the Middle East, a well-managed natural curing process is the more practical and economical choice.

Step 4: Sourcing High-Quality Raw Materials

The quality of a cement block is a direct reflection of the quality of its constituent parts. You can have the most advanced machinery and the most efficient plant layout, but if the raw materials are substandard, the final product will inevitably be compromised. Sourcing high-quality, consistent raw materials is a foundational pillar of running a successful cement block plant. It is a continuous process of procurement, quality testing, and supplier relationship management. The "recipe" for your concrete mix is not just about proportions; it is about the intrinsic quality of each ingredient. Understanding the science behind the mix and establishing reliable supply chains are essential for producing blocks that are not only strong and durable but also consistently meet and exceed customer expectations and regulatory standards.

완벽한 콘크리트 믹스의 과학

At its core, concrete is a composite material made from three basic components: a binder (cement), aggregates (sand and stone), and water. The magic happens during hydration, a chemical reaction between the cement and water that forms a paste, which coats the aggregates and binds them together into a rock-like mass. For block production, a "semi-dry" or "zero-slump" mix is used, which has just enough water to initiate hydration but is stiff enough to hold its shape immediately after being de-molded.

The proportions of these ingredients, known as the mix design or mix ratio, are critical. Different ratios are used to achieve different properties. For example, a high-strength paving block will require a higher proportion of cement compared to a standard hollow block used for non-load-bearing walls. The size and grading of the aggregates also play a crucial role. A good mix will have a well-graded combination of fine aggregates (sand) and coarse aggregates (crushed stone), which allows for denser packing and reduces the amount of cement paste needed to fill the voids, making the block stronger and more economical.

Developing the right mix designs for your products is a key operational task. It often involves creating trial batches and testing the resulting blocks for compressive strength until you achieve the desired performance with the most economical use of materials.

| 제품 유형 | Example Mix Ratio (Cement : Sand : Coarse Aggregate by Volume) | Key Characteristics |

|---|---|---|

| Standard Hollow Block (Non-load-bearing) | 1 : 4 : 6 | Economical, good for partition walls. Focus on dimensional accuracy. |

| Load-Bearing Solid Block | 1 : 2 : 4 | Higher cement content for increased compressive strength. |

| High-Strength Interlocking Paver | 1 : 1.5 : 3 | Very high cement content and quality aggregates for durability and abrasion resistance. |

| Lightweight Block (with fly ash) | 0.8 : 1 : 3 : 5 (Cement:Fly Ash:Sand:Aggregate) | Lower density, improved thermal insulation. Fly ash replaces a portion of cement. |

Note: These ratios are illustrative. The optimal mix design will depend on the specific properties of your local raw materials and must be verified through testing.

Sourcing Cement, Aggregates, and Water

Cement: This is typically the most expensive component of your mix. The most common type used is Ordinary Portland Cement (OPC). It is crucial to source cement from reputable manufacturers who can provide consistent quality that conforms to international or national standards (like ASTM C150 or EN 197-1). Inconsistent cement quality can lead to unpredictable variations in block strength. Building a relationship with a reliable local supplier or distributor is key to ensuring a steady and fairly priced supply.

Aggregates: Sand (fine aggregate) and crushed stone (coarse aggregate) make up the bulk of the concrete's volume. The quality of your aggregates is just as important as the cement. They must be clean, hard, and free from impurities like clay, silt, and organic matter. These impurities can interfere with the cement's hydration process and create weak points in the block. It is essential to identify quarries or suppliers who can provide well-graded aggregates with consistent properties. You should perform regular simple tests, such as a silt test, to check the cleanliness of your sand deliveries. The shape of the aggregate matters too; angular, crushed stone generally provides better interlocking and strength than smooth, rounded river gravel.

물: The water used for the mix must also be clean and free from contaminants like oils, acids, salts, and organic materials. Water that is suitable for drinking is generally suitable for making concrete. Using contaminated water can adversely affect the setting time and final strength of the concrete.

