5 Actionable Steps for Eco-Friendly Brick Production: A 2025 Guide for SEA & Middle East Contractors

9월 19, 2025

초록

The global construction industry is undergoing a significant transformation, driven by environmental imperatives and economic pressures. In regions like Southeast Asia and the Middle East, the traditional reliance on fired clay bricks is becoming increasingly untenable due to its high energy consumption and carbon footprint. This article examines the pivot towards eco-friendly brick production as a viable and profitable alternative for contractors and manufacturers in 2025. It explores the utilization of industrial byproducts, such as fly ash and ground granulated blast-furnace slag, as primary raw materials. Central to this transition is the adoption of advanced machinery, specifically fully automatic concrete block making machines and static hydraulic presses. These technologies enable the large-scale manufacturing of high-strength, dimensionally accurate building units with minimal environmental impact. The analysis demonstrates that by integrating sustainable materials with efficient production technologies, businesses can meet stringent environmental regulations, reduce operational costs, and gain a significant competitive advantage in a market that increasingly values green building solutions.

주요 내용

- Transition to industrial byproducts like fly ash to lower material costs and environmental impact.

- Select an appropriate block making machine to match production scale and material types.

- Optimize the curing process to ensure blocks achieve maximum strength and durability.

- Leverage green certifications to enhance marketability and meet regional building codes.

- Embrace eco-friendly brick production to align profitability with sustainability goals.

- Educate clients on the long-term structural and thermal benefits of sustainable blocks.

- Implement rigorous quality control checks for consistency in every production batch.

목차

- Step 1: Re-evaluating Raw Materials for a Greener Foundation

- Step 2: Selecting the Right Machinery for Sustainable Operations

- Step 3: Optimizing the Manufacturing Process for Efficiency and Quality

- Step 4: Navigating Economic and Regulatory Landscapes

- Step 5: Implementing Quality Assurance and Market Positioning

- 자주 묻는 질문(FAQ)

- 결론

- 참조

Step 1: Re-evaluating Raw Materials for a Greener Foundation

The very essence of a building, its strength and longevity, begins with its smallest component: the brick. For centuries, the fired clay brick has been the default choice, a symbol of permanence baked in tradition. Yet, as we examine our building practices through the lens of ecological responsibility, the true cost of this tradition becomes apparent. The process of quarrying clay scars landscapes, while the firing process consumes enormous amounts of energy and releases significant quantities of carbon dioxide into the atmosphere. For contractors in rapidly developing regions like Southeast Asia and the Middle East, the reliance on this method is not just an environmental concern but an economic one, as resource scarcity and carbon taxes begin to reshape project budgets. The path forward requires a fundamental rethinking of our raw materials, moving away from extraction and towards industrial symbiosis.

The Problem with Traditional Clay Bricks: An Environmental Reckoning

To truly appreciate the need for change, one must understand the journey of a conventional clay brick. It begins with the excavation of topsoil and clay, a process that contributes to soil degradation and habitat loss. The excavated clay is then molded and fired in kilns at temperatures exceeding 1,000°C for several days. This firing process is the most problematic stage. It is intensely energy-hungry, often relying on coal or other fossil fuels, making brick kilns major contributors to greenhouse gas emissions and local air pollution (Manzan, 2022). The emissions include not just CO2 but also sulfur oxides, nitrogen oxides, and particulate matter, which have well-documented impacts on public health.

Consider the sheer scale. With billions of bricks produced annually to fuel construction booms, the cumulative environmental toll is staggering. What if we could create a building block that not only sidesteps this destructive process but also actively helps clean up waste from other industries? This is not a hypothetical question; it is the practical and necessary direction our industry is heading. The solution lies in viewing industrial "waste" not as a liability to be disposed of, but as a valuable resource waiting for a new purpose.

Embracing Industrial Byproducts: The Rise of Fly Ash and Slag

The most promising alternatives to virgin clay are pozzolanic materials, which are substances that form cementitious compounds when mixed with calcium hydroxide and water. Two such materials are abundant and highly effective: fly ash and ground granulated blast-furnace slag (GGBS).

