Um guia prático para a manutenção de máquinas de blocos: 7 passos para um desempenho máximo em 2025

29 de outubro de 2025

Resumo

Effective block machine maintenance is a foundational pillar for operational success in the concrete products industry. This article examines the systematic procedures required to ensure the longevity, reliability, and precision of concrete block manufacturing equipment, with a specific focus on QT series fully automatic machines and static hydraulic presses. It posits that a transition from a reactive repair model to a proactive maintenance culture is not merely beneficial but necessary for optimizing production output and ensuring consistent product quality. The analysis covers seven distinct, yet interconnected, domains of maintenance: daily cleaning, lubrication, hydraulic system integrity, mechanical component inspection, electrical and control system oversight, quality-focused calibration, and the institutionalization of documentation and training. By contextualizing these practices for the demanding operational environments of Southeast Asia and the Middle East, the article provides a comprehensive framework for plant managers and operators to maximize the return on their capital equipment investment and mitigate the significant financial and operational risks associated with unscheduled downtime.

Principais conclusões

- Establish a rigorous daily cleaning routine to prevent abrasive material buildup.

- Follow a detailed weekly lubrication schedule for all critical moving parts.

- Inspect hydraulic systems weekly for leaks, pressure, and fluid quality.

- Consistent block machine maintenance is the best strategy to extend operational life.

- Regularly check electrical components and connections for safety and function.

- Monitor mold and tamper head wear closely to maintain block quality.

- Maintain detailed maintenance logs for effective troubleshooting and planning.

Índice

- A Foundational Philosophy for Machine Care

- Step 1: Instituting a Rigorous Daily Cleaning Regimen

- Step 2: Mastering the Art and Science of Lubrication

- Step 3: Vigilant Hydraulic System Inspection and Care

- Step 4: Ensuring the Integrity of Mechanical Components

- Step 5: Diligent Electrical and Control System Oversight

- Step 6: Monitoring and Calibrating for Unwavering Product Quality

- Step 7: The Power of Documentation and Empowering Your Team

- Perguntas frequentes (FAQ)

- A Final Thought on Stewardship

- Referências

A Foundational Philosophy for Machine Care

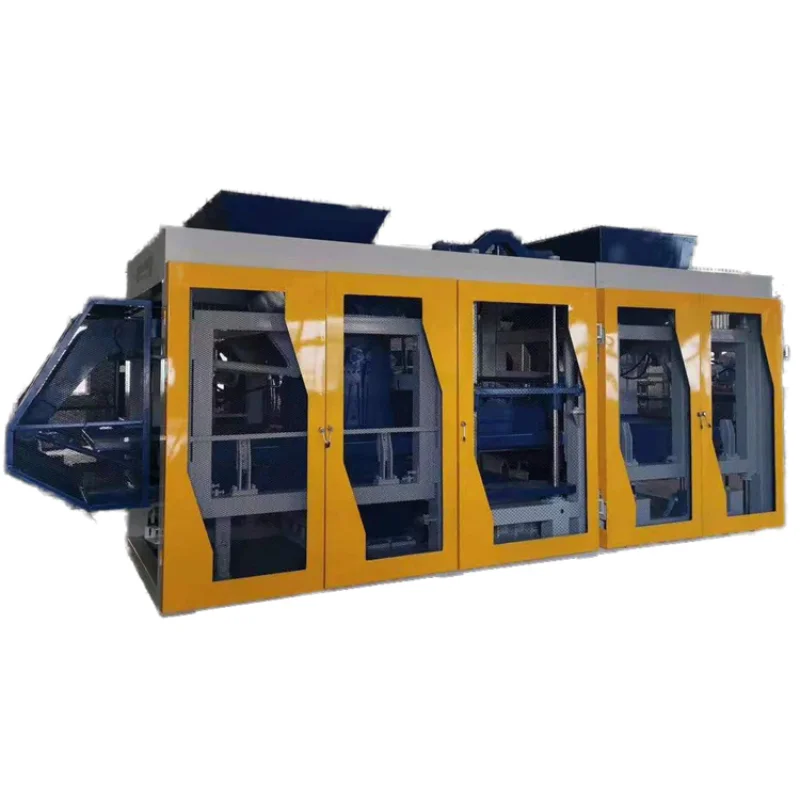

To own and operate a concrete block machine is to engage in a partnership. It is a relationship built not on sentiment, but on a shared purpose: the creation of the very building blocks of our communities. Whether it is a QT series fully auto concrete block making machine humming with automated precision or a robust static hydraulic block pressing machine exerting immense force, the equipment in your plant is more than a collection of steel and wires. It is the heart of your operation, the engine of your productivity, and the guarantor of your reputation. In the demanding climates of Southeast Asia and the Middle East, where heat, dust, and relentless production schedules are the norm, this partnership is tested daily.

