Guia do Comprador do Expert 2025: 5 perguntas a fazer a qualquer marca líder de equipamento de fabrico de tijolos

outubro 11, 2025

Resumo

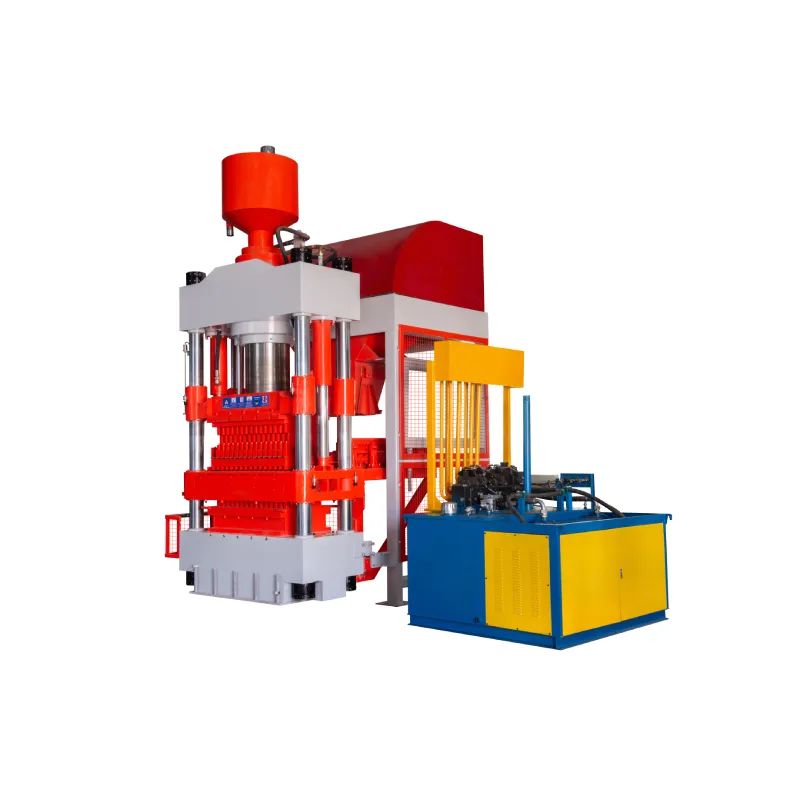

The acquisition of concrete block manufacturing machinery represents a foundational investment for construction enterprises in Southeast Asia and the Middle East. This document provides a rigorous analytical framework for evaluating suppliers in 2025, moving beyond superficial price comparisons to a nuanced assessment of technological suitability, operational support, and long-term value. It examines the critical questions that procurement managers must pose to any leading brick making equipment brand. The analysis centers on the adaptability of machinery, such as the QT series fully auto concrete block making machines, to local raw materials and climatic conditions. It further explores the indispensable nature of regional after-sales support, the verification of performance data through localized case studies, the impact of automation on labor and quality, and the strategic importance of mold customization. By dissecting these five core areas, the paper equips decision-makers with the intellectual tools needed to forge a productive, reliable, and profitable partnership with an equipment manufacturer, ensuring the machinery procured is not merely a purchase but a strategic asset for sustained growth.

Principais conclusões

- Question a machine's adaptability to your region's unique raw materials and climate.

- Prioritize suppliers with robust, localized after-sales service and spare parts availability.

- Demand verifiable performance data and references from projects within your specific region.

- Evaluate how automation levels impact labor costs, skill requirements, and product consistency.

- A leading brick making equipment brand should offer extensive mold customization options.

- Assess the total cost of ownership, not just the initial equipment purchase price.

- Ensure the supplier's training program empowers your local team for operation and maintenance.

Índice

- Question 1: How Does Your Machine's Technology Adapt to Our Local Materials and Climate?

- Question 2: What Is Your After-Sales Support and Spare Parts Availability in Our Region?

- Question 3: Can You Provide Verifiable Performance Data and References from Our Region?

- Question 4: How Does Your Automation Level Impact Labor Requirements and Production Consistency?

- Question 5: What Are the Specific Customization Options for Molds and Product Types?

- Understanding the Core Technologies: A Deeper Examination

- Navigating the Financial and Logistical Landscape

- Perguntas frequentes (FAQ)

- Conclusão

- Referências

Question 1: How Does Your Machine's Technology Adapt to Our Local Materials and Climate?

Embarking on the path of concrete block production begins not with steel or cement, but with a profound understanding of the ground beneath your feet. The sand, the aggregate, the very air in your region—these are the true starting ingredients. A machine, no matter how sophisticated, is an inert object until it can intelligently interact with these local realities. Therefore, the first, most fundamental inquiry you must direct toward any potential supplier concerns adaptability. The question probes deeper than a simple "yes" or "no"; it seeks to uncover the engineering philosophy of the leading brick making equipment brand. Does their design anticipate variability, or does it assume a standardized, idealized world of materials that simply does not exist in the diverse topographies of Southeast Asia and the Middle East?

Understanding Material Variability in Southeast Asia and the Middle East

The geological and industrial landscapes of regions like the Gulf Cooperation Council (GCC) countries or the nations of the Association of Southeast Asian Nations (ASEAN) are anything but uniform. A supplier based in a temperate climate might design a machine calibrated for perfectly graded river sand and crushed granite aggregate. Such a machine, when faced with the fine, often saline desert sands of the Arabian Peninsula or the lateritic soils common in parts of Southeast Asia, may falter. The consequences are not trivial; they manifest as inconsistent block quality, higher cement consumption to compensate for poor aggregate bonding, and increased wear on the machinery itself.

A truly competent manufacturer will not just acknowledge this; they will demand samples of your local materials. They should conduct a thorough analysis, examining properties like particle size distribution (sieve analysis), silt content, organic impurities, and chemical composition. For instance, high chloride content in aggregates, common in coastal or desert regions, can accelerate corrosion of steel reinforcement within concrete structures, a fact that has implications for the type of products you might produce (GRIFFIN, 1969). A leading brick making equipment brand will be able to advise on pre-treatment of materials or adjustments to the mix design to mitigate these issues.