Leveraging Industrial Wastes: Fly Ash and Slag

In an era of increasing environmental awareness and a focus on cost efficiency, the use of supplementary cementitious materials (SCMs) is becoming standard practice in modern concrete production. These are industrial by-products that can replace a portion of the Portland cement in a mix.

플라이 애쉬: This is a fine powder that is a by-product of burning coal in power plants. When used in concrete, it not only reduces the amount of cement needed (and thus the cost and carbon footprint) but also improves the long-term strength and durability of the blocks. The spherical shape of fly ash particles can also improve the workability of the mix. In regions with coal-fired power stations, fly ash is often an abundant and inexpensive resource.

지상 과립형 용광로 슬래그(GGBS): A by-product of the iron and steel industry, slag can also be used to replace a significant portion of cement. It is known to enhance the durability of concrete, particularly its resistance to chemical attack, which can be beneficial in coastal areas or industrial environments.

Incorporating these materials requires some adjustments to your mix design and curing process, but the economic and environmental benefits can be substantial. It positions your cement block plant as a modern, sustainable enterprise.

Building Strong Supplier Relationships

Sourcing is not a one-time transaction; it is about building long-term partnerships. A strong relationship with your suppliers of cement, aggregates, and other materials can provide numerous benefits. A reliable supplier who understands your business needs is more likely to prioritize your orders, provide consistent quality, and offer competitive pricing.

Communicate your quality requirements clearly. When possible, establish a supply contract that specifies the material standards, delivery schedules, and payment terms. This creates a clear framework for your business relationship. Treat your suppliers as partners in your success. Prompt payments and open communication can foster loyalty and ensure that you have a dependable supply of the high-quality raw materials that are the lifeblood of your cement block plant. This collaborative approach is far more effective in the long run than constantly switching suppliers in search of a slightly lower price.

Step 5: Financial Planning, Budgeting, and Securing Investment

A cement block plant, like any manufacturing venture, is a capital-intensive undertaking. A clear and realistic financial plan is the compass that will guide you through the complexities of investment, expenditure, and revenue generation. Without a firm grasp of the numbers, even the most promising business idea can falter. This stage involves moving from the abstract concept of a business to the concrete reality of balance sheets and cash flow statements. It requires a meticulous accounting of every potential cost and a conservative estimation of every potential source of income. This financial blueprint will not only be essential for securing funding from banks or investors but will also serve as your primary tool for managing the financial health of your business once it is operational. It is the process of quantifying your ambition and creating a viable path to profitability.

Estimating Total Capital Expenditure (CAPEX)

Capital expenditure represents the total one-time investment required to get your cement block plant up and running. This is the initial cash outlay before you produce your first block. A comprehensive CAPEX budget must account for every detail to avoid unexpected shortfalls.

-

Machinery and Equipment: This is often the largest single expense. It includes the main block making machine (e.g., a QT10-15), the 콘크리트 배치 플랜트, the cement silo, the concrete mixer, forklifts, a front-end loader for aggregates, and all necessary molds. When obtaining quotes from suppliers, be sure to include the cost of shipping, insurance, import duties, and installation.

-

Land and Site Development: This includes the purchase or long-term lease of a suitable piece of land. You must also budget for site preparation, which may involve grading, paving, fencing, and constructing the necessary drainage systems.

-

Buildings and Infrastructure: This covers the cost of constructing the main factory shed to house the production line, an office building, a workshop for maintenance, a laboratory for quality testing, and shelters for the curing area. You also need to account for the installation of essential utilities: a high-capacity electrical connection, a reliable water supply (possibly including a borehole and water tower), and sanitation facilities.

-

Initial Spare Parts and Pallets: It is wise to purchase an initial inventory of critical spare parts for your machinery along with your main order. You will also need a large number of production pallets (steel or GMT composite). The quantity should be enough to accommodate at least two to three days of production to allow for curing time.

-

Pre-operational Expenses: This category includes costs for business registration, legal fees, permit applications, and any consulting fees for engineering or financial advice.

