Maximize Your ROI: 5 Actionable Steps for Effective Block Machine Training in 2025

November 5, 2025

Abstract

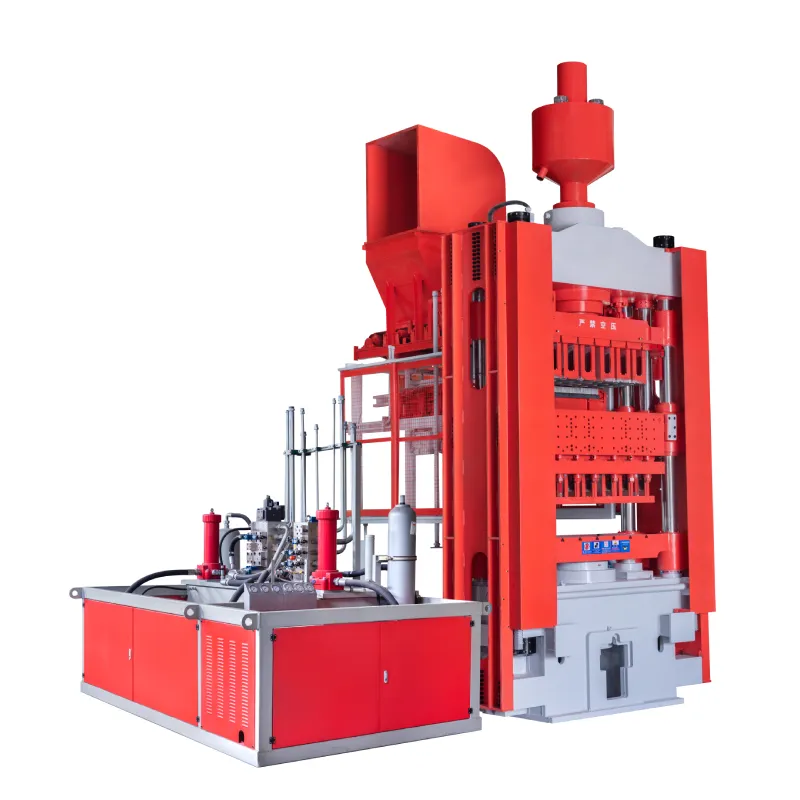

Effective block machine training is a foundational pillar for success in the modern construction materials industry. This document examines the multifaceted process of developing operator proficiency for equipment such as the QT series fully automatic concrete block making machines and static hydraulic block pressing machines. A comprehensive training regimen transcends mere operational instructions; it must integrate a deep understanding of material science, systematic operational protocols, proactive maintenance philosophies, and stringent safety standards. The analysis suggests that a structured, five-step approach, beginning with foundational knowledge and progressing through operational mastery, maintenance culture, safety protocols, and continuous improvement, provides the most robust framework. Such a program directly impacts key performance indicators, including production efficiency, product quality, and operational uptime. The ultimate objective of such training is to transform operators from simple machine minders into skilled technicians who contribute significantly to the plant's overall productivity and profitability, thereby maximizing the return on investment in capital equipment.

Key Takeaways

- Develop a structured curriculum for block machine training, starting with fundamentals and progressing to advanced skills.

- Integrate proactive maintenance schedules into daily operations to drastically reduce costly equipment downtime.

- Enforce strict adherence to Lockout/Tagout (LOTO) procedures to ensure operator safety during maintenance.

- Mastering the science of the concrete mix is as vital as understanding the machine's mechanical functions.

- Track key performance indicators like uptime and waste reduction to measure training effectiveness and ROI.

- Implement a tiered skill system to build a versatile and resilient operational team.

- Continuous improvement and feedback loops are essential for long-term operational excellence.

Table of Contents

- Building a Foundational Knowledge Base

- Mastering Safe and Efficient Daily Operations

- Implementing a Proactive Maintenance Culture

- Cultivating an Unshakeable Safety-First Environment

- Leveraging Advanced Training and Continuous Improvement

- Frequently Asked Questions (FAQ)

- Conclusion

- References

Building a Foundational Knowledge Base

The journey toward mastery of any complex piece of industrial machinery does not begin with the flick of a switch or the press of a button. It starts with a quiet, deliberate process of understanding. To approach a modern concrete block making machine without this foundational knowledge is akin to a pilot entering a cockpit with no grasp of aerodynamics; the potential for inefficiency and danger is immense. Effective block machine training, therefore, is rooted in building a robust intellectual framework before hands are ever laid upon the controls. This initial phase is about deconstructing the machine, not physically, but conceptually, into its constituent parts and principles. It involves learning its language, understanding the materials it consumes, and respecting the documentation that serves as its primary text. This is the bedrock upon which all subsequent operational skills and safety consciousness are built. Without this firm footing, any training becomes a precarious structure, liable to collapse under the pressure of real-world production demands.

Understanding the Heart of the Machine: Core Components and Functions

To truly command a machine, one must first understand its anatomy. A QT series fully automatic block machine or a static hydraulic press is a marvel of integrated systems, each performing a specific role in a highly synchronized dance of production. Think of the machine not as a single entity, but as a team of specialists working together.