Consider the increasing use of industrial by-products like fly ash (from coal power plants) or Ground Granulated Blast-furnace Slag (GGBS) as partial cement replacements. These supplementary cementitious materials (SCMs) are pivotal for sustainable and cost-effective construction. However, they alter the rheology and setting time of the concrete mix. A sophisticated machine, particularly a QT series fully auto concrete block making machine, must have a control system that can be finely tuned to accommodate these changes, perhaps requiring different vibration patterns or a slightly longer compaction cycle to achieve the desired density and surface finish. Your question to the supplier should be specific: "Have you successfully configured your machines to run with a 30% fly ash replacement using fine desert sand? Can you show us the results?"

The Role of Vibration and Hydraulic Pressure

The transformation of a loose mixture of sand, cement, aggregate, and water into a dense, strong block is a mechanical marvel. The two primary forces at play are vibration and hydraulic pressure. It is the precise interplay between these two that defines the quality of the final product. Imagine trying to pack a suitcase. You can simply press down hard on the clothes (pressure), or you can shake the suitcase while pressing (vibration plus pressure). The latter method allows the clothes to settle into the voids, resulting in a much more densely packed case.

Block making operates on a similar principle.

| Caraterística | High-Frequency Vibration | High-Pressure Hydraulics |

|---|---|---|

| Primary Function | Fluidizes the concrete mix, allowing particles to settle and air to escape. | Compacts the settled particles, squeezing out remaining water and air. |

| Effect on Block | Improves internal density and homogeneity; creates a smoother surface finish. | Confers high compressive strength and sharp, well-defined edges. |

| Adjustability | Frequency and amplitude should be variable to suit different mix designs. | Pressure must be precisely controlled and consistently applied across the mold. |

| Common in | Essential for all modern machines, especially QT series automatic models. | The core technology of static hydraulic block pressing machines; also integral to automatic lines. |

A superior machine does not treat these forces as blunt instruments. It deploys them with surgical precision. The vibration system should be adjustable in both frequency (how fast it shakes) and amplitude (how far it shakes). A wet mix might require a different frequency than a dry, "zero-slump" mix to achieve optimal fluidization without causing segregation of the aggregates.

Similarly, the hydraulic system, the muscle of the machine, must be more than just powerful; it must be intelligent. The pressure ramp—how quickly the peak pressure is reached and how long it is held—can have a significant impact on block properties. A leading brick making equipment brand will utilize proportional hydraulic valves controlled by a Programmable Logic Controller (PLC). This allows the operator to save specific "recipes" of vibration and pressure profiles for different products and mix designs, ensuring unparalleled consistency from the first block of the day to the last. When you inquire about this, you are asking about the machine's ability to "learn" and replicate the perfect conditions for your specific materials.

Curing and Climate Considerations

The machine's job ends when it ejects a "green" block, but the process of creating a strong, durable product has only just begun. The next stage is curing, a chemical process where the cement hydrates and forms the crystalline structures that give concrete its strength. This process is intensely sensitive to temperature and humidity.

In the hot, arid climates of the Middle East, a freshly pressed block can lose its moisture to evaporation too quickly. This premature drying halts the hydration process, resulting in a weak, chalky block with poor durability. In the hot, humid climates of Southeast Asia, the opposite challenge might arise, where high ambient humidity affects the rate of water evaporation and early strength gain.

A responsible manufacturer's role extends beyond the machine itself. They should provide expert guidance on setting up an appropriate curing regimen tailored to your climate. This might involve recommendations for:

- Fogging or Misting Systems: To maintain high humidity around the blocks in dry climates.

- Curing Chambers: Enclosed spaces where temperature and humidity can be controlled.

- Curing Compounds: Chemical membranes sprayed onto the block surface to lock in moisture.

- Stacking Patterns: How to arrange the blocks to ensure even air circulation and consistent curing.

Asking a supplier, "What curing system do you recommend for our 45°C, low-humidity environment?" is a powerful test. A dismissive answer suggests they see their responsibility ending at the factory gate. A detailed, thoughtful response, perhaps with diagrams and calculations for water requirements, indicates you are dealing with a true partner—a leading brick making equipment brand that understands the entire lifecycle of your product.

Case Study: Adapting a QT Series Machine for Desert Aggregates

Consider a hypothetical but realistic scenario. A construction company in Riyadh, Saudi Arabia, invests in a QT series fully auto concrete block machine. The local aggregate is primarily fine desert sand, which has a rounded particle shape and a high percentage of fines. The initial test runs produce blocks with low compressive strength and a friable surface.

A generic supplier might blame the local materials and walk away. A superior partner, however, would engage with the problem. Their technical team would analyze the sand and note its poor grading. They would then work with the client to adjust the machine's parameters. They might increase the vibration frequency to better energize the fine particles, while slightly reducing the amplitude to prevent the mix from becoming too "liquid" and losing its shape.

Simultaneously, they would adjust the hydraulic pressure profile, perhaps introducing a "pre-press" stage at lower pressure to initially compact the mix before applying the full force. In the PLC, they would create a new recipe named "Riyadh-Desert-Sand-HollowBlock." Furthermore, they would advise the client on the mix design, suggesting the inclusion of a small percentage of coarser, imported crushed aggregate (if economically viable) or a specific type of water-reducing admixture to improve workability without adding excess water. This holistic approach, combining mechanical adjustment with material science, is the hallmark of a leading brick making equipment brand.

Question 2: What Is Your After-Sales Support and Spare Parts Availability in Our Region?

The moment of purchase is but a single point in time. The relationship you will have with your block-making machine will span years, possibly decades. During this long operational life, its profitability will be defined not just by its performance when running, but by the speed and efficiency with which it can be restored when it is not. A machine that stands idle is not just a silent asset; it is an active liability, incurring labor costs, halting production schedules, and potentially delaying entire construction projects. Therefore, the inquiry into after-sales support and spare parts is not a secondary consideration; it is co-equal in importance with the machine's technical specifications. You are not merely buying a machine; you are investing in uptime.

O verdadeiro custo do tempo de inatividade

Let's engage in a simple thought experiment to illuminate the gravity of this point. Imagine two scenarios.

- Scenario A: You purchase a machine from "Supplier A" for $150,000. It is a technically adequate machine, but the supplier has no local presence in your region. When a critical hydraulic seal fails, it takes two weeks to identify the part, process the international payment, ship it from their home country, and clear customs. During those two weeks, your plant is shut down.