Fly ash is a fine powder that is a byproduct of burning pulverized coal in electric generation power plants. For decades, it was considered a waste product, often dumped in landfills at great expense. However, scientific research has revealed its remarkable properties. When used in concrete and brick production, fly ash acts as a superb pozzolan, reacting with the calcium hydroxide produced during cement hydration to form additional calcium-silicate-hydrate (C-S-H), the very "glue" that gives concrete its strength (Mehta, 2014). Bricks made with a high percentage of fly ash are not just "good enough"; they are often superior to their clay counterparts. They exhibit higher compressive strength, lower water absorption, better thermal insulation, and a smoother, more uniform finish. From an environmental standpoint, every ton of fly ash used in construction is a ton of waste diverted from a landfill and a corresponding reduction in the need for energy-intensive cement production. As some experts note, making bricks from industrial waste is an excellent way to support a circular economy (block-machine.net).

Similarly, GGBS is a byproduct of steel manufacturing. When molten iron is produced in a blast furnace, the resulting slag is rapidly cooled with water, creating glassy, granular particles. When ground into a fine powder, GGBS also exhibits excellent cementitious properties. Its use in block production contributes to a denser, more durable, and less permeable final product, enhancing its resistance to chemical attack and improving its long-term performance.

The transition to these materials represents a profound shift in mindset. It moves construction from a linear model (extract-manufacture-use-dispose) to a circular one (manufacture-use-recycle-repurpose).

| 기능 | Traditional Fired Clay Brick | Fly Ash Brick |

|---|---|---|

| 주요 원자재 | Virgin clay and soil | Industrial byproduct (fly ash), sand, lime/cement |

| Manufacturing Process | High-temperature kiln firing (~1000°C) | Ambient temperature curing or low-pressure steam |

| 에너지 소비량 | Very high | Very low |

| 탄소 발자국 | High (significant CO2 emissions) | Low to negligible (prevents landfilling) |

| 압축 강도 | Variable, typically 3.5-12 N/mm² | High and consistent, typically 7.5-20 N/mm² |

| 수분 흡수 | Higher (15-25%) | Lower (6-12%) |

| Surface Finish | Rough, non-uniform | Smooth, uniform, requires no plastering |

| 리소스 영향 | Depletion of topsoil | Utilization of industrial waste |

Sourcing and Quality Control for Alternative Aggregates

Adopting new materials is not as simple as swapping one powder for another. Success in eco-friendly brick production hinges on rigorous sourcing and quality control. The chemical composition of fly ash, for instance, can vary depending on the type of coal burned and the operational conditions of the power plant. It is classified into two main types: Class F (produced from burning anthracite or bituminous coal) and Class C (from lignite or sub-bituminous coal). Class F fly ash is the preferred type for most high-quality block applications due to its lower lime content and more reliable pozzolanic activity.

Therefore, establishing a relationship with trusted suppliers is paramount, as noted by industry professionals (tabrick.com). A manufacturer must insist on receiving a certificate of analysis with each shipment, detailing its chemical and physical properties. Key parameters to monitor include the content of silica, alumina, and iron oxide (which contribute to strength), as well as the loss on ignition (LOI), an indicator of unburnt carbon content. A high LOI can negatively affect the brick's performance and may require adjustments to the mix design.

Similarly, other aggregates like sand or crushed stone must be clean, properly graded, and free from organic impurities. The particle size distribution of the aggregate is a critical factor influencing the workability of the mix and the density of the final block. A well-graded aggregate mix, containing a balanced distribution of fine and coarse particles, will result in a denser block with fewer voids, leading to higher strength and lower permeability. Getting this mix right is a science, one that pays dividends in product quality and consistency.

Step 2: Selecting the Right Machinery for Sustainable Operations

The transition to eco-friendly materials is only half the story. The other half is the technology used to transform these materials into high-quality building blocks. The era of manual molding and sun-drying is ill-suited for the precision and scale required in modern construction. Advanced block making machines are the engines of this new paradigm, offering the speed, consistency, and power needed to produce superior blocks from alternative aggregates. For a business owner in Dubai or a contractor in Jakarta, choosing the right machine is one of the most significant investment decisions they will make. It determines not only production capacity but also product quality, operational efficiency, and long-term profitability.