Thinking of maintenance merely as a chore, a cost to be minimized, is a profound misunderstanding of its nature. One must instead cultivate an ethos of stewardship. This perspective reframes block machine maintenance from a reactive response to failure into a proactive, continuous dialogue with the machinery. It involves listening to the machine—to the subtle shifts in its sounds, to the feel of its vibrations—and responding not with annoyance at the interruption, but with the focused attention of a skilled physician. The goal is to anticipate needs before they become demands, to address whispers of wear before they become screams of breakdown. This approach, grounded in discipline and foresight, is what separates a struggling operation from a thriving enterprise. It is the difference between perpetually fixing a broken present and intentionally building a reliable future.

The following seven steps are not simply a checklist; they represent a holistic methodology for nurturing the health and performance of your machinery. They are designed to be integrated into the very rhythm of your plant's daily life, transforming maintenance from an isolated task into a shared culture of excellence and care.

Step 1: Instituting a Rigorous Daily Cleaning Regimen

The act of cleaning a block machine at the end of a production shift is perhaps the single most impactful maintenance task one can perform. It is often underestimated, viewed as a simple janitorial duty. Yet, its implications for the machine's longevity and performance are deeply significant.

The Philosophy of Cleanliness: Beyond Aesthetics

Imagine attempting to work efficiently in a room where the floor is covered in sand and gravel. Every step would be an effort, and the constant grit would wear away at your shoes. This is precisely the condition a block machine endures when it is not cleaned properly. Concrete is, by its nature, an aggressive material. The mixture of cement, sand, aggregate, and water is abrasive when wet and becomes as hard as rock when dry.

When this material is allowed to accumulate on the machine, it is not a passive, cosmetic issue. It is an active assault. A layer of hardened concrete on a moving part increases its mass and inertia, forcing the motor or hydraulic cylinder to work harder. This excess strain translates directly into higher energy consumption and accelerated wear on drive components. The abrasive dust generated during production infiltrates every unprotected crevice. It works its way into bearings, chains, and sliding surfaces, grinding away at precision-machined steel. Cement dust, when combined with the humidity prevalent in many parts of Southeast Asia, creates a corrosive slurry that can eat away at the machine's frame and electrical connections. A clean machine is not just a point of pride; it is a fundamental prerequisite for mechanical health and operational safety.

The Post-Shift Shutdown Protocol

A disciplined end-of-day cleaning protocol is the practical application of this philosophy. It must be as routine and non-negotiable as shutting off the main power. The process should be systematic, ensuring no area is overlooked.

First, all residual raw material should be cleared from the batching plant, hoppers, and conveyor systems. Running the conveyors empty is a good first step. Then, using tools like compressed air wands, soft brushes, and plastic or wooden scrapers, the operator should meticulously remove all visible material. Metal scrapers should be used with extreme caution, if at all, as they can easily gouge or scratch precision surfaces like the inside of the mold or the face of the tamper head.

Special attention must be paid to the heart of the operation: the mixer. Any concrete left inside will harden overnight, forming what are often called "dead heads." These chunks of hardened material not only reduce the mixer's effective capacity but can also break free during the next day's operation, damaging the mixing blades or, worse, finding their way into the block machine itself. The mixer should be washed out thoroughly, following the manufacturer's guidelines regarding water usage to avoid damaging bearings or electrical components.

Cleaning Specific Components: A Detailed Look

A closer examination of key areas reveals why this daily ritual is so vital.

-

The Mold Box and Tamper Head: These two components work in concert to define the final shape and quality of the concrete block. Their surfaces must be perfectly clean and smooth. Even a thin, uneven layer of hardened slurry on the tamper head can cause variations in block height and density. Material buildup in the corners of the mold can lead to blocks with rounded edges or imperfections, causing them to be rejected. Cleaning these components is an act of preserving the machine's ability to produce saleable products.

-

Vibration Table and Assemblies: The vibration table is subjected to immense forces. It must be kept free of debris that could dampen or alter its vibration characteristics, leading to poor compaction. The springs or rubber mounts that isolate the vibration from the main frame should be inspected and cleaned, as accumulated grit can accelerate their wear.

-

Sensors, Switches, and Proximity Detectors: Modern automated machines like the QT series rely on a network of sensors to orchestrate their complex movements. A proximity switch tells the machine when a pallet is in place; an optical sensor might monitor material levels in the hopper. A fine layer of cement dust can blind an optical sensor or prevent a limit switch from making contact, leading to sequence errors, collisions, or a complete shutdown of the machine. Wiping these sensors clean with a soft cloth daily is a simple action that prevents immense frustration and downtime.

Step 2: Mastering the Art and Science of Lubrication

If cleaning is about removing harmful elements, lubrication is about introducing a vital, life-sustaining one. In the high-friction, high-vibration world of a block machine, lubrication is the invisible force that stands between smooth operation and catastrophic failure. It is the machine's circulatory system, carrying protection to its most vulnerable points.