- Scenario B: You purchase a superior machine from "Supplier B," a leading brick making equipment brand, for $200,000. They maintain a regional office and warehouse in a major hub like Dubai or Singapore. When the same seal fails, a technician is on-site within 48 hours with the correct part in hand. The machine is down for two days.

Which machine was truly more expensive? The "cheaper" machine in Scenario A may have cost you tens of thousands of dollars in lost production, idle labor wages, and reputational damage with your clients. The higher initial investment in Supplier B's machine was, in effect, an insurance policy against catastrophic downtime. The $50,000 price difference is dwarfed by the financial hemorrhage of a two-week shutdown. When you ask a supplier about their support structure, you are really asking them to justify their machine's total, long-term value proposition.

Localized Technical Teams vs. Remote Support

In our digitally connected age, the allure of remote support is strong. Video calls, augmented reality headsets, and detailed online manuals can certainly solve many common issues. A competent supplier should offer these tools. However, for complex mechanical, hydraulic, or electrical problems, there is no substitute for a skilled technician standing in front of the machine, tools in hand.

The challenges of purely remote support in the context of Southeast Asia and the Middle East are significant. Language barriers can turn a simple instruction into a frustrating miscommunication. Time zone differences mean your machine might fail at the start of your workday, while the supplier's support team is still asleep. Internet connectivity, while improving, can be unreliable in industrial areas, making a stable video link for troubleshooting a matter of luck.

A leading brick making equipment brand demonstrates its commitment to a region by investing in it. This means establishing a physical presence. It means hiring and training local or regionally-based engineers who understand the culture, speak the language, and can navigate the logistics of getting to your site quickly. When you interview a potential supplier, ask them pointedly:

- "Where is your nearest service office to our location?"

- "How many technicians are based there?"

- "What is their guaranteed response time to a critical failure at our site?"

- "Are your technicians factory-trained on the specific QT series model we are considering?"

Their answers will reveal whether their support is a genuine, tangible asset or merely a marketing bullet point.

A Deep Dive into Spare Parts Logistics

A block-making machine is a collection of wearing parts. Molds, tamper heads, hydraulic seals, conveyor belts, and proximity sensors will inevitably need replacement. The question is not if they will fail, but when. A supplier's management of its spare parts inventory is a direct indicator of its operational maturity.

A well-structured spare parts strategy categorizes components:

| Part Category | Descrição | Supplier's Responsibility | Customer's Responsibility |

|---|---|---|---|

| Critical Wear Parts | Items with a predictable, high rate of wear (e.g., mold liners, rubber pads, seals). | Maintain a deep inventory in the regional warehouse for immediate dispatch. | Keep a small "first aid" kit of these parts on-site, as advised by the supplier. |

| Standard Components | Items like electric motors, bearings, or sensors from major brands (e.g., Siemens, SKF). | Provide a clear list of part numbers and specifications so customers can source them locally if desired. | Develop relationships with local industrial suppliers for these common items. |

| Proprietary Components | Custom-fabricated parts specific to the machine (e.g., the main machine frame, specialized hydraulic manifolds). | These are rarely needed but must be available from the central factory with expedited shipping options. | Understand the lead time for these parts and factor it into extreme contingency planning. |

A top-tier supplier will provide you with a recommended spare parts list along with your initial machine quotation. This list should be divided into tiers, such as "Recommended for 1 Year of Operation" and "Critical Spares for On-Site Stock." They should be transparent about which parts are proprietary and which can be sourced from third parties. This transparency empowers you to manage your own inventory and costs effectively, building a relationship based on trust rather than forced dependency.

Training and Skill Transfer: Empowering Your Local Crew

The most advanced machine in the world is ineffective in the hands of an untrained operator. A leading brick making equipment brand understands that their responsibility includes not just commissioning the machine but also transferring knowledge to your team. A comprehensive training program is a non-negotiable component of any serious equipment purchase.

This training should be multifaceted and cater to different roles within your organization:

- Operator Training: This focuses on the day-to-day operation of the machine via its HMI (Human-Machine Interface). It covers starting the machine, selecting production recipes, monitoring the process, performing basic mold changes, and understanding all safety procedures. The goal is to enable your operators to run the machine safely and efficiently to produce high-quality blocks.

- Maintenance Training: This is a deeper, more technical training for your mechanical and electrical staff. It should cover the hydraulic and electrical schematics, routine lubrication schedules, procedures for replacing common wear parts, and basic troubleshooting logic. Your maintenance team should be empowered to solve 80% of problems without needing to call for external support.

- Management Training: This provides an overview of the machine's capabilities, how to analyze its production data (cycle times, stoppage reports), and how to calculate key performance indicators (KPIs) to ensure the asset is delivering the expected return on investment.

This training should ideally be conducted on-site with your actual machine and materials. It should be hands-on, not just a classroom lecture. The supplier's trainer should be not only a technical expert but also a patient teacher, capable of communicating complex ideas clearly (Mahoney, 2022). The quality of the training documentation—manuals, schematics, and troubleshooting guides—is also a reflection of the supplier's professionalism. Are they provided in clear English, or even better, translated into the local language? This attention to detail separates the average suppliers from the true partners.

Question 3: Can You Provide Verifiable Performance Data and References from Our Region?

In the marketplace of industrial machinery, claims are abundant and easy to make. Brochures boast of staggering output figures, and sales presentations promise flawless operation. But claims without proof are mere marketing. A prudent investor must adopt the mindset of a scientist, demanding evidence and reproducible results. The most reliable evidence comes not from the seller, but from those who have already walked the path you are considering. Asking for verifiable performance data and regional references is your method of peer review. It shifts the conversation from the theoretical to the practical, from the showroom floor to the dusty reality of a working block yard.

Deconstructing Performance Metrics: Beyond "Bricks per Hour"

The most common metric touted by manufacturers is "bricks per hour" or "cycle time." While this number is a starting point, it is often presented in a vacuum and can be misleading. A cycle time of 15 seconds sounds impressive, but what does it truly represent? A leading brick making equipment brand should be able to provide a much more granular and meaningful set of performance data.

Your inquiry should press for specifics:

- Cycle Time Breakdown: A 15-second cycle is not a single event. It is composed of multiple sub-processes: material box filling, main compaction, tamper head stripping, and pallet feeding. A supplier should be able to show you the time allocated to each. This reveals the efficiency of the machine's design. Is the time spent on actual compaction maximized?