Understanding Block Making Machine Technologies

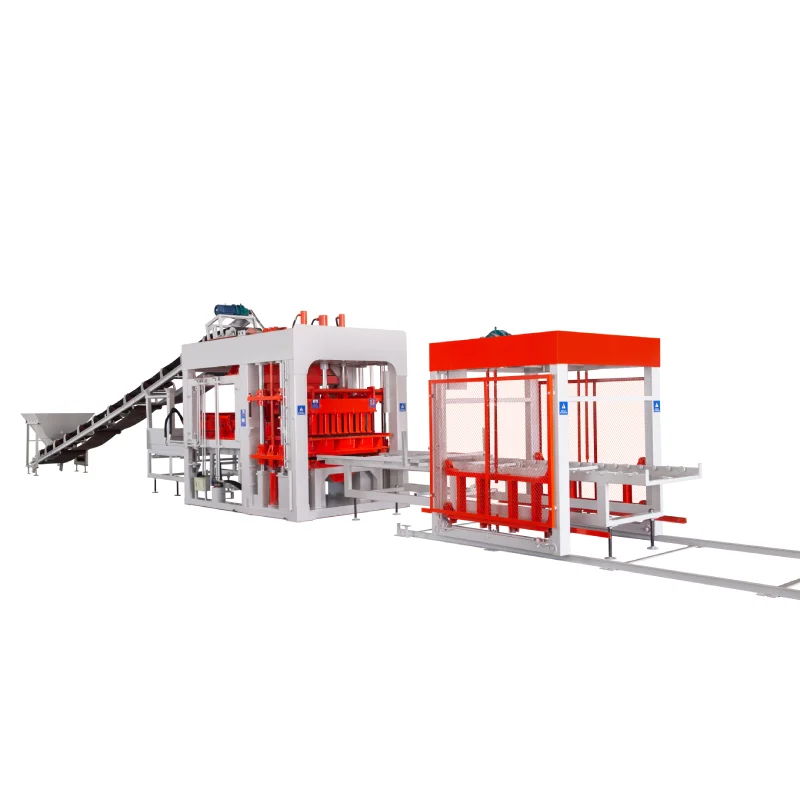

At their core, all block making machines perform a similar function: they compact a precisely measured mixture of raw materials in a mold to form a block. However, the method by which they achieve this compaction varies significantly, leading to different machine types suited for different applications. The two dominant technologies in the market today are fully automatic concrete block making machines (often designated as QT series) and static hydraulic block pressing machines.

A fully automatic machine is an integrated production line. It automates every step of the process, from batching and mixing the raw materials to molding, demolding, and stacking the finished blocks. These systems use a combination of high-frequency vibration and hydraulic pressure. The vibration helps the material particles settle into a dense, tightly packed arrangement within the mold, eliminating air voids. The hydraulic pressure then provides the final compaction, ensuring the block has high strength and dimensional accuracy. The "fully automatic" nature means they require minimal labor and can operate continuously, producing tens of thousands of blocks per day. This makes them ideal for large-scale commercial operations aiming for maximum output and efficiency.

In contrast, a static hydraulic press relies primarily on immense pressure to form the block. These machines typically use a single, powerful hydraulic cylinder to compress the material within the mold. While they may incorporate some vibration, the defining force is static pressure, which can reach extremely high levels. This high pressure is particularly effective for materials that are less free-flowing and require significant force to compact, such as mixes with less water content or certain types of soil-based blocks. These machines can be semi-automatic or fully automatic, but their operational principle is centered on pressure rather than vibration.