Summing these costs will give you a clear picture of the total investment needed. It is a standard practice to add a contingency fund of 10-15% to your total CAPEX budget to cover unforeseen costs.

Calculating Operational Expenditure (OPEX)

Operational expenditure represents the recurring costs of running your cement block plant on a daily, weekly, and monthly basis. Accurately forecasting your OPEX is crucial for setting your block prices and determining your break-even point.

-

원재료: This is your largest variable cost. Based on your target production volume and your mix designs, calculate the monthly consumption of cement, sand, aggregates, and any additives like fly ash.

-

노동: This includes the salaries and benefits for all your staff, from the plant manager and machine operators to the forklift drivers, general laborers, and administrative staff.

-

Utilities: Estimate your monthly bills for electricity (which can be substantial for a large production line), water, and internet/telephone services.

-

Fuel and Maintenance: This covers the diesel for your forklift and front-end loader, as well as the cost of lubricants, hydraulic oil, and replacement parts for routine machinery maintenance. A good rule of thumb is to budget a certain percentage of the machinery's value for annual maintenance.

-

Rent/Lease Payments: If you are leasing your land or buildings, this will be a fixed monthly cost.

-

Marketing and Sales: Include a budget for marketing activities, sales commissions, and transportation/delivery costs.

-

Insurance and Taxes: Account for property insurance, liability insurance, and any applicable business or property taxes.

Understanding your fixed costs (like rent and salaries) versus your variable costs (like raw materials) is essential for effective financial management.

Projecting Revenue and Calculating Return on Investment (ROI)

With your costs clearly defined, you can now project your revenue. This should be based on a realistic assessment of your production capacity and the market prices you identified during your initial research.

Start by calculating your maximum daily production capacity. For example, if your QT8-15 machine has a cycle time of 20 seconds and produces 8 blocks per cycle, you can calculate the hourly and daily output. However, it is prudent to base your initial revenue projections on a more conservative figure, perhaps 70-80% of the maximum capacity, to account for changeovers, maintenance, and other minor stoppages.

Multiply your projected daily sales volume by the average selling price per block to get your daily revenue. From there, you can calculate your monthly and annual revenue.

Gross Profit = Total Revenue – Cost of Goods Sold (primarily raw materials) Net Profit = Gross Profit – All Other Operational Expenses

With your net profit projected, you can calculate the Return on Investment (ROI), a key metric for any investor.

ROI (%) = (Annual Net Profit / Total Capital Expenditure) x 100

Another useful metric is the payback period:

Payback Period (Years) = Total Capital Expenditure / Annual Net Profit

This tells you how many years it will take for the business's profits to "pay back" the initial investment. A shorter payback period and a higher ROI indicate a more attractive investment.

Funding Avenues: Loans, Investors, and Grants

With a comprehensive business plan and detailed financial projections in hand, you are ready to seek funding. There are several potential avenues:

-

Commercial Banks: Many banks offer business loans for capital-intensive projects. They will require your detailed business plan and will often ask for some form of collateral. Your personal capital contribution (equity) will also be a significant factor in their decision.

-

Private Investors/Venture Capital: You could seek investment from individuals or firms who are interested in the construction or manufacturing sector. They will provide capital in exchange for an equity stake in your company. They will be highly focused on your projected ROI and the strength of your management team.

-

Government Programs and Grants: In some countries, governments offer special financing programs, low-interest loans, or even grants for new industrial enterprises, particularly those that create jobs or utilize sustainable technologies (like using fly ash). Research the economic development agencies in your country to see if your project qualifies.

-

공급업체 파이낸싱: Some machinery suppliers may offer financing options or flexible payment terms, which can help to ease the initial capital burden.

Often, the final funding package will be a combination of these sources: your own equity, a bank loan, and perhaps a small government grant. Your meticulously prepared financial plan will be your most powerful tool in these negotiations.