- Block Quality Specifications: The output rate is meaningless if the blocks are not up to standard. What were the quality parameters when the claimed cycle time was achieved? You need to ask for the compressive strength (in MPa or psi), the water absorption percentage, and the dimensional tolerances (+/- mm) of the blocks produced during that test. A fast machine that makes weak or inconsistent blocks is a liability.

- Operational Efficiency (OEE): A machine might have a theoretical output of 10,000 blocks per shift, but what is its actual, real-world output? Overall Equipment Effectiveness (OEE) is a powerful metric that accounts for downtime (both planned and unplanned) and production of non-conforming (reject) blocks. A transparent supplier might state, "Our QT10-15 model has a theoretical cycle time of 15 seconds, and our clients in the UAE typically achieve an OEE of 85-90% after the initial ramp-up period." This is a much more honest and useful piece of data.

- Energy and Resource Consumption: How much electricity (in kWh), water (in liters), and cement (in kg) is consumed to produce 1,000 standard hollow blocks? An efficient machine minimizes resource consumption per unit, directly impacting your operational costs and profitability. A top-tier manufacturer will have this data readily available.

The Importance of Regional References

A reference from a company in Germany or the United States, while perhaps attesting to the machine's general build quality, holds limited value for a buyer in Oman or Vietnam. The operating conditions are simply too different. A regional reference is invaluable because that company has faced the same challenges you will face: the same climate, similar raw materials, comparable labor market dynamics, and the same logistical hurdles.

When a supplier provides a reference in your region, it demonstrates several things:

- Proven Adaptability: It proves their machine can perform not just in a controlled factory test but in the real-world environment of your region.

- Functional Support Network: It proves their after-sales support and spare parts logistics are not just a promise but a functioning reality in your area. If the reference company is satisfied with the support, it is a strong positive signal.

- Cultural and Business Acumen: It shows the supplier knows how to conduct business in your part of the world, understanding the local customs, regulations, and expectations.

Refusing to provide a regional reference, or only providing one from a distant continent, should be considered a significant red flag. It may suggest they have no successful installations nearby, or worse, that their existing regional clients are not satisfied.

How to Conduct a Reference Check

Once you have a reference, conducting the check properly is a skill. It should be more than a cursory "Are you happy with the machine?" phone call. Prepare your questions in advance to extract maximum value from the conversation.

Questions for the Plant Manager or Owner:

- "How long have you been operating the machine? What specific model do you have?"

- "How did the installation and commissioning process go? Was the supplier's team professional and knowledgeable?"

- "What is your average daily production, and how does it compare to the figures promised by the supplier?"

- "What has been your experience with block quality and consistency? Are you able to meet the required standards in our market?"

- "Have you experienced any significant breakdowns? If so, how quickly and effectively did the supplier's support team respond?"

- "How is the availability of spare parts? Have you had any long delays waiting for a part?"

- "Based on your experience, what advice would you give to someone considering buying a machine from this supplier?"

- "If you had to make the decision again, would you choose the same leading brick making equipment brand?"

This structured approach transforms a simple chat into a powerful piece of due diligence. The insights gained from a fellow plant operator are often more revealing than any sales brochure.

Analyzing a Machine's Total Cost of Ownership (TCO)

A sophisticated buyer looks beyond the initial price tag to understand the machine's Total Cost of Ownership (TCO). TCO is a financial estimate intended to help buyers determine the direct and indirect costs of a product or system (Kenton, 2024). A leading brick making equipment brand should be able to help you build a TCO model for their equipment. This analysis frames the purchase not as an expense, but as an investment with a calculable long-term return.

The key components of TCO for a block machine include:

- Acquisition Cost: The initial purchase price of the machine, including shipping, insurance, and taxes.

- Installation & Commissioning Cost: The cost of site preparation, foundation work, and the supplier's fees for installation and training.

- Operating Costs: These are the ongoing, daily costs of running the machine.

- Energy: Electricity consumption of all motors.

- Trabalho: Wages for operators and maintenance staff.

- Matérias-primas: Cement, sand, aggregate, water, admixtures. While not a machine cost, an inefficient machine will waste materials.

- Maintenance & Repair Costs:

- Peças de substituição: The annual budget for replacing wear parts.

- Service Contracts: Any ongoing fees for support agreements.

- Downtime: The projected cost of lost production due to both planned maintenance and unplanned breakdowns.

By projecting these costs over a period of 5 or 10 years, you can make a much more informed comparison between two machines. A machine with a 20% higher purchase price might have a 30% lower TCO over its lifespan due to superior energy efficiency, higher reliability, and lower maintenance needs. A truly transparent supplier will welcome this kind of analysis because it allows the quality and efficiency of their engineering to shine through.

Question 4: How Does Your Automation Level Impact Labor Requirements and Production Consistency?

The question of automation is not a simple choice between "manual" and "automatic." It is a spectrum. The level of automation you choose for your block-making operation will have profound and far-reaching consequences for your business model. It will dictate the size and skill level of your workforce, the consistency and quality of your product, and the scalability of your entire enterprise. When you engage with a supplier on this topic, you are architecting your future factory floor. You need to understand precisely how their offerings, from single static hydraulic block pressing machines to fully integrated QT series production lines, align with your strategic goals.

Comparing Fully Automatic vs. Static Hydraulic Machines

Let's clarify the distinction between the two primary types of machines often discussed. The terms can sometimes be used loosely, so a precise understanding is necessary.

-

Static Hydraulic Block Pressing Machine: This is often a semi-automatic machine. It typically involves more manual labor. For example, the mix might be manually loaded into the machine's hopper, and the finished blocks on their pallet might be manually transported to the curing area. The core pressing action is automated (hydraulic pressure and vibration), ensuring block consistency, but the surrounding processes require human intervention. These machines are an excellent entry point, offering a lower initial investment and simpler maintenance.

-

QT Series Fully Auto Concrete Block Making Machine: This refers to an integrated production line. The "fully automatic" designation implies that from the moment raw materials are batched and mixed, to the point where cured blocks are stacked and packaged, human intervention is minimized. A central PLC control system orchestrates a symphony of conveyors, mixers, the main block machine, a stacker (which stacks the pallets of green blocks), and a cuber (which takes cured blocks off the pallets and stacks them for shipping).