The hydraulic system is the muscle. It is the source of the immense power required to compact the concrete mix into a dense, strong block. It consists of a motor, a pump, hydraulic oil, valves, cylinders, and hoses. The pump, powered by the electric motor, pressurizes the oil. This pressurized oil is then directed by solenoid valves into hydraulic cylinders, which extend or retract to press the mould, eject the finished blocks, and power other moving parts. Understanding this system means appreciating the physics of Pascal's law—how pressure applied to a fluid in a closed container is transmitted equally throughout. An operator who grasps this will intuitively understand why a small leak in a hose can lead to a significant loss of pressing force, resulting in weak, substandard blocks. They will know that the hydraulic oil is not just a fluid; it is the lifeblood of the machine's power, and its cleanliness and temperature are paramount.

The Programmable Logic Controller (PLC) is the brain. Housed within the main electrical cabinet, this industrial computer is the central nervous system that orchestrates the entire production cycle. It receives input signals from a host of sensors—proximity sensors that detect the pallet's position, limit switches that confirm a component has reached its destination, pressure sensors that monitor the hydraulic system. Based on its programming, the PLC processes these inputs and sends output signals to activate motors, solenoids, and vibrators in a precise sequence. For an operator, the PLC's control panel is the primary human-machine interface (HMI). Learning to navigate its screens, interpret its alerts, and adjust its parameters is like learning to communicate directly with the machine's mind. A well-trained operator does not just see an error code; they understand what the PLC is trying to tell them about a specific sensor or actuator, allowing for rapid diagnosis.

The mould assembly is the artist and the shape-giver. It is the component that defines the final product. Comprising the mould box and the tamper head (or pressure head), its precision is non-negotiable. The concrete mix is fed into the mould box, and the tamper head descends to compact it. The quality of the mould—its dimensional accuracy, its hardness, and the smoothness of its surfaces—directly translates to the quality and uniformity of the blocks. An operator must learn to respect the mould as a high-precision tool. They must understand the process of mould changes, the importance of meticulous cleaning to prevent concrete buildup that can mar the block's surface, and the subtle adjustments in tamper head height that can affect the final block dimensions.

| Component System | Analogy | Key Operator Focus | Consequence of Neglect |

|---|---|---|---|

| Hydraulic System | The Muscle | Fluid level, temperature, leaks, pressure gauges | Loss of compaction force, weak blocks, pump failure |

| PLC & Control System | The Brain | HMI alerts, sensor status, cycle parameters | Incorrect sequencing, production halts, misdiagnosis |

| Mould Assembly | The Artist | Cleanliness, alignment, wear and tear | Deformed blocks, poor surface finish, dimensional errors |

| Material Batching/Feeding | The Stomach | Aggregate moisture, mix consistency, feed rate | Inconsistent block strength, material waste, machine jams |

| Vibration System | The Heartbeat | Vibration frequency, amplitude, synchronization | Poor compaction, porous blocks, reduced strength |

The Science of the Mix: Raw Material Properties and Proportions

A block making machine, no matter how advanced, can only work with the material it is given. The creation of a high-quality concrete block is a chemical and physical process, and the operator is, in a very real sense, a practical chemist. The recipe—the precise mix design—is the soul of the final product. A comprehensive block machine training program must dedicate significant time to the science of the mix.

The primary ingredients are aggregates (sand and crushed stone), a cementitious binder (usually Portland cement), and water. The aggregates form the structural skeleton of the block. Their size, shape, and grading (the distribution of different particle sizes) are of immense importance. A well-graded aggregate mix, with a good balance of fine and coarse particles, will require less cement paste to fill the voids, leading to a stronger, more economical block. The operator must learn to visually inspect the aggregate stockpiles. Is the sand too fine? Is the crushed stone contaminated with clay or organic matter? They must also understand the concept of moisture content. Sand that is wet from rain carries extra water that is not accounted for in the batching computer. An operator trained to recognize this can make adjustments, preventing a mix that is too soupy and leads to slumping blocks.

Cement is the glue that binds the aggregates together. When mixed with water, it undergoes a chemical reaction called hydration, forming a crystalline structure that locks the aggregates in place. The operator needs to understand the water-cement ratio, a fundamental concept in concrete technology. Too little water, and the hydration process will be incomplete, resulting in a weak, brittle block. Too much water, and the paste becomes weak, and the finished blocks will have low compressive strength and may slump or deform upon ejection from the mould. The ideal mix for a block machine is a "zero-slump" or "low-slump" concrete—a very dry, stiff consistency often described as feeling like damp earth.

The operator's role is to be the guardian of this consistency. They must learn to perform simple, effective field tests. The "snowball" test, for instance, involves grabbing a handful of the mix from the conveyor belt and squeezing it. Does it hold its shape like a snowball without crumbling or dripping water? This tactile feedback, developed through experience and guided by proper training, is often faster and more practical for real-time adjustments than laboratory testing. A proficient operator can tell by the sound of the mixer, the appearance of the mix, and the feel of a sample whether the batch is right, long before it even reaches the block machine's feed box.

