What Are the Disadvantages of Hollow Bricks?

May 9, 2025

Hollow bricks have gained popularity in the construction industry due to their lightweight, thermal insulating properties, and cost-effective nature. While they offer several advantages, such as energy efficiency and ease of handling, they also come with certain drawbacks that should be considered before choosing them for a building project. In this article, we’ll explore some of the key disadvantages of hollow bricks and how they compare to other building materials.

1. Lower Load-Bearing Capacity

One of the main disadvantages of hollow bricks is their lower load-bearing capacity compared to solid bricks or concrete blocks. Because of their hollow structure, these bricks are generally not as strong when it comes to supporting heavy loads. This can be a significant concern in buildings that require strong foundations, such as multi-story structures or buildings with heavy equipment and furniture. For these types of projects, hydraulic brick machines and other high-strength materials may be a better choice.

For more information about hydraulic brick machines, visit Hydraulic Brick Machine.

2. Limited Fire Resistance

Although hollow bricks have good thermal insulation properties, they generally have a lower fire resistance than solid bricks or concrete materials. In certain cases, hollow bricks may not provide enough protection in the event of a fire, which could compromise the safety of the structure. This is an important factor to keep in mind when designing buildings in areas prone to fires or where fire safety is a primary concern.

To explore more about brick manufacturing machines with enhanced fire resistance, you can check out China Clay Machine.

3. Potential for Cracking and Fragility

Hollow bricks can be more fragile and prone to cracking than solid bricks, especially when they are exposed to sudden impacts or heavy forces. The hollow cavities within the brick structure make them more susceptible to damage under harsh conditions. Therefore, extra care must be taken during transportation and installation to avoid cracks that could compromise the integrity of the building.

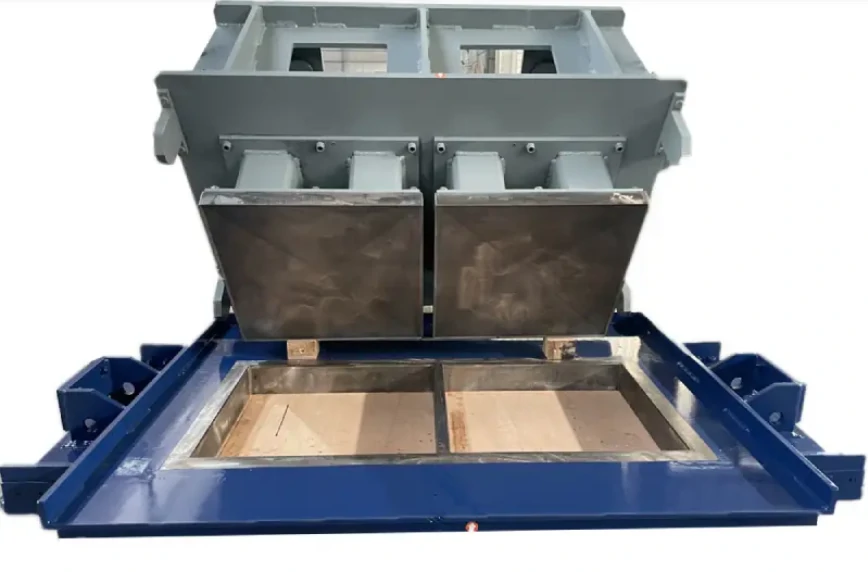

Check out more about hollow brick machines to explore the process of producing sturdy bricks at Hollow Brick Machine.

4. Higher Maintenance Costs

Due to their relatively fragile nature and potential for cracking, buildings made with hollow bricks may incur higher maintenance costs over time. Small cracks or damage can lead to water infiltration, which may weaken the bricks and require costly repairs. Regular inspections and maintenance are essential to ensure the durability of structures built with hollow bricks.

5. Not Ideal for Heavy Construction Projects

Hollow bricks may not be the best choice for heavy construction projects such as bridges, industrial buildings, or any structure that requires strong and durable materials. They are best suited for low-rise residential buildings, partition walls, and other non-load-bearing applications. In projects that require durability and the ability to support significant weight, materials like solid concrete or reinforced steel may be a better option.

Conclusion

While hollow bricks offer many benefits, including thermal insulation, light weight, and affordability, they are not without their disadvantages. From lower load-bearing capacity to potential fragility, these bricks may not be suitable for all types of construction. It’s important to carefully consider the specific requirements of your project before choosing hollow bricks as the building material.

If you’re looking for alternatives or more durable options, you can explore hydraulic brick machines and other manufacturing equipment to produce more resilient bricks suitable for your project needs.