Comparing Fully Automatic vs. Static Hydraulic Presses

Choosing between a fully automatic vibration-based machine and a static hydraulic press depends on several factors: the desired production volume, the specific raw materials being used, the types of blocks to be produced (e.g., hollow, solid, paver), and the available capital investment.

| 기능 | QT Series Fully Automatic Machine | Static Hydraulic Press Machine |

|---|---|---|

| 기본 압축 방법 | High-frequency vibration combined with hydraulic pressure | High static hydraulic pressure |

| 생산 속도 | Very high (e.g., 10,000-100,000 blocks/8 hours) | Moderate to high (e.g., 5,000-40,000 blocks/8 hours) |

| 노동 요구 사항 | Low (highly automated) | Low to moderate |

| 가장 적합한 대상 | High-volume production of standard concrete, hollow, and fly ash blocks. | High-density solid blocks, interlocking pavers, and blocks from semi-dry mixes. |

| 다용도성 | Excellent; molds can be changed to produce a wide variety of block types. | Good; versatile but may be optimized for high-density products. |

| 초기 투자 | 높음 | 보통에서 높음 |

| 에너지 소비량 | Moderate (powers vibration motors, hydraulics, and conveyor systems) | Moderate (primarily for the main hydraulic pump) |

| 블록 밀도 | High and uniform | Very high, can achieve exceptional density |

For a large-scale producer of fly ash bricks for housing projects, a QT series fully automatic block machine would likely be the superior choice. Its high output speed and automation capabilities ensure that production can keep pace with demanding construction schedules. The combination of vibration and pressure is perfectly suited for creating strong, lightweight hollow blocks from fly ash mixes. The ability to quickly change molds also allows the manufacturer to produce a diverse product portfolio, from standard building blocks to decorative pavers, all on the same line.

On the other hand, a company specializing in high-end architectural blocks or heavy-duty industrial pavers might lean towards a static hydraulic press. The immense pressure exerted by these machines can create blocks of exceptional density and strength, with a sharp, clean finish that is aesthetically pleasing. While the production cycle might be slightly slower than a top-end QT machine, the focus is on achieving maximum quality and specific material properties.

Key Machine Specifications for Eco-Friendly Brick Production

When evaluating a block making machine, several technical specifications are of paramount importance for ensuring successful eco-friendly brick production.

First, consider the molding cycle time. This is the time it takes for the machine to complete one cycle of filling, compacting, and demolding a set of blocks. A shorter cycle time (e.g., 15-25 seconds) translates directly to higher daily output.

Second, examine the vibration force and frequency. For fly ash and other fine-particle mixes, high-frequency vibration is key to achieving proper liquefaction and densification of the material. The machine should offer adjustable vibration parameters to allow for fine-tuning the process for different mix designs.

Third, the hydraulic system pressure is a critical indicator of the machine's power. A robust hydraulic system not only provides the necessary compaction force but also ensures the smooth and reliable operation of all moving parts. Look for machines that use components from reputable international brands for their hydraulic pumps and valves, as this is a good indicator of reliability and longevity.

Finally, the versatility of the mold system cannot be overstated. The construction market demands a variety of products. A machine that allows for quick and easy mold changes is a far more valuable long-term asset than one that is limited to a single block type. As one machine manufacturer points out, understanding the different types of machines available is a crucial first step for any prospective buyer (linkedin.com). The investment in a high-quality, versatile machine is an investment in the future adaptability and profitability of the business.

Step 3: Optimizing the Manufacturing Process for Efficiency and Quality

Owning a state-of-the-art block making machine is like having a world-class musical instrument; its potential can only be realized in the hands of a skilled operator who understands the nuances of the process. The manufacturing of high-quality, eco-friendly bricks is a science that demands precision at every stage. From the initial mixing of raw materials to the final curing of the blocks, each step is interconnected, and a small deviation in one area can have a significant impact on the final product. Achieving excellence requires a commitment to process optimization, turning the production floor into a laboratory of efficiency and quality control.

Precision in Batching and Mixing

The foundation of a great brick is a perfect mix. This stage is arguably the most critical in the entire manufacturing process. The goal is to create a homogenous mixture where every particle of cement, fly ash, sand, and aggregate is uniformly coated with a thin film of water. Inconsistent mixing leads to weak spots, variable density, and surface defects in the finished blocks.

Modern block production lines utilize automated batching systems to ensure this precision. Raw materials are stored in separate silos and hoppers, each equipped with load cells or electronic scales. The operator simply enters the desired mix design into a programmable logic controller (PLC), and the system automatically weighs and dispenses the exact required amount of each ingredient into the mixer. This eliminates the human error inherent in manual volume-based batching (e.g., using shovels or buckets) and guarantees consistency from the first block of the day to the last.