Reading the Blueprints: Schematics and Manuals as Your Guide

In the age of digital interfaces and intuitive controls, there is a temptation to overlook the humble instruction manual. This is a grave error. The manufacturer's manual, along with the electrical and hydraulic schematics, is the definitive source of truth for the machine. A core component of any serious block machine training is teaching operators not just to consult the manual when something breaks, but to use it as a primary learning tool.

Think of the manual as a detailed atlas for a new country you are exploring. You would not try to navigate without it. The manual should be introduced on the first day of training. Trainees should be guided through its structure: the safety warnings section, the specifications, the installation guide, the operational procedures, the maintenance schedule, and the troubleshooting charts. Instead of a dry reading assignment, this should be an interactive process. For example, when discussing the hydraulic system, have the trainees open the manual to the hydraulic schematic. Help them trace the lines on the page and then find the corresponding physical components on the machine—the pump, the main relief valve, the directional control valves, the cylinders. This bridges the gap between the abstract diagram and the physical reality.

The troubleshooting section is particularly valuable. It is often structured as a logical decision tree. If the symptom is "Machine cycle will not start," the manual might suggest a sequence of checks: Is the emergency stop button engaged? Is the main power on? Is the PLC showing an error? Is a specific sensor blocked? By working through these scenarios in a controlled training environment, operators learn a systematic approach to problem-solving (Hempenstall, 2025). They move away from panicked guesswork and toward methodical diagnosis. They learn that the manual is not a sign of failure, but a professional tool for resolution. This empowers them, reduces their reliance on external technicians for simple faults, and significantly shortens downtime.

Mastering Safe and Efficient Daily Operations

With a solid foundation of knowledge about the machine's components, materials, and documentation, the trainee is ready to transition from theory to practice. This phase of block machine training is about developing the muscle memory and situational awareness required for the daily rhythm of production. It is where abstract concepts become tangible skills. Mastering daily operations is not about simply repeating a sequence of button presses; it is about cultivating a deep, intuitive connection with the machine. It involves developing a sense of its normal operational state—its sounds, its vibrations, its pace—so that any deviation is immediately noticeable. This mastery is a blend of disciplined routine and adaptive intelligence, ensuring that each production cycle is not only productive but also safe and sustainable. The goal is to transform the operator into a conductor who leads the mechanical orchestra, ensuring every movement is precise, efficient, and harmonious.

The Pre-Flight Check: A Systematic Start-up Routine

The first hour of the production day often determines the success of the next eight. A rushed or haphazard start can lead to unforeseen stoppages, poor quality products, and even safety incidents. A professional operator, much like an airline pilot conducting a pre-flight inspection, begins their day with a systematic and unhurried start-up routine. This is not a chore; it is a professional discipline and a critical part of a comprehensive block machine training curriculum.

Imagine the operator arriving before the main production begins. The first action is not to power on the machine, but to walk around it. This is a sensory inspection. The eyes scan for any obvious issues: a loose bolt on the mould, a frayed wire, a puddle of hydraulic oil on the floor, or debris left on the conveyor from the previous shift. The hands might check the tension of a drive belt or ensure safety guards are securely in place. The nose might detect the faint, acrid smell of an overheating electrical component or the tell-tale scent of leaking hydraulic fluid.

Once this physical walk-around is complete, the focus shifts to key systems. The operator checks the hydraulic oil level in the tank's sight glass—is it within the optimal range? They might glance at the pressure gauge on the pneumatic system's filter-regulator-lubricator (FRL) unit to ensure it is set correctly. They will verify that the aggregate hoppers are sufficiently filled for the day's initial run and that the cement silo has an adequate supply.

Only after these external checks are complete does the operator power up the main electrical panel and the PLC. They watch the HMI screen as it boots up, observing for any initial error messages. Before starting the automatic cycle, they will test critical functions in manual mode. They might inch the pallet feeder forward and back, test the movement of the tamper head, and, most importantly, test every single emergency stop button. This confirms that the ultimate safety controls are functional. This entire process, which may take only 10-15 minutes, is an investment that pays dividends throughout the day by catching small problems before they become catastrophic failures.

The Art of the Cycle: Optimizing Production Flow

Once the machine is running in automatic mode, the operator's role shifts from inspector to overseer and optimizer. A novice operator might see their job as simply watching the machine run and pressing the stop button if something goes wrong. A master operator, however, is actively engaged, using all their senses to monitor and fine-tune the production flow.

The sound of the machine is a rich source of information. The powerful, low-frequency hum of the vibrators during compaction, the sharp 'thump' of the tamper head hitting its stops, the smooth whir of the conveyor moving finished blocks—these sounds form a familiar rhythm. An operator trained to listen will instantly detect a change in this rhythm. A new squeal might indicate a bearing that needs lubrication. A 'clanging' noise from the mixer could mean a foreign object has fallen in. A change in the vibration sound might signal an imbalance or a loose motor mounting.

