concrete block molds suppliers

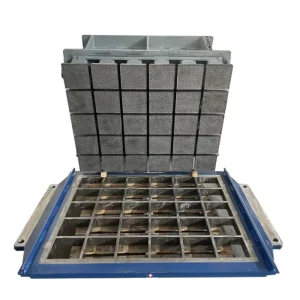

KBL Machinery is one of concrete block molds suppliers, our concrete block molds are engineered for precision and durability, ensuring consistent block production with minimal waste. These molds are perfect for large-scale projects, delivering efficiency and long-term reliability for your construction needs.

Top concrete block molds suppliers

1 Fujian Quan Gong Co.

Core Advantage: As a leading enterprise in China's brick machine industry, QuanGong owns the technical resources of German Zenit Mould Company, whose moulds are made of low-carbon alloy high-strength carburised steel, which are ensured to be smooth and durable on the inner wall through precision wire-cutting and heat treatment process. The types of moulds cover hollow bricks, roadside stones, permeable bricks, water conservancy bricks, etc. They support customised design and are equipped with an intelligent cloud service platform to provide remote maintenance.

Technical highlights: servo vibration system, forced fabric technology and pallet-free process significantly improves product compactness and production efficiency, long mould life and adaptable to construction waste and other special aggregates.

2. Baoding Tengyi Mould Manufacturing Co.

Product Coverage: Focusing on the production of colour bricks, curbstone, manhole cover, slope protection bricks and other cement products moulds, the products are used in high-speed railway, municipal engineering and river slope protection and other fields. Mould materials are mainly plastic and steel, ISO9002 certified, known for high precision and fast demoulding.

Market recognition: cooperation with a number of large-scale projects, mould design focus on practicality, such as drainage manhole cover mould modular structure to facilitate mass production.

3. Shenzhen Kingland Zongrun Building Material Technology Co.

Innovation field: Mainly decorative concrete moulding moulds and imaging film technology, to achieve the art of building surface (such as historical pattern reproduction). Its moulds support the integration of prefabrication and cast-in-place, low cost and high security, has provided the first domestic light and shadow imaging moulds for enterprises such as Yuanda Sumitomo, breaking the dependence on imports.

Technology application: Mould design combined with 3D scanning and customisation services for concrete components with complex geometry.

4. Suzhou Shihao Building Materials New Technology Engineering Co.

Patented technology: With more than 30 patents, it has developed a bidirectional hydraulic forming machine that can achieve pallet-less production, and the mould design is suitable for interlocking blocks and porous blind-hole bricks. Its moulding pressure reaches 2000T/M², which significantly improves the material compactness, and the dry shrinkage rate of the product is as low as 0.36%8.

Industry status: It is listed as the key patent implementation unit in Jiangsu Province, and the product is included in the new technology promotion project of the Ministry of Construction.

5. Zhengzhou Deyi Heavy Industry Machine Manufacturing Co.

Equipment supporting: mainly hydraulic brick presses and aerated concrete equipment, moulds as supporting products serving the production line of fly ash bricks and autoclaved bricks. The mould design focuses on the automation system to support efficient billeting and mixing of raw materials.

Market coverage: products are exported to more than 20 countries, ISO9001 certified, technical team provides customised mould solutions.

Other suppliers to watch

Quanzhou Kimberly Machinery: Its block-moulds supports the production of multi-specification products (e.g. standard bricks, walkway bricks), but further inquiries are required for mould details.

How Concrete Block Mold Technology Can Drive Sustainability in Your Production Line

Concrete block mold technology plays a pivotal role in modern construction, especially for businesses aiming to implement sustainable production practices. Kimberly machinery, a leading construction equipment supplier, offers advanced concrete block mold solutions that significantly reduce material waste and energy consumption. By utilizing high-precision moulds, companies can achieve uniform block sizes, minimizing errors and reducing rework. This efficiency not only improves the production process but also lowers the environmental footprint, promoting more sustainable construction practices.

Durability is another key advantage of KBL Machinery's concrete block mold technology. These moulds are built from high-grade materials to withstand the rigorous demands of heavy-duty production. Fewer replacements are needed, which not only reduces costs but also decreases the environmental impact associated with producing and transporting new moulds. Additionally, KBL Machinery offers customizable solutions that allow manufacturers to adapt moulds for specific projects, further increasing production efficiency and minimizing material waste.

Incorporating Road Brick Moulds and Block Moulds into your production line can also enhance sustainability by enabling the use of eco-friendly and recycled materials. KBL Machinery's innovative moulds maintain the structural integrity of blocks, even when using alternative materials like recycled aggregates. By integrating these advanced moulds into your operations, you can meet both environmental and industry standards while ensuring high-quality output.

Maintenance Practices for Extending the Lifespan of Your Concrete Block Mold

Proper maintenance of your concrete block mold is essential for prolonging its lifespan and maintaining production efficiency. KBL Machinery recommends several key practices to ensure your moulds continue to perform at their best.

| Maintenance Task | Importance | Recommended Action by KBL Machinery |

|---|---|---|

| Regular Cleaning and Inspection | Prevents dirt and debris buildup that can cause wear | Use non-abrasive tools and conduct frequent inspections |

| Lubrication of Moving Parts | Reduces friction and unnecessary wear | Select high-quality lubricants suitable for your mould materials |

| Consistent Temperature Control | Prevents mould deformation due to thermal expansion | Implement temperature controls to maintain dimensional stability |

| Timely Repairs and Part Replacement | Avoids larger issues that could halt production | Replace worn parts, like inserts or plates, before damage escalates |

| Storage in Controlled Environments | Prevents rust and corrosion during periods of non-use | Store moulds in dry, controlled spaces with protective coverings |

| Using Compatible Raw Materials | Ensures mould durability and optimal performance | Choose raw materials that match the mould specifications |

By following these practices, you can ensure your concrete block mold continues to operate efficiently, supporting long-term success and reducing costs. KBL Machinery provides comprehensive maintenance support to help businesses avoid costly downtime and keep production lines running smoothly.

About KBL Machinery

KBL Machinery is a trusted construction equipment supplier known for manufacturing high-quality Block Moulds, Road Brick Moulds, and concrete block molds. With a commitment to innovation, the company delivers solutions that enhance efficiency and productivity in the construction industry. KBL Machinery's products meet international standards and are designed to suit the unique needs of each business, offering customizability and long-term durability. Supported by a professional engineering team and dedicated customer service, KBL Machinery is focused on providing reliable and sustainable equipment for the global market.

Incorporating KBL Machinery's advanced mould technologies into your operations not only drives sustainability but also positions your business to meet the growing demands of the modern construction landscape.