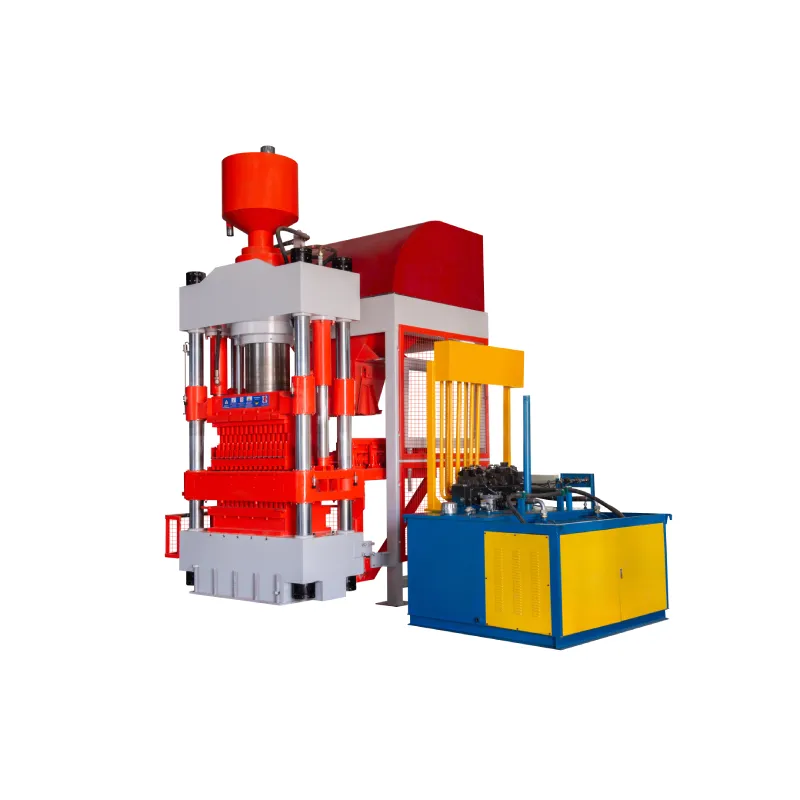

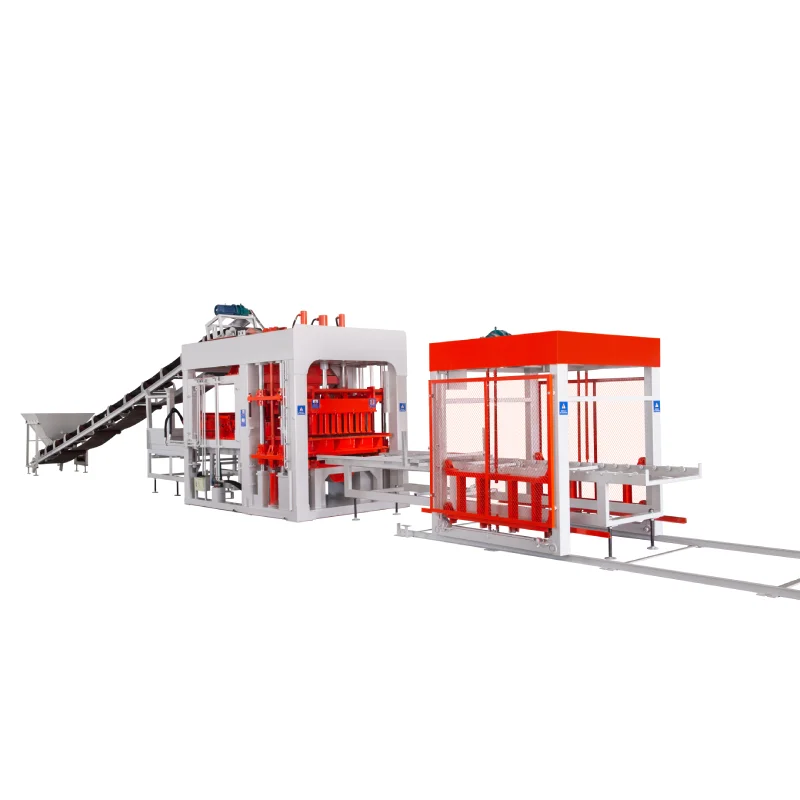

Product Overview

QT15-15 block making machine is with PLC intelligent control Man-machine interface, control system equipped with complete logic control, production program, malfunction diagnosis system and remote control function. So it doesn’t need a professional person but only need a simple training to the operator.

Production scope: QT15-15 hollow block machine concrete is a multi-function machine, it can produce various bricks/blocks including color-face bricks (layered material feeding), through-body tiles, dock linkage blocks, road curb bricks, solid bricks, hydraulic blocks, hollow blocks, perforated bricks, and standard bricks etc.

QT15-15 Block Making Machine Technical Specifications:

| Parameter |

Details |

| Machine Model |

QT15-15 Automatic Hydraulic Brick Making Machine |

| Overall Weight |

20,000 kg |

| Machine Dimensions (L×W×H) |

11,500 × 4,500 × 2,800 mm |

| Installed Power |

69.1 kW |

| Molding Cycle Time |

15 – 23 seconds (depending on block type) |

| Pallet Size |

1,350 × 1,150 mm |

| Vibration Force |

220 kN |

| Max. Vibration Pressure |

31.5 MPa |

| Molding Method |

Hydraulic pressing + Table vibration |

| Production Line Configuration |

Full automatic with PLC control, conveyor, mixer, stacker, and pallet feeder |

| Control System |

Siemens PLC + Touch Screen (customizable) |

| Material Feeding System |

Forced feeding with double-axis rotating blades |

| Hydraulic System |

High-efficiency proportional valve system |

| Operating Personnel Required |

5–6 people per production shift |

| Raw Materials Supported |

Cement, sand, crushed stone, fly ash, slag, construction waste, etc. |

| Cooling System |

Water-cooled hydraulic system (optional oil chiller available) |

QT15-15 Hollow Block Machine Concrete Production Capacity:

| Product Type |

Size (mm) |

Mould Cavities / Cycle |

Output / 8 Hours |

Remarks |

| Hollow Block |

390 × 190 × 190 |

15 pcs |

22,500 – 30,000 pcs |

Common wall block for construction |

| Solid Brick |

238 × 115 × 51 |

84 pcs |

126,000 – 168,000 pcs |

High-density, structural building bricks |

| Porous Block |

240 × 115 × 90 |

40 pcs |

60,000 – 80,000 pcs |

For internal partition walls |

| Interlocking Pavers |

200 × 100 × 60 |

55 pcs |

82,500 – 110,000 pcs |

Sidewalks, driveways, landscaping |

| Curbstone |

1,000 × 300 × 150 |

1–2 pcs |

3,000 – 4,500 pcs |

Roadside curb and edge applications |

| Grass Paver Block |

400 × 200 × 100 |

8 pcs |

12,000 – 16,000 pcs |

Green parking and ecological paving |

| Customized Shapes |

Upon request |

Based on design |

Varies |

Accept OEM molds and special shape requests |

Main Raw Materials:

Fly ash, cement, sand, crash stone, additive, construction garbage etc.

About Kimberly Machinery

Kimberly Machinery is a trusted manufacturer of high-quality concrete block production equipment. As a leading block making machine manufacturer, we provide durable, efficient, and cost-effective machines for global construction projects. With advanced technology, strict quality control, and reliable service, Kimberly Machinery delivers stable performance and long-term value for customers worldwide.