Visual monitoring is equally important. The operator watches the consistency of the concrete mix as it comes down the feed belt. They observe the feed box as it fills the mould, ensuring an even distribution. They watch the blocks as they are ejected onto the pallet. Are the edges sharp and well-defined? Is the top surface (the 'frog') consistent? Are there any cracks or signs of slumping? This constant visual feedback allows for micro-adjustments in real-time. If the block edges are crumbling, it might indicate the mix is too dry. If the blocks are slumping, the mix is too wet. If the block height is inconsistent, perhaps the feed box is not filling the mould evenly.

This is where the 'art' comes in. The operator learns to connect an observed effect with a probable cause and a potential solution. For example, if the block height is slightly too low, they might know to increase the material feed time parameter on the HMI by a fraction of a second. If the blocks seem too porous, they might slightly increase the vibration time. This level of control, which goes beyond the basic training manual, is what separates an average production line from a highly efficient one. It is a dynamic process of observation, analysis, and adjustment that maximizes output, minimizes waste, and ensures every block meets the required quality standards.

The Shutdown Protocol: Securing the Machine and the Workspace

Just as a disciplined start-up is vital, a thorough shutdown protocol is essential for the long-term health of the machine and the safety of the work environment. The end of the production day is not a race to the exit. It is the final act of professional responsibility for the shift. Effective block machine training must emphasize that putting the machine away properly is as important as running it efficiently.

The first step in the shutdown process is to stop the flow of new material. The mixer and the aggregate batcher are emptied and turned off. The machine is then allowed to complete its final cycle, clearing any remaining mix from the feed box and mould. It is a cardinal sin to leave concrete mix in the machine overnight. The mix will harden, and the task of removing it the next day can be arduous, time-consuming, and can even damage the precision surfaces of the mould and feed box.

Once the machine is clear of material, a comprehensive cleaning process begins. High-pressure air is used to blow dust and debris off the machine's surfaces. Scrapers and brushes are used to remove any concrete that has adhered to the mould, tamper head, and pallet feeder. This is not just about aesthetics; it is about function. A clean machine is a machine where potential problems like cracks or leaks are visible. It is a machine where sensors are not obscured by dirt and moving parts are not impeded by hardened concrete.

After cleaning, a final mechanical and safety check is performed. The operator might perform a quick visual inspection, looking for anything that may have loosened or become damaged during the day's production. They will ensure all tools and cleaning equipment are returned to their designated storage locations, leaving the area clear and safe for the maintenance crew or the next shift. Finally, the machine is powered down in the correct sequence as specified by the manufacturer. This often involves turning off the control power first, followed by the main electrical disconnect. This methodical shutdown not only prevents damage but also instills a culture of orderliness and care, which is the hallmark of a professional and safe manufacturing operation.

Implementing a Proactive Maintenance Culture

In the world of manufacturing, there are two opposing philosophies regarding equipment care: the reactive and the proactive. The reactive approach is one of "if it ain't broke, don't fix it." Maintenance is seen as an unfortunate necessity, performed only when a component fails and the production line grinds to a halt. The proactive approach, in contrast, views maintenance not as a cost but as a strategic investment in reliability. It is a culture, not just a department. For a facility operating capital-intensive equipment like modern fully automatic block making lines, adopting a proactive maintenance culture is arguably the single most impactful step towards ensuring long-term profitability. A robust block machine training program must be the primary vehicle for instilling this culture. It must teach operators to see themselves not just as users of the machine, but as its frontline guardians, responsible for its health and longevity.

From Reactive to Predictive: The Maintenance Mindset

Let us consider a simple, relatable analogy. Imagine you own a car. A reactive owner ignores the oil change reminder, drives on tires until they are bald, and only visits a mechanic when the engine makes a terrible noise or the car refuses to start. The result is predictable: a catastrophic failure on the highway, an expensive tow, a massive repair bill, and significant disruption to their life. A proactive owner, however, follows the recommended service schedule. They change the oil regularly, rotate the tires, and replace worn brake pads before they fail. Their costs are smaller, more predictable, and they experience far greater reliability.

The exact same principle applies to a concrete block making machine, but the stakes are much higher. A sudden breakdown of a key component, like the main hydraulic pump, does not just mean a repair bill. It means the entire production line stops. Orders are delayed, delivery trucks are sent away empty, employees are idle, and customer relationships are jeopardized. The total cost of this unplanned downtime can be many times the cost of the replacement part itself.

A proactive maintenance mindset, fostered through effective block machine training, fundamentally changes the operator's perspective. They learn to look for leading indicators of failure. For example, they are taught that a hydraulic pump that is suddenly running hotter than usual or making a new whining sound is not a problem for tomorrow; it is a warning sign that needs to be investigated today. They learn that a regular sample of hydraulic oil can be sent for analysis, which can reveal the presence of microscopic metal particles, indicating internal wear long before the component fails. This shifts the paradigm from reactive (fixing what is broken) to proactive (addressing wear before it becomes a failure) and even to predictive (using data and trends to forecast when a failure is likely to occur). This mindset transforms maintenance from a source of expense and frustration into a powerful tool for maximizing machine uptime and profitability.

