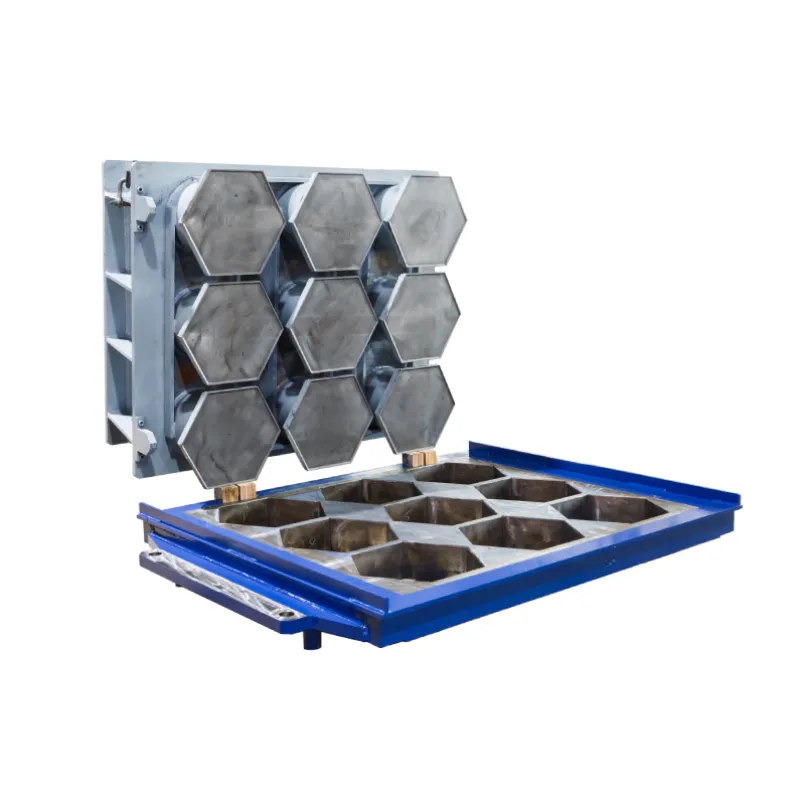

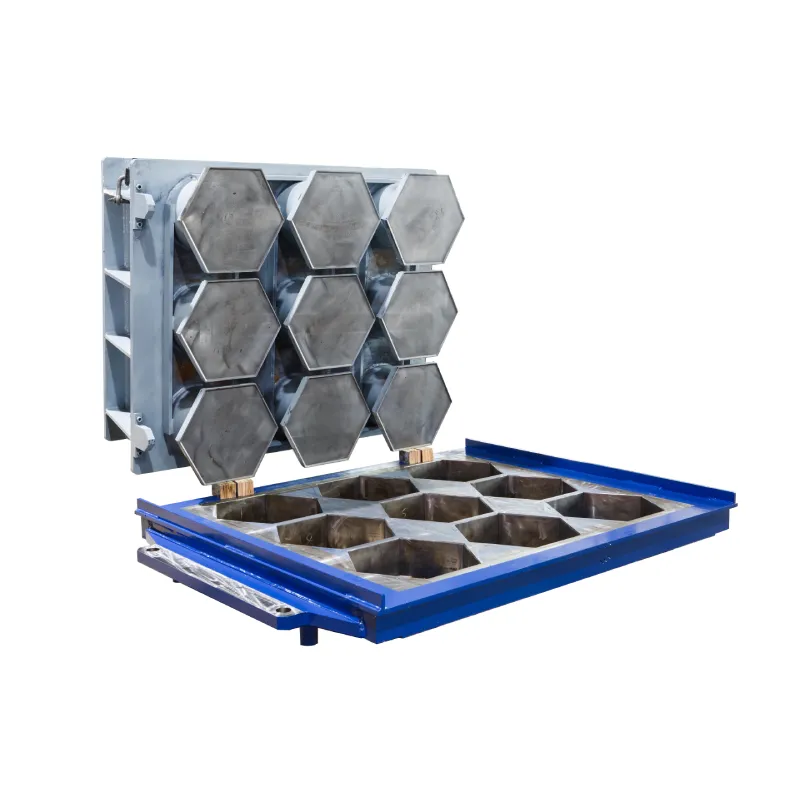

Molde de pedra de relva Molde de pavimento de estrada para parque

Molde de pedra de relva para pavimentação de caminhos de parque

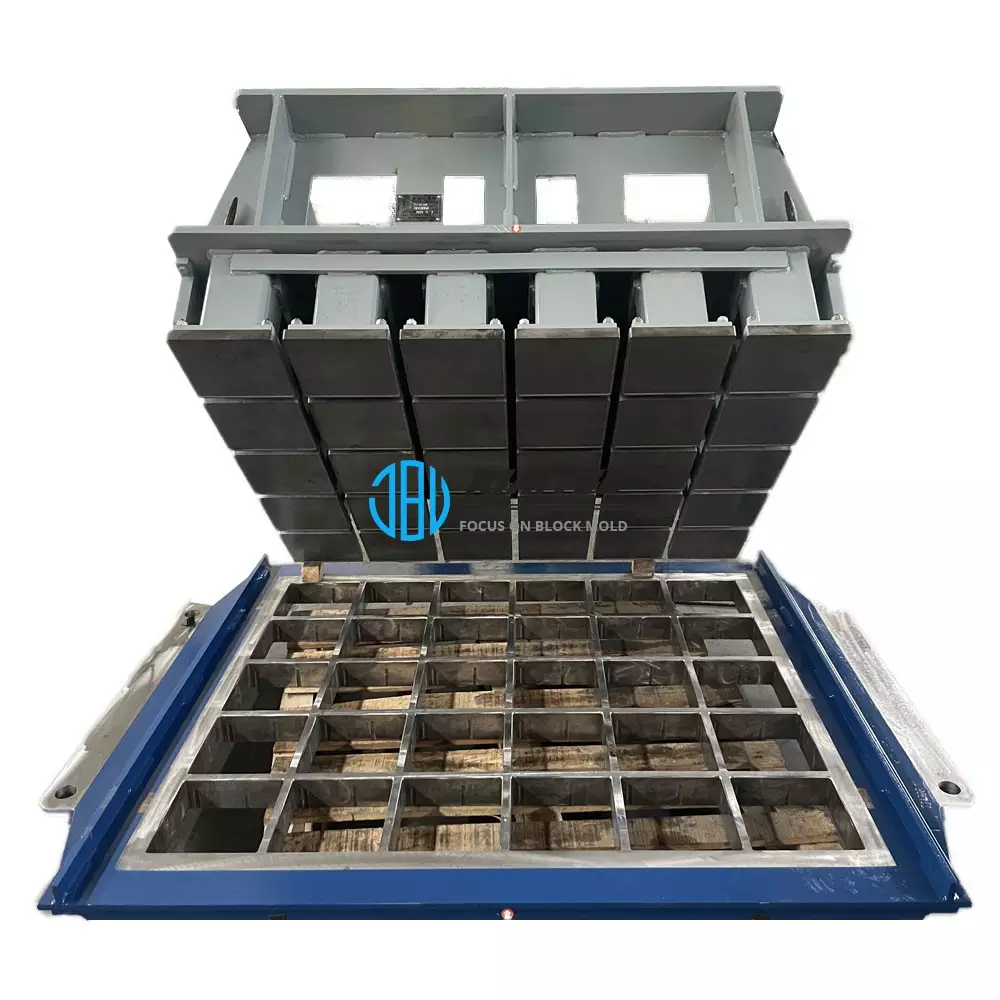

Caraterísticas:

O processo de montagem mais avançado

- Utilizamos uma tecnologia de soldadura avançada e um tratamento de despressurização para garantir a precisão. Se a tensão permanecer no material do molde, a cavidade e o núcleo podem deformar-se durante a utilização, causando erros nas dimensões, forma e tolerâncias. Isto pode fazer com que os produtos qualificados excedam os limites de erro, causar o encravamento de componentes bem combinados ou mesmo inutilizar o molde. Para evitar esta situação, minimizamos a deformação durante o tratamento térmico e efectuamos o revenido após a têmpera para eliminar a tensão interna resultante da maquinagem e do tratamento térmico, assegurando o bom funcionamento do molde.

- Mantemos uma folga do calcador de 0,3-0,8 mm para compatibilidade com a sua máquina.

- Utilizamos parafusos de ligação de alta resistência com peças normalizadas e tratamento anti-afrouxamento para maior durabilidade.

- O nosso processo de montagem normalizado garante uma substituição fácil das peças.

- Incorporamos chapas de aço resistentes ao desgaste de alta qualidade para maior longevidade.

- Os nossos moldes possuem uma função de amortecimento para um funcionamento mais suave.

- Oferecemos um design de superfície digital gratuito para personalização.

Para garantir a durabilidade do molde, aplicamos um tratamento térmico de carbonitretação (60-65HRC)

- Endurecemos a estrutura da matriz e o pé da prensa a 60-65HRC.

- Atingimos uma profundidade mínima de endurecimento de 1,2 mm para uma maior resistência.