Understanding Lubrication's Role in a High-Vibration Environment

At its core, lubrication creates a microscopic film between two moving metal surfaces, preventing direct contact. This simple function has three profound benefits:

- Reduces Friction: Less friction means less energy is wasted as heat, leading to more efficient operation and lower power consumption.

- Prevents Wear: By preventing metal-on-metal contact, lubrication dramatically extends the life of bearings, bushings, pins, and gears.

- Dissipates Heat and Contaminants: The flow of lubricant can carry away heat generated by friction and flush out small contaminants that may have penetrated a seal.

A block machine presents a uniquely challenging environment for lubricants. The intense vibration from the compaction process constantly tries to displace the lubricant film. The heavy loads from pressing and moving tons of material per hour demand lubricants with high film strength. The ever-present abrasive dust seeks to contaminate the lubricant, turning it from a protective fluid into a grinding paste. Choosing the right lubricant and applying it correctly is therefore not just a task, but a science.

Creating a Comprehensive Lubrication Schedule

Hope is not a lubrication strategy. A formal, documented schedule is the only way to ensure that every one of the dozens of lubrication points on a machine receives the correct type of lubricant at the correct interval. This schedule should be a living document, prominently displayed near the machine and integrated into the daily and weekly workflow. A well-structured schedule provides clarity and accountability.

| Componente | Lubricant Type | Frequency | Application Method & Notes |

|---|---|---|---|

| Mold Box Guide Pillars & Bushings | Lithium EP2 Grease | Daily (Every 4-8 hrs) | Grease Gun. Pump until fresh grease is seen purging from the seals. This flushes out contaminants. |

| Tamper Head Guide Rods | Lithium EP2 Grease | Daily (Every 4-8 hrs) | Grease Gun. Clean zerk fittings before applying. Essential for smooth, vertical movement. |

| Main Drive & Mixer Bearings | High-Temp EP2 Grease | Weekly | Grease Gun. Do not over-grease sealed bearings; follow manufacturer's volume recommendation. |

| Conveyor Roller Bearings | Multipurpose Grease | Weekly | Grease Gun or manual application. Listen for noisy bearings, which may indicate imminent failure. |

| Drive Chains & Sprockets | Chain Lubricant (Oil) | Weekly | Brush or drip application. Clean the chain before application for best penetration. |

| Hydraulic Cylinder Pivot Pins | Moly EP2 Grease | Monthly | Grease Gun. These are high-load, low-speed points that require a robust lubricant. |

| Pallet Feeder Sliding Components | Dry Film Lubricant | Weekly | Spray application. Wet lubricants attract too much dust in this area. A dry graphite or PTFE spray is better. |

Note: "EP" stands for Extreme Pressure, an additive package that is vital for the high-load conditions found in a block machine. In the high ambient temperatures of the Middle East, selecting a grease with a high dropping point is particularly important to prevent it from becoming too thin and running out of the bearings.

Common Lubrication Pitfalls and How to Avoid Them

Even with a schedule, errors can occur. Understanding these common mistakes is key to avoiding them.

-

The "More is Better" Fallacy: It is tempting to think that if some grease is good, more must be better. This is false. Over-greasing a bearing can blow out its seals. Once a seal is damaged, it provides an open door for dust and water to enter, leading to rapid failure. Excess grease on the outside of the machine also acts as a magnet for dust, creating a thick, gritty paste that is difficult to clean.

-

Contamination is the Enemy: Lubricants must be kept spotlessly clean. A grease gun left lying in the dust, an open oil container, or a dirty zerk fitting can introduce enough abrasive material to negate the lubricant's benefits completely. Store lubricants in a clean, sealed cabinet. Wipe grease fittings clean before attaching the gun. Treat your lubricants like the precision products they are.

-

Ignoring the Purge: When greasing a component with an open bearing or bushing, the goal is often to pump in new grease until you see the old, dirty grease being pushed out. This "purging" action is a critical part of the process, as it actively removes contaminants from the component. Simply adding a pump or two of new grease without seeing the old grease expelled may not be sufficient.

Step 3: Vigilant Hydraulic System Inspection and Care

The hydraulic system is the muscle of a static hydraulic block pressing machine and a key component of many automated QT series machines. It generates the thousands of pounds of force necessary to compact the concrete mix into a dense, strong block. A healthy hydraulic system is powerful, precise, and responsive. An unhealthy one is weak, erratic, and a major source of downtime and safety hazards.

The Hydraulic System: The Muscle of Your Machine

To appreciate its maintenance needs, one must first understand its basic components. A typical system consists of:

- The Reservoir: A tank that holds the hydraulic fluid (oil).

- The Pump: Driven by an electric motor, it creates the flow of oil.