Step 6: Assembling Your Team and Ensuring Operational Readiness

The transition from a well-laid plan to a functioning, productive cement block plant is powered by people. Machinery and infrastructure provide the potential for production, but it is a skilled, motivated, and well-managed team that transforms that potential into reality. Assembling the right team is an investment as critical as the machinery itself. A state-of-the-art QT series machine can be rendered inefficient by an untrained operator, and production targets can be missed due to poor management or a lack of safety culture. This phase is about breathing life into the physical plant, establishing the human systems, protocols, and knowledge base that will ensure smooth, safe, and high-quality operations from day one and for years to come.

Hiring Skilled and Unskilled Labor

Your workforce will consist of a mix of skilled, semi-skilled, and unskilled labor. Each role is vital to the operational chain.

Skilled Labor:

- Plant Manager/Supervisor: This is a key leadership role. The ideal candidate will have experience in a manufacturing or construction environment, strong management skills, and a basic understanding of mechanical and electrical systems. They will be responsible for overseeing daily production, managing staff, ensuring quality control, and meeting production targets.

- Machine Operator/Technician: This individual (or small team) will be directly responsible for operating the main block making machine and the batching plant. They need to be technically inclined, attentive to detail, and capable of basic troubleshooting. Prior experience with hydraulic or automated machinery is a significant advantage. This person is the guardian of your most expensive asset.

Semi-Skilled Labor:

- Forklift and Front-End Loader Operators: These roles require certified operators who are proficient in safely and efficiently handling heavy equipment. The forklift operator is responsible for moving pallets of blocks, while the loader operator manages the raw material stockpiles. Their efficiency directly impacts the pace of the entire operation.

Unskilled Labor:

- General Laborers: This team will handle a variety of essential tasks, such as plant cleanup, assisting with mold changes, manually stacking cured blocks, and preparing orders for shipment. While the roles are "unskilled," reliability, a strong work ethic, and a willingness to follow safety procedures are crucial attributes.

When hiring, look for a combination of experience and attitude. In many cases, a motivated individual with a good attitude who is willing to learn can be more valuable than an experienced but complacent worker.

The Role of the Plant Manager and Technicians

Let's delve deeper into the two most critical skilled roles. The Plant Manager is the conductor of the orchestra. They are not just sitting in an office; they are on the plant floor, observing the workflow, identifying inefficiencies, and solving problems in real-time. They are the link between the business's financial goals and the physical act of production. Their responsibilities include creating production schedules, managing inventory of raw materials and finished goods, enforcing safety protocols, and generating daily production reports. A good plant manager fosters a culture of quality and accountability.

그리고 Machine Technician is the specialist. Their primary focus is the health and performance of the block making machine. They will be trained by the manufacturer's engineer during installation and will become your in-house expert. Their daily tasks include pre-start checks, monitoring the machine's operation during the shift, making fine adjustments to the PLC settings to optimize block quality, and performing routine maintenance like lubrication and cleaning. When a problem occurs, they are the first line of defense, diagnosing the issue—be it a hydraulic leak, a sensor malfunction, or a mechanical jam—and performing the necessary repairs. Investing in ongoing training for your technician is an investment in minimizing downtime.

Comprehensive Training Programs for Machine Operation

Even the most intuitive PLC touch screen cannot replace proper training. Your machinery supplier should provide comprehensive on-site training as part of the installation and commissioning package. This training is not just for the lead technician; the plant manager and any backup operators should also participate.

The training program should cover:

- Theory of Operation: Understanding how the hydraulic and vibration systems work in concert to produce a quality block.

- PLC Control System: A detailed walkthrough of the control interface, including how to start and stop the machine, select different block recipes, adjust parameters (like vibration time and pressure), and interpret error messages.

- Mold Changing: A practical, hands-on demonstration of the procedure for safely and efficiently changing molds to switch production to a different block type.

- Routine Maintenance: A detailed schedule and procedure for daily, weekly, and monthly maintenance tasks. This includes lubrication points, filter changes, and inspection of key components.

