conhecimento do sector

-

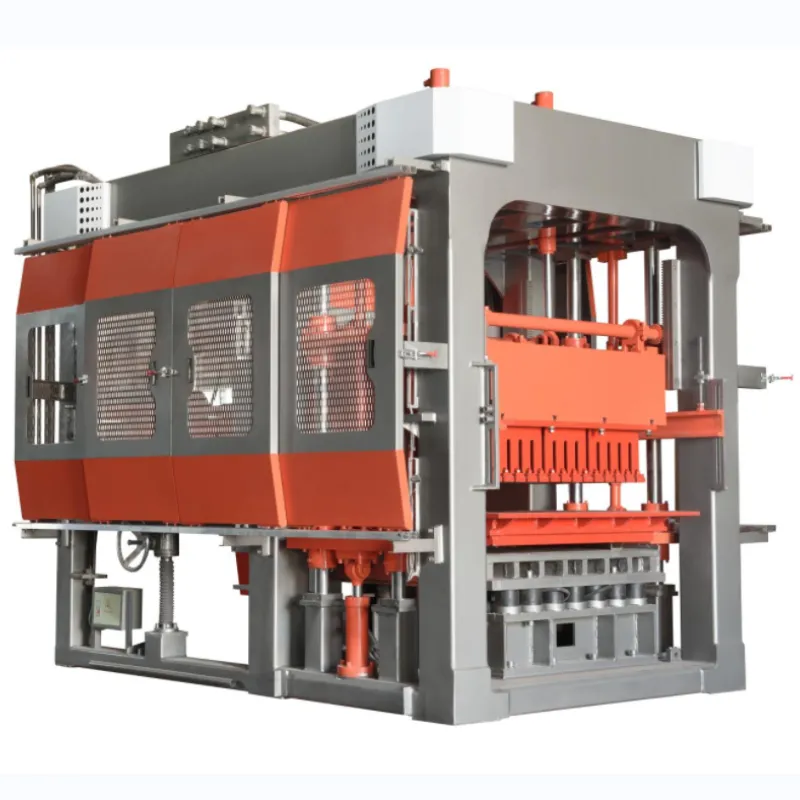

![QT12-15-BrickBlock-Making-Machine-1[1] A Proven Guide to Multi-size brick production capability: Boost Project ROI by 35% in 2026](https://www.kblmachinery.com/wp-content/uploads/2026/02/QT12-15-BrickBlock-Making-Machine-11.webp)

A Proven Guide to Multi-size brick production capability: Boost Project ROI by 35% in 2026

Ler maisAbstract The evolution of construction machinery reflects a broader industrial shift from rigid specialization towards dynamic versatility. This analysis examines the operational and economic implications of multi-size brick production capability in modern concrete block machines, particularly within the rapidly developing markets of Southeast Asia and the Middle East. It posits that the ability of a […]

-

How to Calculate Daily Brick Production Capacity and Scale a Profitable Brick Factory?

Ler maisThe short answer is that daily brick production capacity is determined by a combination of machine configuration, mold design, operating hours, labor efficiency, and curing logistics. For industrial investors and brick manufacturers, understanding this metric is essential because it directly impacts unit cost, return on investment, and market responsiveness. For example, two factories using similar […]

-

What Determines Brick Machine Output Capacity and How Can Manufacturers Optimize It?

Ler maisYes, brick machine output capacity is not determined by a single specification or machine parameter. Instead, it is the result of multiple interrelated technical, operational, and organizational variables working together across the entire production system. For brick manufacturers, investors, and plant managers, understanding brick machine output capacity factors is essential because output directly affects unit […]

-

Fly Ash vs Concrete Brick Machine Differences: Which Technology Delivers Better Long-Term Value for Manufacturers?

Ler maisFly ash vs concrete brick machine differences mainly come down to raw material behavior, production process control, equipment configuration, and long-term operating economics. Fly ash brick machines are designed to process fine, pozzolanic industrial by-products with lower cement content, while concrete brick machines focus on dense aggregate mixtures that prioritize compressive strength and dimensional stability. […]

-

Tipos de máquinas de tijolo: Qual a solução que melhor se adapta à sua estratégia de produção de construção?

Ler maisThe different Types of Brick Machines are designed to meet very different production goals, from small-scale local building projects to fully automated industrial manufacturing. Choosing the right type depends on output capacity, material availability, labor strategy, and long-term return on investment. For contractors, developers, and infrastructure suppliers, understanding these machine types is not just a […]

-

What Materials Can Be Used in a Brick Machine? A Practical Guide for Industrial Buyers

Ler maisWhat materials can be used in a brick machine? In short, modern brick machines can process a wide range of raw materials, including cement, sand, aggregates, fly ash, slag, stone dust, recycled construction waste, and even certain industrial by-products. The exact material combination depends on the brick type, strength requirements, local regulations, and the machine’s […]

-

What Types of Bricks Can a Brick Machine Produce? A Complete Guide for Industrial Buyers

Ler maisIn practice, a modern brick machine can produce a wide variety of concrete and masonry products, including solid bricks, hollow blocks, paving bricks, interlocking blocks, curbstones, and customized special-shaped units. The final product range depends on mold design, machine capacity, vibration and compaction technology, and the raw materials used. For industrial buyers, understanding these product […]

-

American Block Manufacturing vs. Chinese Machinery: A 5-Point Buyer’s Guide for 2026

Ler maisAbstract The global market for concrete block machinery in 2026 presents a complex decision for buyers, particularly those in rapidly developing regions like Southeast Asia and the Middle East. This analysis examines the comparative merits of machinery sourced from traditional American block manufacturing hubs versus the increasingly sophisticated and cost-competitive options from Chinese manufacturers. It […]

-

Turn Waste into Profit: An Expert’s 2026 Guide to the Circular Economy in Building Materials

Ler maisAbstract The global construction industry, a significant contributor to resource depletion and waste generation, stands at a critical juncture in 2026. This analysis examines the transition from a linear "take-make-waste" paradigm to a circular economy in building materials, with a particular focus on its implementation within the rapidly developing regions of Southeast Asia and the […]

-

Expert Guide to Smart Manufacturing in Brick Production: 5 Key 2026 Trends for Buyers in Southeast Asia

Ler maisAbstract The transition toward smart manufacturing in brick production signifies a pivotal evolution for the construction materials industry, particularly within the rapidly developing economies of Southeast Asia and the Middle East. This analysis examines the integration of Industry 4.0 technologies—such as the Internet of Things (IoT), artificial intelligence (AI), robotics, and data analytics—into the block […]