What is a Concrete Block Making Machine?

June 17, 2025

Unlocking the Power of Automation in Modern Construction with KBL Machinery

Modern construction largely depends on the initial stage of concrete block production, and here the all-important element is the very effective and precise concrete block making machine. Moreover, this has become inevitable as cities are growing and houses are being built to be of a certain standard. Investors in the construction industry are looking into a variety of equipment options, but a concrete block manufacturing machine is in high demand. The sector is looking into the procurement of high-performance block machines to raise the quality of the blocks and correspondingly improve the whole value chain.

A Closer Look at the Core Functions

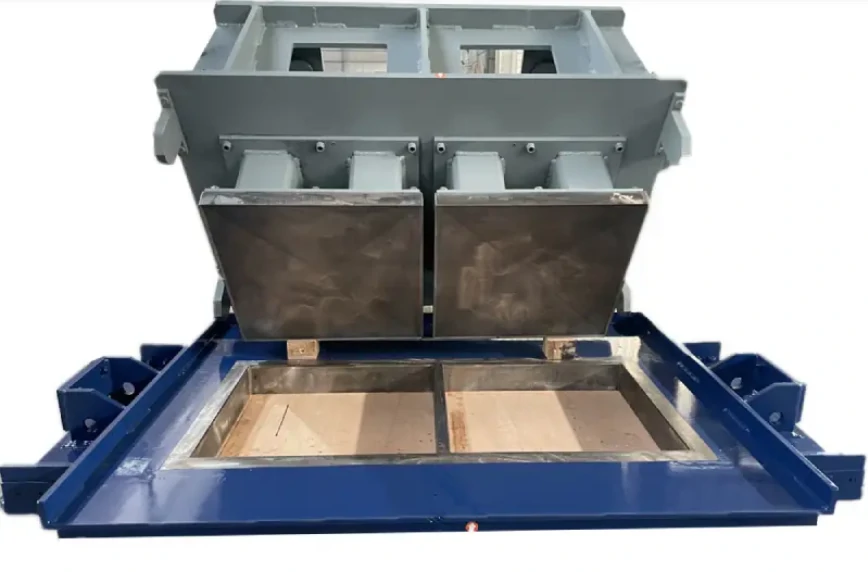

A concrete block making machine is a large mechanical contraption commonly used for the production of a wide variety of concrete blocks. Generally, these units are composed of cement, sand, stone dust, and water. The process is started with the mixing of the raw materials, then filling the molds with the mixture, and finishing with the application of high pressure and vibration to make the mixture dense and mold the blocks into a smooth and solid form.

There are several types of machines available:

- Manual: Ideal for small-scale production and startups.

- Semi-automatic: Combines some manual control with automated functions.

- Fully automatic: Offers maximum efficiency, with minimal human intervention.

The cement block making machine offered by KBL Machinery includes advanced features like automated pallet feeding, hydraulic pressure systems, and programmable logic control (PLC) for seamless operation.

Why Is It Essential for Today’s Builders?

Here are some compelling reasons why concrete block making machines are revolutionizing the construction industry:

- Efficiency & Speed: These machines can produce hundreds or even thousands of blocks per hour, depending on the model.

- Labor Cost Reduction: Automating the process minimizes the need for extensive manual labor.

- Consistency & Quality: Each block meets exact size and strength specifications.

- Design Flexibility: Modern machines can produce hollow, solid, paving, and interlocking blocks with interchangeable molds.

These advantages make block making machines indispensable for large-scale projects and growing construction businesses.

Applications Across Construction Segments

Concrete blocks produced by these machines are used in:

- Residential buildings

- Commercial complexes

- Road and pavement construction

- Retaining walls

- Landscaping and fencing

Whether you’re building a high-rise apartment or a boundary wall, a concrete block making machine ensures every block is strong, durable, and uniform.

KBL Machinery: Leading the Innovation Curve

KBL Machinery has emerged as a trusted name in the global construction machinery market. With years of experience in designing and manufacturing cement block making machines, KBL provides cutting-edge equipment tailored to customer needs. Their machines are built for long-term performance, ease of maintenance, and energy efficiency.

What sets KBL apart?

- High-strength steel frames for machine stability

- Intelligent PLC systems for automation

- Custom mold solutions to match diverse project requirements

- Reliable after-sales support and technical training

From Africa to Southeast Asia, KBL Machinery has helped businesses scale up their production capacity and improve block quality with their advanced equipment.

Points to Consider When Buying a Block Making Machine

Concrete blocks are the backbone of modern construction, and their production is highlighted by the high-end and eco-friendly concrete block making machine police. The use of advanced block production equipment to increase productivity, reduce the number of workers, and eliminate fluctuations in quality has significantly changed the industry. Nevertheless, what is a concrete block making machine, and how does it work?

- Production Capacity: The number of units needed per shift is a good measure of the capacity.

- Automation Level: Depending on the availability of manpower and the budget, one can opt for manual, semi-auto, or fully automated ones.

- Space & Layout: A factor determining the size of your facility or site is essential.

- Raw Material Compatibility: Make sure that the selected machine does not conflict with the available materials.

- After-Sales Support: A supplier who includes training and warranty can be the one to rely on.

KBL Machinery delivers a variety of different free consultations to help clients select the ideal model based on their business goals.

Future of Construction Lies in Automation

The growth of the eco-friendly and super-efficient construction materials sector makes the automated block production a necessity instead of an option. A concrete block making machine is a kind of investment that ensures faster construction, more stable structure, and intelligent operation.