- Troubleshooting: Training on how to diagnose and resolve common operational problems.

Creating your own internal training manuals and checklists, based on the manufacturer's guidance, is a best practice. This ensures that knowledge is retained within the company and can be easily passed on to new employees.

Implementing Safety Protocols and Quality Control

A productive plant is a safe plant. A culture of safety must be embedded from the very beginning. This goes beyond simply providing personal protective equipment (PPE) like hard hats, safety glasses, steel-toed boots, and gloves.

Safety Protocols:

- Lockout/Tagout (LOTO): Implement a strict LOTO procedure for all machinery maintenance. This ensures that the equipment is de-energized and cannot be accidentally started while someone is working on it.

- Machine Guarding: Ensure all moving parts, belts, and chains are properly guarded to prevent accidents.

- Traffic Management: Designate clear pathways for forklifts and personnel to prevent collisions.

- Regular Safety Meetings: Hold brief daily or weekly meetings to discuss safety topics and review any near-miss incidents.

Quality Control (QC): Quality control is not something you do at the end of the line; it is a process that is integrated into every step.

- 원자재 검사: Visually inspect and perform simple tests on incoming raw materials.

- In-Process Checks: The machine operator should be constantly monitoring the green blocks as they are produced. They should regularly check the dimensions, appearance, and green strength of the blocks.

- Cured Block Testing: Establish a regular schedule for testing the compressive strength of your cured blocks. This involves taking sample blocks from production runs and crushing them in a compression testing machine. This data is vital. It proves the quality of your product to customers and provides essential feedback for optimizing your mix design. Keep detailed records of all test results.

By assembling a well-trained team and embedding robust safety and quality control systems into your daily operations, you ensure that your cement block plant not only produces blocks but produces them safely, efficiently, and to a standard that builds a reputation for excellence.

Step 7: Launch, Marketing, and Scaling Your Cement Block Plant

The culmination of extensive research, meticulous planning, and significant investment is the moment your cement block plant comes to life. The hum of the machinery, the sight of the first pallet of perfectly formed blocks, and the beginning of a bustling curing yard mark a major milestone. However, the launch is not the finish line; it is the starting line of a new race. The focus now shifts from construction and setup to production and commerce. Successfully launching, marketing, and scaling your operation requires a different set of strategies, centered on demonstrating quality, building relationships, and creating a sustainable commercial enterprise. This final phase is about transforming your production capacity into a steady stream of revenue and establishing your brand as a trusted name in the regional construction industry.

Initial Production Runs and Quality Assurance

Your first few weeks of operation should be treated as a "soft launch." The primary goal is not to maximize output but to perfect your process and validate your quality.

Begin with one or two of your most in-demand block types. Use these initial runs to fine-tune the parameters on your block making machine. Work closely with your machine technician to adjust vibration times, hydraulic pressure, and mix consistency to achieve the optimal balance of speed and quality. This is a period of learning and calibration.

During this phase, your quality control system is paramount. Visually inspect every batch of green blocks for defects like cracks or crumbling edges. More importantly, implement a rigorous testing schedule for your cured blocks. Take samples from each day's production and let them cure fully. Then, send them to an independent laboratory or use your own compression testing machine to verify their compressive strength.

Document these results meticulously. This data serves two purposes. First, it provides the feedback loop needed to confirm that your mix design and production process are yielding blocks that meet or exceed local building standards. Second, these certified test reports become your most powerful marketing tool. They are undeniable proof of your product's quality. Do not rush to market with untested products. Your reputation is built on the strength of your blocks, and it is worth taking the time to get it right from the very start.

Building a Customer Base: Contractors, Developers, and Retailers

With certified, high-quality blocks ready for sale, your focus shifts to customer acquisition. Your target market can be segmented into several key groups:

-

Small to Medium-Sized Contractors: These are often the easiest to approach initially. They work on smaller residential or commercial projects and frequently require a steady supply of standard blocks. Building personal relationships with these contractors can lead to loyal, repeat business. Offer them a tour of your new, modern plant to showcase your professional operation.