The Schedule of Care: Daily, Weekly, and Monthly Maintenance Tasks

A proactive maintenance culture cannot thrive on good intentions alone; it requires structure. A detailed, written maintenance schedule is the roadmap that guides the entire team. This schedule should be a central part of any block machine training curriculum, and it should be physically posted near the machine for constant reference. The tasks are typically broken down by frequency, creating layers of care that ensure nothing is overlooked.

| Frequency | Task Category | Specific Examples | Rationale |

|---|---|---|---|

| Daily | Cleaning & Inspection | Remove concrete buildup from mould/tamper. Clean sensors. Check hydraulic fluid level and temperature. Inspect for leaks (oil, water, air). | Prevents material accumulation that affects quality. Ensures reliable sensor function. Catches minor issues before they escalate. |

| Weekly | Lubrication & Adjustment | Grease all specified lubrication points (bearings, slides). Check tension and condition of V-belts and chains. Inspect and tighten any loose bolts, especially on the mould and vibrators. | Reduces friction and wear on moving parts. Prevents power loss and component failure. Mitigates vibration-induced loosening. |

| Monthly | Filter & Fluid Checks | Replace hydraulic return line filter. Inspect/clean hydraulic tank suction strainer and air breather. Check for water in the pneumatic system and drain as needed. | Maintains hydraulic fluid cleanliness, which is critical for pump and valve life. Ensures clean, dry air for pneumatic components. |

| Quarterly/Annually | In-depth Inspection & Replacement | Take hydraulic oil sample for analysis. Inspect wear plates in mould and mixer. Check electrical connections in control cabinet for tightness. Replace high-wear components (e.g., rubber buffers). | Predictive analysis of oil can prevent catastrophic hydraulic failure. Manages wear on costly components. Prevents electrical faults. |

This scheduled approach demystifies maintenance. It breaks a large, intimidating responsibility into small, manageable daily, weekly, and monthly tasks. When an operator is trained not just on how to perform these tasks but why they are important—for example, explaining that a $50 hydraulic filter protects a $5,000 pump—they are far more likely to perform them with diligence and care. This schedule becomes the backbone of the plant's reliability program.

Basic Troubleshooting for Common Issues

Even with the best proactive maintenance program, minor issues will occasionally arise. A key goal of block machine training is to empower operators to become first-level troubleshooters. This capability dramatically reduces downtime, as the machine can often be brought back online in minutes, without having to wait for a specialized maintenance technician to become available.

The key to effective troubleshooting is a logical, systematic approach, much like a doctor diagnosing an illness. Guesswork and randomly changing parameters should be strongly discouraged. Instead, operators should be trained to follow a "symptom-to-cause" methodology.

Let's take a common issue: The produced blocks are too short. A trained operator's mental checklist would look something like this:

- Material Issue? Is the concrete mix suddenly wetter than usual? A wetter mix will compact more, resulting in a shorter block. I will perform a quick "snowball" test. If the mix is the issue, I will adjust the water in the next batch.

- Feed Issue? I will watch the feed box. Is it filling the mould completely and evenly on every cycle? Perhaps a piece of debris is partially blocking the feed gate. If so, I will safely clear the obstruction.

- Machine Parameter Issue? Has someone inadvertently changed the material feed time or the mould filling parameters on the HMI? I will check the settings against the standard recipe for this product.

- Mechanical Issue? Is it possible the lower stops that define the block height have come loose or worn down? I will perform a quick visual inspection of the mechanical stops.

This structured thinking prevents panic and focuses the operator's efforts. A similar logic can be applied to other common problems like cracked blocks (often related to mix design or ejection timing), inconsistent textures (often related to vibration), or cycle stoppages (often related to a single faulty sensor). By providing operators with these basic diagnostic frameworks for a handful of the most common faults, a company equips its team to handle the vast majority of daily operational hiccups independently. This not only boosts efficiency but also increases the operator's sense of ownership and professional competence.

Cultivating an Unshakeable Safety-First Environment

In the high-energy environment of a concrete block plant, where powerful hydraulic forces, heavy moving components, and electrical systems converge, there can be no higher priority than the physical well-being of the personnel. A profitable plant is a safe plant, and a safe plant is the result of a deeply ingrained culture, not just a set of rules posted on a wall. This culture begins with, and is sustained by, comprehensive block machine training. To treat safety as a mere add-on to operational training is a fundamental error. Instead, safety must be woven into the very fabric of every procedure, every lesson, and every action. It is a mindset that must be cultivated until it becomes an automatic reflex. The objective is to create an environment where every team member feels not only empowered but also obligated to be a guardian of their own safety and the safety of their colleagues.

Identifying the Hazards: Mechanical, Electrical, and Material Risks

The first step toward mitigating risk is to develop a profound and specific understanding of what the risks are. A vague instruction to "be careful" is functionally useless. Effective safety training requires a direct and unflinching examination of the specific hazards presented by a concrete block making machine.