- The Valves: Directional, pressure, and flow control valves that direct the oil to the right place, at the right pressure, and at the right speed.

- The Actuators: Primarily hydraulic cylinders that convert the fluid pressure into linear force to press the block, move the tamper head, or operate the feeder.

- The Hoses and Fittings: The arteries and veins that carry the high-pressure fluid throughout the system.

- The Filters: Devices that remove contaminants from the fluid.

- The Fluid: The lifeblood of the system, which not only transmits power but also lubricates components and helps dissipate heat.

The immense power of hydraulics comes from Pascal's principle—pressure applied to a confined fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel. This means a small force on a small area can generate a huge force on a larger area, but it also means that the system is incredibly sensitive to leaks and contamination.

A Checklist for Daily and Weekly Hydraulic Checks

Vigilance is the key to hydraulic health. Small problems, if caught early, can be fixed easily. If ignored, they can escalate into catastrophic failures.

Daily Checks (2-5 minutes):

- Check the Fluid Level: Look at the sight glass on the reservoir. The level should be within the specified range. A low level can cause the pump to starve for oil, a condition called cavitation, which sounds like pumping gravel and can destroy a pump in minutes.

- Check the Fluid Temperature: Most systems have a temperature gauge. Note the normal operating temperature. A sudden increase in temperature indicates a problem, such as internal leaking, a stuck valve, or a failing heat exchanger.

- Visual Leak Inspection: Walk around the machine and look for any drips or wet spots around hoses, fittings, and cylinder seals. A small leak is a warning sign. Under high pressure, a pinhole leak can create a jet of fluid capable of piercing skin, causing a severe injection injury.

- Listen to the Pump: Learn the normal, healthy sound of your hydraulic pump. Any new whining, knocking, or grinding noises are immediate causes for concern and investigation.

Weekly Checks (15-30 minutes):

- Inspect Hoses: Look closely at hydraulic hoses for any signs of cracking, blistering, kinking, or abrasion where they might be rubbing against the machine frame. A failing hose is a ticking time bomb.

- Check Fittings: Ensure all fittings are secure, but avoid over-tightening, which can damage the threads or the seal.

- Inspect Cylinder Rods: Look at the polished rods of the hydraulic cylinders. They should be clean and smooth. Any nicks or scratches can tear the rod seal, causing a leak. The rod should also be dry; a film of oil indicates a weeping seal that will soon need replacement.

- Check Filter Indicators: Many hydraulic filters have a pressure gauge or pop-up indicator that shows when the filter is becoming clogged and needs to be changed.

Hydraulic Fluid: Management and Analysis

It is a common misconception that hydraulic fluid lasts forever. In reality, the fluid is a consumable component that degrades over time and is highly susceptible to contamination. Approximately 75% of all hydraulic system failures are directly attributable to contaminated fluid (Zemicheal & Houjun, 2020).

- The Three Enemies: The primary contaminants are solid particles (dust, metal flakes from wear), water (from condensation, especially in humid climates), and air. Particles cause abrasive wear, water promotes rust and reduces lubricity, and air causes spongy, erratic cylinder movement.

- Filter Maintenance: The filters are the system's kidneys. They must be replaced on a regular schedule, not just when they are fully clogged. A clogged filter will go into bypass mode, allowing dirty oil to circulate freely through the entire system.

- Oil Analysis: For a large, critical operation, periodic oil analysis is a powerful predictive maintenance tool. A small sample of oil is sent to a lab, which can identify the type and quantity of contaminants, the presence of water, and the breakdown of the oil's chemical properties. This report can give you an early warning of a failing component (e.g., high levels of brass might indicate a pump is wearing out) long before it fails completely.

- Changing the Fluid: The entire volume of hydraulic fluid should be replaced at intervals recommended by the machine manufacturer, typically every 2000-4000 operating hours. When changing the oil, the reservoir should be thoroughly cleaned to remove any sludge and contaminants that have settled at the bottom.

Step 4: Ensuring the Integrity of Mechanical Components

While the hydraulic and electrical systems provide the force and control, the mechanical structure is the skeleton that bears the load and endures the relentless vibration. Its integrity is paramount for both performance and safety.

The Foundation: Frame, Bolts, and Welds

The constant, violent shaking of the vibration table and the immense pressing forces create a brutal environment for any structure. This is not a static piece of equipment; it is a dynamic system in a constant state of stress.

- The Threat of Vibration: Think of a bolt that is not properly tightened. The machine's vibration will cause a microscopic amount of movement between the bolt head and the frame with every cycle. Over millions of cycles, this tiny movement can be enough to slowly work the nut loose. A single loose bolt in a critical assembly, like a motor mount or a mold clamp, can lead to misalignment, which then causes other components to wear or fail prematurely.