The choice of mixer is also important. For semi-dry mixes used in block production, a pan mixer or a planetary mixer is generally preferred over a traditional drum mixer. A pan mixer uses rotating paddles or stars to force the materials to shear and blend, ensuring a thorough and rapid mix. A planetary mixer is even more advanced, with mixing stars that rotate on their own axes while also revolving around the center of the mixer, ensuring that no "dead spots" are left unmixed. The mixing time is also a critical parameter. Under-mixing results in a non-homogenous blend, while over-mixing can begin to break down the aggregates or needlessly consume energy. Typically, a mixing time of 3-5 minutes is sufficient to achieve the desired consistency.

The Mechanics of Compaction and Molding

Once the material is perfectly mixed, it is transported via a conveyor belt to the hopper of the block making machine. Here, the art of compaction takes center stage. As described earlier, modern machines use a powerful combination of vibration and hydraulic pressure.

Let's visualize what happens inside the mold. The mix is fed into the mold box. Then, the high-frequency vibrators are activated. This energy causes the fine particles (fly ash, cement) and water to form a temporary slurry, which lubricates the larger aggregate particles. This "liquefaction" effect allows the aggregates to settle into their most compact possible arrangement, minimizing the voids between them. It is a bit like shaking a jar of mixed nuts; the smaller nuts will settle down to fill the gaps between the larger ones.

Simultaneously or immediately after, the hydraulic press head descends, applying immense pressure (often upwards of 25-30 MPa) onto the material. This pressure squeezes out any remaining air pockets and excess water, forcing the particles into intimate contact. This dual-action process—vibration for particle arrangement and pressure for final densification—is what enables the production of blocks that are not only strong but also have sharp edges, precise dimensions, and a smooth surface. The entire cycle, from filling to compaction to demolding, can take as little as 15 seconds in a high-performance automatic concrete block making machine.

Curing: The Final Step to Strength and Durability

A freshly molded block is often called a "green" block. It has its shape, but it has not yet developed its final strength. That strength comes from the chemical process of hydration, where the cement and pozzolanic materials (like fly ash) react with water to form a crystalline, rock-like structure. This process is known as curing, and it is absolutely vital for durability. Improper curing is one of the most common causes of poor-quality blocks.

There are several methods for curing. The most basic is air curing, where the blocks are simply stacked in a covered area and allowed to harden naturally. While simple, this method is slow and can be unreliable, as the rate of curing is heavily dependent on ambient temperature and humidity. To ensure proper hydration, the blocks must be kept moist, often by periodically spraying them with water. This process can take 14 to 28 days to achieve sufficient strength (ai-online.com, 2025).

A much more efficient and reliable method is steam curing. In this process, the racks of green blocks are moved into a sealed kiln or chamber. Low-pressure steam is then introduced, raising the temperature and humidity to optimal levels. The heat accelerates the chemical reactions of hydration, allowing the blocks to achieve a significant portion of their final strength in as little as 12 to 24 hours, compared to weeks for air curing. This not only dramatically speeds up the production cycle but also leads to a more consistent and often higher ultimate strength. For any serious commercial operation, investing in a proper steam curing system is not a luxury; it is a necessity for ensuring product quality and production efficiency. The blocks emerge from the curing kiln ready for testing, storage, and shipment to the construction site.

Step 4: Navigating Economic and Regulatory Landscapes

The shift to eco-friendly brick production is not merely a technical or operational change; it is a strategic business decision deeply intertwined with the economic and regulatory environments of the markets served. For contractors and manufacturers in Southeast Asia and the Middle East, a region characterized by rapid urbanization and growing environmental awareness, understanding these external forces is just as important as mastering the production process itself. The most successful enterprises will be those that can skillfully navigate the challenges and opportunities presented by government policies, market demands, and the fundamental economics of green construction.

The Financial Case for Going Green: ROI and Cost Savings

At first glance, the initial capital outlay for a modern, automatic block making machine and associated systems can seem daunting. However, a careful financial analysis reveals a compelling case for the investment, centered on long-term return on investment (ROI) and significant operational cost savings.