The choice between them is a strategic one, not just a technical one. A reputable manufacturer of concrete block machines will offer a range of options and provide clear guidance on the trade-offs.

The Human Element in an Automated Factory

A common misconception is that automation eliminates labor. It does not. It transforms the nature of the labor required. A factory with a semi-automatic static hydraulic press might employ ten low-skilled laborers for tasks like moving pallets and shoveling material. A factory with a fully automatic QT series line might employ only four people, but their roles will be different and require a higher level of skill.

- The Control Room Operator: This individual monitors the entire production line from a computer screen. They need to be able to interpret data from the PLC, understand the production recipes, and make minor adjustments to optimize the process. They are less a manual laborer and more a process technician.

- The Maintenance Technician: With a complex, integrated line, a skilled maintenance team is paramount. They need to be proficient in mechanics, hydraulics, and electronics to perform preventative maintenance and troubleshoot issues quickly. Their work is proactive, aimed at preventing downtime, rather than just reacting to breakdowns.

- The Quality Control Inspector: While automation improves consistency, quality control remains vital. This person will periodically take blocks from the line to test for compressive strength, dimensions, and visual defects, providing feedback to the control room operator to make any necessary adjustments.

So, while a fully automatic line reduces the total number of employees and mitigates challenges associated with managing a large, low-skilled workforce (such as high turnover and inconsistent performance), it necessitates an investment in training and retaining a smaller, more skilled team. When discussing automation with a supplier, the conversation should include the skill profile of the ideal operating crew.

Achieving Consistent Quality Through Automation

Human beings, for all our ingenuity, are inconsistent. An operator on a manual machine may get tired at the end of a shift, filling the mold slightly less each time. Another might be distracted, letting the vibration run for a second too long. These small variations, multiplied over thousands of blocks, lead to a product with inconsistent density, strength, and dimensions.

Automation is the antidote to this variability. A PLC-controlled QT series machine executes the exact same cycle, with the exact same parameters, every single time.

- Precise Material Dosing: The batching plant weighs the sand, aggregate, and cement to within a few grams of the recipe's specification.

- Consistent Mixing: The mixer runs for the precise time required, with the exact amount of water added, ensuring a homogenous mix for every batch.

- Identical Compaction: The block machine applies the programmed vibration pattern and hydraulic pressure profile for every cycle, ensuring every block has the same density and strength.

This level of consistency is a powerful competitive advantage. It means fewer rejected blocks, which saves material and disposal costs. It means your customers—be they large contractors or individual builders—can trust that every block they receive from you is of the same high quality. This builds a reputation for reliability that can be more valuable than any price discount. When you can guarantee that your blocks meet or exceed national and international standards (like ASTM or BS), you can command a premium price and access more demanding projects.

Scalability: Matching Automation to Your Business Growth

Your business today is not your business in five years. A wise equipment choice anticipates future growth. A leading brick making equipment brand will offer a scalable pathway.

Perhaps your initial market analysis suggests starting with a single, robust static hydraulic block pressing machine. This allows for a lower initial capital outlay while you establish your brand and customer base. The supplier you choose should be able to articulate a clear upgrade path. For example:

- Phase 1: Start with the static press, using manual transport for green and cured blocks.

- Phase 2: As demand grows, add an automatic stacker to the output of your existing machine. This reduces labor and improves efficiency in the handling of green blocks.

- Phase 3: Invest in an automatic batching and mixing plant to feed your machine. This dramatically improves mix consistency and reduces labor at the front end of the process.

- Phase 4: As you reach the capacity of the first machine, you can add a second machine or upgrade to a larger, fully automatic QT series line, potentially re-purposing your initial machine for specialized, short-run products.

By choosing a supplier with a wide and modular product range, you are not locking yourself into a single level of technology. You are creating a partnership that allows your production capacity and automation level to grow in lockstep with your business success. This foresight prevents the costly scenario of having to replace an entire system just a few years down the line because it cannot scale with your ambitions.

Question 5: What Are the Specific Customization Options for Molds and Product Types?

A block-making machine is, at its heart, a platform. The machine itself provides the force and the control, but it is the mold that gives the product its identity. The versatility of your operation—your ability to respond to changing market demands and seize new opportunities—is directly tied to the range and quality of the molds you can use. A building project does not just require standard hollow blocks. It requires solid blocks, insulated blocks, decorative pavers for walkways, heavy-duty interlocking blocks for industrial yards, and precisely shaped curb-stones for roads. Your ability to produce this diverse portfolio of products transforms you from a simple block maker into a comprehensive solution provider for the construction industry. Therefore, a deep conversation about molds with any leading brick making equipment brand is a conversation about the future profitability and adaptability of your business.

The World of Concrete Products: Beyond Standard Bricks

The first step is to expand your imagination beyond the ubiquitous hollow concrete block. A modern hydraulic press or QT series machine is capable of producing an astonishing variety of precast concrete products, each with its own market and margin.

- Hollow and Cellular Blocks: The workhorses of wall construction, available in numerous sizes and core configurations for load-bearing and non-load-bearing applications.

- Solid Blocks: Used where higher strength, sound insulation, or fire resistance is required.

- Paving Stones (Pavers): A highly profitable market segment. Pavers come in countless shapes (rectangular, "I" shape, "S" shape), colors, and textures for residential driveways, public squares, and commercial landscaping.

- Interlocking Blocks: These are high-strength, precision-engineered blocks that fit together without mortar. They are used for heavy-duty applications like container ports, airport aprons, and industrial flooring.

- Curb-stones (Kerbs): Essential for road construction, drainage systems, and landscaping. They require high dimensional accuracy and durability.

- Specialty Products: This can include decorative screen blocks, grass pavers (which allow vegetation to grow through), and even insulated blocks that have a core of polystyrene inserted during the manufacturing process.

A forward-thinking supplier will not just present you with a catalog of their standard molds. They will act as a consultant, discussing the construction trends in your specific region (Southeast Asia or the Middle East) and suggesting which products have the highest growth potential. They should be able to show you examples and technical specifications for each product their machine can produce.

The Science of Mold Design and Manufacturing

A mold is not just a shaped piece of steel. It is a high-precision tool subjected to immense abrasive forces and intense vibration in every cycle. The longevity of a mold and the quality of the blocks it produces are determined by sophisticated material science and manufacturing processes.