Mechanical hazards are often the most obvious. These are the risks associated with moving parts. The points where a moving part comes near a stationary part or another moving part are called pinch points. On a block machine, these exist in numerous places: the conveyor system where the pallet moves under the frame, the scissor mechanism of a stacker, and the area around the mould and tamper head during the pressing cycle. Operators must be trained to identify these specific locations and to understand that safety guards are not optional inconveniences but essential shields. Another significant mechanical hazard is stored energy. A hydraulic system, even when the pump is off, can hold immense pressure. Training must emphasize that this pressure must be safely released before any maintenance is attempted on a hose or cylinder.

Electrical hazards are less visible but equally lethal. The main control cabinet contains high-voltage components. Operators must be trained to understand that only qualified and authorized electricians should ever open these panels. They must know the location of the main electrical disconnect switch and understand its purpose: to completely isolate the machine from its power source. They should also be taught to inspect electrical cords and cables for damage, such as cracks or exposed wires, and to report them immediately.

Material and environmental hazards are also a serious concern. The fine dust created from cement, sand, and cured concrete can contain respirable crystalline silica. Prolonged inhalation of this dust can lead to silicosis, a severe and incurable lung disease. Therefore, training must cover the importance of dust control measures (such as water spray systems) and the correct use of personal respiratory protection. Noise is another hazard; the vibration and compaction process can generate noise levels that can cause permanent hearing damage over time. The proper use of hearing protection is non-negotiable.

Personal Protective Equipment (PPE): Your First Line of Defense

Personal Protective Equipment is the last line of defense when engineering controls and safe work practices are not enough to eliminate a hazard. However, it is the operator's most personal and immediate form of protection. Block machine training must go beyond simply listing the required PPE; it must explain the why behind each item to ensure compliance and proper use.

- Hard Hats: While a block machine is typically installed indoors, the surrounding plant environment is often a construction zone. Hard hats protect against falling objects, whether it's a tool dropped from a mezzanine or a piece of aggregate from an overhead conveyor.

- Steel-Toed Safety Boots: These are indispensable. They protect the feet from the obvious risk of a heavy block or a piece of equipment falling on them. They also often feature puncture-resistant soles to protect against sharp debris on the floor.

- Safety Glasses with Side Shields: The eyes are incredibly vulnerable. Concrete spatter, flying debris from cleaning with compressed air, or a ruptured hydraulic line can all cause permanent eye injury. Training should stress that safety glasses must be worn at all times in the production area, not just when performing a specific task.

- Gloves: The type of glove depends on the task. Heavy-duty leather or coated gloves should be used when handling rough concrete blocks to prevent cuts and abrasions. When performing maintenance involving oils or chemicals, nitrile or other chemical-resistant gloves are necessary to protect the skin.

- Hearing Protection: Earmuffs or earplugs are required to reduce the machine's operational noise to a safe decibel level. The training should explain that hearing loss is gradual, cumulative, and irreversible.

- Respirators: In areas where dust cannot be fully controlled, a properly fitted respirator (such as an N95 or better) is vital to protect the lungs from silica dust. Operators must be trained on how to perform a seal check each time they put on their respirator to ensure it is effective.

Explaining that a piece of PPE is not a uniform, but a tool designed to prevent a specific, life-altering injury, creates a much more powerful and lasting safety message.

Emergency Procedures and Lockout/Tagout (LOTO)

No amount of proactive care can eliminate all possibilities of an incident. Therefore, every operator must be thoroughly trained on what to do in an emergency. This includes knowing the location of fire extinguishers and how to use them, understanding the plant's evacuation routes, and knowing who to contact for medical assistance. The most critical emergency procedure specific to the machinery itself, however, is the Emergency Stop. Operators must build the muscle memory to hit the nearest red, mushroom-shaped E-stop button without a moment's hesitation if they see a dangerous situation developing. They must also be trained that an E-stop is for emergencies only, not for a normal shutdown.

Perhaps the single most important life-saving procedure in any industrial setting is Lockout/Tagout (LOTO). This procedure is designed to protect workers from the unexpected startup of a machine or the release of stored energy during maintenance or servicing. The concept is simple but must be followed with absolute rigidity.

The LOTO process, which must be practiced physically during block machine training, involves these steps:

- Announce the shutdown: The person performing the maintenance informs all affected operators that the machine is being shut down for service.

- Shut down the machine: The machine is stopped using the normal shutdown procedure.

- Isolate all energy sources: The main electrical disconnect is moved to the "off" position. If there are hydraulic or pneumatic lines feeding the machine, the valves are closed.

- Apply Lockout/Tagout devices: The person performing the work places their personal lock on the electrical disconnect lever in the "off" position. They then attach a tag that identifies who they are and why the machine is locked out. Every person working on the machine must apply their own lock.

- Release stored energy: The hydraulic pressure is bled off by actuating the controls. Any suspended parts are lowered or blocked.

- Verify isolation: The final, crucial step is to try to start the machine by pressing the "start" button. If the LOTO procedure has been done correctly, nothing will happen. This confirms that the machine is in a zero-energy state and is safe to work on.

