Productos

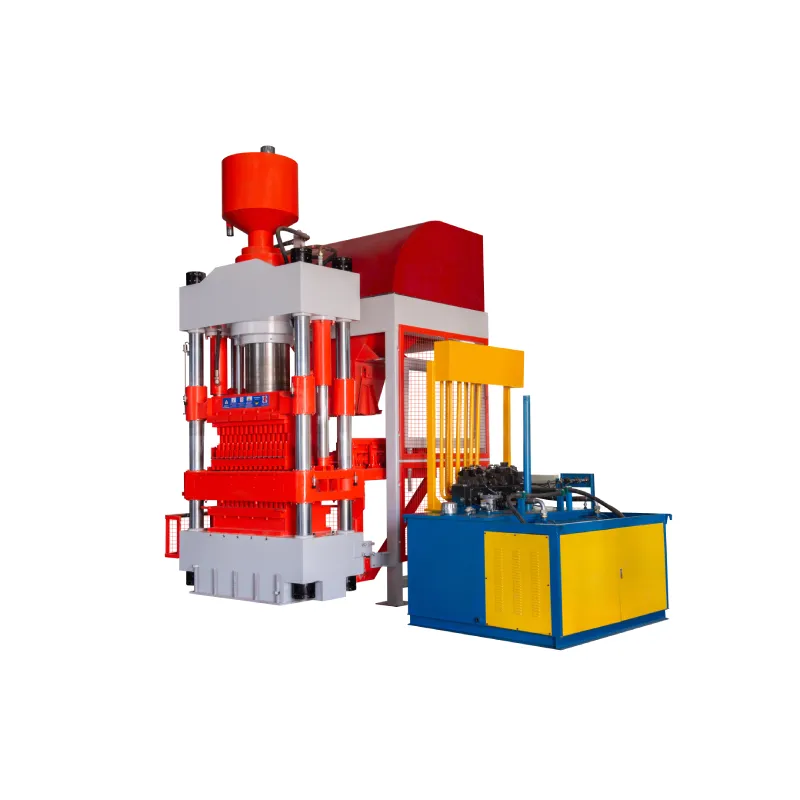

QT15-15 bloque que hace la máquina es con control inteligente PLC interfaz hombre-máquina, sistema de control equipado con control lógico completo, programa de producción, sistema de diagnóstico de mal funcionamiento y la función de control remoto. Así que no necesita una persona profesional, pero sólo necesita un simple entrenamiento para el operador.

Ámbito de producción: La máquina de bloques huecos de hormigón QT15-15 es una máquina multifuncional, puede producir varios ladrillos/bloques incluyendo ladrillos de cara de color (alimentación de material en capas), tejas pasantes, bloques de enlace de muelle, ladrillos de bordillo de carretera, ladrillos macizos, bloques hidráulicos, bloques huecos, ladrillos perforados y ladrillos estándar, etc.

QT15-15 Máquina de fabricación de bloques Especificaciones técnicas:

| Parámetro |

Detalles |

| Modelo de máquina |

QT15-15 Máquina automática hidráulica para fabricar ladrillos |

| Peso total |

20.000 kg |

| Dimensiones de la máquina (L×A×H) |

11.500 × 4.500 × 2.800 mm |

| Potencia instalada |

69,1 kW |

| Duración del ciclo de moldeo |

15 - 23 segundos (según el tipo de bloque) |

| Tamaño de la paleta |

1.350 × 1.150 mm |

| Fuerza de vibración |

220 kN |

| Máx. Presión de vibración |

31,5 MPa |

| Método de moldeo |

Prensado hidráulico + Vibración de la mesa |

| Configuración de la línea de producción |

Totalmente automático con control PLC, transportador, mezclador, apilador y alimentador de palés |

| Sistema de control |

PLC Siemens + Pantalla táctil (personalizable) |

| Sistema de alimentación de material |

Alimentación forzada con cuchillas giratorias de doble eje |

| Sistema hidráulico |

Sistema de válvula proporcional de alta eficiencia |

| Personal operativo necesario |

5-6 personas por turno de producción |

| Materias primas subvencionadas |

Cemento, arena, piedra triturada, cenizas volantes, escoria, residuos de la construcción, etc. |

| Sistema de refrigeración |

Sistema hidráulico refrigerado por agua (enfriador de aceite opcional) |

QT15-15 Máquina de bloques huecos Capacidad de producción de hormigón:

| Tipo de producto |

Tamaño (mm) |

Cavidades del molde / Ciclo |

Producción / 8 horas |

Observaciones |

| Bloque hueco |

390 × 190 × 190 |

15 piezas |

22.500 - 30.000 unidades |

Bloque de pared común para la construcción |

| Ladrillo macizo |

238 × 115 × 51 |

84 unidades |

126.000 - 168.000 unidades |

Ladrillos de construcción estructurales de alta densidad |

| Bloque poroso |

240 × 115 × 90 |

40 unidades |

60.000 - 80.000 unidades |

Para tabiques interiores |

| Adoquines |

200 × 100 × 60 |

55 unidades |

82.500 - 110.000 unidades |

Aceras, calzadas, jardinería |

| Bordillo |

1,000 × 300 × 150 |

1-2 unidades |

3.000 - 4.500 unidades |

Aplicaciones en bordillos y bordes de carreteras |

| Adoquín de hierba |

400 × 200 × 100 |

8 piezas |

12.000 - 16.000 unidades |

Aparcamientos verdes y pavimentos ecológicos |

| Formas personalizadas |

Previa solicitud |

Basado en el diseño |

Varía |

Aceptamos moldes OEM y formas especiales |

Principales materias primas:

Cenizas volantes, cemento, arena, piedra de choque, aditivos, basura de construcción, etc.

Acerca de Kimberly Machinery

Kimberly Machinery es un fabricante de confianza de equipos de producción de bloques de hormigón de alta calidad. Como líder fabricante de máquinas para fabricar bloquesEn Kimberly Machinery, proporcionamos máquinas duraderas, eficientes y rentables para proyectos de construcción globales. Con tecnología avanzada, un estricto control de calidad y un servicio fiable, Kimberly Machinery ofrece un rendimiento estable y un valor a largo plazo a clientes de todo el mundo.