-

Large Construction Companies and Developers: Securing a contract with a large developer can provide a massive, stable source of revenue. However, getting their business is more challenging. They will have stringent quality requirements, demand competitive pricing, and may already have long-standing relationships with other suppliers. Your certified test reports, professional operation, and ability to guarantee large-volume, on-time delivery will be your key selling points. You may need to go through a formal vendor approval process.

-

Building Material Retailers and Wholesalers: Partnering with local hardware stores and building material suppliers can extend your market reach. They can sell your blocks to individual homebuilders and small-scale DIY customers. This channel provides a different, more distributed revenue stream.

-

정부 프로젝트: Keep an eye on public tenders for infrastructure projects like schools, public housing, or roadworks. While the procurement process can be bureaucratic, securing a government contract can be very lucrative and enhance your company's credibility.

Your initial marketing efforts should be direct and relationship-focused. Visit active construction sites in your area, introduce yourself, and leave behind a company profile along with a copy of your block test certificates. Offer competitive introductory pricing or free delivery for the first order to entice new customers to try your product.

Digital Marketing Strategies for a B2B Business

While traditional relationship-based selling is key in the construction industry, a digital presence is increasingly important, even for a B2B business like a cement block plant. It helps to build credibility and reach potential customers who are researching suppliers online.

- Professional Website: Your website is your digital storefront. It should be clean, professional, and easy to navigate. It must feature high-quality photos and videos of your plant and machinery in action. Most importantly, it should have a dedicated "Products" section with clear specifications for each block type you produce, including dimensions and compressive strength data. A "Projects" or "Case Studies" section showcasing where your blocks have been used is also very effective.

- Local SEO: Optimize your website for local search terms like "cement block supplier in [Your City]" or "hollow block manufacturer near me." This involves creating a Google Business Profile and ensuring your contact information is consistent across the web.

- B2B Platforms: Listing your company on B2B platforms like Alibaba or regional construction industry directories can generate leads from outside your immediate local area.

- Content Marketing: You could create simple blog posts or short videos that offer value to your target audience. Topics could include "How to Check the Quality of a Cement Block" or "The Benefits of Using Interlocking Pavers." This positions you as an expert, not just a seller.

Planning for Future Expansion and Diversification

A successful business is always looking forward. Once your initial operation is stable and profitable, you can begin to plan for growth.

Scaling Production: If demand consistently outstrips your supply, your first consideration might be to increase production. This could involve adding a second shift to your daily operations or, in the long term, investing in a second, larger production line. The data from your existing operation will be invaluable in making this decision.

Product Diversification: Your versatile block making machine allows for easy diversification. By investing in new molds, you can expand your product catalog.

- Value-Added Products: Move into higher-margin items like colored interlocking pavers. This involves adding a face mix unit to your block machine and sourcing color pigments, but the potential for increased profitability is significant.

- Architectural Blocks: Produce decorative screen blocks, textured facade blocks, or other architectural concrete masonry units (CMUs) that cater to more design-focused projects.

- Specialized Products: As discussed earlier, you could invest in a static hydraulic press to produce high-density curb-stones, retaining wall blocks, or other specialized civil engineering products.

By continuously reinvesting in your capabilities and responding to market opportunities, your cement block plant can evolve from a single-product startup into a diversified and dominant force in your regional building materials market.

자주 묻는 질문

How much land is required to set up a cement block plant?

The amount of land needed depends on the scale of your operation. A small-scale plant might require a minimum of 2,000-3,000 square meters. A medium to large-scale fully automatic plant would ideally need 5,000 to 10,000 square meters or more. This space must accommodate raw material storage bays, the main production shed, a large curing yard, storage for finished products, office space, and vehicle movement areas.

What is the typical lifespan of a block machine mold?

The lifespan of a mold is heavily dependent on the quality of the steel and the heat treatment process used by the manufacturer, as well as the abrasiveness of your aggregates. A high-quality mold, made from carburized manganese steel, can typically produce between 80,000 to 150,000 cycles. Regular cleaning and proper maintenance can significantly extend its life.