- The Torque Wrench is Your Friend: A regular schedule for checking the torque on critical fasteners is not optional. This is especially important for a new machine during its first few hundred hours of operation as components settle. Create a "torque map" of the machine, identifying the critical bolts and their specified torque values from the manufacturer's manual. A weekly walk-around with a torque wrench to check these key fasteners can prevent a host of problems.

- Weld Inspection: Welds are the points where stress is often concentrated. Periodically, especially around the vibration table mounts and the main press frame, the machine should be cleaned and the welds visually inspected for any signs of cracking. A small crack, often appearing as a thin, dark line in the paint, is a serious warning. It must be addressed immediately by a qualified welder to prevent a major structural failure.

Wear Parts Management: Molds and Tamper Heads

No components have a more direct impact on the final product than the mold and the tamper head (also called the pressure head). They are consumable items, designed to wear out and be replaced. Managing this wear is a core task of block machine maintenance.

The material mix for concrete blocks is highly abrasive. As this mix is fed into the mold and compacted under pressure, it slowly but surely wears away the steel surfaces of the mold liners and the tamper head shoes.

- How Wear Affects Quality: As the mold liners wear, the internal dimensions of the mold increase. This results in oversized blocks. As the tamper head shoes wear, the height of the compacted block changes, leading to inconsistent block heights. This is a major problem for masons on a job site. Uneven wear can also lead to variations in density across the block, resulting in weak spots.

- Measuring and Monitoring: Wear should not be judged by eye. It must be measured with precision tools like calipers and depth gauges. Keep a log of the dimensions of new molds and tamper shoes. On a weekly or bi-weekly basis, take measurements at several key points. When the wear exceeds the manufacturer's specified tolerance (e.g., more than 1.5mm), it is time for action. Investing in high-quality wear parts, like those for a QT series automatic block machine, pays dividends in product consistency and part longevity.

- Repair or Replace?: Some wear components, particularly the face of the tamper head, can be refurbished. The worn surface can be built back up using specialized hard-facing welding techniques and then ground back to its original dimensions. This can be more cost-effective than a full replacement. However, mold liners are typically replaced entirely. Trying to get "a little more life" out of a worn-out mold is a false economy; the cost of producing a pallet of rejected, out-of-spec blocks quickly outweighs the savings.

Conveyors, Chains, and Sprockets

The systems that move raw materials into the machine and finished blocks away from it are also subject to wear and require regular attention.

- Chain and Sprocket Systems: These are often used to drive pallet feeders or material carts. The chain's tension is critical. A loose chain can jump off the sprocket or slap against guards, causing damage. A chain that is too tight puts excessive load on the bearings of the drive motor and shaft. Check the tension weekly and adjust as needed. Also, inspect the teeth on the sprockets. As they wear, they take on a "hooked" appearance. Worn sprockets will rapidly destroy a new chain, so they should always be replaced as a set.

- Conveyor Belts: The main cause of conveyor belt failure is mistracking, where the belt drifts to one side and rubs against the frame. This can quickly shred the edge of the belt. Check the belt tracking daily and adjust the tracking rollers as needed. Also, check the belt tension. If it is too loose, the drive pulley may slip. If it is too tight, it puts stress on the bearings and the belt splice.

Step 5: Diligent Electrical and Control System Oversight

The electrical system is the machine's nervous system. It provides the power for the motors and the intelligence for the controls. While it may seem less prone to the mechanical wear and tear of the rest of the machine, it is highly vulnerable to its own set of environmental enemies: dust, moisture, heat, and vibration.

The Nervous System: Protecting Your PLC and Controls

The brain of any modern automated block machine is the Programmable Logic Controller, or PLC. This industrial computer, housed within the main control cabinet, executes the complex sequence of operations, reads inputs from sensors, and sends commands to motors and hydraulic valves. The PLC and its associated components (drives, relays, power supplies) are the most sophisticated and often the most expensive parts of the machine. Their protection is paramount.

The control cabinet is designed to be a clean, dry, safe house for these sensitive electronics.

- The Sanctity of the Seal: The door of the control cabinet has a gasket for a reason. It is there to keep out the airborne dust and moisture that are pervasive in a block plant. The cabinet door should always be kept closed and latched. If the gasket is damaged or compressed, it should be replaced.

- Cooling and Ventilation: Electronics generate heat. The control cabinet is usually equipped with a filtered fan or an air conditioning unit to dissipate this heat. These filters must be cleaned or replaced regularly. A clogged filter will cause the internal temperature of the cabinet to rise, which can lead to erratic behavior from the electronics and drastically shorten their lifespan. A good rule of thumb is that for every 10°C rise in temperature above the ideal, the life of electronic components is cut in half.

- Vibration Isolation: The control cabinet should be mounted in a way that isolates it from the heavy vibrations of the main machine frame. Check that its mounting hardware and any vibration-damping pads are secure and in good condition.

