コンクリートブロック製造機とは

6月 17, 2025

KBL機械で現代建設におけるオートメーションの力を引き出す

現代の建設は、コンクリートブロック製造の初期段階に大きく依存しており、ここで非常に重要な要素は、非常に効果的かつ正確である。 コンクリートブロック製造機.さらに、都市が発展し、住宅が一定の水準で建設されるようになったため、これは必然となっている。建設業界の投資家は、さまざまな機器の選択肢を検討しているが、コンクリートブロック製造機の需要は高い。この分野では、ブロックの品質を高め、それに対応してバリューチェーン全体を改善するために、高性能ブロック機械の調達を検討している。

コア機能の詳細

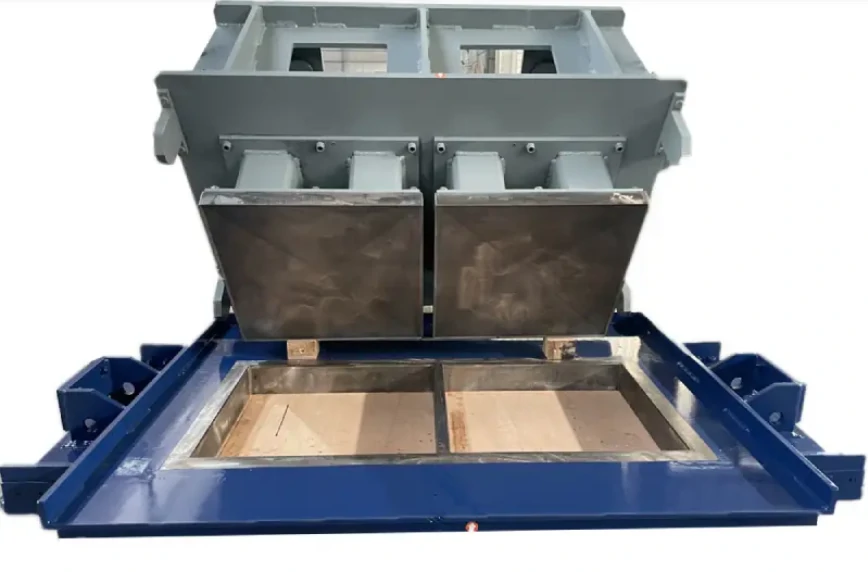

コンクリートブロック製造機は、多種多様なコンクリートブロックの製造に一般的に使用される大型の機械装置である。一般的に、これらのユニットは、セメント、砂、石粉、水で構成されています。工程は、原料の混合から始まり、混合物を型に充填し、混合物を密にし、ブロックを滑らかで固い形に成形するために高圧と振動を加えて仕上げます。

マシンにはいくつかの種類がある:

- マニュアル:小規模生産やスタートアップに最適。

- セミオートマチック:一部の手動制御と自動機能を組み合わせたもの。

- 全自動:最小限の人的介入で最大限の効率を提供。

セメントブロック製造機 KBL機械 自動パレット供給、油圧システム、プログラマブル・ロジック・コントロール(PLC)などの高度な機能を備え、シームレスなオペレーションを実現。

なぜ今日の建設業者に不可欠なのか?

コンクリートブロック製造機が建設業界に革命をもたらしている説得力のある理由をいくつか挙げてみよう:

- 効率とスピード:これらの機械は、モデルによっては1時間に数百から数千のブロックを生産することができる。

- 人件費削減:プロセスを自動化することで、大規模な手作業の必要性を最小限に抑えることができる。

- 一貫性と品質:各ブロックは、正確なサイズと強度の仕様を満たしています。

- デザインの柔軟性:最新の機械は、交換可能な型を使って、中空ブロック、ソリッドブロック、舗装ブロック、インターロッキングブロックを製造できる。

このような利点がある。 ブロック製造機 大規模プロジェクトや成長中の建設事業には欠かせない。

建設分野での応用

これらの機械で製造されたコンクリート・ブロックが使用されている:

- 住宅

- 複合商業施設

- 道路・舗装工事

- 擁壁

- 造園とフェンス

高層アパートの建設でも、境界塀の建設でも、コンクリートブロック製造機を使えば、すべてのブロックが丈夫で耐久性があり、均一な仕上がりになります。

KBLマシナリーイノベーションカーブをリードする

KBL機械 は、世界の建設機械市場で信頼される企業として頭角を現してきた。設計と製造における長年の経験により セメントブロック製造機KBLは、お客様のニーズに合わせた最先端の機器を提供しています。同社の機械は、長期的な性能、メンテナンスの容易さ、エネルギー効率を重視して作られています。

KBLの特徴は?

- マシンを安定させる高強度スチールフレーム

- オートメーション用インテリジェントPLCシステム

- 多様なプロジェクト要件に対応するカスタム金型ソリューション

- 信頼できるアフターサービスと技術トレーニング

アフリカから東南アジアまで、KBLマシナリーは先進的な設備で企業の生産能力の拡大やブロックの品質向上を支援してきた。

ブロック製造機購入時の留意点

コンクリートブロックは現代建築の基幹であり、その生産はハイエンドで環境に優しいコンクリートブロック製造機警察によって強調されている。生産性を高め、作業員の数を減らし、品質のばらつきをなくすために先進的なブロック製造装置を使用することで、この業界は大きく変わった。とはいえ、コンクリートブロック製造機とはどのようなもので、どのように機能するのだろうか。

- 生産能力:1シフトに必要なユニット数が生産能力の目安となる。

- 自動化レベル:人員と予算に応じて、手動、半自動、全自動を選ぶことができる。

- スペースとレイアウト:施設や敷地の広さを決める要素は不可欠です。

- 原材料の互換性:選択した機械が使用可能な材料と競合しないことを確認する。

- アフターセールス・サポート:トレーニングや保証を含むサプライヤーは信頼できる。

KBLマシナリーは、お客様のビジネス目標に基づいた理想的なモデルの選択を支援するため、さまざまな無料コンサルティングを実施しています。

建設の未来はオートメーションにある

環境に優しく超効率的な建設資材分野の成長により、自動化されたブロック製造はオプションではなく必需品となっています。コンクリートブロック製造機は、より迅速な建設、より安定した構造、インテリジェントな操作を保証する一種の投資です。