The first and most direct saving comes from the raw materials. Traditional clay brick production requires quarrying, which involves land acquisition, excavation machinery, and transportation costs. In contrast, fly ash is an industrial byproduct. While not free, it is typically sold at a price significantly lower than that of Portland cement, a portion of which it replaces in the mix. In many cases, power plants may even offer favorable pricing to ensure offtake of their fly ash, as it saves them from incurring landfilling costs. A mix design that replaces 20-30% of cement with fly ash can lead to substantial savings on every single block produced. Over a year of high-volume production, these savings can amount to a significant portion of the initial machinery investment.

Labor cost is another major factor. Traditional brick making is labor-intensive. A fully automatic production line, from batching to stacking, can be operated by a small team of just 3-5 people per shift. This drastic reduction in labor requirements not only lowers payroll expenses but also reduces the challenges associated with managing a large workforce.

Finally, energy costs are dramatically lower. The energy required to run the electric motors and hydraulic pumps of a block machine is a fraction of that needed to fire a kiln at 1,000°C for days on end. This is a direct and substantial saving on the monthly utility bill, a saving that becomes even more significant as energy prices continue to rise. When all these factors are combined—material savings, labor reduction, and energy efficiency—the payback period for the initial investment in green technology is often surprisingly short.

Understanding Environmental Regulations in Southeast Asia and the Middle East

Governments across the globe are increasingly implementing policies to curb industrial pollution and promote sustainable development. The construction sector, as a major consumer of resources and producer of emissions, is a primary focus of these regulations.

In many countries in Southeast Asia, governments are actively promoting the use of fly ash bricks and other green building materials through various incentives. These may include tax breaks for manufacturers, preferential treatment in government construction tenders, and streamlined permitting processes for projects that use certified green materials. At the same time, they are tightening regulations on traditional brick kilns, imposing stricter emission standards, or even banning them in certain areas to combat air pollution. For example, policies in India have mandated the use of fly ash bricks in public construction projects within a certain radius of thermal power plants for years (Building Materials and Technology Promotion Council, n.d.). Similar trends are emerging across the region.

In the Middle East, particularly in nations like the UAE and Saudi Arabia, the focus is on large-scale "giga-projects" and smart cities built on principles of sustainability. These projects often have their own stringent green building codes, such as the Estidama Pearl Rating System in Abu Dhabi or the Dubai Green Building Regulations. These codes explicitly award points for using recycled content and locally sourced materials, making fly ash bricks and other eco-friendly blocks a highly attractive option for contractors looking to meet these standards. Failing to adapt to these regulations is no longer an option; it is a direct threat to a company's ability to compete for and win major projects.

Gaining a Competitive Edge with Green Certifications

In a crowded marketplace, differentiation is key. Simply producing a good product is not enough; you must also communicate its value to your customers. This is where green building certifications come into play. Obtaining a recognized certification for your eco-friendly bricks serves as a third-party validation of your product's environmental claims, building trust and credibility with architects, engineers, developers, and end-users.

Certifications like Leadership in Energy and Environmental Design (LEED), the most widely used green building rating system globally, offer credits for materials that have recycled content and are sourced regionally. By manufacturing fly ash bricks, a producer is directly helping projects achieve these credits, making their product more desirable.

Beyond project-based systems like LEED, manufacturers can seek product-specific eco-labels. These labels, often administered by national standards bodies or environmental agencies, certify that a product meets specific criteria for environmental performance throughout its lifecycle. Displaying such a label on your product and marketing materials acts as a powerful signal to the market that your company is a leader in sustainability. It transforms the brick from a simple commodity into a value-added product, allowing for premium pricing and stronger brand loyalty. It tells a story that resonates with a new generation of builders and consumers who understand that the choices we make in construction have a lasting impact on the world we share.

Step 5: Implementing Quality Assurance and Market Positioning

The final, crucial step in building a successful eco-friendly brick business is to ensure that the promise of a superior product is delivered consistently and communicated effectively to the market. A reputation for quality is the most valuable asset a manufacturer can possess. It is built not by chance, but through a rigorous, systematic approach to quality assurance and a thoughtful strategy for market positioning. This involves not only testing the physical properties of the bricks but also educating the market about their benefits, thereby transforming a sustainable product into a preferred one.