Inspecting Wiring, Sensors, and Motors

The rest of the electrical system extends throughout the machine, and it requires its own inspection routine.

- Wiring and Connections: Vibration can cause screw terminals in junction boxes and on components to become loose over time. A loose connection creates high resistance, which generates heat. This can lead to a melted terminal block or even a fire. During planned downtime, it's a good practice to open major junction boxes and check the tightness of the terminals. Visually inspect conduits and wire sheathing for any signs of abrasion or damage where they might be rubbing against the machine.

- Motor Health: Electric motors are the workhorses of the system. The simplest health check is to listen to them. A healthy motor has a smooth, consistent hum. Any new grinding or squealing noises often indicate failing bearings. You can also carefully check the motor's temperature by hand (or more accurately with an infrared thermometer). A motor that is excessively hot to the touch is either overloaded, has failing bearings, or has an internal electrical fault. Ensure the motor's cooling fins are kept clean of dust buildup, which can act as an insulating blanket.

- Sensor Hygiene: As mentioned in the section on cleaning, sensors are the machine's eyes and ears. Proximity sensors, limit switches, and photoelectric eyes must be kept clean to function. A weekly wipe-down of all sensor faces is a simple task that prevents a multitude of frustrating "ghost" problems and intermittent faults.

Safety Systems Check: A Non-Negotiable Task

The electrical system is also responsible for the machine's safety features. These systems are designed to protect operators from the powerful movements and high pressures of the machine. Their function must never be compromised.

- Emergency Stops: Every E-stop button on the machine and control panel should be physically tested on a weekly basis. Press the button and confirm that it immediately and completely halts all machine motion.

- Interlocks and Guards: Safety gates and physical guards are often fitted with interlock switches that stop the machine if a gate is opened. Test these switches to ensure they are functioning correctly. Never, under any circumstances, should a safety switch be bypassed or "jumpered out." Doing so might seem like a convenient way to fix a faulty switch in the short term, but it defeats a critical layer of protection and exposes operators to the risk of life-altering injury.

Step 6: Monitoring and Calibrating for Unwavering Product Quality

Excellent block machine maintenance and high-quality block production are two sides of the same coin. A well-maintained machine is inherently more capable of producing consistent, high-quality blocks. This step bridges the gap between the maintenance workshop and the quality control lab, creating a feedback loop where product quality informs maintenance priorities.

The Symbiosis of Maintenance and Quality Control

When a pallet of blocks comes out with cracks, inconsistent heights, or a poor finish, the first instinct might be to blame the raw material mix or the operator. While these are possibilities, the root cause often lies in a specific maintenance issue. A quality control problem should always trigger a maintenance investigation.

For example:

- Inconsistent Block Height: Could be caused by worn tamper head shoes, a loose tamper head assembly, inconsistent material feed, or fluctuating hydraulic pressure.

- Cracked Blocks (especially at the top): Often a sign of the tamper head staying on the block for too long during the stripping phase, or the demolding movement being too fast or jerky. This can point to an issue with a hydraulic valve, a PLC timing parameter, or worn guide bushings causing the tamper head to stick.

- Poor Surface Finish: Can be caused by a dirty or pitted mold, incorrect vibration frequency/amplitude, or a worn-out rubber mat on the vibration table.

By learning to read the language of the blocks, an operator can diagnose the health of the machine.

A Quality Control Feedback Loop

Instead of waiting for a customer to complain, an internal quality control system is essential. This does not need to be overly complex.

- Regular Sampling: At the start of each shift and at regular intervals throughout the day, take one or two blocks from a pallet for testing.

- Visual Inspection: Look for surface imperfections, chipped edges, and cracks.

- Dimensional Checks: Use a measuring tape or caliper to check the height, width, and length against the specification. Are they consistent?

- Record Keeping: Log these measurements. If you see a trend—for instance, the blocks are slowly getting taller over several days—it is a clear indicator of a developing wear issue that needs attention.

This process transforms quality control from a passive "pass/fail" gate at the end of the line into an active, predictive tool for guiding maintenance efforts.

| Block Defect | Potential Maintenance Cause | Corrective Maintenance Action |

|---|---|---|

| Vertical Cracks | Vibration is too intense or too long; mix is too dry. | Check vibration motor settings; verify function of amplitude controls. Check water dosing system. |

| Horizontal Cracks | Faulty demolding (stripping); block sticking to tamper head. | Inspect tamper head for cleanliness and wear. Check hydraulic pressure and speed of stripping cylinder. |

| Inconsistent Height | Worn tamper head; inconsistent material feed; low compaction pressure. | Measure tamper head shoes. Calibrate feed box volume. Check main hydraulic pressure settings. |

| Chipped Edges/Corners | Worn or dirty mold; jerky pallet movement. | Inspect mold liners for wear and buildup. Check pallet conveyor for smooth operation. |

| "Honeycomb" Surface | Insufficient compaction; poor material distribution in mold. | Check vibration settings. Inspect feeder box for even material flow. |

| Oversized Block (Width/Length) | Worn mold box liners. | Measure internal mold dimensions. Replace worn liners. |

Key Calibration Points

Calibration is the act of fine-tuning the machine's settings to ensure it is operating at its peak. While some settings are fixed, others require periodic adjustment as components wear or raw materials vary.