When discussing molds, your questions should probe these technical details:

- Steel Quality: What specific grade of steel is used? Is it a standard carbon steel, or a specialized alloy steel known for its wear resistance?

- Heat Treatment: This is arguably the most important factor in a mold's lifespan. A properly heat-treated mold has a very hard surface to resist abrasion from the sand and aggregate, while maintaining a tougher, less brittle core to withstand the shock of vibration. Ask about their specific heat treatment process. Do they use carburizing, nitriding, or induction hardening? What is the target surface hardness (measured in HRC)? A hardness of 60 HRC or more is a good benchmark for a high-quality mold.

- Manufacturing Tolerances: The gap between the tamper head (which presses from above) and the mold box walls is a critical parameter. If it is too large, a fin of material will be pressed into the gap, creating an untidy block and accelerating wear. If it is too small, the parts can jam as they heat up and expand during operation. What are the manufacturing tolerances for their molds? A precision of +/- 0.2mm is a sign of high-quality engineering.

- Design modular: Can the mold be refurbished? Good designs feature replaceable wear liners. This means that when the mold eventually wears, you only need to replace the internal liner plates, not the entire expensive mold box, significantly reducing long-term costs.

A cheap, poorly made mold might save you money upfront, but it will wear out quickly, require frequent repairs, and produce blocks with inconsistent dimensions. Investing in high-quality, properly heat-treated molds from a reputable leading brick making equipment brand is one of the wisest decisions you can make.

The Process of Custom Mold Creation

While a supplier will have a standard library of molds, your market may have a unique requirement—a specific paver design popular in your country or a block size mandated by a local building code. The ability of a supplier to create custom molds efficiently and accurately is a key indicator of their engineering capability.

The custom mold process should be a collaborative one:

- Concept & Design: You provide a drawing, a sample, or even just a concept. The supplier's engineering team should then create a detailed 3D CAD model of the mold for your approval.

- Simulation (Optional but Recommended): Advanced manufacturers may use Finite Element Analysis (FEA) software to simulate the stresses on the proposed mold design, identifying potential weak points before any steel is cut.

- Manufacturing: Once the design is approved, the mold is fabricated using CNC (Computer Numerical Control) machining centers to ensure high precision.

- Heat Treatment & Finishing: The machined parts undergo the critical heat treatment process, followed by grinding or polishing to achieve the final dimensions and surface finish.

- Testing: The completed mold should be tested in a machine at the supplier's factory to ensure it functions correctly and produces a block that meets the design specifications. You should receive photos, videos, and sample blocks from this test run.

Ask the supplier to walk you through this process. What is their typical lead time for a custom mold? Who bears the design cost? This conversation will reveal their level of professionalism and customer focus.

Future-Proofing Your Investment with Mold Versatility

The construction market is not static. Tastes change, building codes evolve, and new architectural styles emerge. The machine you buy today must be able to produce the products that will be in demand five or ten years from now.

The key to this future-proofing is the ease and speed of mold changes. On a well-designed machine, changing a mold should be a straightforward process that can be accomplished in under an hour. This agility allows you to switch production from hollow blocks in the morning to pavers in the afternoon, responding rapidly to customer orders.

Inquire about the mold changing system. Is it a cumbersome, bolt-heavy process, or does it use a quick-clamping hydraulic system? Does the machine's control system (PLC) make it easy to load the specific production recipe for the new mold? A machine that allows for fast mold changes is a more versatile and profitable asset. It empowers you to be an agile and responsive market leader, rather than being locked into producing a single product type.

Understanding the Core Technologies: A Deeper Examination

To truly master the selection of a block-making machine, one must move beyond the operational questions and cultivate a deeper appreciation for the core technologies that reside within the steel frame. Just as a discerning driver understands the difference between a turbo-charged engine and a naturally aspirated one, a savvy block producer should understand the components that dictate a machine's power, intelligence, and endurance. This knowledge transforms you from a mere buyer into an informed partner, capable of engaging with engineers on a more substantive level. Let's dissect the three fundamental systems: the hydraulic system, the PLC control system, and the vibration system.

The Heart of the Machine: The Hydraulic System

If the mold gives the block its shape, the hydraulic system gives it its strength. It is the muscle of the operation, responsible for generating the immense, controlled forces required for compaction. A failure or inefficiency in this system has immediate and severe consequences for production.

At its core, a hydraulic system uses a fluid (typically specialized oil) under pressure to transmit power. The key components you should be aware of are:

- Hydraulic Pumps: This is what generates the flow of oil. High-quality machines often use variable displacement piston pumps. Unlike a simple gear pump that always delivers a fixed volume of oil, a variable pump can adjust its output. This is far more energy-efficient, as it only delivers the flow and pressure required for a specific action, rather than constantly pumping at maximum capacity and dumping the excess pressure through a relief valve (which generates heat and wastes energy).

- Hydraulic Cylinders: These are the actuators that convert the fluid pressure into linear force—the force that drives the tamper head down to compact the concrete. The quality of the seals within the cylinder is paramount. Leaking seals mean a loss of pressure, inconsistent block quality, and a messy, unsafe work environment.

- Hydraulic Valves: These are the gatekeepers that direct the flow of oil to the correct cylinders at the correct time. The most advanced machines use proportional or servo valves. These are not simple on/off valves; they can be opened to any degree with extreme precision. This is what allows a PLC to control the speed and force of the compaction process, creating smooth movements and precise pressure ramps, which reduces shock on the machine frame and produces a better block.

- Arrefecimento e filtragem: Hydraulic oil degrades when it gets too hot, and it can be damaged by contamination. A robust hydraulic system will include an efficient cooling system (either air-cooled or water-cooled) and a multi-stage filtration system to keep the oil clean. Ask the supplier about the brand of their hydraulic components (e.g., Bosch Rexroth, Parker, Eaton, Yuken). The use of internationally recognized, high-quality brands is a strong indicator of overall machine quality and ensures that replacement components can be sourced more easily in the future.

The Brains of the Operation: The PLC Control System

The Programmable Logic Controller (PLC) is the central nervous system of any modern automatic block machine. This ruggedized industrial computer is responsible for executing the production sequence with split-second timing and unwavering repeatability. The quality and user-friendliness of the PLC and its associated Human-Machine Interface (HMI) will define the operator's experience and the machine's flexibility.