Testing for Strength, Absorption, and Durability

Quality assurance begins on the production floor and ends in the laboratory. It is a continuous feedback loop that ensures every batch of bricks meets or exceeds the required standards. The three most important parameters to test for are compressive strength, water absorption, and dimensional accuracy.

Compressive Strength: This is the most common measure of a block's quality. It determines the load it can bear before failing. The test is conducted using a compression testing machine, which applies a slow, steady load to the brick until it fractures. The force at which it breaks, divided by the area of the brick, gives the compressive strength, typically measured in Newtons per square millimeter (N/mm²) or pounds per square inch (psi). For load-bearing walls, standards often require a minimum strength (e.g., 7.5 N/mm²). A robust quality control program will involve testing samples from every production batch to ensure this standard is consistently met. The strength of fly ash bricks is known to continue increasing over a longer period compared to OPC-based blocks, a key benefit that should be tracked and documented.

Water Absorption: This test measures how much water a brick will absorb when submerged for 24 hours. It is an important indicator of durability. A block with high water absorption is more susceptible to damage from freeze-thaw cycles and may allow more moisture to penetrate a wall. Fly ash bricks naturally have a denser, less permeable microstructure, which results in lower water absorption (typically 6-12%) compared to many traditional clay bricks (15-25%). Regular testing confirms this superior performance and provides a powerful data point for marketing.

치수 정확도: Modern construction demands precision. Blocks that vary in size make it difficult for masons to maintain level courses and uniform mortar joints, leading to wasted time and materials. A good block making machine produces blocks with very tight dimensional tolerances. Quality control should include periodically taking random samples from the production line and measuring their length, width, and height with calipers to ensure they fall within the specified tolerance (e.g., +/- 2mm).

Educating Your Market on the Benefits of Eco-Friendly Bricks

Having a technically superior product is of little value if your potential customers—architects, developers, contractors, and homeowners—do not understand its advantages. Many in the construction industry can be conservative, preferring to stick with familiar materials. Overcoming this inertia requires a proactive educational marketing strategy.

This means moving beyond simple sales pitches and becoming a source of valuable information. Develop clear, concise technical data sheets that present the results of your quality testing in an easy-to-understand format. Create comparison charts, like the one presented earlier, that visually highlight the advantages of your fly ash bricks over traditional clay bricks. Host workshops or seminars for local architects and engineers, demonstrating the strength of your products and explaining how their use can help them meet green building standards.

Emphasize the benefits that matter most to each audience. For developers, focus on the cost savings and faster construction cycles. For architects, highlight the aesthetic qualities (smooth finish, uniform color) and the contribution to sustainability certifications like LEED. For homeowners, explain the long-term benefits of better thermal insulation, which leads to lower energy bills for heating and cooling. By educating your market, you are not just selling a product; you are building partnerships and establishing yourself as an industry expert.

Building a Brand Around Sustainability

In the modern economy, a brand is more than a logo; it is a story and a promise. For a producer of eco-friendly bricks, the story is one of innovation, environmental responsibility, and superior quality. This narrative should be at the core of all your branding and marketing efforts.

Your company website, brochures, and even the packaging for your bricks should reflect this commitment to sustainability. Use imagery that shows the clean, modern production process. Share case studies of successful projects that have used your bricks, complete with testimonials from satisfied clients. Engage in content marketing by publishing blog posts or articles (much like this one) that delve into the science of sustainable building materials, positioning your company as a thought leader.

By consistently delivering a high-quality product and effectively communicating its environmental and performance benefits, you build a powerful brand. You move the conversation with your customers away from a simple discussion of price per brick to a more meaningful discussion about long-term value, durability, and shared responsibility for building a better, more sustainable future. This is how a commodity product becomes a premium brand, and how a business thrives in the competitive landscape of 2025.

자주 묻는 질문(FAQ)

Are fly ash bricks as strong as traditional red clay bricks?