Can I use local sand and stone for my concrete mix?

Yes, using local raw materials is the most economical approach. However, it is absolutely essential to test these materials for quality. The sand and stone must be clean, hard, and free from impurities like clay, silt, and organic matter, as these can severely weaken the blocks. You should have your local aggregates tested by a lab before finalizing your mix design.

How many workers are needed for a fully automatic block plant?

A key advantage of a fully automatic line is the reduced labor requirement. A typical plant, including a batching plant, block machine, and stacker, can be operated by a small team of 3 to 5 people per shift. This would usually include a front-end loader operator, a control room/machine operator, a forklift driver, and one or two general assistants.

What is the main difference between a hollow block and a solid block?

A hollow block has one or more large voids or cores, which reduces its weight and improves its thermal and sound insulation properties. They are primarily used for partition walls and infill walls. A solid block has no voids and is much denser and heavier. It offers higher compressive strength and is used for load-bearing walls and structural applications where strength is the primary concern.

How long does it take for a cement block to reach its full strength?

Concrete gains strength over time through a process called hydration. While a block can be handled within 24 hours, it typically reaches about 60-70% of its final design strength in 7 days. The standard industry practice is to wait 28 days for the block to cure fully and reach its specified compressive strength.

Is a cement block business profitable in 2025?

The profitability is highly dependent on local market conditions, raw material costs, and operational efficiency. However, with the ongoing construction booms in many parts of Southeast Asia and the Middle East, the demand for building materials like cement blocks is strong. A well-managed plant with modern, efficient machinery and a focus on quality can be a very profitable venture.

결론

The journey to establishing a thriving cement block plant is a comprehensive endeavor, blending sharp business acumen with a solid understanding of engineering and materials science. As we have explored through this seven-step guide, success is not a matter of chance but the result of deliberate and informed action. It begins with the foundational work of understanding the specific needs of your local market and meticulously charting a financial course. The selection of the right machinery, exemplified by the versatile and efficient QT series, stands as a pivotal decision that will define your production capabilities for years to come.

An efficient plant layout, coupled with a reliable supply of quality-tested raw materials, forms the operational backbone of the enterprise. Yet, these physical assets are only brought to their full potential by a well-trained and safety-conscious team. The final steps of launching, marketing, and scaling are where the manufactured product is transformed into commercial success, building a brand reputation founded on the tangible quality and strength of every block produced. For entrepreneurs in Southeast Asia and the Middle East, the path is clear. The demand is present, and the technology is accessible. By approaching this venture with diligence, a commitment to quality, and a strategic vision for the future, you can build more than just blocks—you can build a lasting and prosperous business that contributes to the very fabric of your region's growth.

참조

Hongfa Machine. (2025). Concrete block and brick making machine manufacturer. Retrieved from

Hongfa Machinery. (n.d.). Block Machine. Retrieved from

Huatong Machinery. (2025). Qt10-15automatic cement block machine block making machine concrete block machine. Made-in-China.com. Retrieved from

Linyi Chuangyun International Trading Co., Ltd. (n.d.). Full automatic hot selling qt 4-25 concrete block making machines. Made-in-China.com. Retrieved from

Mehta, P. K., & Monteiro, P. J. M. (2014). Concrete: Microstructure, properties, and materials (4th ed.). McGraw-Hill Education.

Neville, A. M. (2011). 콘크리트의 특성 (5 판). 피어슨.

Portland Cement Association. (n.d.). Concrete technology. Retrieved from

Siddique, R., & Khan, M. I. (2011). Supplementary cementing materials. Springer.

Taylor, H. F. W. (1997). Cement chemistry (2nd ed.). Thomas Telford Publishing. https://doi.org/10.1680/cc.25929

United Nations. (2022). World economic situation and prospects 2022. Department of Economic and Social Affairs. Retrieved from