Key aspects to evaluate:

- PLC Brand and Model: Just like with hydraulic components, the brand of the PLC matters. Industry leaders like Siemens, Allen-Bradley (Rockwell Automation), and Mitsubishi Electric are known for their reliability and global support. Using a standard, well-regarded brand means it is easier to find trained technicians and support documentation. Be wary of machines that use obscure or unbranded PLCs, as you will be entirely dependent on the machine manufacturer for any software support or troubleshooting.

- A Interface Homem-Máquina (HMI): The HMI is the touch-screen or panel where the operator interacts with the machine. A well-designed HMI should be intuitive and graphical. It should not require a degree in computer science to operate. It should display information clearly: the current stage of the cycle, production counts, any active alarms or faults, and the core machine parameters. The HMI should be available in English and, ideally, other languages relevant to your workforce.

- Recipe Management: A powerful feature of a good PLC system is the ability to create and save "recipes." A recipe is a set of all the parameters for producing a specific block: vibration times and frequencies, hydraulic pressures, material feed times, etc. Your operator should be able to switch from producing a 20cm hollow block to a 10cm solid block simply by selecting the correct recipe on the HMI. This guarantees consistency and makes production changeovers fast and error-proof.

- Diagnostics and Alarms: When a fault occurs—a sensor is blocked, a motor overloads, or a safety gate is opened—the PLC should not just stop the machine; it should tell you exactly what is wrong. A good HMI will display a clear, descriptive alarm message (e.g., "Fault: Proximity sensor on main conveyor failed") rather than a cryptic error code. This drastically reduces troubleshooting time and empowers your maintenance team to resolve issues quickly.

The Power of Vibration: Achieving Optimal Compaction

Vibration is the subtle art in block making. While hydraulic pressure provides the brute force, vibration provides the finesse. Its purpose is to reduce the internal friction between the particles of the concrete mix, allowing them to settle into their most tightly packed arrangement. Proper vibration is what fills the corners of the mold, releases trapped air bubbles, and creates a dense, homogenous block with a smooth surface.

The technology behind the vibration system is a key differentiator for a leading brick making equipment brand:

- Vibration Method: The vibration is typically generated by eccentric weights mounted on shafts that are spun by electric motors. The quality of these motors and the bearings they use is critical for long life, as they operate in a very harsh environment.

- Synchronized Vibration: In high-quality machines, the vibrators (there are often multiple units) are synchronized. This ensures that a consistent, uniform vibration is applied across the entire area of the mold, preventing dense and weak spots within the same block.

- Variable Frequency Drives (VFDs): The most advanced systems use VFDs to control the speed of the vibration motors. This allows the PLC to change the frequency of the vibration during the compaction cycle. For example, it might start with a lower frequency to help fill the mold and then switch to a higher frequency to achieve final consolidation. The ability to control both frequency and amplitude (which is often mechanically adjustable) gives you the ultimate power to optimize the compaction process for any mix design, a concept that builds on the principles of effective explanation by breaking down a complex process into manageable parts (Science of People, 2022). This level of control is a defining feature of a truly top-tier machine.

By developing a facility with these technical concepts, you elevate your discussion with suppliers. You can ask more pointed, intelligent questions that demonstrate your seriousness and force them to move beyond their standard sales pitch. You are better equipped to discern true engineering excellence from superficial gloss.

Navigating the Financial and Logistical Landscape

Purchasing a major piece of industrial equipment like a block-making machine is a complex project that extends far beyond the technical specifications. It involves a web of financial, logistical, and contractual considerations. Successfully navigating this landscape is just as important as choosing the right machine. A failure in shipping can be as costly as a failure in a hydraulic pump. A misunderstanding in payment terms can sour a relationship before the first block is even made. A thoughtful approach to these practical matters ensures a smooth journey from the supplier's factory to a profitable operation on your site.

From Factory to Foundation: Understanding Shipping and Installation

The physical journey of your machine from its country of origin to your facility is a critical phase of the project. A clear understanding of the shipping terms is essential. International commerce relies on a set of standardized terms known as Incoterms, published by the International Chamber of Commerce.

- EXW (Ex Works): The seller makes the goods available at their premises. You, the buyer, are responsible for all shipping, export clearance, and insurance from their factory door onward. This gives you control but also maximum responsibility.

- FOB (Free On Board): The seller is responsible for delivering the goods to the designated port of shipment and loading them onto the vessel. From that point on, the risk and cost transfer to you. This is a very common and balanced arrangement.

- CIF (Cost, Insurance, and Freight): The seller arranges and pays for the cost, insurance, and freight to your destination port. You are responsible for import clearance, duties, and transport from the destination port to your factory. This is convenient but may be more expensive than arranging your own freight.

You must have a frank discussion with the supplier about which Incoterm will govern the sale. You also need to plan for the "last mile" logistics. A block machine is a large, heavy piece of equipment. Do you have a crane with sufficient capacity to offload it from the truck at your site? Is the concrete foundation for the machine prepared according to the supplier's drawings and specifications? A leading brick making equipment brand will provide detailed foundation plans and clear instructions for offloading and positioning the machine. Their installation team's arrival should be coordinated with the machine's arrival to avoid costly delays.

Financing Your Equipment: Options and Considerations

The capital outlay for a high-quality block production line can be substantial. Few businesses pay for such an asset entirely from cash reserves. Exploring financing options is a standard part of the procurement process.

- Bank Loans: The most traditional route is to secure a business loan from a commercial bank in your country. Your bank will require a detailed business plan, financial projections, and a formal quotation for the equipment.

- Leasing: An equipment lease is essentially a long-term rental agreement. You make regular payments for the use of the machine over a set term. At the end of the term, you may have the option to purchase the machine at a predetermined price, return it, or renew the lease. Leasing can be attractive as it may require a lower initial cash outlay and can sometimes offer tax advantages.

- Supplier Financing: Some large equipment manufacturers have their own financing arms or partnerships with financial institutions. They may be able to offer attractive financing packages as part of the sale. This can streamline the process, but you should always compare their rates and terms with what you can secure from your own bank.