Yes, and in most cases, they are significantly stronger. Due to the pozzolanic reaction of fly ash and the high-pressure compaction process, fly ash bricks typically exhibit higher and more consistent compressive strength than fired clay bricks. They also offer superior durability due to lower water absorption.

What is the main difference between a fully automatic and a semi-automatic block machine?

A fully automatic block machine integrates all stages of production, from material batching to block stacking, into a single, PLC-controlled line with minimal labor. A semi-automatic machine requires more manual intervention, particularly in moving the finished blocks from the machine to the curing area, resulting in lower output and higher labor costs.

Can I use local soil or sand to make eco-friendly bricks?

Yes, certain types of machinery, like compressed earth block (CEB) machines, are specifically designed to use local soil stabilized with a small amount of cement or lime. For standard concrete or fly ash block machines, local sand is a primary ingredient, but it must be clean, properly graded, and free of organic contaminants to ensure quality. Other alternatives like recycled concrete can also be used (ai-online.com).

What is the initial investment for starting an eco-friendly brick production plant?

The investment varies widely based on the scale of operation and the level of automation. A complete, high-capacity fully automatic line represents a significant capital investment, while a smaller, semi-automatic machine is more accessible. Prospective buyers should consider not just the machine cost but also the costs for land, sheds, batching equipment, and curing systems. A detailed business plan is essential.

How does using fly ash bricks contribute to green building certifications like LEED?

Using fly ash bricks can contribute to earning points in several LEED credit categories. These include "Building Product Disclosure and Optimization – Sourcing of Raw Materials" for using recycled content (fly ash is considered a pre-consumer recycled material) and "Regional Materials" if the power plant source and manufacturing facility are located close to the project site.

What maintenance is required for a block making machine?

Regular maintenance is vital for longevity and consistent performance. Daily tasks include cleaning the molds and mixer. Weekly checks involve inspecting hydraulic hoses, conveyor belts, and lubricating moving parts. Periodic maintenance includes changing hydraulic oil and filters and checking the wear on mold components. Following the manufacturer's recommended maintenance schedule is the best practice.

How long does it take for fly ash bricks to cure completely?

While steam curing can help fly ash bricks achieve sufficient handling strength in 24 hours, they continue to gain strength for weeks or even months afterward. They typically reach their specified 28-day design strength within that period, but the ongoing pozzolanic reaction means their strength can continue to increase over time, which is a significant advantage over ordinary concrete blocks.

결론

The path toward a sustainable future for construction is not an abstract ideal; it is a practical reality being built today, block by block. The transition to eco-friendly brick production represents a convergence of ecological responsibility and economic sagacity. By harnessing industrial byproducts like fly ash and employing advanced manufacturing technologies such as fully automatic block making machines, contractors and producers in Southeast Asia and the Middle East can overcome the limitations of traditional methods. This evolution allows for the creation of building materials that are stronger, more uniform, and less costly to produce in terms of both currency and environmental impact. Embracing this change is no longer a matter of choice but a strategic imperative for any business looking to thrive in the conscientious and competitive marketplace of 2025 and beyond. The foundation for the cities of tomorrow is not just stone and mortar, but innovation and foresight.

참조

Building Materials and Technology Promotion Council. (n.d.). Fly ash brick technologies. Ministry of Housing & Urban Affairs, Government of India. Retrieved from

라킨, J. (2025, March 18). 속이 빈 블록을 만드는 방법: 단계별 가이드. AI-Online. ai-online.com

Manzan, M. (2022). Energy and environmental analysis of the brick production process. Energies, 15(15), 5697. https://doi.org/10.3390/en15155697

Mehta, P. K. (2014). High-performance, high-volume fly ash concrete for sustainable development. In Proceedings of the International Conference on Sustainable Construction Materials and Technologies.

REIT 머신. (2025, 2월 8일). 블록 제작 기계에 대해 알아야 할 모든 것. reitmachine.com

Tabrick. (2024년 7월 9일). 중공 블록 제조의 7단계. tabrick.com

Thomas, A. (2021). A review on the properties of fly ash-based concrete. Journal of Cleaner Production, 319, 128629.

Zhang, C. (2025, January 1). Fly ash brick machine vs concrete block machine. Lontto Block Machine. block-machine.net