- Material Feed Calibration: The amount of loose material fed into the mold for each cycle is critical. Too little material results in a short, low-density block. Too much material can strain the press and result in an overly dense block that may crack under pressure. The volume of the feed box or the time of the feed conveyor run should be checked and calibrated regularly, especially if you notice changes in material density.

- Vibration Adjustment: The vibration is what settles the material in the mold and helps eliminate voids. The frequency and amplitude of the vibration may need to be adjusted based on the type of aggregate and the desired block properties. The manufacturer's manual provides a starting point, but small adjustments, guided by the appearance of the finished block, are often necessary.

- Pressure Settings: The hydraulic pressure relief valves determine the maximum compaction force. These should be set with a calibrated pressure gauge according to the manufacturer's specifications and should not be altered without a clear understanding of the consequences.

Step 7: The Power of Documentation and Empowering Your Team

The most sophisticated maintenance strategy in the world will fail if it exists only in the mind of one person. To be sustainable, a maintenance culture must be formalized through documentation and embedded in the skills of the entire team.

If It’s Not Written Down, It Didn’t Happen: The Maintenance Logbook

A detailed logbook—whether a physical notebook or a simple computer spreadsheet—is the collective memory of the machine. It is one of the most powerful and yet most overlooked tools in any plant.

Every time a maintenance task is performed, it should be recorded. The entry should include:

- The date and current machine operating hours.

- The task performed (e.g., "Weekly lubrication schedule completed," "Replaced hydraulic return filter").

- Any parts used (including part numbers).

- Any unusual observations (e.g., "Noticed a small leak on cylinder #3's rod seal," "Motor for conveyor #2 seems to be running hot").

The benefits of this simple discipline are immense. The logbook allows you to track the lifespan of wear parts, helping you predict when a replacement will be needed. It helps identify recurring problems, pointing to a root cause that needs to be addressed. It provides an invaluable history for a new technician or for when you need to discuss a problem with the machine manufacturer. It is the foundation of a data-driven approach to block machine maintenance.

Empowering Your Team: The Importance of Operator Training

The machine operator is the first line of defense. They spend more time with the machine than anyone else. Training them to be more than just a "button pusher" is a massive force multiplier for your maintenance efforts.

- Train to Observe: Teach operators what "normal" looks, sounds, and feels like. When they can recognize a subtle change in the machine's rhythm, a new squeak, or an unusual vibration, they can report it before it becomes a serious problem. This transforms them from a passive user into an active monitor of the machine's health.

- Delegate Routine Tasks: The operator is the ideal person to perform the daily cleaning protocol and the simple daily lubrication tasks. This gives them a sense of ownership and a deeper connection to the equipment. It frees up more specialized maintenance personnel to focus on more complex tasks. Proper training is most effective when paired with well-designed equipment, such as a robust hydraulic block pressing machine.

- Provide the "Why": When training, do not just show someone what to do. Explain why they are doing it. Explaining that cleaning a sensor prevents hours of downtime is far more motivating than simply saying "wipe this part." When an operator understands the consequences of neglect, they are far more likely to be diligent in their care.

Building a Spare Parts Inventory Strategy

Downtime is expensive. The cost of lost production often dwarfs the cost of the repair itself. This is especially true in Southeast Asia and the Middle East, where getting a specific part shipped from an overseas manufacturer can take days or even weeks. A strategic spare parts inventory is not a cost; it is an insurance policy against lost revenue.

Using your maintenance logbook and the manufacturer's recommendations, you can develop an intelligent inventory.

- Tier 1: Critical Spares. These are parts that are known to fail and will shut down the entire operation. They may have a long lead time. These must be kept on-site. Examples include a specific PLC input/output card, a critical proximity sensor, a set of seals for the main hydraulic cylinder, or a spare vibration motor.

- Tier 2: Important Spares. These are parts that will be needed eventually but may not cause a complete, immediate shutdown, or parts that can be sourced with a moderate lead time (e.g., a few days). Examples might include a set of mold liners, a hydraulic pump seal kit, or a set of conveyor bearings.

- Tier 3: General/Local Spares. These are common items that can be purchased from a local industrial supplier. Examples include standard nuts and bolts, hydraulic fittings, and common V-belts.

Managing this inventory does not have to be complicated, but it does require discipline. When a part is taken from stores, a system must be in place to reorder it. This simple process ensures that the "insurance policy" is always valid.