When presenting your case to any lender, your ability to articulate the machine's ROI (Return on Investment) will be key. A detailed TCO analysis, as discussed earlier, is a powerful tool in these discussions.

ROI Calculation: A Practical Framework

Ultimately, the purchase of a block machine is an investment, and the purpose of an investment is to generate a positive return. A simplified ROI calculation can help you and your financial backers understand the economic viability of the project.

- Calculate Your Total Investment (I): This is the machine's TCO for the first year, including the acquisition cost, installation, and initial spare parts.

- Calculate Your Annual Production (P): Based on the machine's realistic output (using OEE, not theoretical numbers), calculate the total number of blocks you will produce in a year. (e.g., 8,000 blocks/shift x 1 shift/day x 300 days/year = 2,400,000 blocks).

- Calculate Your Revenue (R): Multiply your annual production by the average selling price per block in your market. (e.g., 2,400,000 blocks x $0.30/block = $720,000).

- Calculate Your Annual Operating Cost (C): This is the sum of all your costs excluding the initial investment. It includes raw materials, labor, energy, and planned maintenance for the year. (e.g., $450,000).

- Calculate Your Annual Gross Profit (G): This is your Revenue minus your Operating Cost. (G = R – C). (e.g., $720,000 – $450,000 = $270,000).

- Calculate Simple ROI: ROI (%) = (G / I) x 100. This tells you the percentage return you are making on your investment each year.

- Calculate Payback Period: Payback Period (in years) = I / G. This tells you how many years it will take for the machine's profit to pay back the initial investment. (e.g., if total investment was $400,000, Payback Period = $400,000 / $270,000 = 1.48 years).

This exercise, while simplified, provides a powerful, data-driven foundation for your decision. It forces you to think critically about every aspect of the business, from production efficiency to market pricing. A supplier who can help you gather the necessary data for these calculations is a supplier who is invested in your success.

Perguntas frequentes (FAQ)

What is the main difference between a hydraulic press and a fully automatic QT series machine? A static hydraulic block pressing machine is typically a standalone unit where the core process of pressing is automated, but ancillary tasks like loading materials and moving finished blocks often require manual labor. A QT series fully auto concrete block making machine describes an entire integrated production line, where processes from raw material batching to final product cubing are automated and controlled by a central PLC, significantly reducing labor and increasing consistency.

How much cement is needed to produce concrete blocks? The amount of cement varies significantly based on the type of block, the quality of other raw materials (sand and aggregate), and the desired compressive strength. A typical ratio for standard hollow blocks might be 1 part cement to 6 parts sand and 4 parts aggregate by volume. However, a leading brick making equipment brand will provide specific, tested mix designs tailored to your materials to achieve required standards with optimal cement consumption.

Can I use desert sand to make blocks? Yes, but with careful management. Desert sand is often very fine and rounded, which can lead to weaker blocks and higher cement demand. To use it successfully, you may need to blend it with coarser, crushed sand or aggregate. Additionally, the machine's parameters, particularly the vibration frequency and hydraulic pressure profile, must be finely tuned to properly compact the fine material.

What is the typical lifespan of a high-quality block machine mold? The lifespan of a mold depends on the abrasiveness of your aggregates, the number of cycles per day, and the quality of the mold itself. A cheap, non-heat-treated mold might only last for 30,000-50,000 cycles. A high-quality mold made from specialized steel and subjected to proper heat treatment (carburizing or nitriding) can last for 150,000 to 250,000 cycles or more, making it a far better long-term investment.

How long does it take to install and commission a new block making machine? The timeline varies with the complexity of the machine. A single static press might be installed and commissioned by a supplier's technician in 7-10 days. A large, fully automatic line can take 3-5 weeks for mechanical and electrical installation, followed by another 1-2 weeks of commissioning, testing, and staff training. This timeline should be clearly defined in your purchase agreement.

What level of electrical power is required for a block production line? The power requirement depends on the size and automation level of the line. A medium-sized QT series automatic line might have a total installed power of 60-90 kW. A supplier must provide a detailed list of all motors and their power ratings so you can ensure your site's electrical supply and transformer are adequate.

Is it necessary to have a covered building for the machine? It is highly recommended. While the machine itself is built to be robust, the electronic components, especially the PLC cabinet and HMI, are sensitive to direct sun, rain, and excessive dust. A roof protects the equipment, improves the working conditions for your staff, and is essential for controlling the curing process of the finished blocks.

Conclusão

The selection of a block manufacturing system is a decision that resonates through a business for years, shaping its productive capacity, its reputation for quality, and its ultimate profitability. The process demands a perspective that transcends the immediate appeal of a low price tag, embracing instead a more rigorous, long-term view grounded in the principles of Total Cost of Ownership. As we have explored, the critical path to a wise investment lies in asking the right questions—questions that probe a supplier's technological adaptability to your unique environment, the tangible reality of their regional support network, the verifiable truth of their performance claims, the strategic implications of their automation solutions, and their capacity for future-proofing your business through customization.

By engaging with potential suppliers on this deeper, more analytical level, you shift the dynamic from a simple transaction to a collaborative partnership. You demonstrate that you are a serious, informed buyer, and in doing so, you compel them to respond with greater transparency and substance. The journey from raw aggregate to a finished, high-quality concrete block is a process of controlled transformation. The journey to selecting the right leading brick making equipment brand to facilitate that process should be no less deliberate and no less informed. The framework outlined here is not a mere checklist but a method of inquiry, designed to empower you to make a decision that will serve as the strong, reliable foundation for your company's growth and success in the dynamic construction markets of Southeast Asia and the Middle East.

Referências

Griffin, D. F. (1969). Corrosion of reinforcing steel in concrete: A general overview of the problem. Naval Civil Engineering Lab Port Hueneme CA.

Kenton, W. (2024). Total cost of ownership (TCO): What it is, what's included. Investopedia. https://www.investopedia.com/terms/t/totalcostofownership.asp

Mahoney, A. J. (2022). An overlooked superpower: How to explain complex concepts. Medium. @a.jeremymah/an-overlooked-superpower-how-to-explain-complex-concepts-2dd14573ac13

Science of People. (2022). How to explain things better (& make people understand). https://www.scienceofpeople.com/how-to-explain-things-better/

SlideModel. (2023). How to present complex concepts: A guide for effective communication. https://slidemodel.com/how-to-present-complex-concepts/