Training must emphasize that only the person who placed a lock is authorized to remove it. This simple, robust system prevents one worker from re-energizing a machine while another is still inside it, performing a repair. It is a procedure that leaves no room for error and is a cornerstone of a truly safe workplace.

Leveraging Advanced Training and Continuous Improvement

Reaching a state of proficiency in daily operations, maintenance, and safety is a significant achievement, but it should not be the final destination. In the competitive landscape of 2025, the most successful enterprises are those that embrace a philosophy of continuous improvement. This means constantly seeking ways to become more efficient, safer, and more productive. For a concrete block manufacturing plant, this philosophy is powered by advanced training and the systematic use of feedback. It involves looking beyond the current operational horizon, incorporating new technologies and methodologies, and building a team that is not just competent but also resilient and adaptable. This final stage of block machine training is about transforming a proficient operation into a world-class one, ensuring a lasting return on the investment in both machinery and people.

The Role of Simulators and Modern Training Aids

Traditional on-the-job training is indispensable, but it has its limitations. Training a new operator on a live production machine can be risky, can lead to material waste, and may cause production slowdowns. This is where modern training technologies, inspired by fields like aviation and medicine, can offer a significant advantage. While full-scale physical simulators for block machines are not yet widespread, the principles of simulation can be applied effectively.

Imagine a training module built around the machine's actual HMI software, running on a standard tablet or PC. A trainee could navigate the control screens, adjust parameters, and respond to simulated error messages in a safe, classroom environment. This allows them to become completely familiar with the machine's "brain" before they ever face the pressure of a live production run. This approach aligns with modern pedagogical strategies that use technology to make teaching more effective and accessible (Mollick, 2023).

Furthermore, the use of augmented reality (AR) is an emerging frontier. A maintenance technician wearing AR glasses could look at the hydraulic system and see a digital overlay showing the flow of oil, the name of each valve, and the steps for a filter change procedure. This technology can provide real-time, context-aware guidance, reducing errors and speeding up maintenance tasks. While this may seem futuristic, the underlying technology is maturing rapidly, and forward-thinking companies should consider how such tools can supplement their block machine training programs. These aids do not replace the need for hands-on experience, but they can dramatically shorten the learning curve and improve knowledge retention.

Cross-Training and Skill Tiering: Building a Resilient Team

A common vulnerability in many manufacturing plants is over-reliance on a single expert—the one "guru" who knows how to fix everything. While this individual is invaluable, they also represent a single point of failure. What happens if they are on vacation, sick, or leave the company? The entire operation can be crippled. A more robust and resilient strategy is to build depth and breadth of skill across the entire team through cross-training and skill tiering.

Skill tiering involves creating a formal progression path for operators.

- Tier 1 Operator: This is the entry-level position. A Tier 1 operator is fully qualified to perform the daily start-up, run the machine in automatic mode, monitor quality, and perform the shutdown and cleaning procedures. They are the masters of daily production.

- Tier 2 Operator: A Tier 2 operator has all the skills of Tier 1, but has also received additional block machine training in basic maintenance and troubleshooting. They are qualified to perform all the weekly maintenance tasks, change a mould, and diagnose and resolve the most common operational faults.

- Tier 3 Technician: This is the highest level. A Tier 3 technician can perform all the tasks of the lower tiers, but also has the skills for advanced diagnostics, including working with the electrical schematics, troubleshooting the PLC, and performing complex mechanical or hydraulic repairs.

This tiered system provides a clear career path for employees, which can improve morale and retention. It also ensures that the appropriate skill level is applied to each task.

Cross-training is the process of training employees to perform jobs other than their primary one. For example, a forklift driver might be cross-trained to become a Tier 1 operator. A Tier 2 operator from one line might be cross-trained on a different type of block machine in the plant. This creates flexibility. When an operator is absent, a cross-trained employee can step in, preventing a production shutdown. It also gives employees a better appreciation for the entire production process, fostering better teamwork and communication.

Feedback Loops and Performance Metrics: The Path to Perfection

The famous management maxim, "You can't manage what you don't measure," is profoundly true in a manufacturing context. A block machine training program cannot be considered complete without a system for measuring its impact and providing feedback for continuous improvement. This is what closes the loop, turning training from a one-time event into an ongoing process.

The key is to identify and track a few meaningful Key Performance Indicators (KPIs). These metrics provide an objective look at the plant's health and the effectiveness of its team. Some of the most valuable KPIs for a block plant include:

- Overall Equipment Effectiveness (OEE): This is a gold-standard metric that combines three factors: Availability (uptime vs. scheduled time), Performance (actual production rate vs. theoretical maximum), and Quality (good blocks vs. total blocks produced). A rising OEE score is a strong indicator of successful training.

- Mean Time Between Failures (MTBF): This metric tracks the average time the machine runs before an unplanned stoppage. A growing MTBF is a direct reflection of a successful proactive maintenance program.

- Mean Time To Repair (MTTR): This measures the average time it takes to get the machine running again after a failure. A decreasing MTTR shows that the team's troubleshooting skills are improving.