Perguntas frequentes (FAQ)

1. How often should I change the hydraulic oil in my block machine? The manufacturer's recommendation is the best guide, but a general rule is every 2,000 to 4,000 operating hours. However, in very hot and dusty environments like those in the Middle East, you may consider more frequent changes. The most scientific approach is to perform periodic oil analysis, which will tell you precisely when the oil's protective properties have degraded.

2. What is the single most common cause of block machine failure? While major mechanical breaks are dramatic, the most frequent cause of downtime is often related to minor electrical or hydraulic issues. Contaminated hydraulic fluid is a leading cause of component failure. Similarly, a dirty sensor or a loose electrical connection can stop a multi-ton machine in its tracks. This highlights why daily cleaning and vigilant inspections are so vital.

3. Can I use generic or locally fabricated spare parts for my machine? For non-critical, standard components like fasteners or some bearings, high-quality generic parts can be acceptable. However, for critical, high-stress, or precision components like mold liners, tamper shoes, specialized hydraulic valves, or electronic components, it is almost always better to use Original Equipment Manufacturer (OEM) parts. These are designed and manufactured to the exact material specifications and tolerances required for the machine, ensuring proper fit, performance, and longevity.

4. My blocks are regularly coming out cracked. What is the first maintenance issue I should check? Start with the demolding or stripping process. Cracks are often formed when the block is being pushed out of the mold. Check that the tamper head is lifting cleanly and not sticking to the top of the block. This could be due to a dirty tamper head surface or an issue with the timing or speed of the hydraulic stripping cylinders. Also, check your vibration settings—excessive vibration can sometimes introduce stress fractures.

5. How does the hot climate in the Middle East specifically affect block machine maintenance? Heat is a major factor. It causes hydraulic oil to thin out and degrade faster, so using the correct high-temperature viscosity grade (e.g., ISO 68 instead of ISO 46) and monitoring oil coolers is critical. Electronics in control cabinets are more susceptible to overheating, making clean fan filters essential. Grease can also melt and run out of bearings, so using a grease with a high "dropping point" is important.

6. What is the main maintenance difference between a fully automatic QT series machine and a simpler static hydraulic machine? The core principles of cleaning, lubrication, and hydraulic care are the same. The main difference lies in the complexity of the control system. A fully automatic machine has a far greater number of sensors, switches, PLCs, and automated sequences. This means electrical and sensor-related troubleshooting becomes a more frequent and complex task. A simpler static machine has fewer moving parts and sensors, making its maintenance more focused on the core mechanical and hydraulic components.

7. How does proper block machine maintenance improve my return on investment (ROI)? Proper maintenance improves ROI in several key ways. It drastically reduces unplanned downtime, which directly increases the machine's productive hours and revenue-generating capacity. It extends the overall operational life of the machine, deferring the massive capital expenditure of a replacement. It ensures consistent product quality, reducing the cost of waste and rejected products. Finally, it lowers energy consumption and prevents minor issues from escalating into catastrophic, expensive repairs.

A Final Thought on Stewardship

The rhythmic pulse of a block machine is a sound of potential. With each cycle, it transforms humble materials into the components of homes, schools, and infrastructure. To care for this machine through diligent, thoughtful maintenance is to be a good steward of that potential. It is an investment in reliability, a commitment to quality, and a recognition that the most successful enterprises are not just built on grand strategies, but on the daily, disciplined execution of essential tasks. Your machine will reward this stewardship with years of faithful, productive service, forming the very foundation of your business's success.

Referências

Girskas, G., & Kligys, M. (2025). 3D concrete printing review: Equipment, materials, mix design, and properties. Buildings, 15(12), 2049. https://doi.org/10.3390/buildings15122049

Kamal, M. A. (2022). Blocos de betão pré-fabricados na construção de edifícios: Uma visão geral. Academia.edu.

Rob, G. (2017). A starter's guide to hollow block manufacturing. Academia.edu.

Simate, G. S. (2011). The production of geopolymer cement from fly ash activated by a mixture of sodium hydroxide and sodium silicate. Minerals Engineering, 24(12), 1387-1393.

Sivakumar, S. S., & Mahendran, N. (2014). Experimental investigation on partial replacement of cement by silica fume and fly ash in concrete. International Journal of Engineering Research & Technology, 3(3), 2038-2042.

Totten, G. E., & Westbrook, S. R. (Eds.). (2002). Hydraulic failure analysis: Fluids, components, and system effects. ASTM International.

Waleed, A. A., & Bheel, N. (2021). Effect of fly ash as a partial replacement of cement on the properties of concrete. Journal of Applied Engineering Sciences, 11(2), 85-90. https://doi.org/10.2478/jaes-2021-0012

Zemicheal, Y., & Houjun, Q. (2020). Design, analysis and development of improved hollow concrete block making machine. International Journal of Engineering Research & Technology, 9(3), 329-334.