- Material Waste Percentage: This tracks the amount of raw material that is discarded versus the amount that goes into saleable products. Reducing this metric is a direct boost to the bottom line.

- Safety Incidents: The ultimate goal is zero. Tracking near-misses as well as actual incidents provides valuable data for refining safety training and procedures.

These metrics should be displayed prominently so the entire team can see them. Regular meetings should be held to discuss the trends. Why did MTTR go up last month? Because we had a hydraulic fault that no one on shift knew how to diagnose. This provides a clear justification for more advanced hydraulic troubleshooting training. Why is our material waste high? Because operators are struggling with mix consistency. This indicates a need for a refresher course on material science. This data-driven approach removes emotion and guesswork from management, creating a powerful, objective cycle of training, measurement, and refinement that propels the operation toward excellence. It is the final step in ensuring that the investment in a high-quality concrete block making machine delivers the maximum possible return.

Frequently Asked Questions (FAQ)

How long does block machine training typically take?

The duration of training varies based on the trainee's prior experience and the complexity of the machine. For a new operator with no experience, a foundational program covering safety, basic operation, and daily maintenance for a QT series machine might take one to two weeks of intensive, supervised instruction. Achieving the proficiency of a Tier 2 operator, including troubleshooting and mould changes, could take several additional months of on-the-job practice and targeted training sessions.

What are the most common mistakes new operators make?

The most frequent errors for novices include neglecting the pre-operation inspection checklist, failing to maintain consistent concrete mix quality by not accounting for aggregate moisture, and improper cleaning at the end of a shift, which leads to hardened concrete buildup. Another common mistake is attempting to make parameter adjustments on the HMI without fully understanding the consequences, leading to production or quality issues.

Can one person operate a fully automatic QT series machine?

Yes, a single, well-trained operator can typically manage the entire operation of a fully automatic line, from monitoring the control panel to overseeing the stacking of cured blocks. However, a safe and efficient plant will always have additional trained personnel nearby to assist with tasks like mould changes, maintenance, and to provide support in case of an emergency.

How do I know if my concrete mix is correct?

The ideal mix for most block machines is a "zero-slump" or very dry consistency. A reliable field test is the "snowball test": take a handful of the mix and squeeze it firmly. It should form a compact ball that holds its shape without crumbling (too dry) or dripping water (too wet). The finished blocks also provide clues: sharp, well-defined edges indicate a good mix, while crumbling edges suggest it's too dry and slumping or deformation means it's too wet.

What is the single most important safety rule?

While all safety rules are important, the most critical life-saving procedure is the strict and unwavering adherence to Lockout/Tagout (LOTO) before any maintenance or cleaning that requires a worker to place any part of their body into a hazardous area. Verifying that the machine is completely de-energized before beginning work is non-negotiable.

How often should the hydraulic oil be replaced?

This depends on the manufacturer's recommendation, the operating environment, and the hours of operation. As a general rule, a full replacement may be recommended every 2,000 to 4,000 operating hours. However, a better practice is to regularly replace the hydraulic filters and to take periodic oil samples for laboratory analysis. This analysis can detect contamination or degradation and provide a much more accurate indication of when the oil needs to be changed, often extending its life and preventing premature component wear.

Is training included with the purchase of a new machine?

Reputable suppliers typically offer initial installation supervision and basic operational training as part of the purchase package. However, the comprehensive, multi-tiered block machine training program described here is an ongoing process. It is a long-term investment a company makes in its own team to maximize the value of their equipment. Discussing the extent and depth of available training options with your supplier is a wise step in the procurement process.

Conclusion

The journey from a novice to a master operator of a concrete block machine is a structured and disciplined path, not a matter of chance. It is a process grounded in the belief that the human element is the most valuable component of any production system. A machine, no matter how technologically advanced, is ultimately a tool, and its potential is only fully realized in the hands of a skilled, knowledgeable, and conscientious operator. A comprehensive block machine training program is the mechanism by which this potential is unlocked. By building a strong foundation of mechanical and material knowledge, instilling disciplined routines for operation and maintenance, and cultivating an unshakeable culture of safety, a company transforms its workforce. Operators cease to be mere button-pushers and become technicians, troubleshooters, and guardians of quality. This transformation is not an expense on a balance sheet; it is a direct and powerful investment in productivity, reliability, and long-term profitability.

References

Hempenstall, K. (2025). What does systematic instruction mean? National Institute for Direct Instruction.

Madrigal, R. V. (2024, February 12). 3 Steps to Explain Complex Topics like a PRO [Video]. YouTube. https://www.youtube.com/watch?v=m9m8e4a9nCU

Mollick, E. (2023, March 17). Using AI to make teaching easier & more impactful. One Useful Thing. https://www.oneusefulthing.org/p/using-ai-to-make-teaching-easier

Smaus, I. (2024). What factors contribute to a person's ability to explain complex ideas in a simple manner? Quora.

U.S. Department of Housing and Urban Development. (2024). 3D Concrete Printed Construction Systems Part 2: An Overview of 3DCP Construction Practices.